Professional Documents

Culture Documents

Column Design

Uploaded by

Arnel DodongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Column Design

Uploaded by

Arnel DodongCopyright:

Available Formats

NSCP 2010 Specification and Equation No.

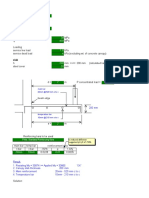

A.S Structural and Engineering Services Structural Engineers and Project Manager Sheet Content : Design of Tied Column Date : Nov. 27, 2011 Project Title : Two Storey Resedential House Location : Brgy. Banale, Pagadian City, Zamboanga Del Sur Client : Address : Engr. Arnel H. Sinconiegue Dagat-Dagatan, Caloocan City, Metro Manila

Prepared by : Date : PRC # : TIN # : Issued On: Issued At:

Arnel H. Sinconigue, C.E Oct. 13, 2011 116853 406-365-953-000 3/24/2011 Quezon City

Design Refference : NSCP Volume 1, Fourth Edition 2010 : Design of Reinforce Concrete, 2 ND Edition by Jack C. McCormac : Fundamentals of Reinforced Concrete (Using USD Method, NSCP 2001) by Besavilla

I. Design Inputs : Axial Demand, Pu = Moment Demand, Mu = Shear Demand, Vu = Unsupported Length, lu = Flexure Capacity Reduction Factor, = Shear Capacity Reduction Factor, = Compressive Block Deep Factor, 1 = II. Material Properties Compressive Concrete Strength, fc' = Steel Yeild Strenght Main Bar, fy = Steel Yeild Strenght Tie Bar, fst = Modulus Elasticity of steel, Es = III. Design Assumption Column Width, b = Column Depth, h = Concrete cover, cc = Main Bar diameter, = Tie Bar diameter , st Stee ratio, act = Effective height factor, k Modification factor, IV. Desgin Calculation ( using static eqautions ) 450.00 450.00 40.00 25.00 10.00 0.02 1.00 1.00 mm mm mm mm mm 20.70 415.00 415.00 200000.00 Mpa Mpa Mpa Mpa 1550.00 150.00 60.00 2.90 0.65 0.75 0.85 KN KN.m KN m

409.4.2.2 409.4.2.3 410.3.7.3

410.10.1 410.13.1.3 411.8.4.3

Calculation for concrete gross area, Ag Ag = b*h Calculation for steel area, Ast Ast = act*Ag Calculatin for db area, Adb Adb = *()2/4 Calculation for No. of db, N N = Ast / Adb Calculation for eccentricity, e e = Mu/Pu Calculation for balance yeild strain, y 96.77 mm Small Eccentricity 8.25 pcs say 8 pcs

2 490.87 mm 2 4050.00 mm 2 202500.00 mm

y = fy/Es Calculation for d1 d1 = h - cc - /2 Calculation for Neutral Axis, c 410.3.7.2 c = (0.003/(0.003+y))*d Calculation for compressive block depth, a 410.3.7.1 a = 1*c V. Check for Slenderness Effect in Compression Members Calculation for slenderness effect 410.11.1.2 410.11.1 r = 0.3*h klu/r = VI. Internal forces and moment

0.0021

397.50 mm

234.98 mm

199.73 mm

135.00 mm 21.48 Neglect Slendeness

Note : drawings are editable and it depends on what calculated above. designers should arrange the reinforcement at his/her instance. calculation done below are also variable it should be incorporated to the drawing.

y

0.003 s3

0.85fc'

Pu x

fs3 C fs2 fs1

Pu Mu

c d s2 s1

Fs3 C Fs2 Fs1

b Section Strain Nominal Stresses

Forces & Moment Arms

Calculation of Strains,s Note: This formula was done by similar triangle 410.3.3 410.3.3 s3 = 0.003( c - (cc+/2))/c s2 = 0.003*(c-h/2)/c

s1 = y

0.0023 0.000127 0.0021

Calculation of Nominal Stresses 410.3.4 410.3.4 410.3.4 fs3 = s3*Es fs2 = s2*Es fs1 = s1*Es 465.94 Mpa 25.47 Mpa 415.00 Mpa

Calculation of Internal Forces N3 = N2 = N1 = 3.00 pcs 2.00 pcs 3.00 pcs

As3 = (*()2/4)*(N3) As2 = (*()2/4)*(N2) As1 = (*()2/4)*(N1) Fs3 = As3*fs3 Fs2 = As2*fs2 Fs1 = As1*fs1 410.3.7 C = 0.85fc'*a*b VII. Check for Axial & Flexural Capacity/Demand ratio,C/D Calculation for Axial Capacity, Pu Fv = 0 Pu = Fs3 + Fs2 + C - Fs1 Calculation for Flexure Capacity, Mu M@ bottom steel = 0 Mu = Fs3(0.32) + Fs2(0.16) + C(0.273) - Pu(0.256) Calculation for Axial = C/D Calculation for Flexure = C/D VIII. Design Vertical Tie Spacing,S

