Professional Documents

Culture Documents

Computer Model

Uploaded by

AnGahBasHaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computer Model

Uploaded by

AnGahBasHaCopyright:

Available Formats

113844839.xls.

ms_office / Energy Balance

INFORMATION ON ENERGY BALANCE IN COMMUNITY

Electric Power Production CCGT System (from Syngas) CCGT System (from Biogas) CCGT System (from imported Natural Gas) Solar Power (Photovoltaic) Wind Power Electric Power Demand Power Demand (All Users) Electric Power Export Export Power (potential) Avoided Energy for Cooling Absorption Refrigeration (from Steam) NG (Heat Value) Import for Electric Power Production NG Usage in CCGT Portion contributed by NG of all El. Power produced Fossil Fuel (Heat Value) Import to Community Natual Gas Imports Gasoline / Diesel Imports 660,795 MWh / Yr 221,500 MWh / Yr 0 75.4 MWh / Hr 25 MWh / Hr 0 (no nuclear, coal, or oil in energy mix for electric power) 0.0% (see Electric Power Plant for Efficiency) MWh / Hr Ton / Yr 40.9 12,338 15.8 10,970 (positive amount shows export potential) 5,489,308 626.6 MWh / Yr 5,162,568 42,188 0 612,468 332,880 6,150,104 MWh / Hr 589 5 0 70 38 702.1 (Averaged for 365 days/yr, 24 hrs/day) 83.9% 0.7% 0.0% 10.0% 5.4% 100.0%

MWh / Yr 358,449 138,446

Heat/LQ Steam Energy Production (not from Electricity) Solar Heat (in Domiciles/Small B.) Steam (LQ) / Heat (from Industry)

MWh / Yr 94,333 2,512,332 2,606,664

MWh / Hr (Averaged for 365 days/yr, 24 hrs/day) 10.8 (should match the heat demand in Dom. / Sm. B.) 286.8 (Amount that is not used for El. Power Prod.) 298 MWh / Hr 10.0 86.0 172.1 28.7 297 0 (positive amount shows export) (should match the total demand)

Heat/LQ Steam Energy Demand (not from Electricity) Heating (in Domiciles/Small B.) Usage in Absorption Refrigeration (in all buildings) Heating (in Industry/Farms/etc.) Process Heat (in Industry/etc.) Heat / LQ Steam Export Export Heat/LQ Steam (selected)

MWh / Yr 88,013 753,699 1,507,399 251,233 2,600,344 0

(Warm Water from Solar System) (from industrial steam) (from industrial steam) (from industrial steam)

Energy Mix Summary in Community El. Power Consumption (gen. from waste and renewable Energies) Steam Usage in Community (from solar and industry) El. Power Consumption in Community (from imported NG) Total Fossil Fuel Import (excl. NG used for el. Power) TOTAL Consumption in Community Electric Power Export Steam Export TOTAL Energy Export from Community

