Professional Documents

Culture Documents

Brochure Unityed

Uploaded by

Helard AlvarezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure Unityed

Uploaded by

Helard AlvarezCopyright:

Available Formats

Engineering & Construction Guide

Tite Liner Engineering & Construction Guide

1.0 Introduction and Overview

United Pipeline Systems developed the Tite Liner system in 1985. Since then, more than 13,000 km (8,000 mi) of pipelines have been lined. Installations of the Tite Liner system have ranged from 50 mm to 1320 mm (2 to 52) in diameter, with larger diameters possible.

2.0 Design Considerations

The following information is required to enable the engineering of a Tite Liner system installation:

The Tite Liner system begins with a high-density polyethylene (HDPE) liner pipe with an outside diameter larger than the inside diameter of the steel pipe it will protect. The steel pipeline is sectioned to allow for the insertion of the HDPE liner pipe. Under normal conditions, average pull lengths are 600-800 meters. Longer pull lengths of a kilometer or more can be achieved depending on the diameter, bends, terrain and condition of the host steel pipe.

2.1 Fluid composition 2.2 Pipeline length 2.3 Steel pipe outside diameter 2.4 Steel pipe wall thickness 2.5 Flange rating 2.6 Type of joint (i.e., welded or mechanical) 2.7 Operating temperature 2.8 Operating pressure 2.9 Test pressure 2.10 Internal condition of line (e.g., scale build-up, etc.) 2.11 System drawing (showing sidebends, overbends, fittings, etc.) 2.12 Site location, right-of-way access and end point access With this information and a possible site visit, United can determine project feasibility and provide a rough budget estimate for your project.

Next, a wireline cable is sent through a section of pipeline and attached to the liner pipe. The wireline pulls the liner pipe through Uniteds Roller Reduction Box, positioned at the insertion end of the pipeline section. The liner pipe is compressed radially as it passes through the Roller Reduction Box. This temporary reduction provides sufficient clearance between the steel pipe and the liner pipe to allow insertion. Until the pulling is complete, the liner is under tension, causing it to remain at a reduced diameter. When the tension is released, the liner pipe expands, creating a tight fit against the inner wall of the steel pipe. Following relaxation of the liner pipe, the polyethylene flange-fittings are attached, and the line is ready for bolt-up and testing.

3.0 Materials and Fittings

The materials and fittings are designed to meet the specific requirements of each pipeline and can be separated into five categories: 3.1 Steel pipe materials 3.2 Polyethylene liner pipe 3.3 Flange connections 3.4 Monitor system 3.5 Lined fittings

Engineering & Construction Guide

3.1 Steel Pipe Materials

The steel pipe portion of a new installation is specified for the pressure and service requirements of the system.

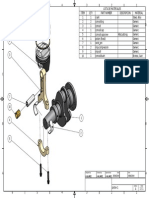

two types of flanged connections for the Tite Liner system:

Tite Liner Flange Connection Slurry Flange Connection

3.2 Liner Pipe for use in the Tite Liner System

High-density polyethylene (HDPE) The polyethylene liner pipe is manufactured to Uniteds specifications by qualified polyethylene pipe manufacturers throughout the world. Typically, the HDPE liner pipe is extruded from PE 80 (PE 3408) or PE 100 (PE 4710) materials in accordance with ASTM specifications. United selects and approves polyethylene manufacturers based on their reputations as leaders in the polyethylene pipe market. Approved manufacturers follow a stringent quality assurance program. Note: United usually installs a customized thin wall liner to provide protection from corrosion, optimize installation lengths and minimize installation costs. A thicker polyethylene liner can be provided for more aggressive abrasive applications. United Pipeline Systems can also offer other alternatives to HDPE for severe service such as sour gas and high temperature fluids outside the HDPE technical envelope. These more exotic thermoplastics typically withstand higher operating temperatures with a lower permeability than HDPE.

