Professional Documents

Culture Documents

269 P

Uploaded by

Anonymous 9kzuGaYOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

269 P

Uploaded by

Anonymous 9kzuGaYCopyright:

Available Formats

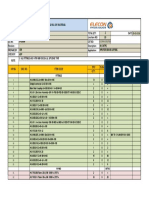

Motor ProtEctIon SyStEM Integrated protection and control for medium sized AC motors

269 Plus

Cost Effective Access to information through standard RS485 serial ports using Modbus RTU Field upgradable settings and firmware Installation flexibility - Remote display and drawout case options

KEy BEnEFItS

Enhanced Thermal Model including current unbalance and RTD biasing Temperature monitoring with programmable RTD inputs for Stator, Bearing and Ambient temperature protection Reduce troubleshooting time and maintenance costs motor running and learned data, last trip data Simplify testing - Built in simulation features

APPlIcAtIonS

Medium size motors

FEAturES

Protection and control

Thermal model biased with RTD and negative sequence current feedback Stator winding & bearing overtemperature Motor multiple starts 8 standard overload curves User defined overload FlexCurve Undercurrent for load loss Locked rotor Rapid trip/mechanical jam Unbalance/single phasing Short circuit Ground fault Phase reversal (meter option) Variable lock-out time Latched main trip relay, alarm relay 2 auxiliary relays Emergency restart capability Pre-trip alarm warnings

Monitoring and Metering

Current & Thermal Capacity metering Data Logger Learned & Statistical Data Optional voltage, power metering 12 RTDs, programmable 5 factory programmed digital inputs 4 output relays 1 programmable analog output

Inputs and outputs

EnerVistatM Software

State of the art software for configuration and commissioning GE Multilin products Document and software archiving toolset to ensure reference material and device utilities are up-to-date EnerVistaTM Integrator providing easy integration of data in the 269 Plus into new or existing monitoring and control systems

Multilin

331

269 Plus Motor Protection System

Protection and control

The 269 Plus is a digital relay designed to provide complete and accurate protection for industrial motors and their associated mechanical systems. Protection functions include:

damage curves, allowing total motor design capacity with complete protection.

unbalance (negative Sequence)

Unbalanced supply voltages means a large increase in the negative sequence current which can result in greatly increased rotor heating. The relay uses the ratio of the negative to positive sequence currents to bias the thermal model. Unbalance and phase loss protection is also provided.

is desirable for maximum stator winding protection. A 50:0.025 A CT or 5 A CT may be used for ground fault detection.

rapid trip/Mechanical Jam

Quick motor shut down can reduce damage to gears, bearings, and other mechanical parts associated with the drive combination. A current surge will cause the relay assigned to the rapid trip/mechanical

10000 9000 8000 7000 6000 5000 4000 3000

Start and running

The motor is protected under both acceleration and running conditions. An alarm or trip may occur based on acceleration time, the number of starts per hour, the time b e t w e e n starts, or motor overload conditions.

undercurrent (Minimum load)

The undercurrent function is used to detect a decrease in motor current caused by a decrease in motor load. This is especially useful for indication of conditions such as loss of suction for pumps, loss of airflow for fans, or a broken belt for conveyors. A separate undercurrent alarm level may be set to provide early warning.

2000

1000 900 800 700 600 500 400 300

overload

One of eight standard overload curves may be programmed based on manufacturers locked ro t o r time capability. Alternatively the user may program a custom curve using the built-in FlexCurve function. The motors service factor value is entered as the overload pickup level.

200

TRIP TIME (SECONDS)

100 90 80 70 60 50 40 30

20

CURVE 8 CURVE 7 CURVE 6

Ground Fault

For zero sequence ground fault protection, all three of the motor conductors must pass through a separate ground fault CT. CTs may be selected to detect either high impedance zero sequence ground faults or residual ground faults. The trip can be instantaneous or time delayed by up to 20 (4) COMMUNICATION ISOLATED seconds. A low level of ground fault pickup with ANALOG

OUTPUTS METERING OPTION VOLTS AMPS

10 9 8 7 6 5 4 3

CURVE 5

CURVE 4

CURVE 3 CURVE 2

Flexcurve

A smooth custom overload curve is created within a selected range using FlexCurve. This curve can be used to protect motors 52 50 50G with different rotor damage and stator

4160V BUS

1 .9 .8 .7 .6 .5 .4 .3

CURVE 1

.2

.1

.1

.2

.3

.4 .5 .6 .7 .8.9 1

6 7 8 910

FULL

LOAD CURRENT SETPOINT

MULTIPLES OF FULL LOAD CURRENT SETPOINT

968516A8.cdr

Eight standard overload curves.

