Professional Documents

Culture Documents

L350F 21D1002740

Uploaded by

dalibor_bogdanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L350F 21D1002740

Uploaded by

dalibor_bogdanCopyright:

Available Formats

!

VolVo Wheel loader

l350F

2

L35CF |s u whoo| |ouoor hu noor comprom|sos. As u who|o, ho

much|no comb|nos ho || urm s,som uno uuchmons wh|ch mu|o

up u o,num|c un|, u so||o comb|nu|on o powor uno |no|||gonco.

ls us, smooh, uno sub|o, uno ||s boh h|gh uno hou,. A ourub|o

|ouoor hu huno|os ho oughos jobs, urouno ho c|oc|, ou, or n|gh.

Increase your proftability

The bigger the machine, the tougher the

demands on reliability. In fact, a big loader

like the L350F is like a factory on wheels

and requires a business-like approach

where revenues far outweigh costs. In light

of this, youll be glad to know that in most

applications, the L350F is more fuel-

effcient than other machines in its class.

Throw in reliability and youre looking at

outstanding economy and productivity.

All together a signifcant increase in

proftability.

A global company with local presence

When you buy a Volvo L350F, you not only

get one of the most reliable wheel loaders

on the market. With our global dealer

and service network you also get Volvo

Construction Equipment as your reliable

and committed partner. Wherever you are,

you get fast access to well-trained service

personnel and the right parts. In short, all

the products, services, and knowledge

you need to optimize your machines

proftability and productivity.

Volvo a partner to trust

Specifcations L350F

Engine: Volvo D16E LA E3

Max power at

28,330,0 r/s

(17001800 rpm)

SAE J1995 gross: 397 kW (540 metric hp)

ISO 9249, SAE J1349 net: 394 kW (535 metric hp)

Breakout force: 472,8 kN*

Static tipping load at full turn: 34 290 kg*

Buckets: 6,212,7 m

3

Log grapples: 5,56,3 m

2

Operating weight: 50,056,0 t

Tires: 35/65 R33

875/65 R33

* Rock bucket: 6,9 m

3

straight edge with teeth and segments,

Tires: 875/65 R33, Standard boom

3

4

Strength that maximizes your income

Tho vo|o L35CF g|os ,ou u wu, o moo moro ons por hour.

Tho poworu| ong|no comb|noo w|h ho u||, uuomu|c runsm|ss|on

g|os |nsun rosponso oon u ho |owos ong|no spooo, uno vo|os

or|oru|n u|wu,s promoos mux|mum powor whon uno whoro |s

nooooo mos. Tho rosu| |s mux|mu| proouc||, uno |owos poss|b|o

cos por on.

Full power even at idle speed

With Volvos new engine generation, Volvo

wheel loaders have become both more

powerful and easier to operate. The L350F

responds immediately with its 540 hp,

electronically controlled low-emission

engine, which delivers full power even at

low rpm.

Always the right gear

Volvos planetary transmission features

smooth shifting with automatic Lock-Up. All

the operator has to do is to select forward

or reverse, and then Automatic Power Shift

(APS) automatically selects the right gear

to suit current engine revs and ground

speed.

Volvos drivetrain provides top reliability

Volvos drivetrain components are tailored

to match each other and dimensioned to

provide top reliability. On the L350F, the

rear axle is mounted in a maintenance-free

axle cradle, which means that the operator

doesnt have to carry out lubrication and

there is no downtime.

Gentle and powerful brakes

The Volvo L350F is equipped with Volvos

hydraulically operated, axle oil-cooled wet

disc brakes. This system is both powerful

and gentle in operation, while ensuring

long service life.

Volvo Engine D16E V-ACT

Volvos engines feature Volvo Advanced

Combustion Technology, V-ACT, an

emission-controlling solution based on

simple yet proven technology

The turbocharged D16E with air-to-air

intercooling features both electronically

controlled fuel injection and hydrostatic

variable-speed cooling fan and overhead

camshaft with four valves per cylinder

Volvo HTE 400 Heavy-Duty

Transmission

Volvos planetary transmission features

smooth shifting with automatic Lock-Up in

second, third, and fourth gears, saving fuel

to reduce costs

The 4th generation APS featuring automatic

mode selector allows the operator to

choose between four different gear shifting

programs these features save fuel and

promote higher productivity

The transmission automaticaly downshifts

to frst gear when needed

Volvo AHW 90 Heavy-Duty Axles

Outboard-mounted wet disc brakes and

planetary hub reductions increase lateral

stability, optimize oil-cooling and simplify

serviceability

Lifetime-lubed rear axle mounting never

needs greasing

Volvo Brakes

The fully hydraulic dual circuit service

brakes increase site safety and the system

can automatically apply the parking brake

in case of engine shutdown or if brake

pressure is too low

Hydraulic dual circuit system for enhanced

safety

Oil circulation-cooled axles with flters ensure

effective braking and a long service life

5

6

Power with precision

W|h |s || urm s,som, |ouosons|ng h,oruu||cs, ous||, oporuoo

soor|ng uno h|gh sub|||,, ho L35CF u||ows ho oporuor oquu|

mousuros o powor uno proc|s|on. Tho |ouosons|ng h,oruu||c

s,som onsuros hu h,oruu||c o|| |s pumpoo urouno ho s,som

on|, whon uno whoro |s nooooo, pro|o|ng h|ghor oc|onc, uno

|owor uo| consump|on.

No power loss through

the loading cycle

The lift arm system delivers high

breakout torque at ground level, allowing

the operator to handle heavy material

without any power loss at any point in the

loading cycle. This is one of the reasons

why the L350F is an exceptionally effcient

production machine.

Powerful and intelligent

The L350F features an intelligent load-

sensing hydraulic system. Two variable

piston pumps provide exactly the fow rate

and pressure required at any given moment

in time, distributing the power where its

needed, when its needed. When fow is

not required in the hydraulic system, all

engine power is diverted to the drivetrain.

This provides smoother operation, lower

fuel consumption, and more precise con-

trol of machine and load. You always get

full power, regardless of revs.

Well-designed steering with precision

makes it easy to maneuver

Steering is easy even at low rpm. The

load-sensing hydrostatic steering system is

activated only when the steering wheel is

turned, resulting in a highly effcient system

where there is no waste of power or fuel.

The electro-hydraulic steering with Comfort

Drive Control (CDC) is easily operated and

precise, and is stable over the whole speed

range. Furthermore, the CDC features an

end-stroke damping that provides smooth,

full-range steering and eliminates frame

shocks that may occur during quick turns.

Volvo Lift Arm System

Volvos proven lift arm system provides

outstanding breakout force

Improved lift arm geometry allows for

exceptional attachment visibility

Dual pin seals reduce wear for improved

durability and long service life

Volvo Load-Sensing Hydraulics

Electro-hydraulic load-sensing system in-

cludes variable displacement piston pumps

to provide fow and pressure, delivering

power where and when its needed, which

means better fuel-effciency

Volvos Boom Suspension System (BSS)*

features two operating modes and is designed

with heavy-duty shock accumulators that

promote faster, more comfortable work cycles,

boosting productivity by up to 20 percent

Volvo Steering

Steering by steering wheel:

Load-sensing steering only uses power

when its needed, thereby saving fuel.

An accumulator system provides operator

comfort and increased productivity.

Steering by CDC:

Signifcantly reduces repetitive steering

wheel movements by integrating fngertip

controls into the left armrest, helping to

lower operator fatigue while increasing

productivity and operator comfort.

Speed-sensitive steering provides

precision in any application.

An accumulator system provides operator

comfort and increased productivity.

End-stroke damping improves operator

comfort, increases productivity and

component reliability.

Volvo Frames

Volvos world-class frames resist high

stresses and provide superior operational

stability, reduce vibrations, and promote

low sound levels

Well-designed articulation joint not only

looks good, it also provides component

and frame reliability with widely spaced

bearings, the frame resists higher forces,

preventing expensive line boring and

increasing bearing service life

*Optional equipment

7

8

W|h b|g |ouoors, uu||ub|||, |s oor,h|ng. l ho much|no sops, wor|

sops. Thus wh, ho L35CF |s oos|gnoo, oown o ho smu||os oou||,

o wor| w|hou oown|mo, no muor how huro ,ou push |. For

oxump|o, vo|o usos |ors on u|| oxpons|o uno |u| componons o

proon cos|, oown|mo uno ropu|rs. ls bu|| o run.

Volvo a quality concept in itself

Before a new machine generation is

launched on the market, every vital

component and newly designed system

has been individually durability and

fatiguetested in test rigs. Only after passing

that stage are they ready to meet the

worlds toughest test environment the

customers reality for thousands of hours

in our prototypes and pre-series machines.

The test hosts provide their feedback and

comments about every detail directly to

Volvos engineering department. Volvos

Reliability Growth test technology means

more test hours, improved measuring

precision, and predictability in quality

assurance. Volvo is a quality concept in

itself. We set our goals a little higher.

High resale value and long service life

The Volvo L350F is not just one of the most

productive loaders on the market; its also

one of the most cost-effective. There are

several reasons for this Volvos renowned

reliability, our benefcial fnancing packages,

the low fuel consumption, the high resale

value, and the minimal service requirement.

All this makes it the most productive and

reliable machine in the business. Shift after

shift, year after year.

