Professional Documents

Culture Documents

High

Uploaded by

Abhimanyu SableOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High

Uploaded by

Abhimanyu SableCopyright:

Available Formats

High-performance fiber-reinforced cementitious composites (HPFRCCs) are a group of fiberreinforced cement-based composites which possess the unique ability

to flex and self-strengthen before fracturing. This particular class of concrete was developed with the goal of solving the structural problems inherent with todays typical concrete, such as its tendency to fail in a brittle manner under excessive loading and its lack of long-term durability. Because of their design and composition, HPFRCCs possess the remarkable ability to strain harden under excessive loading. In laymans terms, this means they have the ability to flex or deform before fracturing, a behavior similar to that exhibited by most metals under tensile or bending stresses. Because of this capability, HPFRCCs are more resistant to cracking and last considerably longer than normal concrete. Another extremely desirable property of HPFRCCs is their low density. A less dense, and hence lighter material means that HPFRCCs could eventually require much less energy to produce and handle, deeming them a more economic building material. Because of HPFRCCs lightweight composition and ability to strain harden, it has been proposed that they could eventually become a more durable and efficient alternative to typical concrete. HPFRCCs are simply a subcategory of ductile fiber-reinforced cementititous composites (DFRCCs) that possess the ability to strain harden under both bending and tensile loads, not to be confused with other DFRCCs that only strain harden under bending loads. Because several specific formulas are included in the HPFRCC class, their physical compositions vary considerably. However, most HPFRCCs include at least the following ingredients: fine aggregates, a superplasticizer, polymeric or metallic fibers, cement, and water. Thus the principal difference between HPFRCC and typical concrete composition lies in HPFRCCs' lack of coarse aggregates. Typically, a fine aggregate such as silica sand is used in HPFRCCs. Strain hardening, the most coveted capability of HPFRCCs, occurs when a material is loaded past its elastic limit and begins to deform plastically. This stretching or straining action actually strengthens the material. This phenomenon is made possible through the development of multiple microscopic cracks, opposed to the single crack/strain softening behavior exhibited by typical fiber-reinforced concretes. It occurs in HPFRCCs as several fibers slip past one another. One aspect of HPFRCC design involves preventing crack propagation, or the tendency of a crack to increase in length, ultimately leading to material fracture. This occurrence is hindered by the presence of fiber bridging, a property that most HPFRCCs are specifically designed to possess. Fiber bridging is the act of several fibers exerting a force across the width of a crack in an attempt to prevent the crack from developing further. This capability is what gives bendable concrete its ductile properties. Listed below are some basic mechanical properties of ECC, or Engineered Cementitious Composite, a specific formula of HPFRCC, developed at the University of Michigan. This information is available in Victor C. Li's article on (ECC)- Tailored Composites through Micromechanical Modeling. [1] The first property listed, the ultimate tensile strength of 4.6 MPa, is slightly larger than the accepted tensile strength of standard fiber-reinforced concretes, (4.3 MPa). More notable, however, is the extremely high ultimate strain value of 5.6% when compared to most FRC's ultimate strain values ranging in the few hundredths of a percent. The first crack stress and first crack strain values are significantly low compared to normal concrete, both the result of the multiple crack phenomenon associated with HPFRCCs.

Civil structures made of steel reinforced concrete normally suffer from corrosion of the steel by the salt, which results in the failure of those structures. Constant maintenance and repairing is needed to enhance the life cycle of those civil structures. There are many ways to minimize the failure of the concrete structures made of steel reinforce concrete. The custom approach is to adhesively bond fiber polymer composites onto the structure. This also helps to increase the toughness and tensile strength and improve the cracking and deformation characteristics of the resultant composite. But this method adds another layer, which is prone to degradation. These fiber polymer composites have been shown to suffer from degradation when exposed to marine environment due to surface blistering. As a result, the adhesive bond strength is reduced, which results in the de-lamination of the composite(1). Another approach is to replace the bars in the steel with fibers to produce a fiber reinforced concrete and this is termed as FRC. Basically this method of reinforcing the concrete substantially alters the properties of the non-reinforced cement-based matrix which is brittle in nature, possesses little tensile strength compared to the inherent compressive strength. The principal reason for incorporating fibers into a cement matrix is to increase the toughness and tensile strength, and improve the cracking deformation characteristics of the resultant composite. In order for fiber reinforced concrete (FRC) to be a viable construction material, it must be able to compete economically with existing reinforcing systems.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Guide To Successful Brickwork Fourth Edition The Brick Development Association (The Brick Development Association) (Z-Library)Document415 pagesGuide To Successful Brickwork Fourth Edition The Brick Development Association (The Brick Development Association) (Z-Library)Jon RaschNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Preparing Coupons For Flexural and Washout Tests On Glass Fiber Reinforced ConcreteDocument2 pagesPreparing Coupons For Flexural and Washout Tests On Glass Fiber Reinforced ConcreteJerome PalicteNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- R. D. S. O.: Rdso/b - 10408/6Document1 pageR. D. S. O.: Rdso/b - 10408/6MUTHU PANDINo ratings yet