Functional Block diagram

52 FUSED CONTACTOR 4160V BUS 400A

400A

MPM

METERING OPTION

50

50G

(4) ISOLATED ANALOG OUTPUTS VOLTS

COMMUNICATION with METERING OPTION

ANSI Device Numbers & Functions

DEVICE PROTECTION

14 Speed Device MPM 3 86 37 Undercurrent/Minimum Load PHASE CTs 50 OPTION / METERING51 49 37 38 Motor/Load Bearing Overtemperature TRIP AMPS RELAY 46 Unbalance - Negative Sequence FUSED GROUND CT 48 Multiple Starts/Locked Rotor 50G 51G 47 55 27 CONTACTOR Stator DEVICE 49 PROTECTION Winding Overtemperature 49/51 Overload Curves/FlexCurve TM 74 48 46 66 50 Short 14 Speed Device Circuit Mechanical Jam/RapidTrip 37 AMBIENT AIR ALARM 3 STATOR RTDs 86 50G/51G Zero Sequence Ground Fault 37 Undercurrent/Minimum Load RELAY 49 PHASE CTs 50 51 49 37 / 50N/51N Residual Ground Fault 38 Motor/Load Bearing Overtemperature TRIP RTD 269 Plus Motor BEARING RTDs RELAY 52B Breaker 46 Unbalance - Negative Sequence 38 System GROUND CT 74 One Alarm Relay,Two 48 Multiple Starts/Locked Rotor Auxiliary Relays 50G 51G Protection27 47 55 86 Main Overtemperature LOAD 49 Stator Winding Trip Latched Relay AUXILIARY MOTOR RELAY #1 Auxiliary Relay No. 49/51 Overload Curves/FlexCurve TM 1 74 Auxiliary Relay No. 2 50 Short Circuit Mechanical Jam/RapidTrip 14 37 AMBIENT AIR ALARM STATOR RTDs SPEED DEVICE Differential Relay Contact Input 50G/51G 87 Sequence Ground Fault Zero RELAY AUXILIARY 49 14 SELF TEST CONTACTS Starts Fault Residual Groundper Hour ALARM50N/51N 66 RELAY #2 RTD 269 Plus Motor BEARING RTDs 47 52B Breaker Volts Phase Reversal (Meter Option) 38 DIFFERENTIAL Protection System 52B 87 87 27 Alarm Relay,Two Auxiliary Relays Undervoltage (Meter Option) 74 One RELAY CONTACTS Frequency (Meter Option) 86 Main Trip Latched Relay LOAD AUXILIARY MOTOR RELAY #1 55 Power Factor Auxiliary Relay No. 1 (Meter Option) RS485 REMOTE SPARE INPUT Auxiliary Relay No. 2 14 COMMUNICATION 968551A8.cdr STARTER AUXILIARY B CONTACT SPEED DEVICE 87 Differential Relay Contact Input 14 SELF TEST AUXILIARY CONTACTS 66 Starts per Hour ALARM RELAY #2 47 Volts Phase Reversal (Meter Option) DIFFERENTIAL 52B 87 87 27 Undervoltage (Meter Option) RELAY CONTACTS Frequency (Meter Option) 55 Power Factor (Meter Option) RS485

48 46 66

SPARE INPUT STARTER AUXILIARY B CONTACT

REMOTE COMMUNICATION

968551A8.cdr

332

www.GEMultilin.com

70 80 90 100

20

30

40

50

60

269 Plus Motor Protection System

6500 HP 13800 Volt INDUCED DRAFT FAN MOTOR ,

10000

Learned negative sequence contribution (K-factor)

extreme ambient temperatures.

1 PROGRAMMED 269 Plus CUSTOM CURVE 2 RUNNING SAFETIME (ROTOR LIMITED) 3 ACCELERATION SAFETIME (ROTOR LIMITED) 4 MOTOR CURRENT @ 100% VOLTAGE 5 MOTOR CURRENT @ 80% VOLTAGE

1000

1

TIME TO TRIP IN SECONDS

2

100

3

10

To learn the cooldown time, the 269 Plus tracks the stator RTD temperature and calculates the rate of cooling. If an ambient air RTD is also used, the relay uses this value in its calculation. The learned accelerating I 2t value is obtained by measuring actual inrush currents and acceleration time. This learned value is only accepted after sufficient starts have been sampled.

rtd Hot Motor compensation

When hot motor compensation is enabled, the RTD feedback on the actual stator temperature (as measured by the RTDs) checks the thermal capacity model. In addition, the 269 Plus allows the user to match the motor thermal characteristics with a dual slope RTD bias curve. The two part curve allows for easy fitting of hot and cold motor damage curves to the RTD bias feature.

THERMAL CAPACITY USED

100%

4 5

1.0

Start Inhibit with Auto-timed lock-out

MotorMatch provides the 269 Plus with the true motor thermal capacity. When the Start Inhibit feature is enabled, the thermal memory has to sufficiently discharge to make the start possible. The 269 Plus uses the learned start capacity required to determine if sufficient thermal capacity is available for a start. The start inhibit lock-out time is automatically adjusted to allow for optimum motor usage.

75%

0.1 6 7 8 9 10 200 300 400 500

MULTIPLE OF FULL LOAD CURRENT SETPOINT

968588A2.cdr

600 700 800 900 1000

0.5

20

30

40

50

0.6 0.7 0.8 0.9 1

60 70 80 90 100

50%

Typical FlexCurve.

jam function to become active. The user may set the pickup level, the trip time delay and an alarm for early warning.

25% 15%

RTD BIAS CENTER T.C.