MWh / Yr 5,489,308 2,600,344 0 496,895 8,586,547 660,795 0 660,795

MWh / Hr 627 297 0 57 980 75 0 75

63.9% 30.3% 0.0% 5.8% 100% 7.7% 0.0% 7.7%

Prepared for Walden 3 Foundation

1 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Electric Power Demands

INFORMATION ON ELECTRIC POWER DEMANDS

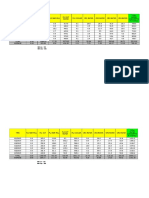

Electric Power Plant (Combined Cycle Gas Turbine System) Total Electric Power (Demand) MWh / hr 664 Electric Power Fraction Days / Year (required) MWh / hr Power Demand by: Domiciles (base load) Domiciles (peak load) Small Business & Organizations Grain Production (Farm) Fruit & Vegetable Production (Farm) Animal Farms Aluminum Plant Assembly & Manufacturing Plant Steel Production Canning Plant Glass Production Bottling Plant Cement Plant Concrete Plant Lime Plant Construction Business Textile Plant Solar System Production Plant Wind Systems Production Plant Wood Mill Pulping Process Paper Production Furniture Manufacturing Tree Farm Meat Processing Dairy Products Grain Processing Fruit & Vegetables (fresh) Processing Fruit & Veg.s (canned & frozen) Processing Transportation Systems Gasification System Plasma Melter Waste Water Treatment Plant Digester (Biogas Plant) Electric Power Plant (CCGT) MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr 5.8 2.5 19.6 0.3 1.5 3.6 9.8 0.9 4.6 0.3 0.8 1.1 0.1 2.0 0.5 0.6 0.9 14.3 15.6 1.4 5.6 0.9 0.4 0.1 0.4 1.3 0.5 4.7 2.7 16.3 442.9 44.4 24.2 0.7 33.2 0.9% 0.4% 2.9% 0.05% 0.2% 0.5% 1.5% 0.13% 0.7% 0.0% 0.1% 0.16% 0.02% 0.30% 0.07% 0.08% 0.13% 2.1% 2.4% 0.2% 0.8% 0.13% 0.1% 0.01% 0.1% 0.2% 0.08% 0.7% 0.4% 2.4% 66.7% 6.7% 3.6% 0.1% 5.0% 365 365 250 300 300 365 365 250 365 250 365 365 260 260 300 250 250 365 250 365 365 365 250 365 365 365 275 150 150 365 365 365 365 365 365 24 9 9 9 9 24 24 9 24 9 24 24 8 8 9 9 9 24 9 24 24 24 9 24 24 24 24 24 24 24 24 24 24 24 24 8760 3285 2250 2700 2700 8760 8760 2250 8760 2250 8760 8760 2080 2080 2700 2250 2250 8760 2250 8760 8760 8760 2250 8760 8760 8760 6600 3600 3600 8760 8760 8760 8760 8760 8760 Base Load 1 PM thru 10 PM 8 AM thru 5 PM 8 AM thru 5 PM 8 AM thru 5 PM Base Load Base Load 8 AM thru 5 PM Base Load 8 AM thru 5 PM Base Load Base Load 8 AM thru 5 PM 8 AM thru 5 PM 8 AM thru 5 PM 8 AM thru 5 PM 8 AM thru 5 PM Base Load 8 AM thru 5 PM Base Load Base Load Base Load 8 AM thru 5 PM Base Load Base Load Base Load Base Load May thru Sept. May thru Sept. Base Load Base Load Base Load Base Load Base Load Base Load 50,575 8,128 44,081 940 4,139 31,144 85,577 2,000 40,289 713 6,827 9,576 311 4,185 1,260 1,247 2,000 124,830 35,185 11,948 49,097 7,488 946 738 3,292 11,803 3,425 17,063 9,575 142,407 3,880,066 389,266 212,246 6,111 290,832 5.8 0 0 0 0 3.6 9.8 0 4.6 0 0.8 1.1 0 0 0 0 0 14.3 0 1.4 5.6 0.9 0 0.1 0.4 1.3 0.5 4.7 2.7 16.3 442.9 44.4 24.2 0.7 33.2 5.8 0 19.6 0.3 1.5 3.6 9.8 0.9 4.6 0.3 0.8 1.1 0.1 2.0 0.5 0.6 0.9 14.3 15.6 1.4 5.6 0.9 0.4 0.1 0.4 1.3 0.5 4.7 2.7 16.3 442.9 44.4 24.2 0.7 33.2 5.8 0 19.6 0.3 1.5 3.6 9.8 0.9 4.6 0.3 0.8 1.1 0.1 2.0 0.5 0.6 0.9 14.3 15.6 1.4 5.6 0.9 0.4 0.1 0.4 1.3 0.5 4.7 2.7 16.3 442.9 44.4 24.2 0.7 33.2 5.8 0 19.6 0.3 1.5 3.6 9.8 0.9 4.6 0.3 0.8 1.1 0.0 0.0 0.5 0.6 0.9 14.3 15.6 1.4 5.6 0.9 0.4 0.1 0.4 1.3 0.5 4.7 2.7 16.3 442.9 44.4 24.2 0.7 33.2 5.8 2.5 19.6 0.3 1.5 3.6 9.8 0.9 4.6 0.3 0.8 1.1 0.1 2.0 0.5 0.6 0.9 14.3 15.6 1.4 5.6 0.9 0.4 0.1 0.4 1.3 0.5 4.7 2.7 16.3 442.9 44.4 24.2 0.7 33.2 5.8 2.5 0.0 0.0 0.0 3.6 9.8 0 4.6 0 0.8 1.1 0 0 0 0 0 14.3 0 1.4 5.6 0.9 0 0.1 0.4 1.3 0.5 4.7 2.7 16.3 442.9 44.4 24.2 0.7 33.2 5.8 2.5 0 0 0 3.6 9.8 0 4.6 0 0.8 1.1 0 0 0 0 0 14.3 0 1.4 5.6 0.9 0 0.1 0.4 1.3 0.5 4.7 2.7 16.3 442.9 44.4 24.2 0.7 33.2 5.8 0 0 0 0 3.6 9.8 0 4.6 0 0.8 1.1 0 0 0 0 0 14.3 0 1.4 5.6 0.9 0 0.1 0.4 1.3 0.5 4.7 2.7 16.3 442.9 44.4 24.2 0.7 33.2 5.8 0 0 0 0 3.6 9.8 0 4.6 0 0.8 1.1 0 0 0 0 0 14.3 0 1.4 5.6 0.9 0 0.1 0.4 1.3 0.5 4.7 2.7 16.3 442.9 44.4 24.2 0.7 33.2 % OPERATIONS Hrs / Day SUM Hrs Comment Total Power MW / yr 6 AM thru 8 AM Power Demand Distribution (24 hr day) 8 AM thru 10 AM thru noon thru 1 1 PM thru 5 5 PM thru 9 PM thru 10 PM thru 5 AM thru 10 AM noon PM PM 9 PM 10 PM 5 AM 6 AM

