Professional Documents

Culture Documents

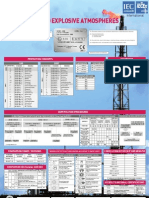

STAHL Poster Safety Reality

Uploaded by

edwardesjrOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STAHL Poster Safety Reality

Uploaded by

edwardesjrCopyright:

Available Formats

_ Our Reality Your Safety

NEC 500 Class I, Division 1, Groups A, B, C, D, T6

NEC 505 IEC CENELEC

Class I, Zone 1, A Ex de IIC T6 Ex de IIC T6 marking according to ATEX Ex* de IIC T6 II 2 G

EQUIPMENT GROUP I (MINING)

Category Category M1 Category M2 Sufcent safety by means of 2 protective measures /2 faults the equipment is intended to be deenergized in the event of an explosive atmosphere

TYPES OF PROTECTION FOR ELECTRICAL APPARATUS IN HAZARDOUS AREAS

Type of protection increased safety ameproof enclosures pressurized enclosures e Diagram Main application

terminal and junction boxes, control boxes for installing Ex-components (with a different type of protection), squirrel-cage motors, light ttings switchgear and control station and indicating equipment, control systems, motors, transformers, heating equipment, light ttings

Standard

EN 60 079 -7 IEC 60 079 -7 EN 60 079-1 IEC 60 079-1 EN 60 079-2 IEC 60 079-2 UL 60 079 -7 FM 3600 UL 60 079-1 FM 3600 NFPA 496 FM 3620

EQUIPMENT GROUP II (OTHER HAZARDOUS AREAS)

Category Category 1 Category 2 Category 3 Atmosphere G (Gas) Zone 0 Zone 1 Zone 2 Atmosphere D (Dust) Zone 20 Zone 21 Zone 22 Sufcent safety by means of 2 protective measures /2 faults frequently occuring equipment faults/1 fault during normal operation intrinsic safety i d

switchgear and control cabinets, analysers, large motors px = for use in Zone 1, 2 py = for use in Zone 1, 2 pz = for use in Zone 2 instrumentation technology, eldbus technology, sensors, actuators ia = for use in Zone 0, 1, 2 ib = for use in Zone 1, 2 [Ex ib] = associated electrical apparatus installation in the safe area

Category (1), (2), (3) = associated electrical apparatus installation in the safe area

EN 60 079-11 IEC 60 079-11

UL 60 079-11 FM 3610

CLASSES AND GROUPS ACC. NEC 500

Class Class I (gas) Substance Acetylene Hydrogen Ethylene Propane Mining Class II (dust) Methane Metal dust Coal dust Grain dust Class III (fibers) Fibers E F G Group A B C D

ZONES

Dangerous explosive atmosphere continously or longterm or frequently likely to/can exist under normal operating conditions not likely to occur or for short period Gas acc. CENELEC/ IEC/NEC 505 Zone 0 Dust acc. IEC/ CENELEC Zone 20 oil immersion

intrinsically safe systems FISCO Ex ia IIC T4 FNICO Ex ia IIC T4 eldbus intrinsically-safe concept (FISCO) for Zone 1 eldbus non-incentive concept (FNICO) for Zone 2 transformers, starting resistors

EN 60 079-25 IEC 60 079-25 EN 60 079-27 IEC 60 079-27 EN 60 079-6 IEC 60 079-6 EN 60 079- 5 IEC 60 079- 5 EN 60 079-18 IEC 60 079-18 EN 60 079-15 IEC 60 079-15 UL 60 079-6 FM 3600 UL 60 079- 5 FM 3600 UL 60 079-18 FM 3600 UL 60 079-15 FM 3600

Zone 1

Zone 21 powder lling q

sensors, display units, electronic ballasts, transmitters

Zone 2

Zone 22

encapsulation

switchgear with small capacity, control and signalling units, display units, sensors ma = for use in Zone 0, 1, 2 mb = for use in Zone 1, 2