Four levels of support,

one level of care

Your machine should be proftable, not

only today but tomorrow as well. At Volvo

we have an extensive range of different

tools, programs, and service agreements

ensuring that your Volvo will give you

optimal usage and proftability for a long

time ahead. The best way to get the most

out of your Volvo is to invest in a Volvo

Customer Support Agreement. Since

different businesses have different needs,

weve made it easy for you to select the

Customer Support Agreement thats right

for your business by creating four

Customer Support Agreement packages

from a program of regular machine

inspections to a comprehensive repair and

maintenance program, which means that

there is no need for an on-site workshop.

Air from all the major components is vented

through easily replaced flters, preventing

dirty air from entering the transmission,

axles, fuel tank and hydraulic tank

Volvos oil-bath pre-cleaner* in combination

with the standard air flter is far more

effective in dusty and dirty operating

conditions

All electrical cables are well protected

against water, dirt and chafng, routed in

sturdily attached conduits with rubber-

sealed connectors and terminal caps all

the most vital components are well

protected inside the cab

Volvo Reliability Growth (RG) tests for

high quality during thousands of hours

Volvo designed and engineered rear axle

trunnion is maintenance-free and lubed for

life

A brake with two-level warning for high

axle oil temperature provides effective

component protection and longer service

life.

*Optional equipment

Sustained endurance year after year

9

!C

Protection to stay focused in operation

vo|o hus oos|gnoo whoo| |ouoors s|nco !954. P|gh rom ho

bog|nn|ng wo pu suo, rs, uno wo huo usoo u|| ho oxpor|onco

uno |now|oogo wo huo umussoo hroughou hoso ,ours o mu|o

ho L35CF us suo us poss|b|o. Bu no u ho oxponso o comor,

oporu|ng jo,, uno powor. Ou|o ho oppos|o. Wo |now hu suo,

uno proouc||, pur|, |s ho rosu| o u su|soo oporuor mun uno

much|no |n poroc hurmon,.

Volvo Care Cab

Volvos world class operators environment

features a larger, more spacious interior,

large storage compartments, front pillar-

mounted switches and in-cab adjustable

return-to-dig, boom kick-out and bucket

position detents

From the fully adjustable operators seat,

armrest and steering column to the foor-to-

ceiling front windshield, long shifts have

never been so comfortable, and with the

new viscous cab mounts unwanted noise

and vibrations are further dampened

The Volvo Care Cab pressurizes and flters

all incoming air twice, promoting a clean

interior and a healthy, happy operator

Automatic Climate Control promises

consistent cab temperatures throughout the

entire shift

Unobstructed 360 degree visibility defnes

the Volvo Care Cab; a wide laminated

windshield, large windows, narrow ROPS-

pillars with a low reinforcement frame and

optimized visibility over all attachments help

increase productivity night work is

simplifed with the powerful front and rear

halogen lights which provide proper

coverage for the operator

* Optional equipment

** Door side is optional

Generous space

You really feel welcome in Volvos latest

cab. Its both wider and deeper than its

predecessor. There is lots of space to

stretch out your legs, and ample space

for storage boxes, boots, and cups. The

comfortable seat suits operators of all

sizes. The large, swept windshield gives

optimized visibility in every direction,

up high as well, making it easy to load

even with Long Boom*. To facilitate

communication with others on the site,

there are sliding windows on both sides**.

All instruments are easy to read, and on

the right side all buttons are very easily

accessible on a sturdy aluminum pillar.

Always a comfortable climate

Volvos unique and patented two-stage

air cleaning recirculates up to 90 percent

of the air, and only 10 percent comes

from the outside. The air in the cab is

cleaned to 98 percent. Automatic Climate

Control (ACC) is standard and ensures

an always comfortable climate in the cab,

regardless of weather and temperature.

And if the operator needs a break, the heat

can be left on even with the engine off*,

which both saves fuel and protects the

environment.

!!

!2

realtime intelligence supporting 24/7 uptime

Fow much|nos wor| us huro uno |n us ough on|ronmons us ho b|ggor

whoo| |ouoors. ln oroor o |oop sops us shor uno ow us poss|b|o,

vo|o pro|oos wurrun|os uno sor|co s,soms hu uro u||oroo o ,our

much|no uno su|oo o ho oughos |mug|nub|o oporu|ng cono||ons,

horob, roouc|ng oown|mo uno mux|m|z|ng up|mo.

Contronic electronic monitoring system

Over-riding computerized electronic and

monitoring system, dependable and easy

to use

Coordination of reliable engine and

machine computers for optimum

performance and safety

Display information in three categories

current operating data, warning texts and

error messages

Available in 24 languages, monitors fuel

consumption, cycle times and service intervals

The system has built-in safety functions that

automatically limit the engines torque and

power output in case of major malfunctions

in order to protect the engine and

transmission, thus reducing the risk of

subsequent damage

Maintenance and uptime

Electronic monitoring of fuid levels

simplifes and reduces the time needed for

daily inspections, and enhances reliability

Long lubrication intervals mean more time

for productive work

Easily accessible hatches and service

points make service easier

Anti-slip service platforms, wide and angled

cab ladders and conveniently located

handrails provide safe movement around the

machine

CareTrack* advanced telematics

GPS positioning, mapping, Geo- & Time-

fence functions monitor your machine feet

GPRS and/or Satellite transfer of operating

data, error codes**, logged machine data**

Service reminders and alarms, including

forwarding by E-mail and text message

* Optional equipment

** Only available with CareTrack Advanced

Service-friendliness means

more time to work

Volvo assists you in your daily maintenance

by providing simple and quick electronic

checks of oil and fuid levels. All flters and

service points are easily accessible. All

the hatches are large and easy to open.

Pressure check connections and quick-

couplings are conveniently grouped for fast

and simple inspection.

CareTrack* on track and in control

With CareTrack installed in your L350F,

you can concentrate on your core business

while your Volvo Dealer takes care of your

machine. CareTrack allows you to remotely

monitor your machines fuel economy and

performance, shift by shift. The system

also allows your Volvo Dealer to monitor

the machines condition, checking for

problems from many miles away. Service

mechanics can get service reminders,

analyze error codes**, and start problem-

solving before making maintenance

visits. Using the CareTrack mapping and

Geo-fence functions, its easy to locate the

machine, and to prevent unauthorized use.

It all adds up to increased peace of mind.

Let Contronic take control

The L350Fs operation and performance

are controlled by a built-in and highly

reliable electronic network, Volvo

Contronic. It works on three levels; the

system keeps an eye on the machines

functions in real-time, and a service

technician can connect the Contronic

service tool to the system and troubleshoot

directly on the site. All operational data

is stored and can be used to analyze

the machines performance and trace its

history since the most recent service. The

machines functions can be optimized

according to changes in operating

conditions via the Contronic service display,

and machine functions can be adapted to

suit changing conditions.

!3

!4

Access and Serviceability

Easily accessed hatches and service points

Centralized, ground level lubrication banks and grouped pressure

check connections

Lubricated-for-life rear axle bearings

Slip protected service platforms, handrails, wide and angled cab

ladders provide safety

Long lubrication intervals allow more time for productive work

World-Class, Volvo Care Cab

Larger, more spacious cab interior with large storage compartments

Care Cab features the markets best cab fltration system

Front pillar-mounted switches

In-cab adjustable bucket and boom detents

Fully adjustable operators seat, armrest, lever carrier, and steering column

Improved allround visibility includes wide, laminated front windshield and

foor-to-ceiling glass

Viscous damping helps to eliminate unwanted noise and vibrations

Commitment to Volvos Core Values: Quality, Safety, and Care for

the Environment

Roll Over Protection System (ROPS) provides safe operation

Non-return valves prevent leakage of both hydraulic and fuel tanks in case of roll-over

High-quality breather flters on all major components

Optional biodegradable hydraulic oil allows environmentally-friendly operation

All Volvo wheel loaders are more than 95% recyclable

All electrical wiring is routed through high-quality conduits with sealed connectors

Volvo Load-Sensing Hydraulics

Electro-hydraulic, load-sensing system provides exact fow and

pressure where and when its needed

Faster cycle times and increased lift force

Speed-sensitive CDC provides high precision in any application

CDC with end-stroke damping improves operator comfort, increases

productivity and component reliability

Volvo Lift Arm System

Lift arm system provides superior force throughout the lift cycle

Increase in dump height increases loading effciency

Optimized attachment visibility and great rollback angles

Dual pin seals prevent contamination of pins

a machine you can always trust

!5

Volvo Contronic Monitoring System

Network monitors operation and performance in real-time

The Contronic system warns the operator in time, troubleshoots for the service

technician, and helps the machine owner to adapt the wheel loader to the application

Fast and easy electronic level checks of oils and fuids

Display shows continuous operating data, warning texts, and error messages

Monitors fuel consumption, cycle times, and service intervals

Available in 24 languages

Volvo HTE 400 Heavy-Duty Transmission

Automatic Power Shift (APS) with automatic

mode selector

The transmission automaticaly downshifts to frst gear

when needed

Smooth shifting planetary transmission with automatic

Lock-Up in second, third, and fourth gears

Volvo Frames

High-quality steel provides stress resistance and operational stability

Low vibrations and incredibly quiet sound levels

Well-organized articulation joint provides visual appeal and reliability

Upper and lower joints are designed to resist large forces

Volvo Designed and Manufactured Engine

Turbocharged Volvo V-ACT D16E, Tier 3/Stage IIIA-approved D16E

provides tremendous power and impressive low-end torque

Couples outstanding fuel economy, high reliability, and durability with

low levels of noise and exhaust emissions

Engine control with overspeed protection for optimal performance in

all operating conditions

Hydrostatically driven, electronically controlled fan works only when

needed, which saves fuel

Volvo AHW 90 Heavy-Duty Axles

Dual circuit service brakes and automatic parking brake application

Outboard-mounted wet disc brakes and planetary reductions

Optional axle oil cooling provides maximized cooling capacity*

Brake wear indicators on each hub simplifes monitoring of brake pad wear

* Optional equipment

!6

Growth in harmony with the environment

vo|os coro u|uos uro quu||,, suo,, uno on|ronmonu| curo. Wo

roguro our comm|mon o ho on|ronmon us u nuuru| pur o our

on|ro oporu|on, ho gou| o wh|ch |s o mux|m|zo proouc||, uno

oc|onc, u ho |owos poss|b|o cos uno m|n|mu| on|ronmonu|

|mpuc. W|h ho L35CF, ,ou go ono o ho mur|os c|ounos uno

mos ro||ub|o whoo| |ouoors.

