Professional Documents

Culture Documents

Cassava Ethanol Wastewater Treatment

Uploaded by

Cong Thang VuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cassava Ethanol Wastewater Treatment

Uploaded by

Cong Thang VuCopyright:

Available Formats

Thermophilic Anaerobic Treatment of Cassava

Ethanol Wastewater in Continuously Stirred Tank

Reactor (CSTR)

Li Xie, Gang Luo, Qi Zhou, Wenjing Sang, Jiawei Sun

College of Environmental Science and Engineering

Tongji University

Shang Hai, China

sally.xieli@gmail.com

AbstractThe high content of organic matter and suspended

solids with relatively low pH of 4 characterizes the cassava

ethanol wastewater. A lab-scale anaerobic continuously stirred

tank reactor (CSTR) was used under thermophilic condition

(55

o

C) to treat cassava ethanol wastewater. Experimental results

showed that successful start up of the reactor inoculated with

mesophilic granular sludge could be obtained after 40 days

continuous operation with step-wise increases in the organic

loading rate. The organic loading rate could reach as high as

14kgCOD/(m

3

d) by decreasing the hydraulic retention time to 5

days. The performance of reactor was stable with TCOD removal

efficiency of 90% and biogas production of 18L/d containing

about 60% methane. Moreover, significant fluctuation in

performance of reactor was not observed with the changes of

organic loading rate. And results showed adjustment of pH or

alkalinity is not necessary due to the sound buffer capacity of the

system.

Keywords-thermophilic anaerobic; CSTR; cassava ethanol

wastewater; suspended solids

I. INTRODUCTION

Utilization of cassava for ethanol production could provide

the most effective use of natural resources, but generate around

15 tons wastewater with high strength organics for each ton

cassava ethanol production during the fermentation and

distillation process. The high content of organic matter and

solid residues from cassava fragments and peels are of great

environmental concern if not properly treated. Such wastewater

is well suited to anaerobic treatment and there are many high

efficiency reactors to treat cassava wastewater such as UASB.

However high suspended solids (SS) content may decrease the

capacity of UASB, it is common practice to remove solids

before treatment, therefore only the soluble part of the

wastewater with small amount of residual solids (up to 500

mg/L) is admitted to use the UASB reactor [1]. The SS

concentration of cassava ethanol production wastewater could

be as high as 30000mg/L, and the solids could not be easily

separated due to the high viscosity of wastewater and therefore

lower the performance of UASB. Additionally, the separated

solids contain low content of protein, fat and high

concentration of cellulose, which limits its usage as feed for

animals [2]. Therefore, it was necessary to develop an

anaerobic technology which could endure high solids

concentration for the treatment of cassava ethanol wastewater

without decantation process.

Anaerobic continuously stirred tank reactor (CSTR) is

widely used for high solids content organic material of

wastewater, such as sludge, piggery wastewater, food wastes

[3] [4], and herein the solids could be partly converted to

biogas without any separation. Meanwhile, CSTR could

provide improvement in performance and stability of wastes

treatment. In recent years, thermophilic anaerobic process has

gained much attention primarily due to its higher loading

capacity. Moreover, Mladenovska and Ahring observed that

specific biogas production rates were higher under

thermophilic conditions than that of under mesophilic

conditions, attributed mainly to the higher maximum specific

growth rate (2-3 times) of thermophilic microbes than that of

mesophilic analogues [5]. This higher gas production may lead

to an improvement in the energy balance of the biogas

technology, and thereby incur less capital cost as a result of

smaller digester size [6].In thermophilic condition, start-up of

reactor is crucial to establish a proper microbial community.

Poor start-up in biological treatment systems could lead to

prolonged period of acclimation [7] and ineffective removal of

organic matter [8].

Considering the temperature of cassava ethanol wastewater

above 60

o

C, the application of thermophilic anaerobic CSTR in

such wastewater may obtain the advantage of thermophilic

anaerobic. Meanwhile, it is not necessary to remove solids

before CSTR and SS can partly convert to biogas, which can

solve the problem of difficult disposal of separated solids.