0% 0C 40C RTD BIAS MIN. VALUE 80C 120C 110C RTD BIAS CENTER VALUE 160C

MAXIMUM STATOR TEMPERATURE

200C

Stator overtemperature

Overtemperature protection of the stator windings is provided by monitoring up to six stator RTDs. If less than six RTDs are used for stator monitoring, the remaining RTDs may be used for any other temperature monitoring function desired. Individual RTD alarm, high alarm and trip levels are set by the user.

Emergency restart

It may be necessary to restart a faulted motor for reasons of production or safety. To override a start inhibit or overload trip lockout condition, the emergency restart feature can be used. This clears the thermal memory, allowing a manual reset and restart. The 269 Plus can be programmed to provide a single shot emergency restart following an overload trip. The accumulated I2t value is automatically reduced to a level that would allow a restart. After the restart attempt, if the relay trips the motor again on running overload, it will remain latched for the appropriate lock-out time.

155C RTD BIAS MAX. VALUE

FACTORY PRESET CURVE: Min.= 40C, Center = 110C & Max.= 155C Center Thermal Capacity = 15% 968570A6.cdr

RTD bias curve sample.

Exponential cooldown

The 269 Plus has a true exponential cooldown characteristic which mimics actual motor cooling rates. This allows motors to be load cycled more frequently since the initial rate of cooling is very steep. Two setpoints are required to use the exponential cooldown, the full load current (FLC) reduction and the running cool time. The FLC reduction is the amount of thermal capacity used when the motor is running at a constant 100% FLC condition. This represents the constant percentage difference between the cold damage curve and the hot damage curve. The running cool time is the time for the thermal memory to discharge from 100% to 0% with the motor running in a non-overload condition. If the motor comes from an overloaded condition to a light load condition, then the cooling rate is much faster initially and the thermal capacity used would be reduced accordingly.

temperature Monitor

A total of 10 RTD inputs are available. Any RTD inputs not used for stator RTD protection can be used for other temperature monitoring functions. Separate alarm and trip level temperatures can be selected for each RTD.

thermal Modeling

A unique feature of the 269 Plus relay is its ability to compute the motor I2t value based on actual motor load current. The thermal model calculates this value in terms of thermal capacity used. The RTDs measuring the stator temperature act as a thermal capacity check to confirm the value calculated by the thermal model. The thermal capacity used is then updated to reflect the higher of the two values. This accounts for heat due to I2t as well as motor heating due to loss of cooling or

MotorMatch

To obtain maximum use from the protected motor, the MotorMatch system modifies the initial relay parameters to match actual measured motor characteristics. The key elements include: 2 n Accumulated I t in the memory

n n n

RTD input to the memory Learned cooldown time from run to stop Learned cooldown time from run-overload to run-normal Learned acceleration time

www.GEMultilin.com

333

269 Plus Motor Protection System

VFd Applications

The 269 Plus is capable of protecting motors fed from variable frequency drives (VFDs), including pulse width modulated (PWM) drives. The 269 Plus has been extensively tested with varying current waveforms and frequencies ranging from 15 to 300 Hz.

contact input . The 52b contact from a circuit breaker gives positive identification of the position of the breaker (open or closed), and should be used in applications to any synchronous machine or induction machine that may run unloaded.

Fault diagnosis

The relay displays the cause of a trip and shows the remaining lock-out time if applicable. In addition, the cause of the last trip and pre-trip values can be recalled for fault diagnosis.

outputs

The 269 Plus has four output relay contacts. The trip relay acts as the main latched output relay. An alarm and two auxiliary output relays have been provided. The alarm relay and Auxiliary 1 relay may be programmed for latched or unlatched modes. The trip, alarm and Auxiliary 1 relays may be programmed fail-safe or non fail-safe. Auxiliary 2 is set to latched and fail-safe. The 269 Plus also has an analog output which can be used to indicate one of motor thermal capacity used, motor current , hottest stator RTD, bearing RTD or CT secondary current.

Statistical data (Stattrac)

Statistical data of motor use for operations monitoring, maintenance, and fault diagnosis is provided by the StatTrac feature. Using the keypad, the user can display the running hours and number of starts since last commissioning, the total number of trips and their types, and the total mega-watt-hours (with the meter option).

current transformers (cts)

The 269 Plus receives its current input from user installed 5 A or 1 A secondary CTs. The CT ratio is programmed using the

THERMAL CAPACITY USED 100 90 80 70 60 50 40 30 20 10 0.00 0.00 27 55 82 110 137 165 192 220 247

FLC Reduction Set @ 20% & 100% FLC.

FLC Reduction is 8% @ 40% FLC.

Self-test

A continuous self-check is maintained with or without the motor running, and an alarm is provided for relay internal malfunctions. The alarm triggers a status indication on the front panel and sends a signal to a user-selectable output relay.

TIME (Seconds X 10)

968579A3.cdr

269 Plus exponential cool down curve graph.

Monitoring and Metering

keypad. The maximum CT ratio is 1500:1 or 1500:5. High resistance ground fault sensing can be accommodated using a 50:0.025 A zero sequence CT. A 5 A CT may be used for low resistance or solidly grounded systems. The 269 Plus offers advanced monitoring and metering functions that include:

MPM Motor Protection Meter

This optional module provides additional measurement and output capabilities. It can only be used as an external option module. One MPM module can be connected to the 269 Plus via a dedicated serial communication link.

