Professional Documents

Culture Documents

Informal Poisson's Ratio

Uploaded by

Omar SaleemOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Informal Poisson's Ratio

Uploaded by

Omar SaleemCopyright:

Available Formats

Table 1: Recorded values of Strain( )

Longitudinal 1 ( ) Initial (un-deflected) Final (deflected) Net Strain = - 4000 6433 2433

i

Lateral 2 ( ) 3536 4286 750

Calculation:

Correction of lateral stain for transverse sensitivity: Note that the longitudinal strain on the bottom of the beam is negative. Therefore, 1 (2433) = = 3.244 2 750 K t = +1.2 From the correction chart : C = 1.04 Corrected lateral strain = 750 C = 780 Calculatio n of Poisson ' s ratio : 750C v= = 0.32 1

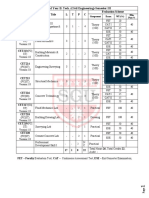

Figure 1: Correction chart used to find the Correction factor Table 2: Actual values of Poissons ratio

Material Aluminum Alloy 2024 Steel Brass C26000 Concrete Lead Plastic (PVC) Glass (Pyrex)

Poissons ratio 0.33 0.30 0.35 0.20 0.44 0.38 0.30

Source (Book Title) Material Science and Engineering An Introduction 7th edition Material Science and Engineering An Introduction 7th edition Material Science and Engineering An Introduction 7th edition Material Science and Engineering An Introduction 7th edition Material Science and Engineering An Introduction 7th edition Material Science and Engineering An Introduction 7th edition Material Science and Engineering An Introduction 7th edition

Figure 2: Wring diagram showing how equipment is connected to take readings

Discussion

2

Poissons ratio is the ratio of transverse strain to the axial strain ,where transverse strain is the deformation in the direction of application of force, while the axial strain is deformation in the directions perpendicular to action of force . The specimen has to be isotropic to get satisfactory results, which means the measured properties do not vary with the direction of measurement. The Poissons ratio also proves that there is no change in volume of a substance when it changes shapes under stress i.e. if for example a beam is stretched in the direction of length causing an increase in length, while the width and thickness of the beam will shrink to counter the effect of this increase in length there by keeping volume constant. Notice that in the experiment the strain gages where placed on the upper and lower surface at the same point to ensure both reading of lateral and longitudinal strain are of the same point. This is because the degree of deformation change at different points depending on the distance from the point where the force is applied.

Conclusion

The Poissons ratio calculated using measured strain values is 0.32 which is very near to the value of Poissons ratio of aluminum alloy which is 0.33 as shown in table 2.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design Water TankDocument83 pagesDesign Water TankHemant Sonawadekar100% (2)

- Staad Pro TutorialDocument572 pagesStaad Pro TutorialSammish8383% (12)

- Building Ordinance SarawakDocument327 pagesBuilding Ordinance SarawakRachel Ingram100% (2)

- Design of Staircase PDFDocument2 pagesDesign of Staircase PDFkarthikaswi70% (10)

- Engineering Fundamentals Laboratory: ME 372 Word Processing NoteDocument46 pagesEngineering Fundamentals Laboratory: ME 372 Word Processing NoteOmar SaleemNo ratings yet

- Week 12 - Design of Pad Footing - 2Document31 pagesWeek 12 - Design of Pad Footing - 2Muhd Fizi100% (1)

- Fe Ce 511 Prestressed ConcreteDocument6 pagesFe Ce 511 Prestressed ConcreteJeana Rick GallanoNo ratings yet

- Staad Pro SyllabusDocument5 pagesStaad Pro SyllabusNikhilRajNo ratings yet

- 23-Design and Construction of The Balanced Arch Bridge On The Deep Foundation PDFDocument8 pages23-Design and Construction of The Balanced Arch Bridge On The Deep Foundation PDFALFREDONo ratings yet

- Design of Deep BeamsDocument81 pagesDesign of Deep BeamsMayank RajputNo ratings yet

- Analysis and Design of MosqueDocument56 pagesAnalysis and Design of MosqueSabid Kanakkayil86% (7)

- Mode Gakuen Cocoon Tower: 79. Architectural SectionDocument5 pagesMode Gakuen Cocoon Tower: 79. Architectural SectionArnas Rahman100% (1)

- Flow Units ConverterDocument1 pageFlow Units ConverterOmar SaleemNo ratings yet

- Table 1: Kitchen - Ground Floor: Item Orientation Area U (FT) (Btu/h FT F)Document4 pagesTable 1: Kitchen - Ground Floor: Item Orientation Area U (FT) (Btu/h FT F)Omar SaleemNo ratings yet

