Professional Documents

Culture Documents

Steel 4340

Uploaded by

skyheighst1594184Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel 4340

Uploaded by

skyheighst1594184Copyright:

Available Formats

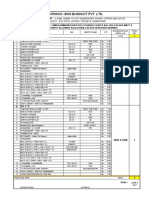

Steel 4340 Property Results Chemistry Data : [top] Carbon Chromium Iron Manganese Molybdenum Nickel Phosphorus Silicon

Sulphur Principal Design Features 0.38 - 0.43 0.7 - 0.9 Balance 0.6 - 0.8 0.2 - 0.3 1.65 - 2 0.035 max 0.15 - 0.3 0.04 max AISI 4340 is a heat treatable, low alloy steel containing nickel,chromium and molybdenum. It is known for its toughness and capability of developing high strength in the heat treated condition while retaining good fatigue strength. Typical applications are for structural use, such as aircraft landing gear, power transmission gears and shafts and other structural parts.

Applications

Machinability

Forming

Welding

Heat Treatment

Forging Hot Working

Cold Working

Annealing

Aging Tempering

Machining is best done with this alloy in the annealed or normalized and tempered condition. It can be machined by all conventional methods. However in the high strength conditions of 200 ksi or greater the machinability is only from 25% to 10% that of the alloy in the annealed condition. 4340 has good ductility in the annealed condition and most forming operations are carried out in that condition. It can be bent or formed by spinning or pressing in the annealed state. Bend radii should be 3t or greater. The alloy can be fusion or resistance welded. Preheat and post heat weld procedures should be followed when welding this alloy by established methods. Heat treatment for strengthening is done at 1525 F followed by an oil quench. For high strength (over 200 ksi) the alloy should first be normalized at 1650 F prior to heat treatment. See "Tempering" for strength levels. Forging may be done in the range of 2250 F max. down to 1800 F. 4340 has very good cold forming capability so that hot working should not be needed. Hot working in any but the annealed condition can affect the strength level. Consult the alloy supplier in regard to hot working. The 4340 alloy may be cold worked, in the annealed condition, by conventional methods and tooling. It has good ductility. A full anneal may be done at 1550 F followed by controlled (furnace) cooling at a rate not faster than 50 F per hour down to 600 F. From 600 F it may be air cooled. Not applicable to this alloy. The temperature for tempering depends upon the strength level desired. Before tempering the alloy should be in the heat treated or normalized & heat treated condition - see

Hardening Other Comments

"Heat Treatment". For strength levels in the 260 - 280 ksi range temper at 450 F. For strength in the 125 - 200 ksi range temper at 950 F. Do NOT temper the alloy if it is in the 220 260 ksi strength range as tempering can result in degradation of impact resistance for this level of strength. The alloy will harden by cold working or by heat treatment -see "Heat Treatment" and "Tempering". AISI 4340 is considered to be a "through hardening" steel such that large section sizes can still be heat treated to high strength.

Physical Data : [top] Density (lb / cu. in.) Specific Gravity Specific Heat (Btu/lb/Deg F - [32-212 Deg F]) Melting Point (Deg F) Thermal Conductivity Mean Coeff Thermal Expansion Modulus of Elasticity Tension Forum Result: What happens to the physical size of 4340 during heat treating? I have some shafts to machine from 4340 51/2" dia stock, to an average size of 5.000" dia x 18" long. Will the material grow or shrink and by how much? It will be quenched and tempered to 40-44 RC. I can tell you from first hand experience the material is going to go crazy on you. I have always heat treat to full hard then draw three times to desired RC. If you can watch the three draws you'll notice the first draw will take it to the desired RC, The second draw at same temp it will go up in RC. The third draw will make it go back down and really really stabilize it for you. leave your self some machine stock. If you have any dowel holes be prepared to chase the holes with a carbide reamer. Be careful if you have to chase a taped thread. Preface... I'm not a heat treater but deal with our heat treater often so can probably head you in the right direction. First off... simple enough to ask your heat treater. They won't mind flexing their know-how for you. I have had lengthy conversations with one particular heat treater we use and he's a wealth of information and just an all around good guy. We're buds and more than once he's extended our tooling life by better understanding what we were doing with a tool. Maybe varying our hardness or suggesting a different grade of material etc... That said... They'll shrink some. They'll also be prone to bending if not positioned correct or supported by something flat during heat treat. You need to ask your heat treater if he can stand them up on end without having them fall etc. Longer shafts it's nice if you can drill & tap shaft end and supply hooks in each shaft on one end so they can be lifted for quench. These are short enough they shouldn't be a problem. They'll fit in a basket but they'll stay straighter if they can stay standing up on end. Far as how much they're going to shrink? Ask your heat treater. It won't be much. Maybe .002-.004 if I had to guess. The bending potential CAN be more of the issue. But... if I were making these things... and spoke with the heat treater about keeping them upright I'd still allow for approx. .03-.04 total (.015-.02 per side) to be machined after heat treat for clean-up. That cut might drop your hardness by a point... if that. If your heat treater whines about giving them special care... find another heat treater. When you say average size of 5.000 I expect there are steps in this part. Best to keep generous radii at all transitions prior to heat treat also. This is to reduce likelihood of cracking during quench. External corners need to at least be broken before heat treat, as they too are a stress concentration area. 0.28 7.8 0.116 2600 21 6.6 33