2 1472.62 mm 2 981.75 mm 2 1472.62 mm

686.16 KN 25.01 KN 611.14 KN 1581.40 KN

1681.43 KN

224.85 KN.m 1.08 1.50 Complaint Compliant

407.11.5.2 407.11.5.2 407.11.5.4

16* = 48*st = least dimension, b = Actual Spacing = Check for shear capacity Shear Demand, Vu =

400.00 mm 480.00 mm 450.00 mm 400.00 mm

60.00 KN 213.99 KN 80.25 KN 160.50 KN Satisfy NSCP 407.11.5 Compliant

411.4.1.2 411.6.6 411.2.1

Vc = 0.17 * ( 1 + Nu/14Ag )**sqrt(fc')*b*d 0.5**Vc = *Vc = Calculation of min. shear reinforcement,Avmin

N.A

N.A Calculation for area of ties, Ast N.A Calculation for number of ties, N N.A IX. Design of lap splices, ld

N.A

mm2

N.A

mm2

N.A

pcs

412.17.1 412.17.1

ld = 0.071*fy*db actual length of splice,ld

736.63 mm 958.00 mm

You might also like

- Two - Way Slab Design - 2Document8 pagesTwo - Way Slab Design - 2Arnel Dodong85% (13)

- Eddie Naldoza Engineering Design Beam AnalysisDocument5 pagesEddie Naldoza Engineering Design Beam AnalysisBong-Bong Rodriguez Bianzon100% (1)

- Concrete Beam DesignDocument3 pagesConcrete Beam DesignArnel DodongNo ratings yet

- Chap6 Stair Design MDMDocument33 pagesChap6 Stair Design MDMJordan Allen BarriosNo ratings yet

- NSCP 2015 Load Combination - Google SearchDocument2 pagesNSCP 2015 Load Combination - Google Searchgodofredo dumali0% (1)

- BEAM DesignDocument45 pagesBEAM DesignJoseph Cloyd L. LamberteNo ratings yet

- Column Design (WSD) Axially LoadedDocument1 pageColumn Design (WSD) Axially Loadedapi-19753598100% (2)

- Roof Truss Analysis Definitions and Load CombinationsDocument2 pagesRoof Truss Analysis Definitions and Load CombinationsVane DG50% (2)

- Design of PurlinsDocument8 pagesDesign of PurlinsLa BeamNo ratings yet

- Design rectangular beam reinforced for tensionDocument8 pagesDesign rectangular beam reinforced for tensionaltavanoarNo ratings yet

- Calculate wind loads and design purlinsDocument56 pagesCalculate wind loads and design purlinsD M100% (1)

- Design Computation of TrussDocument3 pagesDesign Computation of Trussdash19910% (1)

- Steps to determine wind loads on rooftop equipmentDocument8 pagesSteps to determine wind loads on rooftop equipmentJephte Soriba DequiniaNo ratings yet

- An Example Problem On Wind Load Calculation According To NSCP 2010 )Document32 pagesAn Example Problem On Wind Load Calculation According To NSCP 2010 )joshua humirangNo ratings yet

- Roof SlabDocument2 pagesRoof SlabnoneNo ratings yet

- Design of StairDocument5 pagesDesign of StairWilfredoEnghoyNo ratings yet

- Design of Intermediate PurlinsDocument4 pagesDesign of Intermediate PurlinsNiño Ediliz B. Garcia80% (5)

- NSCP 2015 Earthquake Loading ProceduresDocument45 pagesNSCP 2015 Earthquake Loading ProceduresashleyNo ratings yet

- Slab DesignDocument11 pagesSlab DesignCarmel Buniel Sabado100% (22)

- Slab Canopy Design SpreadsheetDocument3 pagesSlab Canopy Design Spreadsheetankit kadamNo ratings yet

- RC Two Way Slab Design (ACI318-05)Document6 pagesRC Two Way Slab Design (ACI318-05)emorider100% (4)

- Reinforced Concrete Design of Beams, Columns, One-Way Slab, and Two-Way Slab With EstimateDocument74 pagesReinforced Concrete Design of Beams, Columns, One-Way Slab, and Two-Way Slab With EstimateEmmanuel LazoNo ratings yet