HAZARDOUS AREA ACC. NEC 500

Division 1 Division 2 likely to/can exist under normal operating conditions abnormal condition

type of protection

n_

all electrical apparatus for Zone 2 nA = non-sparking apparatus nC = sparking apparatus, in which the contacts are protected in a suitable way nL = energy limited apparatus nR = restricted breathing enclosures nZ = apparatus with n-pressurization

TEMPERATURE CLASSIFICATION ACC. NEC 500

Maximum surface temperature 450 C 300 C 280 C 260 C 230 C 215 C 200 C 180 C 165 C 160 C 135 C 120 C 100 C 85 C Temperature classes for gases T1 T2 T2A T2B T2C T2D T3 T3 A T3B T3C T4 T4A T5 T6

GAS GROUPS ACC. IEC, CENELEC AND NEC 505

Explosion group I IIA IIB IIC Typical gas Methane Propane Ethylene Hydrogen

optical radiation

op _

op is = inherently safe optical radiation op pr = protected optical radiation op sh = optical radiation interlock

EN 60 079-28 IEC 60 079-28

TYPES OF PROTECTION FOR ELECTRICAL APPARATUS IN AREAS WITH COMBUSTIBLE DUST

Type of protection protection by enclosures tD Diagram Main application

switchgear and control station, terminal and connection boxes, control boxes, motors, light ttings tD A21 = under procedure A for Zone 21 tD B21 = under procedure B for Zone 21

Standard

EN 61 241-1 IEC 61 241-1

TEMPERATURE CLASSIFICATION ACC. IEC, CENELEC AND NEC 505

Maximum surface temperature 450C 300C 200C 135C 100C 85C Temperature classes for gases T1 T2 T3 T4 T5 T6

pressurization

pD

switchgear and control cabinets, motors

EN 61 241- 4

IEC 61 241- 4

intrinsic safety

iD

measurement and control technology, eldbus technology, sensors, actuators iaD = for use in Zone 20, 21, 22 ibD = for use in Zone 21, 22 [Ex ibD] = associated electrical apparatus installation in the safe area

EN 61 241-11

IEC 61 241-11

encapsulation

mD

switchgear with small capacity, control and signalling units, display units, sensors maD = for use in Zone 20, 21, 22 mbD = for use in Zone 21, 22

EN 61 241-18

IEC 61 241-18

Dust: indication of the max. surface temperature in C

Dust: indication of the max. surface temperature in C

* Ex: from december 2004, EEx: until march 2007 (transition period)

ID-NR. 00 006 37 77 0 S-PB-Ex-Plakat-03-en-10/2006 Printed in the Federal Republic of Germany

R.STAHL Schaltgerte GmbH Am Bahnhof 30, 74638 Waldenburg, Germany Phone + 49 7942 943 - 0, Fax + 49 7942 943 - 4333 E-mail info.ex @ stahl.de

www.stahl.de

You might also like

- GUIDE TO HAZARDOUS AREA EQUIPMENT MARKINGDocument1 pageGUIDE TO HAZARDOUS AREA EQUIPMENT MARKINGSandra Yadhit Higuera ArchilaNo ratings yet

- Acv Automatic Control Valves PDFDocument20 pagesAcv Automatic Control Valves PDFabdallah391No ratings yet

- End-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesDocument6 pagesEnd-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesMuhammad MustafaNo ratings yet

- Sop GSSDocument3 pagesSop GSSArun MurugaiyanNo ratings yet

- Spirax Sarco - Typical Steam Orifice Flowmeter Station PDFDocument3 pagesSpirax Sarco - Typical Steam Orifice Flowmeter Station PDFnasirmuzaffarNo ratings yet

- 200/300 BAR INERT GAS Fire Suppression Systems: JUNE 2017Document7 pages200/300 BAR INERT GAS Fire Suppression Systems: JUNE 2017Amir Hossein SaberNo ratings yet

- AEC - 70 KVA Machine SpecsDocument1 pageAEC - 70 KVA Machine Specssamer8saif100% (1)

- Valve Cavity Relief 2Document2 pagesValve Cavity Relief 2Azar DeenNo ratings yet