Actual Values

Actual values can be viewed for: n Average and individual phase currents

n

RTD temperatures (hottest, individual, maximum) Unbalance ratio (%In/Ip) Ground leakage current Thermal capacity remaining/estimated time to trip at present overload level Motor load as a percent of full load Phase-to-phase or phase-to-neutral voltage (meter option) W, var, MWhr, PF, Hz (meter option)

Inputs and outputs

The 269 Plus features a variety of input and output channels such as:

n n n

Speed Switch Input

The speed switch input terminals allow use of an external speed device. This is typically used to allow a locked rotor condition to be distinguished from a normal start, and to shut down following a short delay.

n n

EnerVistatM Software

The EnerVista Suite is an industry leading set of software programs that will simplify every aspect of using the 369 relay. Tools to monitor the status of your motor, maintain your relay, and integrate information measured by the 369 into HMI or SCADA monitoring systems are available. Also provided are the utilities to analyze the cause of faults and system disturbances using the powerful waveform and Sequence of Event viewers that come with the EnerVista 369 Setup Software that is included with each relay.

Prior Alarms

The 269 Plus can trigger an alarm prior to a trip caused by the following conditions: n Immediate overload/stall warning

n n n n n

differential relay Input

Terminals are provided to accept contact closure from an external differential relay, and to provide a facility for grouping all protective functions through one main relay.

Ground fault Mechanical jam Unbalance Undercurrent RTD overtemperature, broken RTD sensor, low temperature RTD Self-test and service Under/overvoltage (meter option) Low power factor (meter option)

Spare Input

The spare input terminals can be configured to represent either a standard or a specific

n n n

EnerVista launchpad

EnerVista Launchpad is a powerful software package that provides users

334

www.GEMultilin.com

269 Plus Motor Protection System

with all of the setup and support tools needed for configuring and maintaining GE Multilin products. Launchpad allows configuring devices in real-time by communicating using serial, Ethernet, or modem connections, or offline by creating setting files to be sent to devices at a later time. Included in Launchpad is a document archiving and management system that ensures critical documentation is up-to-date and available when needed. Documents made available include: Manuals Application Notes Guideform Specifications Brochures Wiring Diagrams FAQs Service Bulletins

Features

Front View

DISPLAY 48 Character alpha-numeric backlit LCD display for viewing actual values, causes of alarms and trips, and programming setpoints STATUS INDICATORS 4 LEDs indicate when an output is activated. When an LED is lit the cause of the output relay operation will be shown on the display Service LED is lit during a selftest alarm HELP KEY Help key can be pressed at any time to provide additional information KEYPAD Used to select the display of actual values, causes of alarms, causes of trips, fault diagnosis and to program setpoints Rugged, corrosion and flame retardant case. Meets IP40X

EnerVista Integrator

EnerVista TM Integrator is a toolkit that allows seamless integration of GE Multilin devices into new or existing automation systems. Included in EnerVista Integrator is: OPC/DDE Server GE Multilin Drivers Automatic Event Retrieval Automatic Waveform Retrieval

CONTROL POWER 120/125 AC/DC, 240/250 AC/DC, 24 DC, 48 DC 4 OUTPUT RELAYS Programmable alarm and trip conditions activated by programmable setpoints, switch input, remote communication control RTD 7-10 can be assigned to monitor motor and load bearings, and ambient temperature

rear View

drawout case option

The 269 Plus can be ordered with a drawout case option. All of the features available for the standard model are included with the drawout model. Shorting contacts across the CT inputs and main trip output relay contacts allow for removal of the relay for bench testing without shutdown of the motor. The relay can also be tested while remaining in the case using a test plug (XLA test plug) connected to test equipment.

RTD 1-3 Typically used for stator winding protection RTD 4-6 Typically used for stator winding protection

Phase and ground CT inputs

968178A5.eps

Contrast dial

www.GEMultilin.com

335

269 Plus Motor Protection System

typical Wiring

CONTROL POWER L N

NOTES

269Plus TYPICAL WIRING

RTD10 CAN BE USED FOR AMBIENT SENSING ON THE 269 PLUS RELAY. CR CONTACTOR INTERPOSING RELAY.

START

STOP

FUSE

1). OUTPUT RELAY CONTACTS SHOWN :

CR

ALARM

RTD ALARM

SELF TEST ALARM

GROUND BUS

CONTROL POWER APPLIED, NO TRIPS, NO ALARMS & FACTORY CONFIGURATIONS IN EFFECT. TRIP FAILSAFE ALARM NONFAILSAFE AUX.1 NONFAILSAFE AUX.2 FAILSAFE TERMINALS 44 THRU 59 ALSO 84 & 85.

2). USE TWISTED PAIR FOR CONNECTIONS TO 3). ALL RTDs MUST BE OF THE SAME TYPE.