- Loads and Loading Combinations For CE157 StudentsDocument48 pagesLoads and Loading Combinations For CE157 StudentsemssNo ratings yet

- Slab Design ACI With Reinforcment (Sketch)Document7 pagesSlab Design ACI With Reinforcment (Sketch)chemtahir100% (1)

- Moment Coefficients For Continuous Beams and SlabsDocument10 pagesMoment Coefficients For Continuous Beams and Slabsdash1991No ratings yet

- Design of Purlins and TrussesDocument46 pagesDesign of Purlins and TrussesWarrenPresBerdugo100% (1)

- Column DesignDocument2 pagesColumn DesignKYVER PACAÑANo ratings yet

- Sample Beam DesignDocument12 pagesSample Beam DesignmokalnganNo ratings yet

- E.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Document2 pagesE.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Max100% (1)

- Stirrup DesignDocument4 pagesStirrup Designapmintu100% (1)

- Wind Load NSCP 2010 SampleDocument5 pagesWind Load NSCP 2010 SampleRichard Tagle100% (1)

- 05 Footing NSCP 2010Document27 pages05 Footing NSCP 2010Mar Martillano100% (1)

- DECKSLABDocument13 pagesDECKSLABASQ100% (1)

- An Example Problem On Wind Load Calculation According To NSCP 2010Document32 pagesAn Example Problem On Wind Load Calculation According To NSCP 2010Danilo NeryNo ratings yet

- Portal MethodDocument12 pagesPortal MethodJustin Charles AmorNo ratings yet

- 6 - Axially Loaded ColumnsDocument11 pages6 - Axially Loaded ColumnsThe bestNo ratings yet

- Structural Beam ComputationsDocument12 pagesStructural Beam ComputationsJustine LedesmaNo ratings yet

- Wf-Section Compression Strength LRFD Method Per NSCP 2015 Edition (S.I. Units) Developed By: Joel M. Regino, CE, RMPDocument1 pageWf-Section Compression Strength LRFD Method Per NSCP 2015 Edition (S.I. Units) Developed By: Joel M. Regino, CE, RMPjoel reginoNo ratings yet

- Design of Footing 091807Document1 pageDesign of Footing 091807Albert Dimayuga0% (1)

- An Example Problem On Wind Load Calculation According To NSCP 2010Document32 pagesAn Example Problem On Wind Load Calculation According To NSCP 2010Melvin Esguerra89% (9)

- Floor Slab Design Parameters and Reinforcement DetailsDocument18 pagesFloor Slab Design Parameters and Reinforcement DetailsKurt Nicolas Villegas Paquibo86% (7)

- Concrete Footing DesignDocument7 pagesConcrete Footing DesignCarmel Buniel Sabado100% (3)

- Seismic Loads Horizontal Distribution & Torsion PDFDocument7 pagesSeismic Loads Horizontal Distribution & Torsion PDFeplim60100% (2)

- 13 - 8 Design of 2 Way Slab For PrintingDocument7 pages13 - 8 Design of 2 Way Slab For PrintingAlbert DimayugaNo ratings yet

- SHEARDocument11 pagesSHEARJen Burdeos100% (1)

- Design Steps of One Way Slab (RCC)Document7 pagesDesign Steps of One Way Slab (RCC)Saurav_Shrestha93% (30)

- Strap FootingDocument14 pagesStrap FootingAlejandroGonzagaNo ratings yet

- Column DesignDocument7 pagesColumn DesignWin Than100% (1)

- Slab DesignDocument6 pagesSlab DesignJonasIrvinGallegoNo ratings yet

- Structural Design and AnalysisDocument52 pagesStructural Design and AnalysisAmado Nawen Pongtan100% (4)

- Column Design Subjected To Axial and BendingDocument4 pagesColumn Design Subjected To Axial and BendingArnel Dodong0% (1)

- Column Shear DesignDocument2 pagesColumn Shear DesignArnel DodongNo ratings yet

- T208 Bored Pile Design - XLSXDocument3 pagesT208 Bored Pile Design - XLSXerikaren85No ratings yet

- Calculation Sheet: Esign Xample Esign of A Lipped Channel in An Exposed FloorDocument8 pagesCalculation Sheet: Esign Xample Esign of A Lipped Channel in An Exposed FloorMoonzeNo ratings yet

- No Passive & WaterDocument13 pagesNo Passive & WaterArnel Dodong100% (1)

- Column Shear DesignDocument2 pagesColumn Shear DesignArnel DodongNo ratings yet

