Professional Documents

Culture Documents

POURING GRADE POLYSULPHIDE SEALANT

Uploaded by

Neha RathoreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

POURING GRADE POLYSULPHIDE SEALANT

Uploaded by

Neha RathoreCopyright:

Available Formats

TECHNICAL DATA SHEET

KANKOL 625P

Features & Benefits Cold applied Pourability & self-leveling UV resistant Flame and fuels resistance Good weatherability

POURING GRADE TWO- PART POLYSULPHIDE SEALANT DESCRIPTION: Kankol 625P is a two-part elastomeric sealant based on a liquid polysulphide polymer which when mixed with accelerator (curing agent) cures by chemical reaction to form a tough, flexible rubber seal. This sealant has excellent Fuel resistance, adhesion to different substrates like masonry, concrete with excellent movement accommodation.

Standards compliance

British Standard BS: 5212:1990-Type FB (Flame and Fuel Resistance) Cold applied Joint Sealant systems for Concrete pavements. Ministry of Road Transport and Highway (MORTH) specification for Roads and Bridge Works Clause 602.2.8 and clause 602.II.4 State that cold applied two part polysulphide sealant shall meet BS: 5212:1990.IRMRA certification

Movement Accommodation: Butt joints (movement in tension and compression): 30 %. Lap Joints (movement in shear): 50 %

Areas of Application

For sealing and maintenance of horizontal joints in

TECHNICAL DATA Colour Pot Life at 25 C Service Temperature Typical Shore A Hardness Cure Rate at 20 C/65 % RH Chemical Resistance 7 days at 20 C in a typical joint. At lower temperatures Cure rate will be slower. Resistant to most dilute acids and alkalis, petrol, diesel, jet fuel and many solvents and vegetable oils. Grey ( After mixing Base and Hardener) Min 2 hrs - 40 C to + 80 C 15 -20

Aircraft fuelling areas Oil terminals Garage forecourts

Concrete Roads Warehouses

Parking and cargo areas Industrial Floors

TECHNICAL DATA SHEET

Joint Backing Where applicable, appropriate joint filler e.g. closed cell polyethylene foam, should be used to provide the correct joint depth. Joint Size Suitability Joint Width Joint Depth Min6mm,Max25mm(Single application), 50mm(multiple applications) Min 10 mm on porous substrate Min 6 mm on non porous substrate Maximum 25 mm Width Depth ratio Application Instructions Joint preparation The joint surfaces must be clean, dry and free from all contamination. The surfaces should be degreased using the appropriate Cleaner. Primers may be required on some substrates. Insertion of Backup Materials A suitable material is closed cell, medium density, cross linked Polyethylene foam, strip or rod. and correct depth of joint. Masking Tape Application Masking Tape should be used on both sides of the joint to improve the neatness of the finished seal. Priming Apply thin film of kankol porous primer on both sides of the joint with a brush. Allow flash-off of solvent before application of Sealant i.e. surface should be touch-dry. Mixing The base and curing agent ratio controls the adhesion, strength and durability of Kankol 625G. The base and curing agent must therefore be thoroughly mixed. Tooling Depth Gauge may be used to recess sealant as specified in the drawing. Ensure constant : 2:1 butt Joint ,1:1 floor Joints Cleaning

KANKOL 625P

After sealing the joint the tools and equipments should be cleaned immediately with kerosene or any other cleaning solvents/thinners. Packaging KANKOL 625P-Pour Grade 1 KG (approx. 625 ML) 4 KG (approx.2500 ML) 6KG (approx. 3750 ML) KANKOL POROUS PRIMER 250 ML

GUIDE TO KANKOL 625P QUANTITIES Joint Size in mm 5 X5 10 X 5 10 x 10 20 X 10 40 X 20 Health and safety Avoid prolonged contact with skin. If sealant comes into contact with the eyes, flush with cold water and obtain medical attention. Storage Life: 12 months in original unopened packaging stored in a cool, dry place out of direct sunlight Technical Support KANGARU provides technical advisory service supported by teams of specialists in the field. Kg/meter run 0.040 0.080 0.160 0.320 1.28 Meter Run/4kg pack 100 50 25 12.50 3.12

Kangaru Polymers Pvt ltd

Mfg of Sealants, Waterproofing chemicals & Construction Chemicals Website -www.kangarupolymers.com

You might also like

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- Gun Grade NEWDocument2 pagesGun Grade NEWSunny SinghNo ratings yet

- Intergard 251 Tech Data SheetDocument0 pagesIntergard 251 Tech Data SheetL Mahender ReddyNo ratings yet

- Epocoat 111 PDFDocument3 pagesEpocoat 111 PDFjunaid112No ratings yet

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFlhanx2100% (2)

- Polysulphide SealantDocument2 pagesPolysulphide SealantMr. Ashok DwivediNo ratings yet

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- DR Fixit Pidiseal PS 41G and 42P 112 1Document4 pagesDR Fixit Pidiseal PS 41G and 42P 112 1Avinash GuptaNo ratings yet