The seal for both of these connections is achieved by compression of the polyethylene flange-fitting between the faces of the steel flanges. All components of the connection should be specified and supplied as a unit. Specific information needed for this includes: Steel flange rating Thread-o-let rating Steel pipe outside diameter Steel pipe wall thickness Steel pipe and flange material specifications

3.3.1 Tite Liner Flange Connection

3.3 Flange Connections

All sections of steel lined with Tite Liner pipe are joined using weld neck flange connections. These connections are capable of the ANSI pressure rating of the steel flanges. United uses

The standard Tite Liner flange connection is generally used in corrosive applications and is shown in Figure 1. This connection uses raised face weld neck flanges. Each steel flange is machined to match the inside diameter of the steel pipe and inspected to verify that the raised face dimension is correct. A radius that matches the radius of the polyethylene flange-fitting is machined on the inside of the raised face bore. A spacer ring is placed between each of the steel flanges to allow the correct amount of compression of the polyethylene flange-fitting. No gasket is required as the compressed polyethylene flange-fitting provides a pressure seal. The seal spacer ring provides long term stability to the connection. United manufactures the key components used in the connection to ensure the steel flange, the polyethylene flange-fitting and the steel spacer ring can be assembled as a unit. Quality control must be maintained in these items so that the:

Steel flange internal bore matches the inside diameter of the steel pipe

Engineering & Construction Guide

Radius of the steel flange internal bore matches the polyethylene flange-fitting Raised face is square and of the correct diameter and tolerance to mate to the steel spacer ring Spacer ring is manufactured to the correct width and diameter The same connection is used to connect a lined section to an internally lined fitting or unlined connection. In these cases there will only be one polyethylene flange-fitting compressed between the two raised faces to achieve a seal. A special single-width spacer ring is used in this situation to provide the correct compression.

The Slurry Flange connection was designed and tested to meet ASME B31.11 of the Slurry Transportation Piping System Code.

3.4 Monitoring System

A unique benefit of the Tite Liner system, a pipe-within-a-pipe solution, is the ability to monitor the performance of the system. Prior to liner insertion, thread-o-lets are welded to the steel pipe approximately 15 cm (6) from each steel flange. United will drill a 3 mm (1/8) hole through the steel pipe. At appropriate locations, a 12 mm (1/2) riser pipe is connected to the thread-o-let and brought to surface. A valve is attached to this riser pipe above grade (see Figure 3). It is common practice to routinely operate this valve to ensure the integrity of the liner. All riser pipes can be supported with treated wood posts and protected on the surface by a guard fence.

3.3.2 Slurry Flange Connection

For abrasive applications, United recommends the patented Slurry Flange connection shown in Figure 2. Both the steel flange and the polyethylene flange-fitting are machined with specially designed interlocking surfaces. When the two flanges are bolted together, a uniform surface is maintained across the interface, reducing or eliminating excessive wear from turbulence. The sealing method is the same as the standard flange connection. An optional gasket may be available to provide a secondary seal. The Slurry Flange connection incorporates standard bolting geometry to mate with standard flanges.

Engineering & Construction Guide

3.5 Lined Fittings

The Tite Liner system is best installed in long, straight sections. Standard fittings such as tees, short radius elbows and special configurations can be protected with factorylined polyethylene or other suitable internal coatings. United can furnish special fittings internally lined with polyethylene to match the exact dimensions of the pipe sections.

5.0 Tite Liner System Installation

5.1 Site Preparation 5.1.1 Right-of-Way

When the Tite Liner system is installed in new pipelines, the right-of-way is already cleared and all flanges are accessible. However, in rehabilitation of an existing buried line, provisions must be made to locate and access the line.

4.0 Pipeline Preparation 4.1 New Pipeline

United can help to design and/or construct a new steel pipeline to facilitate economical liner pipe installation. With proper section lengths established before construction, flanges can be welded at end points and bends can be specified with acceptable radii. Proper welding techniques will ensure there is no excessive penetration to impede the insertion or damage the liner pipe. All internal weld bead penetrations should be kept to a maximum of 1.6 mm (1/16) as shown in Figure 4.