ALTERNATE CONNECTION FOR COMMON SHIELD

29 30 31 32 33 34 35 36 37 38 39 40 41 42 43

L GND L2 / N

TRIP ALARM AUX. 1 OUTPUT RELAYS AUX. 2 INPUT POWER

Available with 4 wire MOD

28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 86 87 12 11 10 9 8 7 6 5 4 3 2 1

Shield

Com

RTD10

Shield

Com

RTD9

Shield

Com

RTD8

Shield

Com

RTD7

Rx Rx Shield

RS422

Com

RTD3

Shield

Com

RTD2

Shield

Com

RTD1

44 45 84 METER 85 48 DIFFERENTIAL RELAY 49 50 SPEED SWITCH 51 52 ACCESS 53 54 EMERGENCY RESTART 55 56 EXTERNAL RESET 57 ANALOG GND 58 OUT 59 46 RS485 47 Shield 88 Shield 60 61 RTD6 Com 62 63 Shield 64 Multilin 269 Plus Motor Protection System RTD5 65 Com 66 67 Shield 68 69 RTD4 Com 70 71

SPARE INPUT PHASE C C / T GROUND C / T

52b METER COM PORT EXTERNAL CONTACTS EXTERNAL CONTACTS JUMPER OR KEYSWITCH KEYSWITCH EXTERNAL RESET AMMETER OR PROGRAMABLE CONTROLLER RS485 COM PORT GROUNDED AT MASTER ONLY

4). USE EITHER RESIDUAL OR ZERO SEQUENCE

CONNECTION FOR GROUND FAULT INPUT. (NOTE: ZERO SEQUENCE CONNECTION IS RECOMMENDED)

5). USE TWISTED SHIELDED PAIR WHEN USING

USE TWISTED PAIR WHEN USING THE 5 AMP INPUT TERMINALS # 72 & 73

THE 2000:1 INPUTTERMINALS # 73 & 74

6). THE 2000:1 TERMINALS ( # 73 & 74)

ACCEPT INPUT ONL FROM Y A 50:0.025A (2000:1 RATIO) GE PM CURRENT SENSOR. THE USE OF THIS CT IS RECOMMENDED FOR RESISTANCE GROUNDED SYSTEMS. TERMINALS # 73 & 74 DO NOT ACCEPT INPUT FROM A 1 AMP SECONDARY CT . EXTERNALL AS THEY ARE INTERNALLY Y CONNECTED TO THE RELA GROUND TERMINAL Y

PHASE A C/T

PHASE B C /T

1A COM 5A 83 82 81

1A COM 5A 80 79 78

1A COM 5A 77 76 75

5A 74 73 72

2000 :1

COM

7). RTD SHIELD(S) SHOULD NOT BE GROUNDED

# 42.

TWISTED SHIELDED

C A B

A B

L1

L2

PHASE A CT

MOTOR

PHASE B CT PHASE C CT 50:0.025 GROUND CT

L3

ZERO SEQUENCE GROUND CONNECTION

8). THE STARTER AUXILIARY B CONTACT

PHASE A C/T PHASE B C /T PHASE C C / T GROUND C / T SHOULD BE CONNECTED ACROSS TERMINALS (44 & 45). THE APPROPRIATE SETPOINT ON P .5 MUST BE PROGRAMMED TO DETERMINE THE STATUS OF THE STARTER

1A COM 5A 83 82 81

1A COM 5A 80 79 78

1A COM 5A 77 76 75

COM 5A 74 73 72

2000 :1

L1 C A B C A B L2 PHASE A CT

MOTOR

PHASE B CT PHASE C CT

L3

RESIDUAL GROUND CONNECTION (ALTERNATE)

968565B2.cdr

336

www.GEMultilin.com

269 Plus Motor Protection System

technical Specifications

ProtEctIon PHASE currEnt InPutS conversion: Calibrated RMS, sample 2 ms range: 0.05 to 12 x phase CT primary amps setpoint Full scale: 12 x phase CT primary amps setpoint Accuracy: 0.5% of full scale (0.05 to 2 x phase CT primary amps setpoint) 1.0% of full scale (over 2 x phase CT primary amps setpoint) Frequency: 20 400 Hz Ground FAult currEnt InPut conversion: Calibrated RMS, sample time 2 ms range: 0.1 to 1.0 x G/F CT primary amps setpoint (5 A secondary C.T.) 1.0 to 10.0 A, 50:0.025 A (2000:1 ratio) Full Scale: 1 x G/F CT primary amps setpoint (5 A secondary C.T.) 10 A (2000:1 C.T.) Accuracy: 4% of G/F CT primary amps setpoint (5 A secondary C.T.) 0.3 A primary (2000:1 C.T.) Frequency: 20 400 Hz, for 5 A CTs 20 to 150 Hz for 2000:1 CTs oVErloAd curVES trip time Accuracy: 1 sec up to 13 sec 8% of trip time over 13 sec detection level: 1% of primary CT amps rElAy locK-out tIME Accuracy: 1 min with control power applied 20% of total lock-out time with no control power applied unBAlAncE display Accuracy: 2 percentage points of true negative sequence unbalance (In/Ip) EXPonEntIAl cooldoWn Accuracy: 2% of true exponential runnInG HourS countEr Accuracy: 1% PoWEr SuPPly control PoWEr Input: LO: 20 60 VDC 20 48 VAC: 50/60 Hz HI:80 300 VDC 65 265 VAC: 50/60 Hz Maximum power consumption: 20 VA Holdup: 100 ms (@ 120 VAC/125 VDC) InPutS rtd InPutS Sensor types: ct BurdEn duE to connEctIon oF 269 PluS rElAy 10 copper 100 nickel 120 nickel 100 platinum (specified with order) 2 C 0 200 C 3 C 25% of RTD 0 C resistance ct input Burden (A) 1 A (VA) 0.04 (m ) 43 4A 0.5 31 13 A 4.8 28 5A 0.06 2.4 Phase ct 20 A 1 2.5 (5 A) 65 A 8.5 2.01 5A 0.08 3 G/F ct (5 A) 10 A 0.3 3 0.025 A 0.435 696 G/F ct 0.1 A 3.29 329 (50:0.025) 0.5 A 50 200 Phase ct (1 A) EnVIronMEntAl operating temperature range: -25 C to +60 C Humidity: Up to 95%, non-condensing Altitude: Up to 2000 m Pollution degree: 2 tyPE tEStS dielectric strength: Insulation resistance: transients: 2.0 kV for 1 min to relays, CTs, power supply IEC255-5, 500 VDC ANSI C37.90.1 oscillatory 2.5 kV/1 MHz ANSI C37.90.1 fast rise 5 kV/10 ns Ontario Hydro A-28M-82 IEC255-4 impulse/high frequency disturbance Class III level IEC 255-5 0.5 J 5 kV 50 MHz/15 W transmitter C37.90.2 electromagnetic interference @ 150 MHz and 450 MHz, 10 V/m IEC 801-2 static discharge 95% non-condensing -25 C to +60 C ambient IEC 68-2-38 temperature/humidity cycle NEMA 12/IP53 8.6 lbs (3.9 kg) 16 x 11 x 7 (40.6 cm x 27.9 cm x 43.2 cm)