- Lcie Bureau Veritas Atex Poster PDFDocument1 pageLcie Bureau Veritas Atex Poster PDFAncaOniscuNo ratings yet

- Swagelok CatalogDocument66 pagesSwagelok Catalogfeelmybeat100% (1)

- N11 Nozzle CalDocument9 pagesN11 Nozzle Calגרבר פליקסNo ratings yet

- Elmar Pannel - BP ColombiaDocument6 pagesElmar Pannel - BP ColombiaFelipe Augusto Diaz SuazaNo ratings yet

- BS5501 2 PDFDocument12 pagesBS5501 2 PDFDasdasd SadasdNo ratings yet

- Pressure Transmitter Data SheetDocument2 pagesPressure Transmitter Data Sheetneurolepsia3790No ratings yet

- Process Control (Level)Document12 pagesProcess Control (Level)Gino GalanoNo ratings yet

- Advantech - Catalogo Geral - Oil & GasDocument8 pagesAdvantech - Catalogo Geral - Oil & GasMarcelo MarceloNo ratings yet

- Scanner 2000 Hardware ManualDocument154 pagesScanner 2000 Hardware ManualErik TapiasNo ratings yet

- Separator NadobyDocument15 pagesSeparator NadobyVidyasenNo ratings yet

- Control Flownex SimulinkDocument8 pagesControl Flownex SimulinkSrashmiNo ratings yet

- SN74LVC07Document23 pagesSN74LVC07abcdNo ratings yet

- 강도계산프로그램Document16 pages강도계산프로그램심판자No ratings yet

- Temp and Pressure InstrumentDocument5 pagesTemp and Pressure InstrumentAnniza Cornelia AugustyNo ratings yet

- Manua Voith - WSR-E60126-SDocument27 pagesManua Voith - WSR-E60126-SDParente93100% (1)

- 21A Solenoid Valves Series DatasheetDocument40 pages21A Solenoid Valves Series Datasheetportusan2000No ratings yet

- RMT 23 Series Globe Valves Product Bulletinonapplicationrequirements,differentseatmaterials and constructions are available to ensure tightshut-off and long lifeDocument37 pagesRMT 23 Series Globe Valves Product Bulletinonapplicationrequirements,differentseatmaterials and constructions are available to ensure tightshut-off and long lifeNymphetamine AnhNo ratings yet

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3AymanelorbanyNo ratings yet

- Leak Detection in Pipeline-JijoDocument17 pagesLeak Detection in Pipeline-Jijoamulbaby31No ratings yet

- Deluge Valve - SD-DVA PDFDocument15 pagesDeluge Valve - SD-DVA PDFboxyfunNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- Conical Base Cylindrical PE Tanks SpecsDocument4 pagesConical Base Cylindrical PE Tanks SpecsAmoolia Ngo0% (1)

- ATEXDocument1 pageATEXselvan110663No ratings yet

- # 6 - 1 Attachment ABB DCSDocument4 pages# 6 - 1 Attachment ABB DCSKevin NgoNo ratings yet

- Prysmian - Instrumentation Cables CatalogueDocument2 pagesPrysmian - Instrumentation Cables Cataloguebharatsehgal00100% (1)

- ActuationDocument12 pagesActuationSrimp sasaNo ratings yet

- ControlMaster Select Service ManualDocument46 pagesControlMaster Select Service ManualJoss Maykol Mundaca VasquezNo ratings yet

- DPT Smart Pressure TransmitterDocument15 pagesDPT Smart Pressure Transmitterprasanta_bbsrNo ratings yet

- Annexure D - For Cable Cellar MVWS SystemDocument1 pageAnnexure D - For Cable Cellar MVWS SystemVaibhav SawantNo ratings yet

- Flow-Switch-RapidropDocument4 pagesFlow-Switch-RapidropNOMANNo ratings yet

- Why We Use End of Line (EOL) Resistor in Fire and Gas SystemDocument8 pagesWhy We Use End of Line (EOL) Resistor in Fire and Gas SystemInter TungNo ratings yet

