Professional Documents

Culture Documents

Environmental Scanning of Reliance Textile Industries

Uploaded by

BhawikOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Environmental Scanning of Reliance Textile Industries

Uploaded by

BhawikCopyright:

Available Formats

A Brief Report on Environmental Scanning Of RelianceTextiles

Submitted by: Group 1 (Renuka, Sanjukta, Akriti, Ayush, Sunil, Zishan) Group 10 (Monica, Ritesh, Apoorv, Ashutosh, Sahil, Bhawik)

Introduction - Reliance Textile Industries is a leading manufacturer and exporter of home textiles.The company design, manufacture and market a coordinated line of value-added home textile products. It consists of packaged bedroom furnishings such as comforters, bed sheets, pillowcases, shams, bed skirts, curtains quilt covers and draperies.

Government Intervention - I n t h e p a s t , I n d i a h a s b e e n o n e o f t h e m o s t i m p o r t a n t players in the global textile market. It is estimated that about t h r e e c e n t u r i e s a g o i t p r o d u c e d c l o s e t o 2 5 % o f t h e w o r l d s cloth. But, the international competitiveness of Indian textile industry went through a sharp decline in the era during Second World War. The British manufacturers penetrated so much into Indian economy that there was influx of foreign goods into the Indian markets. As Ox-ford History of India puts it, 'the machine g o o d s o f L a n c a s h i r e t o g e t h e r w i t h t h e f r e e t r a d e p o l i c y h a d killed the Indian cotton industry. In the mid 1960's the government of India introduced an export promotion scheme under which the earnings from the export of rayon fabrics could be used for the import of nylon fiber. Another program the High Unit Value Scheme introduced by GoI in 1971 gave tremendous boost to reliance textiles. The scheme allowed the import of polyester filament yarn against the export of nylon fabrics. RCC was benefited the most from this scheme and its export contributed more than 60% of the exports under this scheme. Like many other countries, the textile sector then became one of the most significant sectors for the economy of India. Soon after abolition of quotas in 2005 India strengthen itself in i n t e r n a t i o n a l t e x t i l e m a r k e t . I t i s t o d a y I n d i a s m o s t r o o t e d sector which provides direct employment (formal and informal) to an estimated 38 million people nationwide.

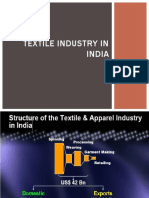

Role of Textile Industry in Indian Economy - The textile industry in India is one of the major and most important sectors in the economy especially in terms of foreign exchange earnings, employment and production in the country. It is presently growing at 20% and accounts for 4% of Indias GDP. It also contributes 14% to the Industrial Production and employs about 35 million people. The entire size of the textile sector is worth $ 47 billion in w h i c h d o m e s t i c m a r k e t i s a t $ 3 0 b i l l i o n a n d t h e o v e r s e a s market at $17 billion. This industry attracted Rs. 33000 crore of investment during the fiscal year, which was up by 51percent from Rs. 21850 crore in the former year.

Core Competencies - Core competency is a buzz phrase generally employed as a post-facto rationalisation for strategic decisions. The core competency of this industry is the scale at which the production and distribution is carried out. Technology - Vimal, the flagship textile brand of Reliance Industries Ltd. (RIL) uses a pioneering innovation' in the textile industry of treating fabrics with a chemical that would arrest the growth of fungi and bacteria keeping it fresh and anti-odour even after day-long wearing in humid and warm climates like India. Low cost manufacturing capabilities.

Assets - Reliance strategy is to step out of the businesses that contribute less than 12% to the company's annual revenues. The textiles business accounts for around 2% of RIL's total turnover of around Rs 850 billion.

Intellectual Capital In the mid 1960's Dhirubai Ambani decided to switch from the spice industry to textiles. In 1966, he set up a spinning mill at naroda, 20 kms from Ahmedabad, with borrowed funds of Rs. 280000 and registered it (reliance textile industries) as a powerloom unit with a paid up capital of Rs.150000.