Powerful, dependable, and

environmentally optimized

With the new generation of diesel engines,

Volvo has taken yet another giant stride

ahead to reduce emissions, without any

dramatic changes that reduce engine

power. This is possible thanks to the new

V-ACT (Volvo Advanced Combustion

Technology). The systems secret lies in

its advanced method of fuel injection, its

enhanced electronic control of engine

operation, and its smart system of exhaust

gas recirculation. This new engine makes

the L350F more environmentally optimized,

without affecting fuel consumption.

More than 95 percent recyclable

Volvo wheel loaders are almost entirely

recyclable. Components such as the

engine, transmission, and hydraulic system

are re-engineered and reused in our Parts

Exchange Program. For us, this is an

obvious and natural part of our undertaking.

Quality

All major components including

transmission, axles, fuel tank, and hydraulic

tank are well-protected from contamination

with high-quality breather flters, only

replaced every 2000 hours to ensure long

machine life and prevent oil misting

All electrical wiring is routed through high-

quality conduits with rubber-sealed end

connectors, providing true protection from

water, dust, vibration and abrasion

Safety

Dual circuit wheel brake system

Electronic brake testing in Contronic

The parking brake is activated automatically

when the engine is switched off

The Volvo Care Cab has been tested and

approved according to the requirements in

ROPS ISO 3471 and FOPS ISO 3449

Warning signs offer clear information in

the form of symbols and illustrations

Optimized allround visibility gives effective

control over the entire working area

All steps and platforms are provided with

an slip protected surface, as well as

well-positioned handrails

Environment

Volvo wheel loaders are manufactured in

environmentally certifed factories

according to ISO 140001

The Volvo D16E engine meets all existing

emission requirements according to Stage

IIIA and Tier 3

The load-sensing hydraulic system

contributes to low fuel consumption

Optional biodegradeable hydraulic oil

allows environmentally-friendly operation

All Volvo wheel loaders are more than 95%

recyclable with all plastic parts marked

according to ISO standards to simplify

recycling

Low interior and exterior noise levels

!7

!8

Volvo genuine attachments for a perfect match

vo|o whoo| |ouoors uro ronownoo or ho|r h|gh quu||, uno vo|os

gonu|no uuchmons oor oxuc|, ho sumo h|gh quu||,. Th|s |s

ucuu||, un ubso|uo procono||on or our much|nos o oo||or whu

wo prom|so ho h|ghos poss|b|o proouc||,. Much|nos uno

uuchmons hu uro muoo or ouch ohor wor| bos ogohor.

Best penetration capability

and long service life

Genuine Volvo attachments are durable

and last up to three times as long as some

other makes. This high quality stems partly

from our long experience and partly from

our close cooperation with some of the

worlds best material manufacturers. The

high quality also applies to the buckets

wear parts. Their design and the materials

from which they are made give Volvos

edge savers, teeth, and segments the best

penetration capability, long service life, and

short time for replacement of wear parts.

Eogo soo| w|h oxru huroonoo uno oughonoo

wour p|uos o up o 5CC Br|no|| g|os ho buc|o

|ongor oporu|ng ||o

Buc|o sho|| uno s|oo p|uos o up o 4CC Br|no||

o w|hsuno ubrus|o wour

Po|norcoo moun|ng po|ns whoro ho uuchmon |s

|nsu||oo g|o |oss wour

Buc|o cu|ng oogos o ubrus|oros|sun soo| o

up o 5CC Br|no||

Pop|ucoub|o bo|on wour p|uos on buc|o |oor,

5CC Br|no||

Bo|on oogo suors uno sogmons prooc ho

cu|ng oogo rom unnocossur, wour, 5CC Br|no||

vo|o Tooh S,som w|h bo|on or wo|oon uoupors

o up o 5!5 Br|no|| g|os oxco||on ponoru|on uno

|oss buc|o wour

Spuoo noso roc| buc|o w|h ooh uno sogmons

L|gh muor|u| buc|o w|h bo|on oogos

Sru|gh oogo roc| buc|o w|h ooh uno sogmons

Oonoru| purposo buc|o w|h bo|on oogos

S|oooump buc|o w|h bo|on oogos

B|oc| huno||ng or|

!9

Volvo optional equipment boosts your profit

Long boom

A long boom gives the extra dump

height and reach necessary for

loading high trucks or feeders. The

additional reach also gives added

protection when loading the bucket

by keeping the machine farther

away from the material.

Boom Suspension System

(BSS)

BSS utilizes gas/oil accumulators

connected to the lift cylinders

to absorb shocks and smooth

out rough roads for faster cycle

times, less spillage, and increased

operator comfort.

3rd hydraulic function

3rd hydraulic function enable

use of hydraulically attachments.

Automatic Lubrication System

Our factory-installed Automatic

Lubrication System takes care

of greasing while the machine

is in operation. This means

less downtime for scheduled

maintenance and more time for

productive work.

Mudguards

Swing-out rear mudguards to

protect the machine in extreme

conditions. Permit rear boarding.

Rear-view camera system

Rear-view camera system reduces

blind spots and increases site

safety when reversing and also

improves operator comfort.

Limited Slip

Volvos Limited Slip differentials

provide dependable traction in

tough ground conditions, which

reduces tire slip and simplifes

operation.

Engine air pre-cleaners

Volvos own oil-bath pre-cleaner is

available for increased purifcation

of the engine induction air. In

addition to increased cleaning

capacity, these air pre-cleaners

extend service intervals, thereby

reducing maintenance time.

CareTrack telematics system

Remote monitoring of the

machines position, utilization, and

performance. Forwarding of

error codes, alarms, and service

reminders. Position on map plus

Geo & Time-fence functions.

Selection of Volvo optional equipment

2C

IdgfjZ

EdlZg

aW[[i

g$b^c

IdgfjZ

EdlZg

-%% &%%% &'%% &)%% &+%% &-%% '%%%

&* '% '* (% (* g$h

:Xdcdb^Xldg`^c\gVc\Z

]e

&.%%

&-%%

&,%%

&+%%

&*%%

'%%%

&)%%

'+%%

')%%

''%%

'%%%

Cb

`L

)%%

(-%

(+%

()%

('%

(%%

'-%

'+%

**%

*%%

)*%

)%%

(*%

Volvo l350f IN deTaIl

Drivetrain

Torque converter: 3o|omon ,!sugo, !phuso orquo conoror w|h

Loc|Up unc|on uno roowhoo| suor. Transmission: P|unour, Powor

Sh| runsm|ss|on w|h u|| moou|uoo o|ocron|cu||, conro||oo sh||ng o

4 gours orwuro uno roorso. vo|o Auomu|c Powor Sh| (APS) gour sh||ng

s,som w|h u||, uuomu|c sh||ng !4 (Loc|Up |n 34) uno mooo so|ocor

w|h 4 o|oron gour sh||ng progrums, |nc|uo|ng AUTO mooo. Axles: Fu||,

ou|ng ux|o shus w|h p|unour,,po hou,ou, hub roouc|ons. F|xoo ron

ux|o uno osc|||u|ng rour ux|o. Optional: L|m|oo S||p o|oron|u|s |n ron uno

rour ux|o.