Therefore the objectives of this study were to evaluate the

feasibility of thermophilic anaerobic CSTR for cassava ethanol

wastewater treatment and operational conditions such as pH,

alkaline, and biogas production in the reactor were investigated.

II. MATERIALS ANDMETHODS

A. Cassava ethanol wastewater

Cassava ethanol wastewater used in this study was

collected directly from Taicang cassava ethanol plant, located

in Jiangsu province, China. After collected, samples were

pretreated and submitted for analysis.

B. Experimental Set-up and Start-up Conditions

Laboratory-scale equipment was illustrated in Fig.1. An

automatic biological fermentation tank (5L) (Shiyuan,

Shanghai) was used as CSTR with working volume 4L. The

This work was sponsored by the Bayer Sustainable Development Foundation

and the Science Committee Project of Shanghai (No. 062307038)

978-1-4244-1748-3/08/$25.00 2008 IEEE 3001

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

0 20 40 60 80

Time(d)

O

L

R

(

k

g

C

O

D

/

m

3

d

)

0

10

20

30

40

50

60

70

80

90

100

T

C

O

D

R

e

m

o

v

a

l

(

%

)

OLR

TCOD Removal

Fig.1.Schematic Diagram of Experimental Equipment

headspace about 1L was connected to a biogas collector. The

temperature was automatically maintained at 551

o

C in a

heated water bath. The pH of the mixture could be measured

on-line by the installed probe. Wastewater was pumped into

the feeding port, and was continuously mixed at 200rpm by a

mechanical stirrer in the reactor. The effluent was pumped

from the outlet port and separated in the followed settling tank.

Settled sludge was recycled to reactor periodically with

recycling ration of 1:1.

CSTR was started with granular sludge as inoculum from a

mesophilic UASB reactor of Taicang cassava ethanol plant

(Jiangsu Province, China). The pH, volatile suspended solids

and total suspended solids concentration of the inoculums were

7.5, 42g/L, 70g/L, respectively. The reactor was fed with 1L of

granular sludge and 3L raw wastewater diluted with tap water

by 5 times initially, and then operated with stirring for 3 days

without influent and effluent until the pH raised from 6.50 to

7.10. After that the CSTR was continuously operated for 2

weeks until the TCOD removal efficiency was 80%, and then

the organic loading rate (OLR) of the reactor was increased

step by step by decreasing the dilution times of raw wastewater.

Raw wastewater could be directly fed to the reactor after 53

days operation with stable TCOD removal efficiency of 90%.

Successful start-up of CSTR was obtained and later the

hydraulic retention time (HRT) was gradually shortened to

increase the OLR.

C. Analytical Methods

Influent and effluent COD, pH, Alkalinity, VFA, biogas

production were daily determined during the reactor operation.

The other parameters, SS and methane, were determined twice

every week.

Total and soluble COD, SS, VSS, bicarbonate alkalinity

were analyzed in duplicate according to Standard Methods of

APHA [9]. Organic and volatile fatty acids (VFA) were

determined in triplicate by gas chromatograph (HP5890II-FID)

using a CPWAX52CB column. Biogas flow was measured

with a device based on liquid displacement by the outgoing

biogas, and methane content of biogas was determined by

using a Shimadzu GC-8A gas chromatograph equipped with a

flame ionization detector (FID) and a 10m Heliflex AT-1000

capillary column.

Samples were centrifuged at 3500 rpm for 10 min and

filtrated through 0.45m filters for the determination of SCOD,

VFA.