display accuracy: trip/alarm setpoint range: dead band: Maximum lead resistance: ouPutS rElAy contActS

M/c M/c Voltage cont. 0.2 sec Break 30 VDC 10 A 30 A 10 A Ac resistive 125 VDC 10 A 30 A 0.5 A 250 VDC 10 A 30 A 0.3 A 30 VDC 10 A 30 A 5A dc inductive 125 VDC 10 A 30 A 0.25 A (l/r = 7 ms) 250 VDC 10 A 30 A 0.15 A 120 VAC 10 A 30 A 10 A Ac resistive 250 VAC 10 A 30 A 10 A 120 VAC 10 A 30 A 4A Ac inductive PF=0.4 250 VAC 10 A 30 A 3A configuration: Form C NO/NC contacts: Silver Alloy Minimal permissible load: 5 VDC, 100 mA; 12VAC, 100 mA AnAloG currEnt outPut (4 20 MA StAndArd) output Max load Max output Accuracy Polarity Isolation Update time: ProGrAMMABlE 0 1 mA 0 20 mA 4 20 mA 2000 300 300 1.01 mA 20.2 mA 20.2 mA 1% of full scale reading Terminal 58 () must be at ground potential (ie. output is not isolated) Non-isolated, active source 250 ms max

Impulse test: rFI: EMI:

Static: Humidity: temperature: Environment: dust/moisture: PAcKAGInG Weight: Shipping dimensions:

ProductIon tEStS dIElEctrIc StrEnGtH tESt 2200 VAC, 50/60 Hz, for 1 sec Ground (terminal 42) to Output contacts (terminals 29 to 40) Control power (terminals 41 and 43) Current transformer inputs (terminals 72 to 83)

*Specifications subject to change without notice.

APProVAlS ISO: Manufactured to an ISO9001 Certified Program UL: Recognized under E83849 CSA: Approved under LR41286 Conforms to IEC 947-1, 1010-1 : Conforms to EN55011/CISPR11, EN50082-2

dimensions

269 Plus

TRIP ALARM

7.57" (192)

0.50" (13)

4.25" (108)

Inches (mm)

4.80" (122)

6.85" (174) 6.125" (156) (4) 0.218" DIA (6)

11.375" (289)

AUX. 2 SERVICE

ACTUAL VALUES

SET POINTS

HELP

CUTOUT

PAGE

LINE

VALUE

PAGE

LINE

VALUE

RESET

CLEAR

STORE

269 Plus Motor Management Relay

FRONT VIEW

MOUNTING SURFACE

SIDE VIEW

REAR VIEW

PANEL CUTOUT

8.125" (206,4)

269 Plus drawout

9.00" (229)

MOUNTING SURFACE

30 33 36 38(40) 42

4.062" (103,2)

29 31 34(32) 37(35) 39

10.875" (276)

968540A8.cdr

HOLE LEGEND 0.312" Dia. 0.218" Dia. (5 PLACES) 20.75 Lb ( 9.5 Kg ) UNPACKAGED.

AUX. 1

TRIP ALARM

15.50" (394)

AUX. 2 SERVICE

ACTUAL VALUES

SET POINTS

HELP

14.125" (359)

12.0" (304,8)

6.0" (152,4)

PAGE

LINE

VALUE

PAGE

LINE

VALUE

RESET

CLEAR

STORE

269 Plus Motor Management Relay

81(83)

78(80)

75(77)

73

41

82

79

76

74(72)

43

0.70" (18)

FRONT VIEW

7.55" (192)

SIDE VIEW

7.125" (181)

REAR VIEW

3.562" (90,5) 7.125" (181)

CUTOUT

WEIGHT: 26.4 Lb ( 12 Kg ) FULLY PACKAGED.