Competitors The main competitors of reliance textiles was Bombay dyeing. After the relaunch however, Grasim also came up as a strong competitor. Other brands that posed as a competition to Vimal throughout its life span were Raymonds, Reid & Taylor, Mayur Suitings, Siyarams, Donear, OCM, Arvind Suitings, Bombay Suitings, Peter England, etc.

Growth of Vimal Textiles - Reliance Industries Ltd. (Textile Division) is Indias largest manufacturer-exporter of suiting fabrics and has expanded its production capacity to over 20 million meters per year. Large volume is exported to over 58 countries to some of the biggest international brands across the globe involved in the business of Suits, Pants and Coats. Largest vertically integrated fabric production facilities in India, to convert wool tops to finished fabrics through different processes of Dyeing, Spinning, Weaving and Processing / Finishing using state-of-the-art plant and machinery. Formalized stringent quality checks at each stage and process (with ISO 9001 & ISO 14001 Certification) which enables the superior quality and consistent fabrics at par with global standards consistently. Company manufactures over 20,000 design-shade combinations each year in Light Wool, Polyester Wool and Woolen, Polyester Viscose and Polyester Cotton fabrics under the VIMAL brand. Constant and continuous research on products/ designs to ensure creation of innovative future trends.

DISTRIBUTION CHANNEL: Ready to wear range is sold in the companys exclusive stores and franchisees, it is also counting on Reliance Retails own stores to help promote the mens wear brand, especially Vimal Red. Already, fabric sales have been initiated at Reliance Trendz and Reliance Mart stores. Reliances vimal done its homework very well in every aspects i.e. advertising, promotion and distribution channel but it was very difficult for vimal to establish its brand as it was in late 80s and early 90s.

ADVERTISING & PROMOTION: A 60 second commercial by Grey Worldwide shows the root values of company, Ad shows- a father readying his son to take over his business empire. He picks his own brand Vimal, of course and ends with original theme tune and tagline. First time any textile company showed its machinery etc in ads to boast that Vimal fabrics were made in the most modern plant in India. Company spent Rs 40 crore on promotion through television, radio spots and print ads, apart from extensive point-of-sale promotions for high visibility.

REASONS FOR RELAUNCH OF VIMAL: Indian textile or garment market is expected to grow by 100% in next five years from Rs 95,000 crore to Rs 190,000 crore. Mens wear market is booming and having Rs 22,000 crore market of which nearly 60 per cent was accounted for by branded apparel. According to Images Technopak, Mens apparel (the largest segment with a 44.9 per cent share) shows a value growth of 12.7 per cent and a volume growth of 4.6 per cent, while the industry as a whole grew by 14.7 and 5.3 per cent, respectively, in 2006. High end technology set up and project management skill of Mukesh dhirubhai Ambani. There is very tough competition for vimal in relaunch because of various well established players and no. of international brands. Indian brands like Park Avenue from Raymond, Madura Garments (Louis Phillipe, Allen Solly, Van Heusen), Arvind Brands (Arrow), Zodiac and Reid & Taylor.Meanwhile, premium international brands like Brioni, Alfred Dunhill and Ermenegildo Zegna have also entered the Indian market.

REASONS FOR DEATH OF BRAND VIMAL: In late 90s reliance focus was changed from textiles to petrochemicals and they were less concerned about their textile division. Marketing myopia, company hasnt foreseen the shift in consumers preferences from suitings to readymade garments. Lack of marketing support Vimal was known for its quality and style. Still people remember its simple baseline "Only Vimal". Lack of marketing support had virtually killed the brand. Now the position that Vimal occupied is now owned by Raymonds and Reid & Taylor.