DEMAND Baseload (BL) Peakload (PL) SUM PRODUCTION CCGT (BL) Wind Power (BL) SUM Solar PV : 365 9 dys/yr hr/day 612,468 3,285 hr/yr 75% 25% Solar (PV) BL Solar (PV) PL SUM POWER BALANCE

yr-round MWh / Yr 5,384,174 105,134 5,489,308

6 to 8 MWh / hr 619 0.0 619

8 to 10 10 to noon MWh / hr MWh / hr 619 619 42.8 662 42.8 662

noon to 1 MWh / hr 619 40.6 660

1 to 5 MWh / hr 619 45.3 664

5 to 9 9 to 10 MWh / hr MWh / hr 619 619 2.5 622 2.5 622

10 to 5 MWh / hr 619 0.0 619

5 to 6 MWh / hr 619 0.0 619

5,204,756 332,880 459,351 153,117 6,150,104 660,795 Note:

594 38 52 0 685

594 38 52 47 731

594 38 52 47 731

594 38 52 47 731

594 38 52 47 731

594 38 52 0 685

594 38 52 0 685

594 38 52 0 685

594 38 52 0 685 65

65 69 69 71 67 63 63 65 1. Only if the sum in the balance becomes negative, increase NG usage 2. Values in row Q provide year-around numbers 3. Values in R 53 thru Z 53 are calculated as 356 day/yr load, -> causing the negative values

Prepared for Walden 3 Foundation

2 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / CCGT System

INFORMATION ON ELECTRIC POWER GENERATION

Electric Power Plant (Combined Cycle Gas Turbine System)

Total Peak Power Demand Specific Energy Usage Operation (CCGT) Electric Power Usage

MWh / hr MW/MW pr. Hrs / Yr MWh / hr

664.40 0.050 664.00 8760 33.20 0.0% 0 0.001 5,820 0.000 0 0.10 582,015

Enter this value

Waste Ratio 1 (Recyclable) ton w/ MWh pr. Waste Production (Recyclable TBD) ton / yr Waste Ratio 2 ton w/ MWh pr. Waste Production (Non-Fuel Waste TBD) ton / yr Waste Ratio 3 ton w/ MWh pr. Waste Production (Fuel Waste TBD) ton / yr Waste Water Ratio ton w.w./ MWh Waste Water Production ton / yr Electric Power Production Syngas Supply (from Gasifier) SG Heat Value (32vol-% CO,