5.1.2 Excavation of Buried Line

At each end or mid-point, the line must be excavated to allow straight entry of the wireline cable and liner pipe. The figure below shows typical lengths and configurations of excavations. The length and width of the excavation required depends on numerous factors, including the line size and the depth of cover. United can provide project-specific excavation details and requirements once pertinent site information is obtained.

4.2 Existing Pipeline

An existing steel pipeline will normally require more preparation than a new pipeline. A pressure test can be performed to ensure structural integrity of the pipeline. Depending on the service, an existing steel pipeline may require cleaning (see Section 5.2.1). Fittings must be located and removed, after which a sizing pig is pulled through the line. The sizing pig will locate any obstructions such as protruding weld beads, dents, fittings or changes in wall thickness.

Sample midpoint bellhole detail

Engineering & Construction Guide

5.2 Line Preparation 5.2.1 Line Cleaning

Although cleaning is not usually required in a new line, an existing line may require cleaning once it is taken out of service prior to attaching steel flanges. Any significant hydrocarbon and/or corrosion scale products that would impede the insertion of the liner must be removed. Both the amount and type of hydrocarbon, corrosion or scale deposits must be considered. If cleaning is required, it can often be accomplished by the use of pigs and/or chemicals.

5.2.3 Removal of Tight Bends, Fittings, etc.

Fittings and excessive bends that prohibit the installation of the liner pipe must be removed and replaced with internally-lined flanged fittings or suitable replacement bends welded in place. The ideal bend radius is approximately 50 pipe diameters (50D). A tighter bend radius can be utilized, although the length of the installation segment including the bend may be reduced.

5.2.4 Size Verification

Once end-points have been excavated, steel flanges installed and all known restrictions removed, the size of the line is verified to ensure no further restrictions exist. The unobstructed bore of the steel pipe is established by passing a sizing pig through the steel pipeline. The sizing pig is made of steel and can break through rough weld tips or icicles. If it reaches a point that it cannot pass, the obstruction must be removed. The following table shows sizing pig dimensions through 406.0 mm (16).

Nominal O.D. of Steel Pipe mm (inches) 60.3 to 168.3 (2 to 6) 219.1 to 323.8 (8 to 12) 355.6 to 406.0 (14 to 16) Sizing Pig O.D. Amount Less Nominal Steel I.D. mm (inches) 5.08 (0.20) 6.35 (0.25) 7.62 (0.30)

5.2.2 Liner Section Lengths

When a line is buried, excavations are made at each section end-point as described in Section 5.1.2. The steel line is cut at each excavation, and the flange connections are welded in place. Installation segments are normally determined jointly by the owner/engineer and United. This is determined primarily by bends and other factors such as terrain, accessibility and pipe cleanliness, with care taken not to exceed achievable installation lengths. Typical Average Pull Lengths

Liner Size 2 3 4 6 8 10 12 Typical Average Pull Lengths* 400 meters 500 meters 600 meters 700 meters 800 meters 800 meters 800 meters

*Typical average pull lengths in straight, flat sections. Pull lengths can be longer or shorter depending on many factors, as discussed herein.

Engineering & Construction Guide

5.2.5 Polyethylene Liner Installation

Polyethylene pipe used in the Tite Liner system is manufactured to a custom diameter and wall thickness. Diameters of 4 or smaller may be delivered in coiled lengths up to 800 m (2500 ft) in length. Larger sizes are delivered in joint lengths up to 20 m (65 ft) and joined using the thermal fusion process.

5.2.8 Bolt-up & Pressure Test

After all lined sections are bolted together and a low pressure air test completed, the pipeline can then be pneumatically or hydrostatically tested and all flanged connections and thread-o-lets inspected for leaks.