You might also like

- Leshark Global LLP - InternshipDocument38 pagesLeshark Global LLP - InternshipSowmya LakshmiNo ratings yet

- Fast Fashion, Fashion Brands and Sustainable ConsumptionFrom EverandFast Fashion, Fashion Brands and Sustainable ConsumptionNo ratings yet

- Textile Industry in IndiaDocument15 pagesTextile Industry in IndiaKannan Krishnamurthy50% (2)

- Indian Textile Industry - UnlockedDocument15 pagesIndian Textile Industry - UnlockedHarish BullsNo ratings yet

- Last Nightshift in Savar: The Story of the Spectrum Sweater Factory CollapseFrom EverandLast Nightshift in Savar: The Story of the Spectrum Sweater Factory CollapseNo ratings yet

- Textile Industry in India PDFDocument13 pagesTextile Industry in India PDFarunNo ratings yet

- Indian Textile IndustryDocument0 pagesIndian Textile Industrydianty_marienkafergsNo ratings yet

- Marketing Strategy VIMAL RelianceDocument37 pagesMarketing Strategy VIMAL RelianceM Navneeth Roy100% (1)

- Neva Marketing ProjectDocument92 pagesNeva Marketing ProjectujranchamanNo ratings yet

- Arvind Mills AnalysisDocument18 pagesArvind Mills AnalysisAnup AgarwalNo ratings yet

- Textile Industry in IndiaDocument0 pagesTextile Industry in IndiashanujssNo ratings yet

- Ahmedabad University (AU) H.L. Institute of Commerce (HLIC) Project Assignment For Fundamental of Accountancy Topic-Textile Group No. - 14Document14 pagesAhmedabad University (AU) H.L. Institute of Commerce (HLIC) Project Assignment For Fundamental of Accountancy Topic-Textile Group No. - 14Nishit PatelNo ratings yet

- ChapterDocument35 pagesChaptermohamedthayubsm mbastudentNo ratings yet

- Inventory Management JapanDocument4 pagesInventory Management JapanSURUCHI KUMARINo ratings yet

- Arvind Mills Company ProfileDocument23 pagesArvind Mills Company ProfileBharath Chandra B KNo ratings yet

- MGT541 - Group2 - Final AssignmentDocument21 pagesMGT541 - Group2 - Final AssignmentParth ThakerNo ratings yet

- Swot Analysis of The Indian Textile IndustryDocument30 pagesSwot Analysis of The Indian Textile IndustryDeepali Choudhary57% (14)

- ShahinaDocument20 pagesShahinakurashiNo ratings yet

- Group Assingment of Indian EconmyDocument10 pagesGroup Assingment of Indian EconmyPARMESH SHARMANo ratings yet

- Readymade Garment InfoDocument15 pagesReadymade Garment Infojayti desaiNo ratings yet

- Strategic Management - Textile Industry (Arvind LTD)Document58 pagesStrategic Management - Textile Industry (Arvind LTD)Diana Aloys82% (17)

- Textile IndustryDocument8 pagesTextile IndustryAarav AggarwalNo ratings yet

- Textile Industry in IndiaDocument7 pagesTextile Industry in IndiaSandeep YadavNo ratings yet

- CREYATE: Arvind's Omni Channel AvatarDocument13 pagesCREYATE: Arvind's Omni Channel AvatarAtul GuptaNo ratings yet

- Jury AmukDocument14 pagesJury Amukpranesh kamalNo ratings yet

- A Brief Report On Textile Industries in IndiaDocument10 pagesA Brief Report On Textile Industries in IndiaShreshta KhimesraNo ratings yet

- Reliance IndustriesDocument28 pagesReliance IndustriesKunalRajpalNo ratings yet

- PCL Cotton Spinning Mills (2)Document16 pagesPCL Cotton Spinning Mills (2)Kawalpreet Singh MakkarNo ratings yet

- Case Study On The Denim War Will Arvind Come Out A Winner: Submitted byDocument8 pagesCase Study On The Denim War Will Arvind Come Out A Winner: Submitted bySunit MishraNo ratings yet

- Lalbhai Group - ArvindDocument4 pagesLalbhai Group - Arvindvinoth_17588No ratings yet

- Mahendra R & TDocument73 pagesMahendra R & THarshith ShettyNo ratings yet

- KitexDocument57 pagesKitexRijo M EliasNo ratings yet

- Textile Industry in Developing CountriesDocument18 pagesTextile Industry in Developing CountriesWilson KagaboNo ratings yet