62% H2, 5% CO2, 1%CH4)

Syngas Power Biogas Import (from Digester) Biogas (60 vol.-% CH4, Bal. CO2) Heat Value Biogas Power

ton / hr Btu / lb MWh / ton MWh / hr ton / hr Btu / lb MWh / ton MWh / hr

202.0 8,523 5.5 1,112 1.7 8,427 5.4 9.1 90.0% 123.6 -114.5 0.0 17,371 11.2 0.0 99.2% 0.0 1,121.0 53.0% 594.2 20.0% 0 0 303 0 75.4 12.7%

MWh / Yr 9,740,695

MWh / Yr 5,162,568

MWh / Yr 79,599

MWh / Yr 42,188

Desired Portion SG (Balance Biogas, NG) Power required from NG (or Biogas) MWh / hr Difference Biogas Power to min. NG MWh / hr Additional NG Usage NG Heat Value (88 vol.-% CH4, Bal. CO2) ton / hr Btu / lb MWh / ton Additional NG Power MWh / hr SG Fraction in total Fuel Gas (Bal.: Biogas, NG) Gasoline / Diesel Usage Total Fuel Gas Input Power CCGT Efficiency Electric Power Output System (e.g., Heat) Losses Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Net Power for Export (from Community) MWh / Yr MWh / hr

Adjust Here

MWh / Yr 0 MWh / Yr 0

MWh / Yr 9,820,294 MWh / Yr 5,204,756

MWh / Yr 5,204,756

MWh / hr

MWh / hr MWh / hr MWh / hr MWh / hr MWh / hr

Staffing Requirements (for utilities) Staffing Category 1 Engineering) (e.g., Staffing Category 2(e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff

15 80 20 30 145

Prepared for Walden 3 Foundation

3 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Steam

Information on Steam Demand and Usage

Fossil Fuel Usage in Community Total Demand (Import) MWh / yr 306,525 364,275 Steam Demand LQ HQ 0 0 0 0 0 0 10,000 140,000 0 0 0 0 0 20,000 0 4,000 131,400 1,125 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 306,525 0 0 0 0 0 0 20,000 210,000 0 0 0 0 0 40,000 0 6,000 87,600 675 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 364,275 2,791,479 210,000 Steam Production LQ HQ 0 0 0 0 0 0 0 140,000 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 2,651,479 2,791,479 90% 2,512,332 30% 60% 10% 0% MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr 1,507,399 0 753,699 1,507,399 251,233 0 0 0 0 0 0 0 0 210,000 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 210,000 90% 189,000 70% 0% 30% 0% 132,300 0 56,700 0 Operation Hrs / Yr

Power Demand by: Domiciles Small Business & Organizations Grain Production (Farm) Fruit & Vegetable Production (Farm) Animal Farms Aluminum Plant Assembly & Manufacturing Plant Steel Production Canning Plant Glass Production Bottling Plant Cement Plant Concrete Plant Lime Plant Construction Business Textile Plant Solar System Plant Wind Systems Production Wood Mill Pulping Process Paper Production Furniture Manufacturing Tree Farm Meat Processing Dairy Products Grain Processing Fruit & Vegetables (fresh) Processing Fruit & Veg.s (canned/frozen) Processing Gasification System Plasma Melter Waste Water Treatment Plant Digester (Biogas Plant) Electric Power Plant (CCGT) Total Steam Av. Efficiency in Distribution Steam Availability Usage for Electric Power Production Usage for Building Heating Usage for Process Heat For Export Usage for Cooling in Buildings Usage for Building Heating Usage for Process Heat For Export Balance (Demand minus available Steam) MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr 8,760 2,250 2,700 2,700 8,760 8,760 2,250 8,760 2,250 8,760 8,760 2,080 2,080 2,700 2,250 2,250 8,760 2,250 8,760 8,760 8,760 2,250 8,760 8,760 8,760 6,600 3,600 3,600 8,760 8,760 8,760 8,760 8,760

-1,200,874 364,275

(negative amount indicates surplus steam available)

Note:

The full usage of steam requires determination of the quality of steam/heat on a case-by-case basis. Low Quality (LQ) steam may have different distribution efficiencies than High Quality (HQ) steam.