Transmission vo|o HTE 4CC

Torque multiplication, stall ratio 2,65

Maximum speed, forward/reverse

1st gear 6,8 / 7,5 |m/h

2nd gear !2,! / !3,2 |m/h

3rd gear 2!,C / 22,9 |m/h

4th gear 35,7 / 38,2 |m/h

Measured with tires 35/65 P33 L4

Front axle/rear axle vo|o AHW 9C/AHW 9C

Rear axle oscillation !2

Ground clearance at 12 osc. 55C mm

Engine

Engine: vACT Sugo lll A/T|or 3, !6 ||or, 6c,||noor |n||no urbochurgoo,

u|rou|r |norcoo|or o|oso| ong|no w|h ooub|o roc|ors uno lnornu| Exhuus

Ous Poc|rcu|u|on (lEOP). Onop|oco c,||noor houo w|h our u|os por c,||noor

uno ono oorhouo cumshu. Tho ong|no hus wo rop|ucoub|o c,||noor ||nors uno

rop|ucoub|o u|o gu|oos uno u|o sous. Mochun|cu||, ucuuoo o|ocron|cu||,

conro||oo un| |njocors. Tho hro|o upp||cu|on |s runsm|oo o|ocr|cu||, rom

ho hro|o poou|. Air cleaning: Throo sugo c,c|ono proc|ounor pr|mur, |or

soconour, |or. Cooling system: H,orosu|c, o|ocron|cu||, conro||oo un

uno |norcoo|or o ho u|rou|r ,po.

Engine vo|o D!6E LAE3

Max power at 28,33C,C r/s (!7CC!8CC r/m|n)

SAE J1995 gross 397 |W (54C mor|c hp)

ISO 9249, SAE J1349 net 394 |W (535 mor|c hp)

Max torque at 23,3 r/s (!4CC r/m|n)

SAE J1995 gross 255C Nm

ISO 9249, SAE J1349 net 2532 Nm

Economic working range !CCC!5CC r/m|n

Displacement !6,! |

2!

Cab

Instrumentation: A|| |mporun |normu|on |s conru||, |ocuoo |n ho oporuors

o|o o |s|on. D|sp|u, or Conron|c mon|or|ng s,som. Houor uno oorosor:

Houor co|| w|h |oroo rosh u|r, un w|h uuo unc|on uno !! munuu||,

so|ocub|o sops, oorosor ons or u|| w|noow urous. Operators seat:

Oporuors sou w|h uojusub|o suspons|on uno rorucub|o soubo|. Tho

sou |s mounoo on u bruc|o on ho rour wu|| uno oor. Tho orcos rom ho

rorucub|o soubo| uro ubsorboo b, ho sou ru||s. Standard: Tho cub |s osoo

uno upprooo uccoro|ng o POPS (lSO 347!, SAE J!C4C), FOPS (lSO 3449).

Tho cub moos w|h roqu|romons uccoro|ng o lSO 6C55 (Oporuor oorhouo

prooc|on lnousr|u| ruc|s) uno SAE J386 (Oporuor Posru|n S,som).

Sound level in cab according to ISO 6396 LpA 72 oB (A)

External sound level according to ISO 6395 LwA !!! oB (A)

Ventilation 9 m

3

/m|n

Heating capacity !3 |W

Air conditioning 8 |W

Lift arm system

Zbur ||n|ugo s,som w|h h|gh brou|ou orcos. Tho || urms uro s|ng|o p|uo

consruc|on w|h u h|ghsrongh soo| cus cross ubo. Tho s|ng|o bo|| crun|

uno buc|o ||n| uro noou|ur |ron cus|ngs.

Lift cylinders 2

Cylinder bore 2CC mm

Piston rod diameter !!C mm

Stroke !264 mm

Tilt cylinder !

Cylinder bore 26C mm

Piston rod diameter !2C mm

Stroke 728 mm

Brakes

Service brake: Sor|co bru|os uro ouu| c|rcu| u||h,oruu||c mu||o|sc

bru|os w|h n|rogonchurgoo uccumu|uors uno uuomu|c s|uc| uojusors.

Oubouromounoo o||coo|oo, wo o|sc bru|os u ouch whoo|. Trunsm|ss|on

o|songugomon our|ng bru||ng cun bo proso|ocoo |n Conron|c. Parking brake:

Wo mu||o|sc ,po |n runsm|sson hous|ng. Spr|ngupp||oo, o|ocroh,oruu||cu||,

ro|ousoo w|h u sw|ch on |nsrumon puno|. App||os uuomu|cu||, whon ho

|o, |s urnoo o. Secondary brake: Duu| c|rcu| ux|ob,ux|o s,som. Acuuoo

b, sor|co bru|o poou|. Low prossuro u|urm. Douo ong|no bru||ng cupub|||,

pro|ooo b, hroo n|rogonchurgoo uccumu|uors. Standard: Tho bru|o s,som

comp||os w|h ho roqu|romons o lSO 345C:!996.

Number of brake discs per wheel !!

Accumulators 6x!,C |

Accumulators for parking brake !xC,5 |

Electrical System

Central warning system: Conron|c o|ocr|cu| s,som w|h conru| wurn|ng ||gh

uno buzzor or o||ow|ng unc|ons: Sor|ous ong|no mu|unc|on Low soor|ng

s,som prossuro Oorspooo wurn|ng ong|no lnorrup|on |n commun|cu|on

(compuor orror) Conru| wurn|ng ||gh uno buzzor w|h gour ongugoo or ho

o||ow|ng unc|ons: Low ong|no o|| prossuro H|gh ong|no o|| omporuuro

H|gh churgou|r omporuuro Low coo|un |oo| H|gh coo|un omporuuro

H|gh crun|cuso prossuro Low runsm|ss|on o|| prossuro H|gh runsm|ss|on

o|| omporuuro Low bru|o prossuro Engugoo pur||ng bru|o Bru|o

churg|ng u||uro Low h,oruu||c o|| |oo| H|gh h,oruu||c o|| omporuuro

Oorspooo|ng |n ongugoo gour H|gh bru|o coo||ng o|| omporuuro ron

uno rour ux|os.

Voltage 24 v

Batteries 2x!2 v

Battery capacity 2x!7C Ah

Cold cranking capacity, approx. !CCC A

Reserve capacity 33C m|n

Alternator rating 228C W/8C A

Starter motor output 7,C |W (9,5 hp mo.)

22

Volvo l350f IN deTaIl

Steering System

Steering system: Louosons|ng h,orosu|c ur|cu|uoo soor|ng w|h un

uccumu|uor s,som. P||ooporuoo h,oruu||c u|os uno nonprossur|zoo un|.

System supply: Tho soor|ng s,som hus pr|or|, ooo rom u |ouosons|ng

ux|u| pump w|h ur|ub|o o|sp|ucomon. CDC: Spoooooponoon o|ocro

h,oruu||c powor soor|ng s,som w|h c|osoo conor h,orosu|c buc|up uno

onosro|o oump|ng.

Steering cylinders 2

Cylinder bore !!C mm

Rod diameter 7C mm

Stroke 586 mm

Working pressure 26,C MPu

Maximum fow 354 |/m|n

Maximum articulation 37

Hydraulic System

System supply: Two |ouosons|ng ux|u| p|son pumps w|h ur|ub|o

o|sp|ucomon. Tho soor|ng unc|on u|wu,s hus pr|or|, rom ono o ho pumps.

vu|os: Doub|ouc|ng 2spoo| u|o. Tho mu|n u|o |s conro||oo b, un o|ocr|c

p||o. Lift function: Tho u|o hus our pos||ons, ||, ho|o, |owor, uno ou

pos||on. lnouc|o/mugno|c uuomu|c boom ||c|ou cun bo sw|choo on uno

o uno |s uojusub|o o un, pos||on bowoon mux|mum rouch uno u|| ||n|ng

ho|gh. Tilt function: Tho u|o hus hroo unc|ons, ro||buc|, ho|o, uno oump.

lnouc|o/mugno|c uuomu|c buc|o pos||onor cun bo sw|choo on uno o.

Cylinders: Doub|ouc|ng c,||noors or u|| unc|ons. Filter: Fu||ow |ru|on

hrough 2C m|cron (ubso|uo) |or curr|ogo. H,oruu||c o|| coo|or: A|rcoo|oo o||

coo|or mounoo on ruo|uor.

Working pressure maximum, pump 1 25,C MPu

Flow

at

engine speed

256 |/m|n

!C MPu

3C r/s (!8CC r/m|n)

Working pressure maximum, pump 2 26,C MPu

Flow

at

engine speed

354 |/m|n

!C MPu

3C r/s (!8CC r/m|n)

Working pressure maximum, pump 3 26,C MPu

Flow

at

engine speed

84 |/m|n

!C MPu

3C r/s (!8CC r/m|n)

Cycle times

Raise* 8,C s

Tilt* !,9 s

Lower, empty 4,7 s

Total cycle time !4,6 s

w|h |ouo uccoro|ng o lSO !4397 uno SAE J8!8

Service

Service accessibility: Lurgo, ous,oopon sor|co ooors w|h gus srus.

Sw|ngou ruo|uor gr|||. F|u|o |ors uno componon brouhor |ors promoo

|ong sor|co |noru|s. Poss|b|||, o mon|or, |og, uno unu|,zo ouu o uc|||uo

roub|oshoo|ng.

Refll capacities

Fuel tank (total) 66C |

Fuel, usable 62C |

Engine oil 4C |

Engine coolant 68 |

Transmission oil 79 |

Axle oil front/rear !55 |

Hydraulic oil tank 365 |

23

24

L

K

J

H

G

E

S

T

U

N

M

Z

P

O

R1

R

15

D

C

B

A

F1

F

F2

a4

a1

a3

a2

V

X

Y

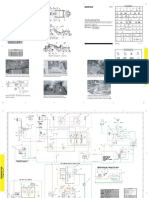

Tires: 35/65 R33 RL5K L5 Goodyear

Standard boom Long boom

Curr, pos||on SAE

Bucket Selection Chart

Tho o|umo huno|oo ur|os w|h ho buc|o || uno |s oon grouor hun

|no|cuoo b, ho buc|os lSO/SAE o|umo. Tho ub|o shows op|mum buc|o

cho|co w|h roguro o ho muor|u| oons|,.