You can look up... Jominy test 4340... on the www or ask your heat treater what the depth of hardness might end up at. A part that thick will still be soft in the center. I'd expect that the heat affected zone will only be about 1/2" deep with hardness tapering off closer to center you get. That's usually not a bad thing in the applications I've seen this material used. Tough center with wear resistant surface. Keep this in mind when rough machining. If steps on these shafts are deep you will lose hardness at the smaller diameters. Also always a good practice to call out a double temper on things like this. This will help ensure a complete transition of the grain. This is more critical in different grades and depends some on the application, but just a good habit to get into. Costs you an extra 50 bucks or whatever but can make or break a tool. Especially in more critical tooling applications. Tooling built for any sort of shock loads... like Hot work tool steels or S grades etc. are much tougher or less susceptible to cracking if a double or triple temper is performed. Need that smooth transition of grain and nice even equally sized grain. Another tid bit. We've used vacuum heat treat on 4140-4340 in the past and although we had a little less distortion... the gas quench couldn't strip the heat out of the material quickly enough to get the hardness up at the initial quench like good old oil can. Meaning I doubt you'll achieve 44 RC surface on 5 inch diameter in a vacuum furnace. Might be wrong though? Could look into that if these aren't critical and you don't want to do a finish cut. Thanks for the info. Yes there are steps in the shafts but not much difference in diameter. The diameters are critical so finishing after heat treating will be necessary, I was going to leave .06 to make sure straightness wont be a problem. They do have the means (high tonage press) to straighten them if necessary. There are 3/4-10 holes in each end so lifting by hooks will be provided. Thanks again for the info so I feel I would be safe with my original plan. 40 RC wont be that hard to cut for some finishing and to correct the length. Quenching and tempering steel will actually grow the part. After heat treating, the part is hardest just under the surface. Plus, the very surface can have decarb and grain boundary oxide, both of which are undesireable. Since you'll be grinding the shaft to finish dimensions, material growth and undesireable surface effects will be removed and you'll be left with hard and healthy material at the susrface (assuming the part doesn't suffer grinding burn during final machining).

STEEL 1. Processes (Heat treatment): a. Quenching b. Annealing, Cryogenic Treatment, Thermomechanical processing Focus on heat treat procedure for: Ultrahigh strength materials, maraging steels, powder metallurgy ferrous alloys 2. Hardening of steel: a. Flame hardening b. Conventional treatment like Carburizing, nitriding and carbonitriding c. High energy processes using laser beams/ electron beams. Surface modification Techniques a. Ion implantation b. PVD/CVD coatings c. Surface melting/ surface alloying processes Linear changes are approximately one-third the volume changes. During the formation of austenite from an original microstructure of ferrite and pearlite or tempered martensite, the volume (and hence the length) decreases with the formation of the dense austenite

3.

1. 2.

phase (see Fig. 3). From the elongation curves, the start and finish times for austenite formation, usually defined as 1% and 99% transformation, respectively, can be derived. These times are then conveniently plotted on a temperature-log time diagram (Fig. 4). Also plotted in this diagram are the Ac1 and Ac3 temperatures. Below Ac1 no austenite can form, and between Ac1 and Ac3 the end product is a mixture of ferrite and austenite. Notice that a considerable overheating is required to complete the transformation in a short time. The original microstructure also plays a great role. A finely distributed structure like tempered martensite is more rapidly transformed to austenite than, for instance, a ferriticpearlitic structure. This is particularly true for alloyed steels with carbideforming alloying elements such as chromium and molybdenum. It is important that the heating rate to the hold temperature be very high if a true isothermal diagram is to be obtained. The transformation start curve shows as an upper-limiting estimate of the time (in seconds) for nucleation, . The isovolume fraction curves x can semiempirically be described by a relation of the type (Ref 12): /8 exp( / ) . ( ) x 2N . Q RT f I X T t= D (Eq 1) where x is the volume fraction of the transformed phase, Q is an activation energy related to the boundary diffusion activation energies for the alloying elements, N is the ASTM grain size number for austenite, T is the temperature (in degrees Kelvin), T is the undercooling (A3 - T) for ferrite, (A1 - T) for pearlite and an empirical value for bainite, f is a linear function of the volume fractions of carbon and alloying elements and I is the volume fraction integral giving the dependence of the transformed phase on the volume fraction. The combined effect of the I/T3 factor, which increases with decreasing undercooling (that is, increasing temperature) and the exp (Q/RT) factor, which increases with decreasing temperature, results in long nucleation times, x, for high and low temperatures and short nucleation times for intermediate temperatures. The C-shape can thus be obtained and understood. The factor 2N/8 is included to take into consideration the fact that the transformation rate is larger for smaller austenite grain sizes.