Absorption Refrigeration for Cooling of all type of buildings (Domiciles, business, industry) Steam Quality required Availability Energy Efficiency Cooling energy from Absoption TBD MWh / yr MWh / yr

753,699 25% 188,425

132,300 25% 33075

Prepared for Walden 3 Foundation

4 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Fossil Fuel Usage

Information on Fossil Fuel Usage

Fossil Fuel Usage in Community Total Demand (Import) MWh / yr 358,449 Natural Gas (NG) 138,446 Fraction Gasoline, Diesel Fraction % % 3.6% 1.5% 1.3% 1.2% 12.7% 0.8% 0.1% 42.6% 0.0% 8.2% 0.1% 0.0% 0.3% 3.4% 0.0% 0.0% 1.8% 1.8% 1.1% 2.0% 2.1% 0.0% 0.2% 1.3% 5.0% 1.4% 5.4% 2.1% 0.0% 0.0% 0.0% 0.0% 0.0% 0 5,510 11,402 8,278 20,378 1,802 250 0 0 13,192 0 865 11,634 560 4,989 100 0 2,199 3,983 14,028 22,465 95 1,475 4,736 7,383 232 146 2,745 0 0 0 0 0 138,446 0.0% 4.0% 8.2% 6.0% 14.7% 1.3% 0.2% 0.0% 0.0% 9.5% 0.0% 0.6% 8.4% 0.4% 3.6% 0.1% 0.0% 1.6% 2.9% 10.1% 16.2% 0.1% 1.1% 3.4% 5.3% 0.2% 0.1% 2.0% 0.0% 0.0% 0.0% 0.0% 0.0% Operation Hrs / Yr

Power Demand by: Domiciles Small Business & Organizations Grain Production (Farm) Fruit & Vegetable Production (Farm) Animal Farms Aluminum Plant Assembly & Manufacturing Plant Steel Production Canning Plant Glass Production Bottling Plant Cement Plant Concrete Plant Lime Plant Construction Business Textile Production Solar System Plant Wind Systems Production Wood Mill Pulping Process Paper Production Furniture Manufacturing Tree Farm Meat Processing Dairy Products Grain Processing Fruit & Vegetables (fresh) Processing Fruit & Veg.s (canned/frozen) Processing Gasification System Plasma Melter Waste Water Treatment Plant Digester (Biogas Plant) Electric Power Plant (CCGT) Total Power Demand MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr 12,750 5,510 4,620 4,139 45,465 2,702 250 152,833 38 29,399 504 68 921 12,180 0 100 6,570 6,597 3,983 7,014 7,488 95 738 4,669 18,069 5,020 19,251 7,477 0 0 0 0 0 358,449 8,760 2,250 2,700 2,700 8,760 8,760 2,250 8,760 2,250 8,760 8,760 2,080 2,080 2,700 2,250 2,250 8,760 2,250 8,760 8,760 8,760 2,250 8,760 8,760 8,760 6,600 3,600 3,600 8,760 8,760 8,760 8,760 8,760

Prepared for Walden 3 Foundation

5 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Production Overview

INFORMATION ON PRODUCTION IN COMMUNITY

Production by Community Domiciles Small Business & Organizations Farming Grain Processing Farming Fruit & Vegetables (fresh) Processing Fruit & Veg.s (canned & frozen) Processing Animal Farms 0 TBD 14,057 14,057 36,423 17,960 18,462 8,311 2,592 1,670 2,073 499 1,477 8,311 21,452 1,061 2,073 20,121 29,500 39,825 52,532 18,721 1,419 12,000 10,000 70,000 5,000 24,000 20,160 4,150 55,800 20,000 155,908 2,000 5 165,517 50 1,432,640 1,769,310 169,246 228,482 21,224,559 Waste Water Treatment Plant Digester (Biogas Plant) Electric Power Plant (CCGT) Clean Water CH4 Production CCGT (SG/CH4) Power Production Heat Production ton / yr ton / yr ton / yr MHh / yr MHh / yr 19,420,471 611,148 14,623 1,783,933 5,204,756 2,651,479 Processing