Material Bucket fll, % Material density, t/m

3

Eurh

C|u,

Suno

Oruo|

Poc|

Tho s|zo o roc| buc|os |s op|m|zoo or op|mu| ponoru|on uno |||ng cupub|||,

ruhor hun ho oons|, o ho muor|u|.

SPeCIFICaTIoNS

A(*%;

1,2 1,4 1,6 1,8 2,0

110% 100% 95% 105%

1,0 0,8

Material density (t/m

3

)

Type ol

boom

Type ol

bucket

S

t

a

n

d

a

r

d

b

o

o

m

P

o

c

k

G

e

n

e

r

a

l

p

u

r

p

o

s

e

|SO/SAE

Bucket

volume

Bucket lill

L

i

g

h

t

m

t

r

l

P

o

c

k

L

o

n

g

b

o

o

m

L

i

g

h

t

m

t

r

l

G

e

n

e

r

a

l

p

u

r

p

o

s

e

STE

8,4 m

3

6,9 m

3

9,2 8,4

SPN 6,9 m

3

6,9 6,6

6,9 6,6

SPN ?,? m

3

?,? ?,3

12,? m

3

12,?

12,?

12,? m

3

8,5 ?,?

6,9 6,6

6,5 6,2

6,9 6,6

?,? m

3

STE 6,9 m

3

SPN 6,5 m

3

SPN 6,9 m

3

How to read bucket lill lactor

Supplemental Operating Data

Width

over tires

(mm)

Ground

clearance

(mm)

Operating

weight

(kg)

Static tipping load,

full turn (kg)

Standard

boom

Long

boom

Where applicable, specifcations and dimensions

are according to ISO 7131, SAE J732, ISO 7546,

SAE J742, ISO 14397, SAE J818.

!!C !!5 !,4 !,6

!!C !2C !,4 !,6

!CC !!C !,6 !,9

!CC !!C !,7 !,9

75 !CC !,5 !,9

B 9!3C mm 956C mm

C 43CC mm

D 55C mm

F 4!8C mm

F

!

398C mm

F

2

322C mm

O 2!3C mm

J 492C mm 54CC mm

K 534C mm 58!C mm

O 6C 58

P

mux

46

P 43 45

P

!

49 5C

S 66 72

T !2C mm !3C mm

U 66C mm 77C mm

v 397C mm

X 272C mm

Y 363C mm

Z 423C mm 465C mm

u

2

824C mm

u

3

46!C mm

u

4

37

35/65 P33 XLD D! L4 M|cho||n +!C 2C !!4C !C3C 9!C

35/65 P33 XLD D2 L5 M|cho||n +!C 2C 44C 58C 5!C

35/65 P33 XM|no D2 L5 M|cho||n +2C 2C +26C 5C 4C

35/65 R33 RL5K L5 Goodyear

25

STANDARD BOOM ROCK

GENERAL

PURPOSE

LIGHT

MATERIAL

Tires 875/65 R33 RL5K L5 GY

Pin-on buckets

Teeth

Teeth &

Segments

Bolt-on

edges

Teeth

Teeth &

Segments

Bolt-on

edges

Teeth &

Segments

Bolt-on

edges

Bolt-on

edges

Bolt-on

edges

vo|umo, houpoo lSO/SAE m

3

Su|c |pp|ng |ouo, sru|gh |g

u 35 |g

u u|| urn |g

Brou|ou orco |N

A mm

E mm

H) mm

L mm

M) mm

N) mm

v mm

u

!

c|ourunco c|rc|o mm

Oporu|ng wo|gh |g

) Mousuroo o ho |p o ho buc|o ooh or bo|on oogo. Dump ho|gh o buc|o oogo. Noo: Th|s on|, upp||os o gonu|no vo|o uuchmons.

Mousuroo u 45 oump ung|o. (Spuoo noso buc|os u 42.)

LONG BOOM ROCK

GENERAL

PURPOSE

LIGHT

MATERIAL

Tires 875/65 R33 RL5K L5 GY

Pin-on buckets

Teeth

Teeth &

Segments

Bolt-on

edges

Teeth

Teeth &

Segments

Bolt-on

edges

Teeth &

Segments

Bolt-on

edges

Bolt-on

edges

Bolt-on

edges

vo|umo, houpoo lSO/SAE m

3

Su|c |pp|ng |ouo, sru|gh |g

u 35 |g

u u|| urn |g

Brou|ou orco |N

A mm

E mm

H) mm

L mm

M) mm

N) mm

v mm

u

!

c|ourunco c|rc|o mm

Oporu|ng wo|gh |g

) Mousuroo o ho |p o ho buc|o ooh or bo|on oogo. Dump ho|gh o buc|o oogo. Noo: Th|s on|, upp||os o gonu|no vo|o uuchmons.

Mousuroo u 45 oump ung|o. (Spuoo noso buc|os u 42.)

6,6 6,9 6,9 6,8 6,9 6,9 7,7 7,7 8,4 !2,7

4C C3C 39 C6C 39 34C 38 92C 38 23C 38 73C 37 8!C 38 33C 38 8!C 37 83C

35 7!C 34 78C 35 C6C 34 64C 33 95C 34 46C 33 55C 34 C7C 34 55C 33 56C

35 22C 34 29C 34 58C 34 !5C 33 47C 33 98C 33 C6C 33 59C 34 C7C 33 C8C

5C4,7 472,8 474,8 392,6 372,3 373,9 356,8 358,3 4!9,! 376,4

!C 99C !! C7C !C 74C !! 43C !! 5CC !! !8C !! 6CC !! 27C !C 97C !! !6C

!62C !67C !39C 2CCC 2C5C !77C 2!3C !85C !59C !76C

379C 372C 394C 35CC 343C 365C 337C 359C 379C 364C

746C 746C 746C 743C 743C 743C 755C 755C 728C 773C

!83C !79C !59C 2!6C 2!2C !92C 2!8C !98C !74C !89C

273C 268C 253C 298C 292C 279C 296C 283C 264C 27CC

397C 397C 397C 397C 3 97C 397C 397C 397C 397C 45CC

!8 C9C !8 !CC !7 96C !8 3!C !8 32C !8 !7C !8 37C !8 2!C !8 C6C !865C

49 8!C 5C 23C 5C C2C 5C 28C 5C 7CC 5C 55C 5C 94C 5C 79C 5C !3C 5! C3C

6,2 6,5 6,5 6,4 6,5 6,5 6,9 6,9 7,7 !2,7

37 8!C 36 95C 37 22C 36 86C 36 2!C 36 67C 35 96C 36 42C 36 8!C 35 59C

33 62C 32 8CC 33 C7C 32 7CC 32 C5C 32 52C 3! 8!C 32 28C 32 66C 3! 45C

33 !5C 32 32C 32 6CC 32 23C 3! 58C 32 C5C 3! 34C 3! 8!C 32 !8C 3C 98C

47!,7 442,4 443,6 365,9 347,6 348,5 338,! 339,! 396,8 34!,2

!! 37C !! 43C !! !!C !! 79C !! 86C !! 54C !! 92C !! 6CC !! 3CC !! 58C

!64C !69C !4CC 2C4C 2C8C !79C 2!4C !85C !57C !83C

429C 422C 444C 4C!C 394C 4!6C 39CC 4!2C 43!C 4!3C

787C 787C 787C 785C 784C 784C 79CC 79CC 765C 82CC

!8CC !77C !56C 2!2C 2C9C !89C 2!3C !93C !69C !9!C

3C6C 3C!C 285C 33!C 325C 3!!C 328C 3!4C 295C 3C5C

397C 397C 397C 397C 397C 397C 397C 397C 397C 45CC

!8 38C !8 39C !8 24C !86CC !8 6!C !8 45C !8 64C !8 48C !8 33C !8 96C

5! 32C 5! 74C 5! 53C 5! 79C 52 2!C 52 C6C 52 33C 52 !8C 5! 58C 52 66C

26 26

STANDARD EQUIPMENT

Service and maintenance

Eng|no o|| romoo oru|n uno ||

Trunsm|ss|on o|| romoo oru|n uno ||

Oroupoo |ubr|cu|on po|ns, grouno uccoss|b|o

Prossuro choc| connoc|ons: runsm|ss|on uno h,oruu||c, qu|c|connoc, groupoo on

conso|o or ous, uccoss

Too| box, |oc|ub|o

Whoo| nu wronch ||

Engine

Throo sugo u|r c|ounor, proc|ounor, pr|mur, uno soconour, |or

lno|cuor g|uss or coo|un |oo|

Prohou|ng o |nouc|on u|r

Fuo| pro|or w|h wuor rup

Fuo| |or

Crun|cuso brouhor o|| rup

Electrical system

24 v, prow|roo or op|onu| uccossor|os

A|ornuor 24v/ 8CA

Buor, o|sconnoc sw|ch w|h romoub|o |o,

Fuo| guugo

Hour moor

E|ocr|c horn

lnsrumon c|usor:

Fuo| |oo|

Trunsm|ss|on omporuuro

Coo|un omporuuro

lnsrumon ||gh|ng

Poorso u|urm

L|gh|ng:

Tw|n hu|ogon ron houo||ghs w|h h|gh uno |ow boums

Pur||ng ||ghs

Doub|o bru|o uno u|| ||ghs

Turn s|gnu|s w|h ush|ng huzuro ||gh unc|on

Hu|ogon wor| ||ghs (4 ron uno 4 rour)

Contronic monitoring system

Mon|or|ng uno |ogg|ng o much|no ouu

Conron|c o|sp|u,

Fuo| consump|on

Amb|on omporuuro

C|oc|

Bru|o os

Tos unc|on or wurn|ng uno |no|cuor ||ghs

Wurn|ng uno |no|cuor ||ghs:

Buor, churg|ng

Pur||ng bru|o

Wurn|ng uno o|sp|u, mossugo:

Eng|no coo|un omporuuro

Churgou|r omporuuro

Eng|no o|| omporuuro

Eng|no o|| prossuro

Trunsm|ss|on o|| omporuuro

Trunsm|ss|on o|| prossuro

H,oruu||c o|| omporuuro

Bru|o prossuro

Pur||ng bru|o upp||oo

Pur||ng bru|o NOT upp||oo

Bru|o churg|ng

Oorspooo u o|roc|on chungo

Ax|o o|| omporuuro

Soor|ng prossuro

Crun|cuso prossuro

Auchmon |oc| opon

Loo| wurn|ngs:

Fuo| |oo|

Eng|no o|| |oo|

Eng|no coo|un |oo|

Trunsm|ss|on o|| |oo|

H,oruu||c o|| |oo|

Wushor u|o |oo|

Eng|no orquo roouc|on |n cuso o mu|unc|on |no|cu|on:

H|gh ong|no coo|un omporuuro

H|gh ong|no o|| omporuuro

Low ong|no o|| prossuro

H|gh crun|cuso prossuro

H|gh churgou|r omporuuro

Eng|no shuoown o |o|o |n cuso o mu|unc|on |no|cu|on:

H|gh runsm|ss|on o|| omporuuro

S||p |n runsm|ss|on c|uchos

Ko,puo, buc|grouno ||

Sur |nor|oc| whon gour |s ongugoo

Drivetrain

Auomu|c Powor Sh| (APS) w|h oporuor conro||oo runsm|ss|on o|songugomon

whon bru||ng uno mooo so|ocor w|h AUTO mooo

Fu||, uuomu|c gour sh||ng, !4

Pu|so W|oh Moou|u|on (PWM) conro||oo gour sh||ng

Torquo conoror w|h Loc|Up

Auomu|c Loc|Up sh||ng, 34 (gour so|ocor |n 4) uno 2 (gour so|ocor |n 2)

Forwuro uno roorso sw|ch b, h,oruu||c |oor conso|o

lno|cuor g|uss or runsm|ss|on o|| |oo|

Brake system

Wo o|| c|rcu|u|oncoo|oo o|sc bru|os on u|| our whoo|s

Duu| bru|o c|rcu|s

Duu| bru|o poou|s

Soconour, bru|o s,som

Pur||ng bru|o, o|ocr|ch,oruu||c

Bru|o wour |no|cuors

Cab

POPS (lSO 347!), FOPS (lSO 3449)

Acous|c |nnor ||n|ng

Ashru,

C|guroo ||ghor, 24 v powor ou|o

Loc|ub|o ooor

Cub hou|ng w|h rosh u|r |n|o uno oorosor

Frosh u|r |n|o w|h wo |ors

Auomu|c c||muo conro| (ACC)

F|oor mu

Duu| |nor|or ||ghs

Duu| |nor|or rour|ow m|rrors

Duu| oxor|or rour|ow m|rrors

S||o|ng w|noow, r|gh s|oo

T|noo suo, g|uss

Oporuors sou, KAB, u|rsusponooo, hou,ou,

Lup,po rorucub|o soubo| (SAE J386)

Ergonom|c hou,ou, oporuors sou w|h uojusub|o pos||on uno suspons|on

Soumounoo uojusub|o |oor conso|o, wor||ng h,oruu||cs

Aojusub|o soor|ng whoo|

Sorugo compurmon

Documon poc|o

Sun |sor

Boorugo ho|oor

W|nosh|o|o wushor ron uno rour

W|nosh|o|o w|pors ron uno rour

lnoru| unc|on or ron uno rour w|pors

Sor|co p|uorms w|h s||p proocoo surucos on ron uno rour onoors

Comor Dr|o Conro| (CDC)

Hydraulic system

Mu|n u|o, ooub|ouc|ng 2spoo| w|h o|ocr|c p||os

vur|ub|o o|sp|ucomon ux|u| p|son pumps (3) or:

Soor|ng s,som, wor||ng h,oruu||cs

Wor||ng h,oruu||cs, bru|os

Coo||ng un, bru|os

E|ocr|ch,oruu||c soro conro|

E|ocr|c |oo| |oc|

Boom ||c|ou, uuomu|c, uojusub|o rom cub

Pournoo|g, uuomu|c, uojusub|o rom cub

Buc|o pos||onor, uuomu|c, uojusub|o rom cub

Doub|ouc|ng h,oruu||c c,||noors w|h onooump|ng

lno|cuor g|uss or h,oruu||c o|| |oo|

H,oruu||c o|| coo|or

External equipment

Fonoors, ron w|h rubbor oxons|ons

v|scous cub mouns

Pubbor ong|no uno runsm|ss|on mouns

L||ng o,os

Eus,oopon s|oo puno|s w|h gus srus

Frumo, jo|n |oc|

vunou||sm |oc| propuroo or

Buor|os

Eng|no compurmon

Puo|uor

T|ooown o,os

Pocoor, o,os

Tow h|ch

27 27

OPTIONAL EQUIPMENT

Service and maintenance

Too| ||

Auomu|c |ubr|cu|on s,som

Auomu|c |ubr|cu|on s,som or |ong boom

Po|| pump or uuomu|c |ubr|cu|on s,som

O|| sump||ng u|o

Engine

A|r proc|ounor, o||buh ,po

A|r proc|ounor, c,c|ono ,po

Eng|no b|oc| houor, 23C v

Eng|no uuo shuoown

ESW, |ncrousoo ong|no prooc|on

ESW, o|sub|oo ong|no prooc|on

Huno hro|o conro|

Fuo| || sru|nor

Fus || uo| s,som

Fuo| houor

Poors|b|o coo||ng un

Puo|uor, churgou|r coo|or, ACCconoonsor, corros|onproocoo

Mux. un spooo, ho c||muo

Electrical system

A|ornuor, 8C A w|h u|r |or

A|ornuor, !!C A

Buor,, h|gh cupuc|,

An|ho oo|co

Wor| ||ghs ron, h|gh |nons|, o|schurgo (HlD)

Wor| ||ghs ron, on cub, ouu|

Wor| ||ghs rour, on cub

Wor| ||ghs rour, on cub, ouu|

Wurn|ng boucon, rou|ng

Contronic monitoring system

Pomu|n|ng uo| uno coo||ng oc|onc, |normu|on |n o|sp|u,

Cab

Puo|o w|h CD p|u,or

Puo|o w|h cussoo upo p|u,or

Puo|o |nsu||u|on || |nc|. !! A, !2 v ou|o, |o s|oo

Puo|o |nsu||u|on || |nc|. !! A, !2 v ou|o, r|gh s|oo

Pour|ow cumoru |nc|. mon|or, co|our

Pour|ow m|rrors, o|ocr|cu||, uojusub|o uno houoo

Asbosos ous prooc|on |or

Curbon |or

Auomu|c c||muo conro| puno|, w|h Fuhronho| scu|o

Lunchbox ho|oor

Armros (|o) or KAB oporuor sou

Soubo|, 3, (w|oh 75 mm)

Soor|ng whoo| |nob

Sun b||no, rour w|noow

Sun b||no, s|oo w|noows

T|mor cub hou|ng

S||o|ng w|noow, ooor

W|noow s||o|ng, ooor

Un|orsu| ooor/|gn||on |o,

Drivetrain

L|m|oo S||p o|oron|u|, rour ux|o

L|m|oo S||p o|oron|u|, ron uno rour ux|o

Spooo ||m|or, 2C |m/h

Spooo ||m|or, 3C |m/h

Brake system

O|| coo|ors or ron uno rour ux|os

Hydraulic system

Boom suspons|on s,som w|h s|ng|ouc|ng || unc|on

Arc|c ||, p||o hosos, bru|o uccumu|uors uno h,oruu||c o||

3ro o|ocroh,oruu||c unc|on

3ro o|ocroh,oruu||c unc|on or |ong boom

H,oruu||c o|| coo|or, corros|onproocoo

H,oruu||c uuchmon bruc|o

Sopuruo uuchmon |oc||ng

B|ooogruoub|o h,oruu||c u|o

F|roros|sun h,oruu||c u|o

Ho c||muo h,oruu||c u|o

External equipment

Long boom

Protective equipment

Ouuros or ron houo||ghs

Ouuros or u|| ||ghs

Ouuros or u|| ||ghs, hou,ou,

Ouuros or rour wor| ||ghs

Ouuros or ruo|uor gr|||

W|noows, s|oo uno rour guuros

W|nosh|o|o guuro

Bo||, guuro, ron

Bo||, guuro, rour

Muoguuros xoo ron uno sw|ng ou rour, muoguuros w|oonors |nc|.