- Mathcad - Column C-1Document7 pagesMathcad - Column C-1lnt4No ratings yet

- Beam DesignDocument2 pagesBeam DesignArnel DodongNo ratings yet

- Calculation Sheet: Esign Xample Esign of A Two Span Trapezoidal Roof SheetingDocument8 pagesCalculation Sheet: Esign Xample Esign of A Two Span Trapezoidal Roof SheetingettypasewangNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Project Sheets 1Document1 pageProject Sheets 1Arnel DodongNo ratings yet

- Concrete Crack Repair ManualDocument62 pagesConcrete Crack Repair ManualShamsul Bahrin Sulaiman100% (1)

- CCAC PreconstructionMeetingGuideDocument7 pagesCCAC PreconstructionMeetingGuideArnel DodongNo ratings yet

- SikaLoadflex PdsDocument2 pagesSikaLoadflex PdsArnel DodongNo ratings yet

- 6032a4a PDFDocument2 pages6032a4a PDFArnel DodongNo ratings yet

- 2010 Lysaght Product Catalogue 15 Dec 09Document88 pages2010 Lysaght Product Catalogue 15 Dec 09Arnel DodongNo ratings yet

- 2010 Lysaght Product Catalogue 15 Dec 09Document88 pages2010 Lysaght Product Catalogue 15 Dec 09Arnel DodongNo ratings yet

- TAP Marrickville Geotechnical-Investigation Apr 2013Document22 pagesTAP Marrickville Geotechnical-Investigation Apr 2013Arnel DodongNo ratings yet

- NZTIF Specifying TimberDocument9 pagesNZTIF Specifying TimberArnel DodongNo ratings yet

- Ocean Wave Forecasting at Ecmwf Version 201402Document58 pagesOcean Wave Forecasting at Ecmwf Version 201402Arnel DodongNo ratings yet

- DCP TestDocument10 pagesDCP TestRicardo Alfaro100% (1)

- Hot Rolled Sheet PileDocument52 pagesHot Rolled Sheet Pileswarup_datta03100% (1)

- Brainard Retaining Wall Design SpecsDocument4 pagesBrainard Retaining Wall Design SpecsArnel DodongNo ratings yet

- Asok Fence Final DraftDocument14 pagesAsok Fence Final DraftArnel DodongNo ratings yet

- SR187Document37 pagesSR187Arnel DodongNo ratings yet

- SECTION B - Structural Provisions and DemolitionDocument15 pagesSECTION B - Structural Provisions and DemolitionArnel DodongNo ratings yet

- Scope of Services - Revised 30 Nov 15Document2 pagesScope of Services - Revised 30 Nov 15Arnel DodongNo ratings yet

- Technical Standard Ts 35-31-26 50 - Fixed Type Private Jetties On Water Way BanksDocument20 pagesTechnical Standard Ts 35-31-26 50 - Fixed Type Private Jetties On Water Way BanksArnel DodongNo ratings yet

- Building Code - Contents, Preface & IntroductionDocument17 pagesBuilding Code - Contents, Preface & IntroductionArnel DodongNo ratings yet

- Drumaheglis Canoe JettyDocument10 pagesDrumaheglis Canoe JettyArnel DodongNo ratings yet

- SECTION de - Dwellings and Outbuildings - Services & EquipmentDocument13 pagesSECTION de - Dwellings and Outbuildings - Services & EquipmentArnel DodongNo ratings yet

- SPECIFICATION A1.3 - Standards Adopted by ReferenceDocument7 pagesSPECIFICATION A1.3 - Standards Adopted by ReferenceArnel DodongNo ratings yet

- SECTION DD - Dwellings and Outbuildings - Access & EgressDocument8 pagesSECTION DD - Dwellings and Outbuildings - Access & EgressArnel DodongNo ratings yet

- SPECIFICATION A2.4 - Early Fire Hazard TestDocument2 pagesSPECIFICATION A2.4 - Early Fire Hazard TestArnel DodongNo ratings yet

- SPECIFICATION A2.3 - Fire Resistance of Building ElementsDocument28 pagesSPECIFICATION A2.3 - Fire Resistance of Building ElementsArnel DodongNo ratings yet

- SECTION A - All BuildingsDocument32 pagesSECTION A - All BuildingsArnel DodongNo ratings yet

- CCECC 28-Aug-15Document5 pagesCCECC 28-Aug-15Arnel DodongNo ratings yet

- Guide to Installing Timber Roof TrussesDocument32 pagesGuide to Installing Timber Roof TrussesArnel DodongNo ratings yet

- Proposed Site Survey and Soil TestingDocument6 pagesProposed Site Survey and Soil TestingArnel DodongNo ratings yet