5.2.9 Clean Up

Following bolt-up and testing, the monitoring riser pipes are attached to the thread-o-lets. The steel flanges are then externally coated, if required, and the line is ready for backfilling and service.

The wireline cable is attached to a pig and sent through the section of steel pipe with compressed air. A pulling head is fused to one end of the polyethylene pipe and connected to the wireline cable. The polyethylene pipe is then pulled into the steel pipe through the United Roller Reduction Box.

5.2.6 Fusion Bead Removal

The external HDPE fusion bead is removed on all liners. The internal fusion bead may be removed for abrasive applications or for future pigging.

5.2.7 Polyethylene Flange-Fitting

Sufficient time for relaxation of the polyethylene pipe must be allowed before the polyethylene flange-fittings are attached. Once installed, the polyethylene flange-fitting provides a continuous lining in the steel pipe and onto the face of the steel flange.

Engineering & Construction Guide

2008 Insituform Technologies, Inc. 9/08

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- McDonnell Douglas DC-10 Flight Crew Operating ManualDocument68 pagesMcDonnell Douglas DC-10 Flight Crew Operating ManualTamás Varga100% (4)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- INNOVAIR VM Blutec Condenser Service Manual 2nd GenDocument46 pagesINNOVAIR VM Blutec Condenser Service Manual 2nd GenEdgard Martin Mejia Solano100% (1)

- MonorailDocument3 pagesMonorailHelard AlvarezNo ratings yet

- Technical Evaluation Overhead CranesDocument4 pagesTechnical Evaluation Overhead CranesHelard AlvarezNo ratings yet

- AUTOSAR Specification of CAN Driver Ver 4.0.0 PDFDocument101 pagesAUTOSAR Specification of CAN Driver Ver 4.0.0 PDFJoshwa2elNo ratings yet

- Asiatech Development & Builders (Adb) Corporation: Concrete Pouring ChecklistDocument1 pageAsiatech Development & Builders (Adb) Corporation: Concrete Pouring ChecklistGenevieve GayosoNo ratings yet

- Thorn Technical Handbook PDFDocument252 pagesThorn Technical Handbook PDFAlvaro GonzalezNo ratings yet

- SRG Tower The Structural Challenges of One of The Worlds Slenderest Residential TowersDocument38 pagesSRG Tower The Structural Challenges of One of The Worlds Slenderest Residential TowersDarshan NakawalaNo ratings yet

- Viga Testera DEMAGDocument56 pagesViga Testera DEMAGHelard AlvarezNo ratings yet

- Trinidad Barangay Evaluation Criteria & ConsolidationDocument14 pagesTrinidad Barangay Evaluation Criteria & Consolidationapi-19750334No ratings yet

- Prefab Shelter BrochureDocument6 pagesPrefab Shelter BrochurepradeepqNo ratings yet

- Engineering drawing layout guideDocument1 pageEngineering drawing layout guideHelard AlvarezNo ratings yet

- Viga Testera DEMAG PDFDocument20 pagesViga Testera DEMAG PDFHelard AlvarezNo ratings yet

- Cisterna ModelDocument1 pageCisterna ModelHelard AlvarezNo ratings yet

- Eje Con DiagramasDocument13 pagesEje Con DiagramasHelard AlvarezNo ratings yet

- Weldsheet SolutionDocument1 pageWeldsheet SolutionHelard AlvarezNo ratings yet

- Crane Beam ExampleDocument1 pageCrane Beam ExampleHelard AlvarezNo ratings yet

- Ensamble de PoleaDocument1 pageEnsamble de PoleaHelard AlvarezNo ratings yet

- Porta RodamientoDocument1 pagePorta RodamientoHelard AlvarezNo ratings yet

- Vistas AuxiliaresDocument1 pageVistas AuxiliaresHelard AlvarezNo ratings yet

- Vol 56 No 03 - Shaft and Hub Keyway and Key SizesDocument4 pagesVol 56 No 03 - Shaft and Hub Keyway and Key SizesramsesluNo ratings yet