ton / yr Grain ton / yr ton / yr Fruit & Vegetables ton / yr ton / yr ton / yr Total ton / yr Cattle ton / yr Swine ton / yr Chicken ton / yr Turkey ton / yr Fish ton / yr Meat Processing ton / yr Dairy Products ton / yr Cheese ton / yr Milk ton / yr Other ton / yr Other Food Products ton / yr Tree Farm ton / yr Wood Mill ton / yr Pulping Process ton / yr Paper Production ton / yr Furniture ton / yr Aluminum Plant ton / yr Assembly & Manufacturing Plant ton / yr Steel Production ton / yr Canning Plant ton / yr Glass Production ton / yr Bottling Plant ton / yr Cement Plant ton / yr Concrete Plant ton / yr Lime Plant ton / yr Construction Business ton / yr Textile Production ton / yr Solar (PV) cell Production MW online capacity / yr 2 m / yr Solar Cells Wind Systems Plant MW online capacity / yr Gasification System Plasma Melter Gasifier SG Production Melter Slag production ton / yr ton / yr ton / yr ton / yr

Prepared for Walden 3 Foundation

6 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Materials Import & Export

Overview on Materials Import and Export

Subsystem GOODS / MATERIALS ton / yr ton / yr ton / yr ton / yr Grain Production (Farm) ton / yr ton / yr Fruit & Vegetable Production (Farm) ton / yr ton / yr Animal Farms ton / yr ton / yr ton / yr ton / yr Meat Processing ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr Dairy Products ton / yr ton / yr ton / yr ton / yr ton / yr Grain Processing ton / yr ton / yr ton / yr ton / yr ton / yr Fruit & Vegetables (fresh) Processing ton / yr ton / yr ton / yr Fruit & Veg.s (canned/frozen) Processing ton / yr ton / yr ton / yr Tree Farm ton / yr ton / yr Wood Mill ton / yr Lumber ton / yr Pulping Process ton / yr Pulp ton / yr Paper Production ton / yr ton / yr Furniture Manufacturing ton / yr ton / yr Steel Production Iron Ore ton / yr Coal ton / yr Limestone ton / yr Oxygen ton / yr Cold Rolled Steel Products ton / yr Hot Rolled Steel Products ton / yr Canning Plant ton / yr ton / yr Glass Production Sand stone ton / yr Limestone ton / yr Soda ton / yr Glass Products ton / yr Bottling Plant ton / yr Bottles (glass & content) ton / yr Aluminum Plant Bauxite ton / yr TBD ton / yr TBD ton / yr Aluminum Products ton / yr Cement Plant Clay ton / yr Limestone ton / yr Coal (Coke) ton / yr Gypsum ton / yr Cement Products ton / yr Concrete Plant Sand ton / yr Aggregate (Stone) ton / yr Concrete Product ton / yr Lime Plant Limestone ton / yr Coke ton / yr Coal ton / yr Lime Products ton / yr Construction Business Gravel & Sand ton / yr Construction Products ton / yr Assembly & Manufacturing Plant TBD ton / yr ton / yr Solar System Plant Sand (Silicon basis) ton / yr MW cap. online/yr Wind Systems Plant TBD ton / yr MW cap. online/yr IMPORT/EXPORT GOODS & MATERIALS ton / yr Small Business & Organizations WASTE STREAMS Waste Conversion System 1 (Gasification) Waste Conversion System 2 (Vitrification) Waste Water Treatment Plant Digester Electric Power Plant IMPORT/EXPORT WASTE STREAMS ENERGY / FUELS Electric Power NG Gasoline / Diesel Steam / Direct Heat IMPORT/EXPORT ENERGY/FUELS MWh / yr MWh / yr MWh / yr MWh / yr MWh / yr 496,895 358,449 138,446 0 660,795 660,795 Fuel Waste Non-Fuel Waste Waste Water Sewage/ Manure ton / yr ton / yr ton / yr ton / yr ton / yr SUM Domiciles TBD TBD TBD TBD TBD (all grain processed) TBD (all fruit & veg. processed) TBD Eggs Animals (no exports) Milk (see Dairy Products) TBD Cattle (Meat) Swine (Meat) Chicken (Meat) Turkey (Meat) Fish (Meat) TBD Cheese (nat. & processed) Milk (cond. & evapor.) Milk ( fluid) Other (frozen, yoghurt, etc.) TBD Wheat Flour Corn Products Rice Other TBD Fruit (fresh, processed) Vegetable (fresh, processed) TBD Fruit (canned, frozen) Vegetable (canned, frozen) TBD Trees (unprocessed) Materials Import Materials may be available within community limits TBD TBD TBD TBD TBD 0 TBD 0 TBD 229 N/A N/A TBD 864 557 592 115 738 TBD 67 84 559 5,679 TBD 1,019 157 177 53 TBD 731 1,065 TBD 867 979 TBD 0 TBD 2,943 TBD 0 TBD 1,971 TBD 284 65,285 27,542 1,813 5,591 1,060 1,060 TBD 750 3,990 1,508 1,092 2,400 TBD 5,616 10,694 777 2,007 1,800 3,320 1,245 311 208 830 63,188 22,320 11,160 36,000 2,380 60 10,000 62,363 TBD 2,500 5,000 4.5 TBD 264,331 400,000 0 5,000,000 0 0 0 5,400,000 0 90.0 113,268 0 4,000 Export