- Awk Quick GuideDocument42 pagesAwk Quick GuideMurat TanırNo ratings yet

- Dell EMC Avamar NDMP Accelerator For NASDocument58 pagesDell EMC Avamar NDMP Accelerator For NASmanish.puri.gcpNo ratings yet

- Axial Piston Pump Series PV: Variable DisplacementDocument32 pagesAxial Piston Pump Series PV: Variable DisplacementGyanaranjan NayakNo ratings yet

- Digital Electronics Basics - Flip-FlopsDocument6 pagesDigital Electronics Basics - Flip-FlopsPaolopiniNo ratings yet

- Manual ApolloDocument263 pagesManual ApolloJose Luis CristanchoNo ratings yet

- Cavalieri Principle (Kin Y. Li)Document4 pagesCavalieri Principle (Kin Y. Li)Hicham ElyassamiNo ratings yet

- Materials and Techniques Used For The "Vienna Moamin": Multianalytical Investigation of A Book About Hunting With Falcons From The Thirteenth CenturyDocument17 pagesMaterials and Techniques Used For The "Vienna Moamin": Multianalytical Investigation of A Book About Hunting With Falcons From The Thirteenth CenturyAirish FNo ratings yet

- H-I SUPER-DEHYDRATION WITH GLYCOLSDocument15 pagesH-I SUPER-DEHYDRATION WITH GLYCOLSDiego1980bNo ratings yet

- CSC4212 Lecture 3 - 3D Viewing - Projection TransformationDocument31 pagesCSC4212 Lecture 3 - 3D Viewing - Projection TransformationAhmad AbbaNo ratings yet

- ZTE NODE-B ConnectivityDocument19 pagesZTE NODE-B ConnectivitySanjeet Doodi100% (7)

- Ecen 326 - Lab 2 ReportDocument7 pagesEcen 326 - Lab 2 Reportapi-241454978No ratings yet

- Motor Control Center Details for Umiam Stage-II Hydro ProjectDocument14 pagesMotor Control Center Details for Umiam Stage-II Hydro ProjectKunik Swaroop0% (1)

- UNIT IV: Calculating Probability Using Fundamental ConceptsDocument15 pagesUNIT IV: Calculating Probability Using Fundamental ConceptsGaurav SonkarNo ratings yet

- 0580 w13 QP 41Document20 pages0580 w13 QP 41Haider AliNo ratings yet

- To Design and Simulate Priority EncoderDocument6 pagesTo Design and Simulate Priority EncoderShubham GargNo ratings yet

- Detroit GHG17 Heavy Duty Troubleshooting Manual PDFDocument3,104 pagesDetroit GHG17 Heavy Duty Troubleshooting Manual PDFJoel Colter100% (17)

- Sand, Salt, IronDocument1 pageSand, Salt, IronKevin ChoyNo ratings yet

- Astm-e855 Изгиб МеталлаDocument8 pagesAstm-e855 Изгиб МеталлаАлесь БуяковNo ratings yet

- ELEN3017A Project Brief 2022 Rev2Document3 pagesELEN3017A Project Brief 2022 Rev2Dick MabhidaNo ratings yet

- Service Manual: NSX-SZ100Document27 pagesService Manual: NSX-SZ100Goran ChaparNo ratings yet

- Quantitative Reasoning: Factors, HCF & LCM, FactorialsDocument2 pagesQuantitative Reasoning: Factors, HCF & LCM, FactorialsNaman JainNo ratings yet

- GPT 7000L User: Manual'Document26 pagesGPT 7000L User: Manual'Adel Abo AdamNo ratings yet

- Transient Step Response Specification of Z-Source DC-DC ConverterDocument5 pagesTransient Step Response Specification of Z-Source DC-DC ConverterijsretNo ratings yet

- Materials Refractive Index and Extinction CoefficientDocument276 pagesMaterials Refractive Index and Extinction CoefficientDr-Mandeep SinghNo ratings yet

- Solution To Solved Problems: 1.S1 Make or BuyDocument3 pagesSolution To Solved Problems: 1.S1 Make or BuyHIEN TRAN THENo ratings yet

- Induction - George Ricarrson 2501987261Document11 pagesInduction - George Ricarrson 2501987261George RYNo ratings yet

- Mid-Term Engr 6201 2020Document3 pagesMid-Term Engr 6201 2020Naseri ShaunNo ratings yet

- The Practical Reference Guide ForDocument21 pagesThe Practical Reference Guide ForIgnacio SantiagoNo ratings yet

- Backing Up BitLocker and TPM Recovery Information To AD DSDocument14 pagesBacking Up BitLocker and TPM Recovery Information To AD DSnoNo ratings yet

- Ups Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVADocument1 pageUps Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVASebastian Matias CruzNo ratings yet