You might also like

- Drdiecast 2012marDocument1 pageDrdiecast 2012marsobheysaidNo ratings yet

- Metallurgy of KnivesDocument4 pagesMetallurgy of KnivesOliver AlfaroNo ratings yet

- Term Paper - 1 Flame HardeningDocument11 pagesTerm Paper - 1 Flame HardeningSiva PrasadNo ratings yet

- Tooling Materials&Heat TreatmentDocument13 pagesTooling Materials&Heat TreatmentVinod MadireddyNo ratings yet

- MaterialData - 14076 HDS H13Document2 pagesMaterialData - 14076 HDS H13Amol KulkarniNo ratings yet

- GN06 Post Weld Heat Treatment of Welded PDFDocument11 pagesGN06 Post Weld Heat Treatment of Welded PDFGregory FenwickNo ratings yet

- Gear Heat TreatmentDocument13 pagesGear Heat TreatmentvishalNo ratings yet

- Kulliyyah of Engineering: Heat TreatmentDocument15 pagesKulliyyah of Engineering: Heat TreatmentWafa ZullfakherNo ratings yet

- Residual Stress in SteelDocument14 pagesResidual Stress in SteelAhmed BdairNo ratings yet

- Spesifikasi AISI 4340Document3 pagesSpesifikasi AISI 4340Muh FarhanNo ratings yet

- Chapter 10 Thermal Processing of Metal AlloysDocument44 pagesChapter 10 Thermal Processing of Metal Alloyssyed izzuddin alhadyNo ratings yet

- Heat TreatmentDocument5 pagesHeat TreatmentLaxman GautamNo ratings yet

- Sol 11Document9 pagesSol 11AndyNo ratings yet

- Carburization of SteelDocument9 pagesCarburization of SteelRtr Ahmed Abidemi CertifiedNo ratings yet

- Introduction To Heat TreatmentDocument10 pagesIntroduction To Heat TreatmentAzhar AliNo ratings yet

- Back To Basics: Molten Metal ManagementDocument2 pagesBack To Basics: Molten Metal ManagementArgenis Emmanuel Rodriguez MarianoNo ratings yet

- SS 2018 Spring TheSchaeferGroup enDocument2 pagesSS 2018 Spring TheSchaeferGroup enArgenis Emmanuel Rodriguez MarianoNo ratings yet

- All About The Design of HeatsinksDocument40 pagesAll About The Design of Heatsinks조용규No ratings yet

- Shell and Plate Article Sept 2009 HCEDocument3 pagesShell and Plate Article Sept 2009 HCENgoVietCuongNo ratings yet

- Basic Points of P91Document4 pagesBasic Points of P91Asad Bin Ala Qatari100% (1)

- Interlloy 440C MartensiticDocument4 pagesInterlloy 440C MartensiticGuillaume BoyerNo ratings yet

- Heat TreatmentDocument4 pagesHeat TreatmentAshish BoraNo ratings yet

- Why Is Preheating NecessaryDocument3 pagesWhy Is Preheating NecessaryahmedNo ratings yet

- Strip Heater Technical CatalogueDocument8 pagesStrip Heater Technical CataloguechikoopandaNo ratings yet

- 174 PHDocument2 pages174 PHSuriyachai NiamsornNo ratings yet

- Heat Treatment of SteelsDocument6 pagesHeat Treatment of SteelsSrinivas LaishettyNo ratings yet

- Heat Treatments For Improving The Weldability and Formability of Udimet 700Document9 pagesHeat Treatments For Improving The Weldability and Formability of Udimet 700Enary SalernoNo ratings yet

- Post Weld Heat TreatmentDocument10 pagesPost Weld Heat Treatmentcristian291011No ratings yet