- Arvind Mills Restructuring PlanDocument21 pagesArvind Mills Restructuring PlanPrarrthona Pal Chowdhury50% (2)

- Aysha OsDocument37 pagesAysha OsMUHAMMED USSAIN SHAFINo ratings yet

- Saraswati FinalDocument50 pagesSaraswati FinalNaga SudhaNo ratings yet

- Raymond GroupDocument12 pagesRaymond GroupBhukti DhoruNo ratings yet

- RN 15 Entrepreneurship DevelopmentDocument6 pagesRN 15 Entrepreneurship DevelopmentShane McmillanNo ratings yet

- Textile IndustryDocument23 pagesTextile Industryharshit-kanodia-14No ratings yet

- SCM Pantaloons Project Report Group 11Document19 pagesSCM Pantaloons Project Report Group 11GunjeshJha100% (1)

- Industry Analysis and ResearchDocument22 pagesIndustry Analysis and ResearchMrinal Hashishin YadavNo ratings yet

- HR Policies and Its ImplementationDocument69 pagesHR Policies and Its ImplementationRaj Kumar100% (2)

- Garment IndustryDocument37 pagesGarment IndustryPuneet TandonNo ratings yet

- Chapter - 1: Analysis of Garment IndustryDocument71 pagesChapter - 1: Analysis of Garment IndustryKetan LakumNo ratings yet

- Arvind Mills LimitedDocument4 pagesArvind Mills LimitedMedha PimpleyNo ratings yet

- Synopsis BUSHRA HOSSAINDocument11 pagesSynopsis BUSHRA HOSSAINAhmed BaharNo ratings yet

- A Project Report OnDocument15 pagesA Project Report OnAnkit MourNo ratings yet

- The Raymond Limited: A Study: Director (Research) ICSI-CCGRT, Navi MumbaiDocument14 pagesThe Raymond Limited: A Study: Director (Research) ICSI-CCGRT, Navi Mumbaioptra ceraNo ratings yet

- The Raymond LTD PDFDocument14 pagesThe Raymond LTD PDFVibhav TiwariNo ratings yet

- MENSWEAR Power Point PresentationDocument16 pagesMENSWEAR Power Point PresentationDavid Phillipowsky0% (1)

- INDIAN TEXTILES INDUSTRY Corporate Catalyst India A Report On Indian Textiles IndustryDocument26 pagesINDIAN TEXTILES INDUSTRY Corporate Catalyst India A Report On Indian Textiles IndustryJyoti Kanoi BhimsariaNo ratings yet

- Pioneer Institute of Professional Studies: SWOT Analysis of Arvind LimitedDocument32 pagesPioneer Institute of Professional Studies: SWOT Analysis of Arvind LimitedAneri PrajapatiNo ratings yet

- Nithyakalyani - Main ChaptersDocument25 pagesNithyakalyani - Main Chaptersselva100% (1)

- Company Profileof RajaniDocument77 pagesCompany Profileof RajaniPrasanth PouloseNo ratings yet

- Marketing Strategies of Readymade Garments Industry of IndiaDocument14 pagesMarketing Strategies of Readymade Garments Industry of IndiaShabbiQureshiNo ratings yet

- A Study of Export Competitiveness On Indian Textile IndustryDocument23 pagesA Study of Export Competitiveness On Indian Textile IndustryYashveer Singh RathoreNo ratings yet

- Indian Textile and Nahar SpinningDocument25 pagesIndian Textile and Nahar SpinningrinekshjNo ratings yet

- Assessing The Impact of GI On Kota Doria Weaver's ViewpointDocument12 pagesAssessing The Impact of GI On Kota Doria Weaver's ViewpointEditor IJTSRDNo ratings yet

- Simple Max I Skirt PDF Pattern 1Document18 pagesSimple Max I Skirt PDF Pattern 1benny8racheal100% (1)

- Multi Layer Fabric Design RulesDocument27 pagesMulti Layer Fabric Design RulesusmanteNo ratings yet