III. RESULTS AND DISCUSSION

A. Characteristics of Cassava Ethanol Wastewater

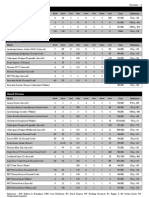

TABLE I. CHARACTERISTICS OF CASSAVA ETHANOL WASTEWATER

Table 1 shows the physicochemical characteristics of the

cassava ethanol wastewater. The temperature of the wastewater

was about 60

o

C. High concentrations of COD and SS in the

range of 40000-70000mg/L and 20000-30000mg/L

respectively characterized the wastewater with relatively low

pH of 4.0. Soluble fraction of the COD varied between 50%

and 75%. The ratio of COD: N: P of the wastewater was about

200:5:1, which was suitable for its bioconversion to methane,

and it is not necessary to add nutrients into the anaerobic

reactor.

B. Performance of CSTR

Fig.2 shows the effect of varying OLR on TCOD removal

efficiency of the CSTR during the start-up and operation period.

OLR was increased progressively at constant step of

1.0kgCOD/(m

3

d) during the start-up period. Initially, the

TCOD of the diluted waste water was about 8000mg/L and the

average TCOD removal efficiency was 60%, which was

contributable to the inadaptability of mesophilic sludge to

thermophilic environment. After 20 days operation

continuously, the inoculum was gradually acclimated to the

Fig.2. Variation of OLR and TCOD removal efficiency during start-up and

operation of CSTR

Parameter Value

Total COD(mg/L) 4000070000

Soluble COD(mg/L) 3000035000

SS(mg/L) 2000030000

pH 4.04.2

Total N(mg/L) 800900

Total P(mg/L) 200400

automatic control

device

CSTR pump

distributing tank

settling tank

effluent

temperature probe

pH probe

biogas

mechanical

mixer

water

bath

gas gathering equipment

3002

b

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

0 20 40 60 80

Time(d)

O

L

R

(

k

g

C

O

D

/

m

3

d

)

0

100

200

300

400

500

600

700

800

V

F

A

(

m

g

/

L

)

OLR

VFA

a

0

1000

2000

3000

4000

5000

6000

A

l

k

a

l

i

n

i

t

y

(

m

g

C

a

C

O

3

/

L

)

6.50

6.60

6.70

6.80

6.90

7.00

7.10

7.20

7.30

7.40

7.50

p

H

Alkalinit y

pH

|

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0 20 40 60 80

Time(d)

M

t

h

u

u

Y

`

'

d

m

3

l

_

T

C

O

D

m

o

v

u

'

)

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

M

e

t

h

a

n

e

Y

i

e

l

d

(

m

3

/

k

g

S

C

O

D

r

e

m

o

v

a

l

)

methane yield(TCOD)

methane yield(SCOD)

a

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

O

L

R

(

k

g

C

O

D

/

m

3

d

)

0

2

4

6

8

10

12

14

16

18

20

B

i

o

g

a

s

P

r

o

d

u

c

t

i

o

n

(

L

/

d

)

OLR

Biogas Production

Fig.3. Variation of acidity and alkalinity during start-up and operation of

CSTR.a.Variation of Alkalinity and pH in the reactor; b.relation of VFA to

OLR

thermophilic condition, and 90% of the TCOD removal

efficiency was obtained. The reactor was gradually adapted to

the raw wastewater at the corresponding OLR of

5.0kgCOD/(m

3

d) with stable TCOD removal efficiency of

90% (Fig.2). After the start-up period (days 1-55), OLR was

continuously increased from 5.0kgCOD/(m

3

d) to

14.0kgCOD/(m

3

d) at the step of 2-3kgCOD/(m

3

d) with the

decrease of HRT from 10 days to 5 days, and TCOD removal

efficiency could still maintain at 90%. Sun and his colleagues

observed that the changes of OLR below 7kgCOD/(m

3

d) could

lead to obvious fluctuation in COD removal efficiency in the

study of stability of anaerobic baffled reactor [10]. However, in

this study, stable operation performance of thermophilic

anaerobic CSTR was observed with the increase of OLR, even

at 14kgCOD/(m

3

d). The performance of reactor was not

affected by the SS concentration of the wastewater. The

effluent SS concentration was lower than 3000mg/L with stable

removal efficiency of above 80% in the whole operation period.