- EGPM-10-DAS-MOV-ISO-01 - Datasheet For MOV IsolatorDocument4 pagesEGPM-10-DAS-MOV-ISO-01 - Datasheet For MOV IsolatordrkongalaNo ratings yet

- Digital Output Unit Technical SpecificationsDocument10 pagesDigital Output Unit Technical SpecificationsRio YuwandiNo ratings yet

- KITZ ProductDocument44 pagesKITZ Productkingathur26681No ratings yet

- Knife Gate Valve - For Reference OnlyDocument16 pagesKnife Gate Valve - For Reference Onlysj_scribdNo ratings yet

- Auma Sa 07.2-Sa 16.2....Document56 pagesAuma Sa 07.2-Sa 16.2....Q Llanos HenryNo ratings yet

- FCI 70-2-2006 PreDocument1 pageFCI 70-2-2006 PreIkhsan LyNo ratings yet

- BCH Electric Ltd-Limit Switch-CatalogueDocument6 pagesBCH Electric Ltd-Limit Switch-CataloguesachmayaNo ratings yet

- Thermon Heat Tracing PDFDocument12 pagesThermon Heat Tracing PDFanisNo ratings yet

- Your Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6Document1 pageYour Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6And WebNo ratings yet

- Hazardous Area Chart - StahlDocument1 pageHazardous Area Chart - StahlDanang Prakosa100% (1)

- Types of Protection for Electrical and Non-Electrical Equipment in Explosive AtmospheresDocument1 pageTypes of Protection for Electrical and Non-Electrical Equipment in Explosive AtmospheresHimanshu ChichraNo ratings yet

- Normes-Ex Poster EngDocument1 pageNormes-Ex Poster Engbuco2312No ratings yet

- Hazardous Area Chart - BartecDocument1 pageHazardous Area Chart - BartecPutraSumatera100% (1)

- Safety. Everywhere.: Electrical Equipment Non-Electrical EquipmentDocument1 pageSafety. Everywhere.: Electrical Equipment Non-Electrical EquipmentNavin KeralaNo ratings yet

- EX Plakat GBDocument1 pageEX Plakat GBBohumil NáplavaNo ratings yet

- Intertek Poster A1 (HazLoc - Guide) - 0Document1 pageIntertek Poster A1 (HazLoc - Guide) - 0Antonio FilipeNo ratings yet

- Ingress SafetyDocument1 pageIngress Safetyjohn_tigerNo ratings yet

- Basics of Explosion Protection - IecDocument4 pagesBasics of Explosion Protection - IecbenounaomarNo ratings yet

- Classification of Hazardous AreasDocument1 pageClassification of Hazardous Areasadhi2001No ratings yet

- Bartec Hazardous Class PosterDocument1 pageBartec Hazardous Class PosterDen Andri Nchu100% (2)

- Serci - Mineral - Processing I e IIDocument1 pageSerci - Mineral - Processing I e IIedwardesjrNo ratings yet

- Bachelor of Science: Four Year (120 Credits)Document3 pagesBachelor of Science: Four Year (120 Credits)edwardesjrNo ratings yet

- Cirteq Technical ManualDocument88 pagesCirteq Technical ManualedwardesjrNo ratings yet

- MonGrinding in Ball Mills: Modeling and Process Controlov, Sokolov, Stoenchev Pp51 68Document18 pagesMonGrinding in Ball Mills: Modeling and Process Controlov, Sokolov, Stoenchev Pp51 68Felipe Andres Riveros ArandaNo ratings yet

- 100912sol Fly Sucess Story 10103 enDocument2 pages100912sol Fly Sucess Story 10103 enedwardesjrNo ratings yet

- Roata TibetanaDocument1 pageRoata TibetanaObaciuIonelNo ratings yet

- Roata TibetanaDocument1 pageRoata TibetanaObaciuIonelNo ratings yet

- Key Personnel'S Affidavit of Commitment To Work On The ContractDocument14 pagesKey Personnel'S Affidavit of Commitment To Work On The ContractMica BisaresNo ratings yet