- Lab ReportDocument5 pagesLab ReportOmar SaleemNo ratings yet

- Free & Forced VibrationDocument25 pagesFree & Forced VibrationOmar SaleemNo ratings yet

- Example: Workpiece Size: 4 in X 4 in Depth of Groove: 0.125 inDocument2 pagesExample: Workpiece Size: 4 in X 4 in Depth of Groove: 0.125 inOmar SaleemNo ratings yet

- Mechanisms Final ReportDocument44 pagesMechanisms Final ReportOmar SaleemNo ratings yet

- Familiarization With and Performance Check Of, Vibration Testing & Measuring EquipmentDocument33 pagesFamiliarization With and Performance Check Of, Vibration Testing & Measuring EquipmentOmar Saleem100% (1)

- EES Assignment 1Document1 pageEES Assignment 1Omar SaleemNo ratings yet

- Flow Through A Venturi MeterDocument10 pagesFlow Through A Venturi MeterOmar Saleem78% (9)

- Balancing of Rotating DisksDocument23 pagesBalancing of Rotating DisksOmar Saleem100% (1)

- HW 1 PhiloDocument5 pagesHW 1 PhiloOmar SaleemNo ratings yet

- Transverse Shear - Part 2Document22 pagesTransverse Shear - Part 2Talat ÇelebiNo ratings yet

- S Max-A-Form AgDocument40 pagesS Max-A-Form AgMacelevi DareviNo ratings yet

- S5 - EC8 - Lisbon - Design and Detailing of Secondary Seismic Elements - FARDISDocument27 pagesS5 - EC8 - Lisbon - Design and Detailing of Secondary Seismic Elements - FARDISdavidNo ratings yet

- Retrofitting of Existing Building Kathmandu UniversityDocument19 pagesRetrofitting of Existing Building Kathmandu UniversityOfficial 074BCEGHNo ratings yet

- Project 2 - Preliminary ProjectDocument6 pagesProject 2 - Preliminary ProjectajdarkobejNo ratings yet

- Second Year B. Tech. (Civil Engineering) - Semester III: Course Code Course Title L T P C Evaluation SchemeDocument27 pagesSecond Year B. Tech. (Civil Engineering) - Semester III: Course Code Course Title L T P C Evaluation SchemeAmeyNo ratings yet

- Lecture 7a Deflection of Beams (Determinate)Document14 pagesLecture 7a Deflection of Beams (Determinate)Nile DizonNo ratings yet

- Doka Large Formwork User ManualDocument21 pagesDoka Large Formwork User ManualNasir AryaniNo ratings yet

- Review Module 36 - Steel Design 1 - Part 2Document1 pageReview Module 36 - Steel Design 1 - Part 2Haoh JamjamNo ratings yet

- HW #12 - Moment of Inertia PDFDocument2 pagesHW #12 - Moment of Inertia PDFKumarNo ratings yet

- ConWag - Design of Cable Stay Pedestrian Footbridge - Modelling With Strand7Document13 pagesConWag - Design of Cable Stay Pedestrian Footbridge - Modelling With Strand7Nelson ChinNo ratings yet

- Leo Chelsea Portfolio CheckpointDocument23 pagesLeo Chelsea Portfolio CheckpointLeo SpurginNo ratings yet

- JSSC Je Syllabus PDF 58Document15 pagesJSSC Je Syllabus PDF 58Apurb KumarNo ratings yet

- AMI The Mesh: Autodesk® Moldflow® Insight 2012Document94 pagesAMI The Mesh: Autodesk® Moldflow® Insight 2012ks2000n1No ratings yet

- QS 2Document65 pagesQS 2Imani AsalankiNo ratings yet

- H9 SeismicDesign IS800Document15 pagesH9 SeismicDesign IS800Amey Gudigar100% (1)

- Presentaion SampleDocument39 pagesPresentaion SampleHamza ZejnilagićNo ratings yet

- Task 1: Ρ = 7860 Kg/M, Modulus Of Elasticity = 200 Gpa. For Cross-Section, A = 15Mm X 15Mm A) Maximum Deflection Of BeamDocument14 pagesTask 1: Ρ = 7860 Kg/M, Modulus Of Elasticity = 200 Gpa. For Cross-Section, A = 15Mm X 15Mm A) Maximum Deflection Of BeamAkash Kirubakaran RtrNo ratings yet

- DISEÑO de Cerchas de Acero TallerDocument25 pagesDISEÑO de Cerchas de Acero TallerJose SierraNo ratings yet