7.063" (179,4)

965068A4.cdr

14.125" (358,8)

AUX. 1

10.20" (259)

10.45" (265)

www.GEMultilin.com

337

269 Plus Motor Protection System

ordering

269 PluS 269PluS

*

SV d/o

1 2 3 4 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

100P 10c 100n 120n

HI lo

269 Plus motor management relay Standard version Drawout version Phase ct 1 Ground ct (required for d/o only) :5 2000:1 :5 :5 :1 2000:1 :1 :5 relay fail safe code2 (required for d/o only) Trip Alarm Aux1 Aux 2 FS NFS NFS FS NFS FS NFS FS FS FS NFS FS NFS NFS FS FS FS NFS FS FS NFS FS FS FS FS FS FS FS NFS NFS NFS FS 3 relay contact arrangement (required for d/o only) Alarm Aux1 Aux2 N.O. N.O. N.O. N.O. N.O. N.C. N.O. N.C. N.O. N.O. N.C. N.C. N.C. N.O. N.O. N.C. N.O. N.C. N.C. N.C. N.O. N.C. N.C. N.C. 100 Ohm platinum RTD 10 Ohm copper RTD 100 Ohm nickel RTD 120 Ohm nickel RTD 80 300 VDC/65 265 VAC control power 20 60 VDC/20 48 VAC control power

Accessories for the 269 Plus :

Multinet Serial to Ethernet converter Multinet-FE Viewpoint Monitoring D485 Devicenet converter P485 Profibus converter VP-1 D485-C P485-C

Visit www.GEMultilin.com/269Plus to:

View Guideform Specifications Download the instruction manual Review applications notes and support documents Buy a 269 Plus online

338

www.GEMultilin.com

0213-v3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Wagon TipplerDocument17 pagesWagon TipplerAnonymous 9kzuGaYNo ratings yet

- A Review of Deterministic Optimization Methods inDocument15 pagesA Review of Deterministic Optimization Methods inAnonymous 9kzuGaYNo ratings yet

- Sampling LMI MGR KoRBADocument2 pagesSampling LMI MGR KoRBAAnonymous 9kzuGaYNo ratings yet

- Trolley Manufacturer's Details Address PhoneDocument1 pageTrolley Manufacturer's Details Address PhoneAnonymous 9kzuGaYNo ratings yet

- New Doc 2018-07-01 - 1Document1 pageNew Doc 2018-07-01 - 1Anonymous 9kzuGaYNo ratings yet

- Java ProgramingDocument5 pagesJava ProgramingAnonymous 9kzuGaYNo ratings yet

- Iriset: इरिसेट आउट डोि ससगनसलिंग प्रयोगशाला इरिसेट / ओ डी एस - 43 Experiment No.: Ods - 43Document7 pagesIriset: इरिसेट आउट डोि ससगनसलिंग प्रयोगशाला इरिसेट / ओ डी एस - 43 Experiment No.: Ods - 43Anonymous 9kzuGaYNo ratings yet

- Led Signalling HandbookDocument68 pagesLed Signalling HandbookAnonymous 9kzuGaYNo ratings yet

- 2V Range For Signalling Telecommunication - 1Document2 pages2V Range For Signalling Telecommunication - 1Anonymous 9kzuGaYNo ratings yet

- Ddrm00155 IntDocument1 pageDdrm00155 IntAnonymous 9kzuGaYNo ratings yet

- Rti Act HindiDocument26 pagesRti Act HindiGhanendra KumarNo ratings yet

- BSNL Payment Receipt Rs. 3817 SuccessfulDocument1 pageBSNL Payment Receipt Rs. 3817 SuccessfulAnonymous 9kzuGaYNo ratings yet

- NTPC Badarpur PPT 2012Document33 pagesNTPC Badarpur PPT 2012Anonymous 9kzuGaYNo ratings yet

- ABB 615 Series RelayDocument54 pagesABB 615 Series RelayAnonymous 9kzuGaYNo ratings yet

- 10 Bom Pu Boom LuffingDocument2 pages10 Bom Pu Boom LuffingAnonymous 9kzuGaYNo ratings yet

- Class Vi Paper PDFDocument29 pagesClass Vi Paper PDFGidharNo ratings yet

- JavaDocument1 pageJavaAnonymous 9kzuGaYNo ratings yet

- FireDocument22 pagesFireAnonymous 9kzuGaYNo ratings yet

- JavaDocument2 pagesJavaLam Sin WingNo ratings yet

- JavaDocument4 pagesJavaAnonymous 9kzuGaYNo ratings yet

- CHP2Document54 pagesCHP2Anonymous 9kzuGaY100% (1)

- 1 - Lmi CHPDocument162 pages1 - Lmi CHPAnonymous 9kzuGaYNo ratings yet

- Govt Schemes Final RbiDocument64 pagesGovt Schemes Final RbiAnonymous 9kzuGaYNo ratings yet