- HardenabilityDocument7 pagesHardenabilityZaidee AliasNo ratings yet

- Data 2 PDFDocument2 pagesData 2 PDFSalem GarrabNo ratings yet

- 410 Spec SheetDocument2 pages410 Spec SheetThomasJolyNo ratings yet

- Product Design Guide For ForgingDocument31 pagesProduct Design Guide For ForgingVikram Borkhediya100% (1)

- Max Kilnshell Temp PDFDocument8 pagesMax Kilnshell Temp PDFGiequatNo ratings yet

- Specification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Document2 pagesSpecification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Rahul KhoslaNo ratings yet

- Aluminium and Aluminium Alloys - Heat Treatment of Aluminium and Aluminium AlloysDocument3 pagesAluminium and Aluminium Alloys - Heat Treatment of Aluminium and Aluminium Alloysdshine2010No ratings yet

- 17 4PH Spec SheetDocument2 pages17 4PH Spec Sheettrong tan dongNo ratings yet

- PWHT, HT, Igc, MawpDocument40 pagesPWHT, HT, Igc, Mawpsachinshirnath100% (1)

- Manuale Saldatura WellerDocument0 pagesManuale Saldatura WellerTorero CamomilloNo ratings yet

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- Effect of Process Parameters On Hot Machining of 17-7 PH Martensitic Stainless Using Oxy-Acetylene GasDocument25 pagesEffect of Process Parameters On Hot Machining of 17-7 PH Martensitic Stainless Using Oxy-Acetylene GasSurya TejaNo ratings yet

- Swedish College of Engineering and Technology Wah Cantt TaxilaDocument8 pagesSwedish College of Engineering and Technology Wah Cantt TaxilaM. RazaNo ratings yet

- 4418 DatasheetDocument5 pages4418 DatasheetwholenumberNo ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- HT and Non-HT AlloysDocument8 pagesHT and Non-HT AlloysfranzkurniawanNo ratings yet

- Hard Turning Report En8Document51 pagesHard Turning Report En8Muthu KumarNo ratings yet

- Barry Robinson SAFE Presentation 2Document22 pagesBarry Robinson SAFE Presentation 2mmairaalvarado90No ratings yet

- AsdkfmlsdkfmDocument8 pagesAsdkfmlsdkfmJohnNo ratings yet

- 4140HW Alloy Steel Technical DataDocument8 pages4140HW Alloy Steel Technical DatawinasharNo ratings yet

- EN26Document3 pagesEN26Moldoveanu TeodorNo ratings yet

- The Purpose of PreheatDocument6 pagesThe Purpose of PreheatSankar GaneshNo ratings yet

- Module 3-CUTTING TOOL MATERIALSDocument88 pagesModule 3-CUTTING TOOL MATERIALSsushilNo ratings yet

- Heat Treatments: PERFECT - HK - Creativity in FasteningDocument2 pagesHeat Treatments: PERFECT - HK - Creativity in Fasteningdivya2prabakarNo ratings yet

- Reflow SolderingDocument6 pagesReflow Solderingputut margandonoNo ratings yet

- Effect of Annealing Temperature On The Microstructure, Microhardness, Mechanical Behavior and Impact Toughness of Low Carbon Steel Grade 45Document4 pagesEffect of Annealing Temperature On The Microstructure, Microhardness, Mechanical Behavior and Impact Toughness of Low Carbon Steel Grade 45hpsingh0078No ratings yet

- Improve Energy Efficiency in Induction MeltingDocument13 pagesImprove Energy Efficiency in Induction MeltingAmit PathakNo ratings yet

- How To Determine The Best Heat Treatment For Your PartsDocument10 pagesHow To Determine The Best Heat Treatment For Your Partswilderness_666No ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Soldering Electronic Components 2nd EditionFrom EverandSoldering Electronic Components 2nd EditionRating: 3 out of 5 stars3/5 (2)

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Definition of IntelligenceDocument7 pagesDefinition of Intelligenceskyheighst1594184No ratings yet

- Management Lessons From 3 Idiots MovieDocument14 pagesManagement Lessons From 3 Idiots MoviesonarevankarNo ratings yet

- C Vvs TripodDocument3 pagesC Vvs Tripodskyheighst1594184No ratings yet

- EN24Document1 pageEN24skyheighst1594184No ratings yet

- Chemical Bonding ExerciseDocument6 pagesChemical Bonding Exerciseapi-386303659No ratings yet

- Standard Nail Size Table Chart and Nail TermsDocument4 pagesStandard Nail Size Table Chart and Nail TermsKarthic MannarNo ratings yet