The changes of operational parameters of pH and alkalinity

at different OLR are presented in Fig.3a. The pH of the mixture

was stabilized around 7.30 in the whole period with the

influent pH of 4.2. The alkalinity index could further reflect the

buffer capacity of reactor. As shown in Fig.3a, the alkalinity in

start-up period and operation period is between 1500~2000mg

CaCO

3

/L and 2000~5000mg CaCO

3

/L, respectively. The

higher OLR of 10-14kgCOD/(m

3

d) didnt lead to the decrease

of alkalinity in reactor, which may contributed to the maturity

Fig.4. Variation of Biogas in the start-up and operation process of CSTR.

a.Relation of biogas production to OLR; b.Variation of Methane yield in the

reactor

of anaerobic sludge obtained from start-up period. The range of

alkalinity obtained in this study is well in agreement with

Hashimotos research that alkalinity levels in anaerobic

digesters should maintain from 2500 to 5000mg CaCO

3

/L for

methane production [11]. Additionally, Fig.3b shows that the

total VFA concentration in reactor was almost below 200mg/L

at different OLR. The results described above indicated that the

thermophilic CSTR has strong buffer capacity for cassava

ethanol wastewater and could operate stably without influent

pH adjustment or alkaline addition into the reactor.

C. Biogas Production

The volumetric biogas production (L biogas/d) increased

with the increase in ORL as Fig.4a presents. Biogas production

of 18L/d was obtained at the highest OLR of 14kgCOD/(m

3

d).

Jin et al. noticed that OLR above 4kgCOD/(m

3

d) could inhibit

biogas production when using mesophilic anaerobic digester to

treat food waste [12]. However, no inhibition to biogas

production was observed in this study even at OLR of

11~14kgCOD/(m

3

d). Previous study of temperature effect on

reactor performance has confirmed that organic loading

potentials of anaerobic reactors in thermophilic condition are

substantially higher than that in mesophilic condition and the

reaction rate proceed faster [13]. Methane content in the biogas

was in the range of 55% to 61%. Specific methane yield

calculated by TCOD and SCOD respectively in the whole

period is shown in Fig.4b. The methane yield calculated by

TCOD was relatively stable in the range of 0.20~0.25m

3

, and

the value was obviously lower than theoretical methane yield

3003

of 0.35m

3

/COD removal. However, the methane yield

calculated by SCOD was from 0.37 m

3

to 0.52 m

3

that was

higher than theoretical value. The relatively lower or higher

methane yield counted by TCOD and SCOD should be

attributable to the high SS content of wastewater. Most of SS

was converted to SCOD in the anaerobic reactor, which led to

the higher methane yield calculated by SCOD. More studies

should be conducted to understand the transformation of SS in

CSTR in near future.

IV. CONCLUSIONS

The high content of organic matter and SS from cassava

fragments and peels with relatively low pH of 4 characterizes

the cassava ethanol wastewater. Thermophilic anaerobic

treatment of high strength cassava ethanol wastewater in CSTR

is a robust and reliable process. The overall conclusion from

the research results can be summarized as:

Successful start-up of thermophilic anaerobic CSTR

inoculated with mesophilic granular sludge could be

achieved with the increase in OLR gradually (step by

step) at 1kgCOD/(m

3

d). Raw wastewater without any

dilution could be fed into reactor and the OLR was

5kgCOD/(m

3

d).

In the operation period, the OLR was increased at the

step of 2~5kgCOD/(m

3

d), with the decrease in HRT.

After 80-days operation, the OLR could be as high as

14kgCOD/(m

3

d) with stable TCOD removal

efficiency of 90%, biogas production of 18L/d

containing about 60% methane.

The pH of the mixture was stabilized around 7.30 and

the range of alkalinity was from 2000 to 5000 mg

CaCO

3

/L, indicating the system has good buffer

capacity and influent pH adjustment or addition of

alkaline into reactor is not required.

The methane yield counted on SCOD was

0.37~0.52m

3

, which is higher than theoretical value

due to the bioconversion of SS to SCOD.