- Types of Mud Wall ConstructionDocument23 pagesTypes of Mud Wall ConstructionJency Kuruvilla71% (14)

- T DP CatalogDocument17 pagesT DP CatalogzebidiansNo ratings yet

- Granite & Marble WorksDocument11 pagesGranite & Marble WorksQAQC Nandanam100% (1)

- Manhole DetailsDocument1 pageManhole DetailsJanakiram GoudNo ratings yet

- Lecture10 Mat FoundationsDocument65 pagesLecture10 Mat FoundationsCao_Thanh_470896% (24)

- Blockchain NotesDocument5 pagesBlockchain NotesAbhimanyu Sable100% (1)

- 50 Deg FluentDocument1 page50 Deg FluentAbhimanyu SableNo ratings yet

- AptechDocument2 pagesAptechAbhimanyu SableNo ratings yet

- 6 Combined BendingDocument2 pages6 Combined BendingAbhimanyu SableNo ratings yet

- 12 ReferencesDocument1 page12 ReferencesAbhimanyu SableNo ratings yet

- Assignment No. 3 Advanced Structural Mechanics: Submitted by Abhimanyu A Sable Roll No. 123040040 Mtech Structural EnggDocument11 pagesAssignment No. 3 Advanced Structural Mechanics: Submitted by Abhimanyu A Sable Roll No. 123040040 Mtech Structural EnggAbhimanyu SableNo ratings yet

- Dar HR ContactDocument2 pagesDar HR ContactAbhimanyu SableNo ratings yet

- With Grey Water PDFDocument2 pagesWith Grey Water PDFAbhimanyu SableNo ratings yet

- Strain Stress (Mpa) : Load (Ton) Load (KN)Document2 pagesStrain Stress (Mpa) : Load (Ton) Load (KN)Abhimanyu SableNo ratings yet

- Assignment 5Document2 pagesAssignment 5Abhimanyu SableNo ratings yet

- Calgary Courts Centre: CANADA - 2005 - 2008Document3 pagesCalgary Courts Centre: CANADA - 2005 - 2008Georgiana StanciuNo ratings yet

- Pipe LineDocument75 pagesPipe Linekiran raghukiranNo ratings yet

- Traditional Residential Buildings of KangraDocument29 pagesTraditional Residential Buildings of KangraRajat DhimanNo ratings yet

- 1.6.2 FLS Report - NUAD-20190219Document33 pages1.6.2 FLS Report - NUAD-20190219awais zubairNo ratings yet

- IMD C C04 Basic Construction Materials Ok PDFDocument5 pagesIMD C C04 Basic Construction Materials Ok PDFRatnani AshishNo ratings yet

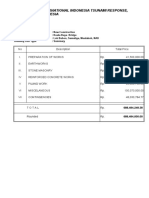

- Contoh Formulir Pelaporan Penggunaan DanaDocument43 pagesContoh Formulir Pelaporan Penggunaan DanaRahma MalabarNo ratings yet

- Solar Energy Centre GurgaonDocument10 pagesSolar Energy Centre Gurgaonishika0% (1)

- BoQ Floc-Sed-Filtermodel 2021.07.03Document15 pagesBoQ Floc-Sed-Filtermodel 2021.07.03Po RaksmeyNo ratings yet

- Residence Design Cold & Sunny Climate-LadakhDocument14 pagesResidence Design Cold & Sunny Climate-LadakhVibhuti Trehan100% (1)

- 08-08-2019Document18 pages08-08-2019KBR GADAGNo ratings yet

- CM Exam Prep Notes-Part 3Document5 pagesCM Exam Prep Notes-Part 3SuthaNo ratings yet

- 15 1 3 Mechanical InsulationDocument7 pages15 1 3 Mechanical Insulationfarshan296015No ratings yet

- Paquete 7.5 - 10.0 Tons Heat PumpDocument36 pagesPaquete 7.5 - 10.0 Tons Heat PumpSeeClaro100% (1)

- Elevator Terms DictionaryDocument12 pagesElevator Terms DictionaryEgemen KudunNo ratings yet

- Gtech SpecificationDocument1 pageGtech Specificationfrengky silabanNo ratings yet

- Waterproofing SystemsDocument24 pagesWaterproofing SystemsKC OcumenNo ratings yet

- Ermias Asalif Final ReportDocument47 pagesErmias Asalif Final Reportermias asalifNo ratings yet

- 1.behavior of Eccentrically Loaded Circular Tubed Steel-Reinforced Concrete Short Columns Using High-Strength ConcreteDocument12 pages1.behavior of Eccentrically Loaded Circular Tubed Steel-Reinforced Concrete Short Columns Using High-Strength ConcreteSakib 31No ratings yet

- MERKx Ke2Document3 pagesMERKx Ke2TaniaGhinaNo ratings yet

- Heat Load CapacityDocument23 pagesHeat Load CapacityIsrael MuhiNo ratings yet

- DasdDocument2 pagesDasdAnonymous lApm6PsfNo ratings yet

- Puffer Riscaldamento Scheda TecDocument3 pagesPuffer Riscaldamento Scheda TecAlexander CiutiNo ratings yet