- Piston / Inline Design General Characteristics: Flow Switch 1.1. Fluvamat MR-... GM/GKDocument2 pagesPiston / Inline Design General Characteristics: Flow Switch 1.1. Fluvamat MR-... GM/GKJavier AffifNo ratings yet

- Technical Review On Alumina InclusionDocument15 pagesTechnical Review On Alumina InclusionMubeenNo ratings yet

- The Welding Journal 1958 6Document161 pagesThe Welding Journal 1958 6Alexey100% (1)

- Geosynthetics Final PDFDocument34 pagesGeosynthetics Final PDFvinod choudhariNo ratings yet

- Cannabis ManufacturingDocument6 pagesCannabis ManufacturingSebastián RamirezNo ratings yet

- INDUSTRY GUIDE T48 Guide To Industrial Floors and Pavements Design Construction and Specification PDFDocument121 pagesINDUSTRY GUIDE T48 Guide To Industrial Floors and Pavements Design Construction and Specification PDFHeriberto Yau B100% (1)

- Em 2Document2 pagesEm 2Baugh Graphic DesignNo ratings yet

- AZEK Trim & Moulding Install GuideDocument12 pagesAZEK Trim & Moulding Install GuideCarlos CardenasNo ratings yet

- Hardened Concrete - Methods of Test: Indian StandardDocument16 pagesHardened Concrete - Methods of Test: Indian StandardjitendraNo ratings yet

- Colloids and SuspensionsDocument4 pagesColloids and SuspensionsJulius Macaballug100% (1)

- Unit Cost DerivationDocument46 pagesUnit Cost Derivationapi-197535980% (1)

- The Main Advantages of Secant Pile Walls AreDocument2 pagesThe Main Advantages of Secant Pile Walls Aredwarika2006No ratings yet

- Aeroshell Fluid 41: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Fluid 41: Main Applications Specifications, Approvals & Recommendationsabdul rehmanNo ratings yet

- Cbse Sample Papers For Class 11 Chemistry Download PDFDocument4 pagesCbse Sample Papers For Class 11 Chemistry Download PDFPIPARIYANo ratings yet

- CBSE Class 12 Chemistry Quick Revision Notes Co-Ordination CompoundsDocument8 pagesCBSE Class 12 Chemistry Quick Revision Notes Co-Ordination CompoundsAbid waniNo ratings yet

- G B Veeresh Kumar, P S Shivakumar Gouda, R Pramod, CspraoDocument6 pagesG B Veeresh Kumar, P S Shivakumar Gouda, R Pramod, CspraoShivu RajNo ratings yet

- 4.2 Bonding, Structure and The Properties of MatterDocument6 pages4.2 Bonding, Structure and The Properties of MatterEashwar RajakumarNo ratings yet

- Lot No. 2: Garryson (Stellram) All Solid Carbide Drills, Cutters, Reamers All European Manufacture Description Make QtyDocument5 pagesLot No. 2: Garryson (Stellram) All Solid Carbide Drills, Cutters, Reamers All European Manufacture Description Make QtykhalidNo ratings yet

- Entraco-Bks Busduct Pvt. LTD.: Packing List ForDocument1 pageEntraco-Bks Busduct Pvt. LTD.: Packing List ForsubhajiyroyNo ratings yet

- DWR 03-23Document1 pageDWR 03-23Nicon Famarin FameronagNo ratings yet

- Hot Dip Galvanizing Design ConsiderationsDocument22 pagesHot Dip Galvanizing Design Considerationsabhi_akNo ratings yet

- Gujarat Technological Univercity: C.K. Pithawala College of Engineering & TechnologyDocument17 pagesGujarat Technological Univercity: C.K. Pithawala College of Engineering & TechnologyParth AnajwalaNo ratings yet

- 10.betonske Konstrukcije - Prvi Deo - 8 PDFDocument4 pages10.betonske Konstrukcije - Prvi Deo - 8 PDFIvan JovanovicNo ratings yet

- About Dissimilar MetalsDocument1 pageAbout Dissimilar MetalsIsabel Christina Gonzalez MoralesNo ratings yet

- Dental Materials (Review Center)Document11 pagesDental Materials (Review Center)yellow rangerNo ratings yet

- Effect of Recast Layer Thickness On The Mechanical Characteristics of INCONEL 718 Machined by Spark EDM ProcessDocument7 pagesEffect of Recast Layer Thickness On The Mechanical Characteristics of INCONEL 718 Machined by Spark EDM Processhasib_07No ratings yet

- Chapter 15 (Acid and Bases)Document46 pagesChapter 15 (Acid and Bases)aliefyan4769No ratings yet

- OintmentDocument12 pagesOintmentErfaneh FNNo ratings yet