Other equipment

Soconour, soor|ng w|h uuomu|c os unc|on

Loggor ors|on

B|oc| huno|or ||

B|oc| huno|or ||, hou,ou,

CEmur||ng

Souno oocu|, EU

CuroTruc|, OSM

CuroTruc|, OSM/Suo|||o

Tires and Rims

35/65 P33 (875/65 P33):

L4

L5

P|ms, 3328.CC/3,5:

F|o p|oco

F|o p|oco, wooo proocoo

F|o p|oco, hou,ou,

Attachments

Buc|os (p|non):

Poc|, sru|gh oogo

Poc|, spuoo noso

Poc|, s|oooump, spuoo noso

Oonoru| purposo, sru|gh oogo

L|gh muor|u|

Wour purs:

Aoupors or ooh, bo|on uno wo|oon

Tooh

Sogmons, bo|on

Eogo suors, bo|on

B|oc| huno||ng oqu|pmon (hoo|on):

Poc| buc|o

Sono or|

Brou|or |no

Pu|o

Log grupp|os

Ref. No. 21 D 100 2740 English

Printed in Sweden 2007.073,0 WLO

Volvo, Eskilstuna

Not all products are available in all markets. Under our policy of continuous improvement, we reserve the right to change

specifcations and design without prior notice. The illustrations do not necessarily show the standard version of the machine.

vo|o Consruc|on Equ|pmon |s o|oron. ls oos|gnoo, bu||

uno supporoo |n u o|oron wu,. Thu o|oronco comos rom

un ong|noor|ng hor|ugo o oor !75 ,ours. A hor|ugo o

h|n||ng rs ubou ho poop|o who ucuu||, uso ho much|nos.

Abou how o ho|p hom bo suor, moro comorub|o, moro

proouc|o. Abou ho on|ronmon wo u|| shuro. Tho rosu|

o hu h|n||ng |s u grow|ng rungo o much|nos uno u g|obu|

suppor nowor| ooo|cuoo o ho|p|ng ,ou oo moro. Poop|o

urouno ho wor|o uro prouo o uso vo|o. Ano woro prouo o

whu mu|os vo|o o|oron More care. Built in.

You might also like

- Operator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesFrom EverandOperator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesRating: 5 out of 5 stars5/5 (3)

- Ew160c Eu EngDocument20 pagesEw160c Eu Engdalibor_bogdan100% (2)

- L110 120FDocument32 pagesL110 120Fdalibor_bogdan100% (1)

- L110 120FDocument32 pagesL110 120Fdalibor_bogdan100% (1)

- Motor Grader Rig Out Catalog: Aftermarket Components and Common Maintenance PartsDocument40 pagesMotor Grader Rig Out Catalog: Aftermarket Components and Common Maintenance PartsZeena DeamilNo ratings yet

- Operational PrincipleDocument270 pagesOperational PrincipleVinod GuptaNo ratings yet

- Caterpillar 854G - Specifications - AEHQ5308-01 (12-1999) PDFDocument20 pagesCaterpillar 854G - Specifications - AEHQ5308-01 (12-1999) PDFmarioNo ratings yet

- Joint Memorandum Circular (JMC) No. 2021Document49 pagesJoint Memorandum Circular (JMC) No. 2021Nicey RubioNo ratings yet

- R30CDocument4 pagesR30CEnrique MurgiaNo ratings yet

- L150 180 220FDocument36 pagesL150 180 220Fdalibor_bogdan33% (3)

- BL61Document12 pagesBL61dalibor_bogdan50% (2)

- John Deere Product BrochureDocument7 pagesJohn Deere Product Brochureapi-309873138No ratings yet

- Yanmar Marine Diesel Engine 2QM20H 3QM30H Service ManualDocument349 pagesYanmar Marine Diesel Engine 2QM20H 3QM30H Service ManualPer ForsbergNo ratings yet

- OMLVU10940Document140 pagesOMLVU10940drwskatefilmsNo ratings yet

- 980H 2006 Engl (d01) PDFDocument20 pages980H 2006 Engl (d01) PDFjude tallyNo ratings yet

- Clark PWD 25 Forklift Service Repair ManualDocument20 pagesClark PWD 25 Forklift Service Repair ManualkfsmmeNo ratings yet

- SWE25B Operator's ManualDocument91 pagesSWE25B Operator's ManualIisakkiNo ratings yet

- Wheel Loader L 586: Product InformationDocument16 pagesWheel Loader L 586: Product InformationcraigNo ratings yet

- Service Manual: TractorDocument41 pagesService Manual: TractorRulax MtzNo ratings yet

- TR60 Tier2 8391Document482 pagesTR60 Tier2 8391Arbey GonzalezNo ratings yet

- Texto Español 994FDocument269 pagesTexto Español 994FEugenio Pizarro MondacaNo ratings yet

- Sebp3021 88 02 AllDocument945 pagesSebp3021 88 02 AllEdin raul Yalle rafaelNo ratings yet

- Chirala, Andhra PradeshDocument7 pagesChirala, Andhra PradeshRam KumarNo ratings yet

- Marketing Management NotesDocument115 pagesMarketing Management NotesKajwangs DanNo ratings yet

- PDF Reply Position Paper For ComplainantDocument4 pagesPDF Reply Position Paper For ComplainantSheron Biase100% (1)

- SPC 10Document3 pagesSPC 10Muhammad Ahsan AkramNo ratings yet

- Ax Wagon LeafletDocument40 pagesAx Wagon LeafletemmanolanNo ratings yet

- CAT Brochure ATRC 12 PageDocument12 pagesCAT Brochure ATRC 12 PageSupriyo AdiNo ratings yet

- Ew140c Eu EngDocument24 pagesEw140c Eu Engdalibor_bogdanNo ratings yet

- Ec240c Eu EngDocument28 pagesEc240c Eu Engdalibor_bogdanNo ratings yet

- Volvo Wheel Loader L60F To L90FDocument36 pagesVolvo Wheel Loader L60F To L90FAshok Subramaniyan50% (2)

- Caterpillar Cat 320d2 Excavator Prefix XBB Service Repair Manual Xbb00001 and Up 1588418222Document23 pagesCaterpillar Cat 320d2 Excavator Prefix XBB Service Repair Manual Xbb00001 and Up 1588418222rayendraNo ratings yet

- Sec of Finance Purisima Vs Philippine Tobacco Institute IncDocument2 pagesSec of Finance Purisima Vs Philippine Tobacco Institute IncCharlotte100% (1)

- Operator Manuals English Version 5.1Document40 pagesOperator Manuals English Version 5.1Alberto Garcia OliverNo ratings yet

- Stick Cylinder - Pala Hidraulica 6040FSDocument9 pagesStick Cylinder - Pala Hidraulica 6040FSAbel Jairo Santos CabelloNo ratings yet

- Volvo Construction ProductsDocument36 pagesVolvo Construction Productsdalibor_bogdan83% (6)

- Ecr145c Eu EngDocument20 pagesEcr145c Eu Engdalibor_bogdan100% (2)

- L30B L35B Pro BrochureDocument14 pagesL30B L35B Pro Brochuredalibor_bogdanNo ratings yet

- Harvesters: 703JH 753JH 759JHDocument18 pagesHarvesters: 703JH 753JH 759JHrossini_danielNo ratings yet

- 777D Off-Highway Truck UpdatesDocument54 pages777D Off-Highway Truck UpdatesGabo Gabo100% (1)

- WA380 7 BrochureDocument24 pagesWA380 7 BrochureAvaa Amgaa100% (1)

- Toro Wheel Horse 268H Lawn and Garden Tractor Operators ManualDocument44 pagesToro Wheel Horse 268H Lawn and Garden Tractor Operators Manualrop703406100% (1)

- Ec360c Eu EngDocument24 pagesEc360c Eu Engdalibor_bogdanNo ratings yet

- 992K With Efficiency Updates SpecalogDocument36 pages992K With Efficiency Updates SpecalogeddyfredyNo ratings yet

- Track-Type Tractor: Engine Engine (Continued)Document24 pagesTrack-Type Tractor: Engine Engine (Continued)eddyfredy100% (1)

- PC138US 8 ExcavatorDocument375 pagesPC138US 8 ExcavatorJuan Camilo Tejada OrjuelaNo ratings yet

- Motos Serie H PDFDocument4 pagesMotos Serie H PDFCarlos GajardoNo ratings yet

- DG716Document153 pagesDG716Ravinder Singh100% (1)

- Adjust Pre Load Wheel Bearing 777 AGCDocument4 pagesAdjust Pre Load Wheel Bearing 777 AGCFaidh Allanz FairhiaNo ratings yet

- EC20B BrochureDocument10 pagesEC20B Brochuredalibor_bogdan100% (1)

- Catalogo CargadorDocument32 pagesCatalogo CargadorMatias ValenzuelaNo ratings yet

- Hydraulic Shovel: Engine Bucket Operating SpecificationsDocument32 pagesHydraulic Shovel: Engine Bucket Operating SpecificationserallatuasanNo ratings yet