- Financial Analysis of Yellow Fashion HouseDocument59 pagesFinancial Analysis of Yellow Fashion HouseOnEy JulfikerNo ratings yet

- Causes of Industrial Backward NessDocument2 pagesCauses of Industrial Backward NessFawad Abbasi100% (1)

- The Mapusa MarketDocument2 pagesThe Mapusa MarketSohraab SarinNo ratings yet

- Textile DocumentDocument28 pagesTextile DocumentKhandaker Sakib FarhadNo ratings yet

- Gridlock Free Quilt InstructionsDocument5 pagesGridlock Free Quilt InstructionsArt Gallery FabricsNo ratings yet

- Enterprise Map of TanzaniaDocument210 pagesEnterprise Map of TanzaniaRavinder Casley GeraNo ratings yet

- Bhanero Textile Mills Limited Annual Report 2019 PDFDocument80 pagesBhanero Textile Mills Limited Annual Report 2019 PDFShahzad QasimNo ratings yet

- Project 2Document2 pagesProject 2jumi shaNo ratings yet

- Digital Textile 2011 Issue 2Document40 pagesDigital Textile 2011 Issue 2james.rex8445No ratings yet

- Alexander McQueenDocument16 pagesAlexander McQueenjaredNo ratings yet

- Projet TomDocument47 pagesProjet TomTom Thomas100% (1)

- Final - Year - B.Tech - MMFT 2021-22Document15 pagesFinal - Year - B.Tech - MMFT 2021-22Adarsh VishwakarmaNo ratings yet

- Current Scenario of Textile MachineryDocument19 pagesCurrent Scenario of Textile MachineryAnonymous aXFUF6No ratings yet

- Textile Training-Maintannance+knittingDocument60 pagesTextile Training-Maintannance+knittingAlamin KhanNo ratings yet

- Roshan Jain (Summer Training Project Report)Document31 pagesRoshan Jain (Summer Training Project Report)roshmyc50% (4)

- Usm Garment CompanyDocument29 pagesUsm Garment CompanyTasya Aryun NingtyasNo ratings yet

- Online Processing of Zari YarnDocument11 pagesOnline Processing of Zari YarnRajkumar BalusamyNo ratings yet

- Overview of Cotton Industry of PakistanDocument11 pagesOverview of Cotton Industry of PakistanRahim Ejaz100% (2)

- b2 Acles Sample ExamDocument19 pagesb2 Acles Sample ExamHoangTruongNo ratings yet

- Variaciones 3011Document80 pagesVariaciones 3011patricia.granadosNo ratings yet

- Consumer PerceptionDocument59 pagesConsumer PerceptionDevnag GaneshanNo ratings yet

- Amigurumi Graduation BookwormDocument3 pagesAmigurumi Graduation BookwormLaura Adams100% (2)

- Khoadd - Uog1@st - Uel.edu - Vn-Diep Dang Khoa-BM5104-UoG0112-Assessment 2Document11 pagesKhoadd - Uog1@st - Uel.edu - Vn-Diep Dang Khoa-BM5104-UoG0112-Assessment 2Khoa Diệp Đăng100% (1)

- Woven Fabric CalculationDocument4 pagesWoven Fabric CalculationHeba Zakaria Abou HashishNo ratings yet

- MHADA INFORMATION BOOKLET ENGLISH Chap-15Document4 pagesMHADA INFORMATION BOOKLET ENGLISH Chap-15Joint Chief Officer, MB MHADANo ratings yet

- TL Annual Report FY 22 Fdbd2f85d7Document123 pagesTL Annual Report FY 22 Fdbd2f85d7Ketan JoshiNo ratings yet

- DCU 7330 X User Manual PDFDocument24 pagesDCU 7330 X User Manual PDFfixitflowNo ratings yet

- PPL Exam Secrets Guide: Aviation Law & Operational ProceduresFrom EverandPPL Exam Secrets Guide: Aviation Law & Operational ProceduresRating: 4.5 out of 5 stars4.5/5 (3)