ACKNOWLEDGMENT

The authors wish to thank Taicang cassava ethanol plant for

their raw cassava ethanol wastewater samples and valuable

practical experience.

REFERENCES

[1] G.D. Zupani, M.Straiar, M.Ro, Treatment of brewery slurry in

thermophilic anaerobic sequencing batch reactor, bioresource

technology, vol 98, pp 2714-2722, 2007.

[2] K.X.Li, T.P.Wang, Z.J.Zhang, Study on the technology of potato

ethanol wastewater treatment, Chinese Journal of Industrial Water

Treatment, vol 25, pp 13-15, 2005.

[3] I.Angelidaki, X.Chen, J.Cui, P.Kaparaju, L.Ellegaard, Thermophilic

anaerobic digestion of source-sorted organic fraction of household

municipal solid waste: Start-up procedure for continuously stirred tank

reactor. Water Reasearch, vol 40, pp 2621-2628, 2006.

[4] M.A.Rubia, M.Perez, L.I.Romero, D.Sales, Effect of solids retention

time on pilot scale anaerobic thermophilic sludge digestion, Process

Biochemistry, vol 41, pp 79-86, 2005.

[5] Z.Mladenovska, B.K.Ahring, Growth kinetics of thermophilic

Methanosarcina spp. Isolated from full-scale biogas plants treating

animal manure. FEMS Microbiol. Ecol, vol 31, pp225-229, 2000.

[6] H.Bouallagui, O.Haouari, Y.Touhami, R.BenCheikh, L.Marounani,

M.Hamdi, Effect of temperature on the performance of an anaerobic

tubular reactor treating fruit and vegetable waste, Process Biochem, vol

39, pp2143-2148, 2004.

[7] J.H.Wu, W.T.Liu, I.C.Tseng, S.S.Cheng, Characterization of a 4-

methylbenzoate-degrading methanogenic consortium as determined by

small-subunit rDNA sequence analysis. Journal of Bioscience and

Bioengineering, vol 91, pp 449-455, 2001.

[8] M.E.Griffin, K.D.McMahon,R.I.Mackie, L.Raskin, Methanogenic

population dynamics during start-up of anaerobic digesters treating

municipal solid waste and biosolids. Biotechnol. Bioeng, vol 57, pp

342355, 1998.

[9] APHA(American Public Health Association, American Water Works

Association, Water Pollution Control Federation). Standard Methods for

the examination of water and wastewater.17

th

ed. Washington: Rhodes

Trussell Eds, 1995.

[10] J.H.Sun, J.F.Wu, B.Zhang, Effect of shock loads on performance of an

anaerobic reactor, Chinese Journal of Technology of Water Treatment,

vol 30, pp 362-364, 2004.

[11] A.Hashimoto, Y.Chen, V.Varel, S.Robinson, Anaerobic fermentation

of agricultural residue.In:M.L.Shuler,Editor,Utilization and Recycle of

Agricultural Wastes and Residues, CRC Press, Bocar Raton, Florida, pp

145-146,1980.

[12] J.X.Jin, S.H.Wang, XF Xiao, C.S.Yang, Experimental Study on

Traditional Anaerobic Digestion Process for Food Waste Treatment,

Chinese Journal of China Water & Wastewater, vol 23, pp 55-57, 2007.

[13] J.H.Ahn, C.F.Forster, The effect of temperature variations on the

performance of mesophilic and thermophilic anaerobic filters treating a

simulated papermill wastewater, Proc Biochem, vol 37, pp 589-

594,2002.