- JavaDocument2 pagesJavaLam Sin WingNo ratings yet

- Details Binarytodecimal: Public Class Public Int Int Int Decimal Int While True If Break Else Int DecimalDocument1 pageDetails Binarytodecimal: Public Class Public Int Int Int Decimal Int While True If Break Else Int DecimalAnonymous 9kzuGaYNo ratings yet

- JavaDocument2 pagesJavaLam Sin WingNo ratings yet

- Details Binarytodecimal: Public Class Public Int Int Int Decimal Int While True If Break Else Int DecimalDocument1 pageDetails Binarytodecimal: Public Class Public Int Int Int Decimal Int While True If Break Else Int DecimalAnonymous 9kzuGaYNo ratings yet

- Java Employee Class with Constructor and MethodsDocument1 pageJava Employee Class with Constructor and MethodsAnonymous 9kzuGaYNo ratings yet

- FactsDocument7 pagesFactsAnonymous 9kzuGaYNo ratings yet

- Largest Number PDFDocument1 pageLargest Number PDFAnonymous 9kzuGaYNo ratings yet

- DCP Orientation HandbookDocument30 pagesDCP Orientation HandbookOnin C. OpeñaNo ratings yet

- MAZAK M PLUS T PLUS Memory Upgrade InstructionsDocument10 pagesMAZAK M PLUS T PLUS Memory Upgrade InstructionsraviNo ratings yet

- Pacemaker InstructionsDocument10 pagesPacemaker InstructionsIvan HicksNo ratings yet

- ch1 1Document46 pagesch1 1Rohan ChalisgaonkarNo ratings yet

- Weighing Systems For The Heavy Industries ABBDocument12 pagesWeighing Systems For The Heavy Industries ABBEJECUTIVO_10% (1)

- East Kilbride Arts Centre Technical InformationDocument9 pagesEast Kilbride Arts Centre Technical InformationJames Brendan CuskerNo ratings yet

- Panasonic Tc-P42gt30a (SM)Document112 pagesPanasonic Tc-P42gt30a (SM)Anonymous UPlbstfs100% (1)

- DS MinarcMig Adaptive 170 180 AD706 1010 enDocument3 pagesDS MinarcMig Adaptive 170 180 AD706 1010 enjannw0% (1)

- Quick Start Guide: 32-Port 100G Ethernet Switch Package ContentsDocument5 pagesQuick Start Guide: 32-Port 100G Ethernet Switch Package ContentsAlexNo ratings yet

- How To Configure Microplex Print Server For Automatic RCF CommandsDocument4 pagesHow To Configure Microplex Print Server For Automatic RCF CommandsJoseph AlbertNo ratings yet

- RTAI InstallDocument18 pagesRTAI InstallPramod Kumar ReddyNo ratings yet

- 7733v3.0 (G52 77331X2) (B75IA E33) 100x150Document204 pages7733v3.0 (G52 77331X2) (B75IA E33) 100x150Antreas DionysiouNo ratings yet

- Coa by EshaanDocument64 pagesCoa by EshaanJust As I AmNo ratings yet

- GPUs for OFDM SDR Prototyping: A Comparative StudyDocument4 pagesGPUs for OFDM SDR Prototyping: A Comparative Studydang2327No ratings yet

- Unit 1 SpecDocument8 pagesUnit 1 Specapi-485038382No ratings yet

- Asus ROG Zephyrus Duo 15 - A Sample of The Final WorkDocument2 pagesAsus ROG Zephyrus Duo 15 - A Sample of The Final WorkUmesh SiddarthNo ratings yet

- 060-4199-180 LMMDocument58 pages060-4199-180 LMMPeter LapthorneNo ratings yet

- AD-360X2 Parts Manual PN - 450558 (Rev-1)Document32 pagesAD-360X2 Parts Manual PN - 450558 (Rev-1)naokito AkemiNo ratings yet

- Si1145 46 47 M01Document70 pagesSi1145 46 47 M01Iñaki PereaNo ratings yet

- Transporting Data Across PlatformsDocument21 pagesTransporting Data Across PlatformstonNo ratings yet

- Schmit Trigger SwitchDocument19 pagesSchmit Trigger SwitchlolypopNo ratings yet

- Lenovo Yoga C630 Compal LA-G611P R03Document57 pagesLenovo Yoga C630 Compal LA-G611P R03Bong BarcelitaNo ratings yet

- My Collection NET Framework 4Document184 pagesMy Collection NET Framework 4geko1No ratings yet

- E-Book TestDocument6 pagesE-Book Testjeff_klassen8313No ratings yet

- MTINV 1-D interpretation of magnetotelluric EM soundingsDocument8 pagesMTINV 1-D interpretation of magnetotelluric EM soundingsAnnisa Trisnia SNo ratings yet

- hmc125 PDFDocument12 pageshmc125 PDFMohamed ElmakkyNo ratings yet

- Example Health Check ReportDocument22 pagesExample Health Check ReportTechypyNo ratings yet

- Dot Hill Assured San 24xx4-Fig-Guide-3q15-FinalDocument44 pagesDot Hill Assured San 24xx4-Fig-Guide-3q15-FinalRichard WoodNo ratings yet

- DRV Dev IntroDocument57 pagesDRV Dev IntroĐinh LuậnNo ratings yet