- XDM-300 IMM ETSI B00 8.2.1-8.2.2 enDocument386 pagesXDM-300 IMM ETSI B00 8.2.1-8.2.2 enHipolitomvn100% (1)

- The Standard 09.05.2014Document96 pagesThe Standard 09.05.2014Zachary Monroe100% (1)

- Import Sample 2Document63 pagesImport Sample 2akkyNo ratings yet

- Raj Priya Civil Court Clerk FinalDocument1 pageRaj Priya Civil Court Clerk FinalRaj KamalNo ratings yet

- Vital StatisticsDocument35 pagesVital StatisticsRadha100% (1)

- OWASP Dependency-Check Plugin: DescriptionDocument10 pagesOWASP Dependency-Check Plugin: DescriptionFelipe BarbosaNo ratings yet

- Some Technical Aspects of Open Pit Mine Dewatering: Section2Document11 pagesSome Technical Aspects of Open Pit Mine Dewatering: Section2Thiago MarquesNo ratings yet

- Neuroimaging - Methods PDFDocument372 pagesNeuroimaging - Methods PDFliliana lilianaNo ratings yet

- Declarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Document13 pagesDeclarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Jair Luiz S. FilhoNo ratings yet

- Trusted Cloud Computing by Helmut Krcmar, Ralf Reussner, Bernhard Rumpe (Eds.)Document335 pagesTrusted Cloud Computing by Helmut Krcmar, Ralf Reussner, Bernhard Rumpe (Eds.)Hari HaranNo ratings yet

- Naruto Vol 4Document171 pagesNaruto Vol 4Andrew WongNo ratings yet

- Reg OPSDocument26 pagesReg OPSAlexandru RusuNo ratings yet

- Teaching and Learning in the Multigrade ClassroomDocument18 pagesTeaching and Learning in the Multigrade ClassroomMasitah Binti TaibNo ratings yet

- 797B Commissioning Guidebook 07 (Procesos)Document65 pages797B Commissioning Guidebook 07 (Procesos)wilmerNo ratings yet

- Applied SciencesDocument25 pagesApplied SciencesMario BarbarossaNo ratings yet

- DMGT403 Accounting For Managers PDFDocument305 pagesDMGT403 Accounting For Managers PDFpooja100% (1)

- Sensors 18 02175Document15 pagesSensors 18 02175Deepak D MishraNo ratings yet

- How To Retract BPS Data Back To R3 When There Is No Standard RetractorDocument3 pagesHow To Retract BPS Data Back To R3 When There Is No Standard Retractorraphavega2010No ratings yet

- Admission Notice 2023-24Document2 pagesAdmission Notice 2023-24Galav PareekNo ratings yet

- The Meaning of Solar CookerDocument4 pagesThe Meaning of Solar CookerJaridah Mat YakobNo ratings yet

- European Heart Journal Supplements Pathophysiology ArticleDocument8 pagesEuropean Heart Journal Supplements Pathophysiology Articleal jaynNo ratings yet

- Dxgbvi Abdor Rahim OsmanmrDocument1 pageDxgbvi Abdor Rahim OsmanmrSakhipur TravelsNo ratings yet

- CVCITC Smoke-Free Workplace Policy & ProgramDocument2 pagesCVCITC Smoke-Free Workplace Policy & ProgramKristine Joy CabujatNo ratings yet

- Final Reflective Essay by Georgi ShopovDocument7 pagesFinal Reflective Essay by Georgi ShopovMd Siddique UllahNo ratings yet

- Base Is OkDocument84 pagesBase Is OkajaydevmalikNo ratings yet

- Canary TreatmentDocument117 pagesCanary TreatmentRam KLNo ratings yet

- Reference Letter For Employment AustraliaDocument8 pagesReference Letter For Employment Australiabcqy21t7100% (2)

- Abinitio Interview QuesDocument30 pagesAbinitio Interview QuesVasu ManchikalapudiNo ratings yet

- 2018 JC2 H2 Maths SA2 River Valley High SchoolDocument50 pages2018 JC2 H2 Maths SA2 River Valley High SchoolZtolenstarNo ratings yet