- Anillo Truarc N5000 SeriesDocument7 pagesAnillo Truarc N5000 Seriescapellini2010No ratings yet

- Para VistasDocument1 pagePara VistasHelard AlvarezNo ratings yet

- Piston 1Document1 pagePiston 1Helard AlvarezNo ratings yet

- Capstone Project Requirements Definition GuideDocument2 pagesCapstone Project Requirements Definition GuideHelard AlvarezNo ratings yet

- EGR 280 - Mechanics Problem Set 1: Ans: R = 393 lb, θ = 353°Document2 pagesEGR 280 - Mechanics Problem Set 1: Ans: R = 393 lb, θ = 353°Helard AlvarezNo ratings yet

- Eriez SEMag BrochureDocument6 pagesEriez SEMag BrochureadiscribdNo ratings yet

- Car Jack ModeloDocument1 pageCar Jack ModeloHelard AlvarezNo ratings yet

- Work Inspection RequestDocument1 pageWork Inspection RequestMohammed JavidNo ratings yet

- Wallace TreeDocument9 pagesWallace TreeS Vasu KrishnaNo ratings yet

- Properties and Production Methods of Foam ConcreteDocument29 pagesProperties and Production Methods of Foam Concretegonzalez_m_aNo ratings yet

- Bajo Su Sombra The Narration and Recept PDFDocument354 pagesBajo Su Sombra The Narration and Recept PDFDayami Abella PadronNo ratings yet

- Dry Lintel ArchDocument80 pagesDry Lintel ArchGunjan UttamchandaniNo ratings yet

- Encore ENH908-NWYv3 ManualDocument6 pagesEncore ENH908-NWYv3 ManualMarceloPeresNo ratings yet

- 20NiMo9-7 - Liga MetálicaDocument4 pages20NiMo9-7 - Liga MetálicalutherblackNo ratings yet

- The Rheingold Docs On PE ExecutablesDocument38 pagesThe Rheingold Docs On PE ExecutablesfurzraucherNo ratings yet

- Gradle VM Options Android StudioDocument3 pagesGradle VM Options Android StudioJoseNo ratings yet

- Contoh CV PDFDocument1 pageContoh CV PDFFaiz Ivan DharmawanNo ratings yet

- 4 AEGEA Camillas PDFDocument32 pages4 AEGEA Camillas PDFjavier jimenezNo ratings yet

- Ground Floor DimensionsDocument1 pageGround Floor DimensionsMEMES HOUSENo ratings yet

- EOC-5610 v1.3.1 Change LogDocument7 pagesEOC-5610 v1.3.1 Change LogIbrahin AlonsoNo ratings yet

- Single Argument, Which Is An Array of Two Integers. FD (0) Is Set Up For Reading, FD (1) Is Set Up For WritingDocument7 pagesSingle Argument, Which Is An Array of Two Integers. FD (0) Is Set Up For Reading, FD (1) Is Set Up For Writinganiket sriwastvaNo ratings yet

- GE Lighting Systems Decashield Series Spec Sheet 1-76Document2 pagesGE Lighting Systems Decashield Series Spec Sheet 1-76Alan MastersNo ratings yet

- AP Art History - Unit 4Document5 pagesAP Art History - Unit 4Molly MintonNo ratings yet

- Alvar Aalto A Life's WorkDocument10 pagesAlvar Aalto A Life's WorkSanyung LeeNo ratings yet

- HURRAY Henie 3.10Document19 pagesHURRAY Henie 3.10Henie GallyNo ratings yet

- ACO Balcony and Terrace Drainage PDFDocument16 pagesACO Balcony and Terrace Drainage PDFValiNo ratings yet

- Sample Skills ExamDocument6 pagesSample Skills ExamAnkit PatelNo ratings yet

- MUFundamentals4.1 SetupDocument6 pagesMUFundamentals4.1 SetupDoru VadkNo ratings yet