- 2023/2024 ASVAB For Dummies (+ 7 Practice Tests, Flashcards, & Videos Online)From Everand2023/2024 ASVAB For Dummies (+ 7 Practice Tests, Flashcards, & Videos Online)No ratings yet

- Medical Terminology For Health Professions 4.0: Ultimate Complete Guide to Pass Various Tests Such as the NCLEX, MCAT, PCAT, PAX, CEN (Nursing), EMT (Paramedics), PANCE (Physician Assistants) And Many Others Test Taken by Students in the Medical FieldFrom EverandMedical Terminology For Health Professions 4.0: Ultimate Complete Guide to Pass Various Tests Such as the NCLEX, MCAT, PCAT, PAX, CEN (Nursing), EMT (Paramedics), PANCE (Physician Assistants) And Many Others Test Taken by Students in the Medical FieldRating: 4.5 out of 5 stars4.5/5 (2)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- The Science of Self-Discipline: The Willpower, Mental Toughness, and Self-Control to Resist Temptation and Achieve Your GoalsFrom EverandThe Science of Self-Discipline: The Willpower, Mental Toughness, and Self-Control to Resist Temptation and Achieve Your GoalsRating: 4.5 out of 5 stars4.5/5 (77)

- Preclinical Physiology Review 2023: For USMLE Step 1 and COMLEX-USA Level 1From EverandPreclinical Physiology Review 2023: For USMLE Step 1 and COMLEX-USA Level 1No ratings yet

- Outliers by Malcolm Gladwell - Book Summary: The Story of SuccessFrom EverandOutliers by Malcolm Gladwell - Book Summary: The Story of SuccessRating: 4.5 out of 5 stars4.5/5 (17)

- NCLEX-RN Exam Prep 2024-2025: 500 NCLEX-RN Test Prep Questions and Answers with ExplanationsFrom EverandNCLEX-RN Exam Prep 2024-2025: 500 NCLEX-RN Test Prep Questions and Answers with ExplanationsNo ratings yet

- NCLEX-RN Exam Prep 2024-2025: 500 NCLEX-RN Test Prep Questions and Answers with ExplanationsFrom EverandNCLEX-RN Exam Prep 2024-2025: 500 NCLEX-RN Test Prep Questions and Answers with ExplanationsNo ratings yet

- CUNY Proficiency Examination (CPE): Passbooks Study GuideFrom EverandCUNY Proficiency Examination (CPE): Passbooks Study GuideNo ratings yet

- Airplane Flying Handbook: FAA-H-8083-3C (2024)From EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Rating: 4 out of 5 stars4/5 (12)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Textbook of Plastic and Reconstructive SurgeryFrom EverandTextbook of Plastic and Reconstructive SurgeryDeepak K. Kalaskar B.Tech PhDRating: 4 out of 5 stars4/5 (9)

- Note Taking Mastery: How to Supercharge Your Note Taking Skills & Study Like a GeniusFrom EverandNote Taking Mastery: How to Supercharge Your Note Taking Skills & Study Like a GeniusRating: 3.5 out of 5 stars3.5/5 (10)

- Substation Maintenance Electrical Technician: Passbooks Study GuideFrom EverandSubstation Maintenance Electrical Technician: Passbooks Study GuideNo ratings yet

- The Official U.S. Army Survival Guide: Updated Edition: FM 30-05.70 (FM 21-76)From EverandThe Official U.S. Army Survival Guide: Updated Edition: FM 30-05.70 (FM 21-76)Rating: 4 out of 5 stars4/5 (1)

- Certified Professional Coder (CPC): Passbooks Study GuideFrom EverandCertified Professional Coder (CPC): Passbooks Study GuideRating: 5 out of 5 stars5/5 (1)

- 2024/2025 ASVAB For Dummies: Book + 7 Practice Tests + Flashcards + Videos OnlineFrom Everand2024/2025 ASVAB For Dummies: Book + 7 Practice Tests + Flashcards + Videos OnlineNo ratings yet