3004

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 5528 PDFDocument33 pages5528 PDFPham The TuNo ratings yet

- SR5 TOOL Equipment, Drones (Buyable), Compiled ListDocument3 pagesSR5 TOOL Equipment, Drones (Buyable), Compiled ListBeki LokaNo ratings yet

- How To Check The Lms For MR PostingDocument7 pagesHow To Check The Lms For MR PostingMica FloresNo ratings yet

- ENG - B1.1.0106S Talking On The Phone PDFDocument23 pagesENG - B1.1.0106S Talking On The Phone PDFankira78No ratings yet

- Ax1g OmDocument59 pagesAx1g Omskipscooter100% (1)

- Practice Final Exam For CH 1-10 IT Essentials PC Hardware and Software Version 4.1Document10 pagesPractice Final Exam For CH 1-10 IT Essentials PC Hardware and Software Version 4.1Raine Bao75% (4)

- Motion-Sensing Home Automation With VocalizationDocument7 pagesMotion-Sensing Home Automation With VocalizationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Service Product Training - EWAD-EWYD-BZ - Chapter 1 - General Info - Presentations - EnglishDocument23 pagesService Product Training - EWAD-EWYD-BZ - Chapter 1 - General Info - Presentations - Englishjmdc100% (1)

- vs6 Installation and Operation Manual - 2015Document27 pagesvs6 Installation and Operation Manual - 2015Rahmat HidayatNo ratings yet

- ML320 02 Mid-Rear Center Console RemovalDocument7 pagesML320 02 Mid-Rear Center Console RemovalJonathan RojasNo ratings yet

- Recruitment (Robotic) Process Automation (RPA)Document6 pagesRecruitment (Robotic) Process Automation (RPA)Anuja BhakuniNo ratings yet

- 3 Complaint LettersDocument6 pages3 Complaint LettersCarolina Sorto CastañonNo ratings yet

- Parvez Faridi ResumeDocument2 pagesParvez Faridi ResumeNikhil BhattNo ratings yet

- Iec 60287-3-1-2017Document54 pagesIec 60287-3-1-2017markos carrasco100% (2)

- SAP UnifierDocument4 pagesSAP UnifierRajeshNo ratings yet

- Prgframe Without OpDocument63 pagesPrgframe Without Opnitin100% (1)

- ProfinetDocument4 pagesProfinetIulian CernatNo ratings yet

- Research Project ReportDocument21 pagesResearch Project ReportinternationalbankNo ratings yet

- 1MRK504141-BEN A en Product Guide Transformer Protection RET670 2.0Document125 pages1MRK504141-BEN A en Product Guide Transformer Protection RET670 2.0Insan AzizNo ratings yet

- Small Signal Stability Analysis of Jepirachi Wind Park.: Y. Ulianov S. LaínDocument6 pagesSmall Signal Stability Analysis of Jepirachi Wind Park.: Y. Ulianov S. LaínGabriel Andres ValenciaNo ratings yet

- DR - Web Anti-Virus - How To Remove Virus (BackDoor - hupigon2.YBS) - (DRWEBHKDocument2 pagesDR - Web Anti-Virus - How To Remove Virus (BackDoor - hupigon2.YBS) - (DRWEBHKSyazwan Hj ShahNo ratings yet

- Statement 6476869168 20230609 154402 37Document1 pageStatement 6476869168 20230609 154402 37kuttyNo ratings yet

- Unit-5 Wheels and TyresDocument31 pagesUnit-5 Wheels and TyresRahul Verma50% (2)

- 3102354-EN R015 VS Series Compatibility ListDocument20 pages3102354-EN R015 VS Series Compatibility ListFrancisco CanoNo ratings yet

- HMC 045Document12 pagesHMC 045Mohamed ElmakkyNo ratings yet

- Temp-Rise Testing For Synch GeneratorsDocument4 pagesTemp-Rise Testing For Synch GeneratorsdazzawNo ratings yet

- MikrotikDocument4 pagesMikrotikShinichi Ana100% (1)

- Deep Excavation KLCCDocument20 pagesDeep Excavation KLCCamirriyyah100% (1)

- Banana Peel ScriptDocument4 pagesBanana Peel ScriptALoma JaneNo ratings yet

- Cavitation - ANSYS CFD PDFDocument4 pagesCavitation - ANSYS CFD PDFMohsen SalehiNo ratings yet