- Interbond 808Document4 pagesInterbond 808shameelNo ratings yet

- Cicobond ACR 61Document2 pagesCicobond ACR 61mud444100% (1)

- Nitoseal 290Document4 pagesNitoseal 290Venkata RaoNo ratings yet

- ShaliSeal PS PGDocument3 pagesShaliSeal PS PGpoojaNo ratings yet

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYNo ratings yet

- Carbocoat 8215 PDS 6-10Document2 pagesCarbocoat 8215 PDS 6-10Mayur PatelNo ratings yet

- 15 07 17 FT SiMP High TackDocument4 pages15 07 17 FT SiMP High TackAmon AlastorNo ratings yet

- D9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetDocument2 pagesD9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetPrashant MalveNo ratings yet

- High-performance epoxy coating data sheetDocument2 pagesHigh-performance epoxy coating data sheetamadan64No ratings yet

- PDS en-GB 1736g19840Document2 pagesPDS en-GB 1736g19840nihad_mNo ratings yet

- Interbond 501Document4 pagesInterbond 501Trịnh Minh KhoaNo ratings yet

- Inter Shield 300 PICDocument2 pagesInter Shield 300 PICRifqi Fajri PrayudiNo ratings yet

- Carboguard 885 PDSDocument2 pagesCarboguard 885 PDSsyazwanjohnmazlanNo ratings yet

- Ferreko No 3 pc560Document2 pagesFerreko No 3 pc560vijayarangam1984No ratings yet

- Tds Flexbond102a Flexbond202c enDocument4 pagesTds Flexbond102a Flexbond202c enali aitNo ratings yet

- Interzone 1000: Glass Flake EpoxyDocument4 pagesInterzone 1000: Glass Flake EpoxyAnindya Aulia PratiwiNo ratings yet

- Sikafloor261sys1 PdsDocument4 pagesSikafloor261sys1 PdsTPNo ratings yet

- DP8805NS + DP8810NS Tech Data SheetDocument6 pagesDP8805NS + DP8810NS Tech Data SheetPaul TushausNo ratings yet

- X-Tech CrystalClear 3Document2 pagesX-Tech CrystalClear 3EGO AnimationNo ratings yet

- Interline985 - Matcote DatasheetDocument4 pagesInterline985 - Matcote DatasheetLee PachecoNo ratings yet

- CEILCOTE 163 CorocreteDocument2 pagesCEILCOTE 163 CorocreteGabor VictorNo ratings yet

- Mastertop 1210 Pds Asean 020811Document2 pagesMastertop 1210 Pds Asean 020811hemajsuryaNo ratings yet

- Interzone 954Document0 pagesInterzone 954hennawijayaNo ratings yet

- Fosroc Dekguard PU: Constructive SolutionsDocument4 pagesFosroc Dekguard PU: Constructive SolutionsganmosesNo ratings yet

- X-Tech UraFloor CSDocument2 pagesX-Tech UraFloor CSLONG LASTNo ratings yet

- Sikaflex 11FCDocument3 pagesSikaflex 11FCthe pilotNo ratings yet

- Plasite 7159 PDS 1-07 PDFDocument2 pagesPlasite 7159 PDS 1-07 PDFFabricio Jiménez TNo ratings yet

- PlastisealDocument4 pagesPlastisealVenkata RaoNo ratings yet

- Intergard 269 DatasheetDocument4 pagesIntergard 269 DatasheetBalasubramanian AnanthNo ratings yet

- Nitocote EN901Document4 pagesNitocote EN901kalidindivenkatarajuNo ratings yet

- Sylgard 160Document3 pagesSylgard 160diogocNo ratings yet

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerNo ratings yet

- Carbo Guard 893 SGDocument2 pagesCarbo Guard 893 SGsuzilamatsallehNo ratings yet

- Protective Coating-3Document0 pagesProtective Coating-3Sivaratnam NavatharanNo ratings yet

- Basf 9665 Conipur M 865 Z enDocument3 pagesBasf 9665 Conipur M 865 Z enMarijana JukicNo ratings yet

- Interzone 954Document4 pagesInterzone 954johnson_regoNo ratings yet

- Graphit 33Document2 pagesGraphit 33Manuel Armindo RibeiroNo ratings yet

- Sikacem Gunit 133Document2 pagesSikacem Gunit 133the pilotNo ratings yet

- Basf Masterprotect 1815 TdsDocument3 pagesBasf Masterprotect 1815 TdsEngTamer100% (1)

- PolyguardDocument2 pagesPolyguardJack MayNo ratings yet

- Sikaflex 11FC - PDS PDFDocument4 pagesSikaflex 11FC - PDS PDFrajeevNo ratings yet

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocument2 pagesRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNo ratings yet

- Carboguard 888 PDSDocument3 pagesCarboguard 888 PDSsalamrefighNo ratings yet

- Soudaflex Construction FCDocument2 pagesSoudaflex Construction FCAvijitSinharoyNo ratings yet

- CEILCOTE 505 Coroline.Document2 pagesCEILCOTE 505 Coroline.stuart3962No ratings yet