- Off-Highway TruckDocument28 pagesOff-Highway Truckardi juNo ratings yet

- Downloaded From Manuals Search EngineDocument241 pagesDownloaded From Manuals Search EngineGuillermo GiordaniNo ratings yet

- Esquema Hidráulico Trailla 631GDocument2 pagesEsquema Hidráulico Trailla 631GJose Carlos Annicchiarico BritoNo ratings yet

- Hydraulic Mining Excavators Tripower The Magic TriangleDocument17 pagesHydraulic Mining Excavators Tripower The Magic TriangleMiguel Angel Rodriguez100% (1)

- Brochure OTR CAT 2016 PDFDocument9 pagesBrochure OTR CAT 2016 PDFdanang_apriyantoNo ratings yet

- Volvo EC700 CDocument24 pagesVolvo EC700 CForomaquinas67% (3)

- A4 G930 - G960 Product Brochure enDocument24 pagesA4 G930 - G960 Product Brochure endalibor_bogdanNo ratings yet

- Ripper (GEJQ0200-04) Prod Bulletin An (English)Document4 pagesRipper (GEJQ0200-04) Prod Bulletin An (English)GARY BAUTISTANo ratings yet

- 5110B Performance Report I (PR00263)Document5 pages5110B Performance Report I (PR00263)suwarjitechnicNo ratings yet

- M 315 CspecalogDocument28 pagesM 315 CspecalogNemanja Subic0% (1)

- Bucyrus 495BII vs. 495HR2 Rope Shovel DifferencesDocument4 pagesBucyrus 495BII vs. 495HR2 Rope Shovel DifferencesManuel VargasNo ratings yet

- HCR 1500 IIDocument4 pagesHCR 1500 IIgiapy0000100% (1)

- ECR28 ECR38 BrochureDocument12 pagesECR28 ECR38 Brochuredalibor_bogdanNo ratings yet

- Retroexcavadora Cat 385CDocument24 pagesRetroexcavadora Cat 385CMax Tapia Castillo100% (1)

- Off-Highway Truck: Engine Operating SpecificationsDocument28 pagesOff-Highway Truck: Engine Operating SpecificationsRobert AndresNo ratings yet

- Liebherr 942 Oil FlowDocument10 pagesLiebherr 942 Oil FlowLiebherr100% (2)

- L60F L350FDocument6 pagesL60F L350FBabu SubramaniamNo ratings yet

- L60F L70F L90FDocument36 pagesL60F L70F L90Fdalibor_bogdanNo ratings yet

- Bl71, Bl71 PlusDocument16 pagesBl71, Bl71 Plusdalibor_bogdanNo ratings yet

- L20B L25BDocument12 pagesL20B L25Bdalibor_bogdan0% (1)

- EW160C Elevated-Cab ENGDocument4 pagesEW160C Elevated-Cab ENGdalibor_bogdanNo ratings yet

- L60F L70F L90FDocument36 pagesL60F L70F L90Fdalibor_bogdanNo ratings yet

- L40B 45B BrochureDocument12 pagesL40B 45B Brochuredalibor_bogdan100% (1)

- L20B L25B Brochure GB 21 4 430 5591Document14 pagesL20B L25B Brochure GB 21 4 430 5591dalibor_bogdanNo ratings yet

- Ew180c Eu EngDocument24 pagesEw180c Eu Engdalibor_bogdanNo ratings yet

- Ecr235c Eu EngDocument20 pagesEcr235c Eu Engdalibor_bogdan100% (1)

- Ec700b Eu EngDocument24 pagesEc700b Eu Engdalibor_bogdanNo ratings yet

- Volvo EC700 CDocument24 pagesVolvo EC700 CForomaquinas67% (3)

- Ec460c Eu EngDocument24 pagesEc460c Eu Engdalibor_bogdanNo ratings yet

- ECR28 ECR38 BrochureDocument12 pagesECR28 ECR38 Brochuredalibor_bogdanNo ratings yet

- Ec360c Eu EngDocument24 pagesEc360c Eu Engdalibor_bogdanNo ratings yet

- Ec290c Eu EngDocument28 pagesEc290c Eu Engdalibor_bogdan100% (1)

- EC210B Forestry Spec SheetDocument2 pagesEC210B Forestry Spec Sheetdalibor_bogdanNo ratings yet

- Ec160c Eu EngDocument24 pagesEc160c Eu Engdalibor_bogdanNo ratings yet

- Ec235cnl Eu EngDocument16 pagesEc235cnl Eu Engdalibor_bogdanNo ratings yet

- Ec180c Eu EngDocument24 pagesEc180c Eu Engdalibor_bogdanNo ratings yet

- EC55B Pro BrochureDocument12 pagesEC55B Pro Brochuredalibor_bogdan100% (1)

- Ec210c Eu EngDocument28 pagesEc210c Eu Engdalibor_bogdanNo ratings yet

- Ec140c Eu EngDocument12 pagesEc140c Eu Engdalibor_bogdanNo ratings yet

- EC55C Brochure GB 21 A 100 3879Document16 pagesEC55C Brochure GB 21 A 100 3879dalibor_bogdanNo ratings yet

- University Assignment Report CT7098Document16 pagesUniversity Assignment Report CT7098Shakeel ShahidNo ratings yet

- A Dream Takes FlightDocument3 pagesA Dream Takes FlightHafiq AmsyarNo ratings yet

- Concept, Types, Characteristics and ClassificationsDocument6 pagesConcept, Types, Characteristics and ClassificationsCJ FaNo ratings yet

- Manual de Instalare Centrala de Incendiu Adresabila 1-4 Bucle Teletek IRIS PRO 250bucla 96 Zone 10000 EvenimenteDocument94 pagesManual de Instalare Centrala de Incendiu Adresabila 1-4 Bucle Teletek IRIS PRO 250bucla 96 Zone 10000 EvenimenteAlexandra DumitruNo ratings yet

- Czar Alexander IIDocument11 pagesCzar Alexander IIMalachy ChinweokwuNo ratings yet

- FilesDocument12 pagesFilesRajesh TuticorinNo ratings yet

- Laporan Mutasi Inventory GlobalDocument61 pagesLaporan Mutasi Inventory GlobalEustas D PickNo ratings yet

- JWCh06 PDFDocument23 pagesJWCh06 PDF007featherNo ratings yet

- Itec 3100 Student Response Lesson PlanDocument3 pagesItec 3100 Student Response Lesson Planapi-346174835No ratings yet

- Risk Ology ManualDocument2 pagesRisk Ology ManualGregoryNo ratings yet

- Research Grants Final/Terminal/Exit Progress Report: Instructions and Reporting FormDocument13 pagesResearch Grants Final/Terminal/Exit Progress Report: Instructions and Reporting FormBikaZee100% (1)

- Hilti X-HVB SpecsDocument4 pagesHilti X-HVB SpecsvjekosimNo ratings yet

- Acknowledgment: George & Also To Our Group Guide Asst. Prof. Simy M Baby, For Their Valuable Guidance and HelpDocument50 pagesAcknowledgment: George & Also To Our Group Guide Asst. Prof. Simy M Baby, For Their Valuable Guidance and HelpKhurram ShahzadNo ratings yet

- Examination: Subject CT5 - Contingencies Core TechnicalDocument7 pagesExamination: Subject CT5 - Contingencies Core TechnicalMadonnaNo ratings yet

- Kunci Jawaban Creative English 3BDocument14 pagesKunci Jawaban Creative English 3BLedjab Fatima67% (3)

- Current Affairs Q&A PDF June 9 2023 by Affairscloud 1Document21 pagesCurrent Affairs Q&A PDF June 9 2023 by Affairscloud 1Yashika GuptaNo ratings yet

- 11 Dole Philippines vs. Maritime Co., G.R. No. L-61352 PDFDocument8 pages11 Dole Philippines vs. Maritime Co., G.R. No. L-61352 PDFpa0l0sNo ratings yet

- Converting An XML File With Many Hierarchy Levels To ABAP FormatDocument8 pagesConverting An XML File With Many Hierarchy Levels To ABAP FormatGisele Cristina Betencourt de OliveiraNo ratings yet

- Schedule of Charges General Banking 2022Document18 pagesSchedule of Charges General Banking 2022Shohag MahmudNo ratings yet

- Corena s2 p150 - Msds - 01185865Document17 pagesCorena s2 p150 - Msds - 01185865Javier LerinNo ratings yet

- Product Data: Airstream™ 42BHC, BVC System Fan CoilsDocument40 pagesProduct Data: Airstream™ 42BHC, BVC System Fan CoilsMaxmore KarumamupiyoNo ratings yet

- Safety interlock switches principlesDocument11 pagesSafety interlock switches principlesChristopher L. AlldrittNo ratings yet

- Factors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawatDocument26 pagesFactors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawathumeragillNo ratings yet

- Model Paper 1Document4 pagesModel Paper 1Benjamin RohitNo ratings yet

- ADC Driver Reference Design Optimizing THD, Noise, and SNR For High Dynamic Range InstrumentationDocument22 pagesADC Driver Reference Design Optimizing THD, Noise, and SNR For High Dynamic Range InstrumentationAdrian SuNo ratings yet