- High performance anti-carbonation coatingDocument4 pagesHigh performance anti-carbonation coatingDejan MicicNo ratings yet

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerNo ratings yet

- Nitocote EN901Document4 pagesNitocote EN901ArieIndrawanNo ratings yet

- TDS - Emaco CP 60Document3 pagesTDS - Emaco CP 60Venkata RaoNo ratings yet

- Nitoseal 125Document2 pagesNitoseal 125Hantu TuahNo ratings yet

- Primastic UniversalDocument5 pagesPrimastic UniversalaleventNo ratings yet

- Handbook Bandsaw BladeDocument82 pagesHandbook Bandsaw Bladewisnu_bayusaktiNo ratings yet

- Historical Background of Apparel Industry in BangladeshDocument3 pagesHistorical Background of Apparel Industry in BangladeshFoysaliub100% (6)

- Smart Solutions Delivers Cutting-Edge Precast Concrete and Building ProductsDocument29 pagesSmart Solutions Delivers Cutting-Edge Precast Concrete and Building Productssurya0588No ratings yet

- Testing For Failure Analysis - BriefDocument2 pagesTesting For Failure Analysis - BriefMohd Nazri SalimNo ratings yet

- Hoja Datos Danfoso TermostotaosDocument2 pagesHoja Datos Danfoso TermostotaosAlex Lopez0% (1)

- Daimlerfinalpresentationpdf 111122092224 Phpapp02Document39 pagesDaimlerfinalpresentationpdf 111122092224 Phpapp02Marius CiuculanNo ratings yet

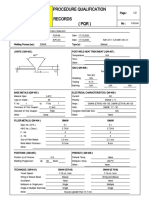

- Procedure Qualification Record PQRDocument2 pagesProcedure Qualification Record PQRWalid BdeirNo ratings yet

- Astm A27Document4 pagesAstm A27Rafael Elles100% (2)

- Acrylic rod & tube manufacturing tolerances guideDocument1 pageAcrylic rod & tube manufacturing tolerances guidemhNo ratings yet

- Standard Costs and Variance Analysis MCQs by Hilario TanDocument17 pagesStandard Costs and Variance Analysis MCQs by Hilario TanJoovs Joovho100% (1)

- Unitoperations and ProcessesDocument19 pagesUnitoperations and ProcessesnirbhaykumarNo ratings yet

- Ti809 07Document136 pagesTi809 07SusandiHarahapNo ratings yet

- Sic 33991Document38 pagesSic 33991Aldo J AN0% (1)

- Diamond and CBN English 07Document26 pagesDiamond and CBN English 07Vk PrabakranNo ratings yet

- Astm F 30 - 96 R02 - RJMWDocument5 pagesAstm F 30 - 96 R02 - RJMWphaindikaNo ratings yet

- Volume 3 Burning WorkshopDocument59 pagesVolume 3 Burning WorkshopmkpqNo ratings yet

- Manualsolutionsformachinedesignbykhurmiandgupta 121124075743 Phpapp01 PDFDocument50 pagesManualsolutionsformachinedesignbykhurmiandgupta 121124075743 Phpapp01 PDFMOHANNo ratings yet

- Demo Asme PWHT PreheatDocument54 pagesDemo Asme PWHT PreheatWalter TrajadaNo ratings yet

- 03 Welding Imperfections 30-03-07 (2Document20 pages03 Welding Imperfections 30-03-07 (2geokovoorNo ratings yet

- Alpema Standards Rev1 2000Document8 pagesAlpema Standards Rev1 2000anonimppNo ratings yet

- Director Facilities Management in Boston MA Resume Jana DenglerDocument2 pagesDirector Facilities Management in Boston MA Resume Jana DenglerJanaDengler100% (1)

- Niir Steel Rolling Technology Handbook Niir ContentDocument10 pagesNiir Steel Rolling Technology Handbook Niir ContentSailen GopeNo ratings yet

- About TVS Logistics PVTDocument4 pagesAbout TVS Logistics PVTSaif Ul IslamNo ratings yet

- Rail Integrity Manual 82011Document71 pagesRail Integrity Manual 82011Ovidiu PruteanuNo ratings yet

- MN 304 - Production Economics - 6Document59 pagesMN 304 - Production Economics - 6Nipuna Thushara WijesekaraNo ratings yet

- Wu 31 12 2013 enDocument11 pagesWu 31 12 2013 enpvaibhav08No ratings yet

- PhoenixPET 990 - PDS 10th Nov 14 FINAL-2015Document1 pagePhoenixPET 990 - PDS 10th Nov 14 FINAL-2015Raja Pandi0% (1)

- BT2 ConcreteDocument7 pagesBT2 ConcreteMicah Dianne DizonNo ratings yet

- NASA Bolting Design ManualDocument98 pagesNASA Bolting Design ManualjoshhinesNo ratings yet

- Gypsum BoardDocument11 pagesGypsum BoardFavorSea Industrial Channel Limited, Building Materials DivisionNo ratings yet