Prepared for Walden 3 Foundation

7 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Gasification System

Information on Waste Treatment Plants

Waste Conversion System 1 (Gasification of Fuel Waste) Total Fuel Waste ton / yr ton/hr 1,432,640 164 Fuel Waste ton/yr 36,500 3,375 20,260 63,966 13,217 876 400 3,500 100 2,400 806 15,591 0 0 2,000 100 3 25 1,991 44,484 18,721 19 2,096 5,966 4,732 3,991 9,525 25,387 742,860 9,749 0 400,000 0 1,432,640 429,792 1,862,432 2.08 3,880,066 8,760 443 30.0% 429,792 90.0% 0 0 0 0 3.5% 50,142 45.0% 22,564 27,578 10.0% 42,979 0 0 1,769,310 202 5 25 8 12 50

Fraction % 2.5% 0.2% 1.4% 4.5% 0.9% 0.1% 0.0% 0.2% 0.0% 0.2% 0.1% 1.1% 0.0% 0.0% 0.1% 0.0% 0.0% 0.0% 0.1% 3.1% 1.3% 0.0% 0.1% 0.4% 0.3% 0.3% 0.7% 1.8% 51.9% 0.7% 0.0% 27.9% 0.0%

Domiciles Small Business & Organizations Grain Production (Farm) Fruit & Vegetable Production (Farm) Animal Farms Aluminum Plant Assembly & Manufacturing Plant Metal Forming Plant Canning Plant Glass Production Bottling Plant Construction Business Cement Plant Concrete Plant Lime Plant Textile Plant Solar System Plant Wind Power Production Wood Mill Pulping Process Paper Production Furniture Manufacturing Tree Farm Meat Processing Dairy Products Grain Processing Fruit & Vegetables Processing Waste Conversion System 2 Waste Water Treatment Plant Digester Electric Power Plant IMPORT from other Communities EXPORT to other Communities Total Fuel Waste Process Water Total Input Specific Energy Usage Electric Power Usage Operation Water Ratio Water (clean) Consumption Water converted to Syngas Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Waste Ratio 2 (Solid Content) Waste Production (Non-Fuel Waste Incombustibles) Conversion to slag (in Gasifier) Slag Production Waste Production (Non-Fuel Waste to Melter) Waste Water Ratio Waste Water Production NG Usage Gasoline / Diesel Usage Syngas Production Staffing Requirements

ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr MWh / ton MWh / yr hrs / yr MWh / yr ton w / ton w. ton / yr

MWh / hr MWh / hr MWh / hr MWh / hr ton / yr ton / yr ton / yr ton / yr MWh / yr MWh / yr ton / yr ton / hr

Staffing Category (e.g., Engineering) 1 Staffing Category 2 (e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff Note: R&D, manufacturing, and field servicing

Prepared for Walden 3 Foundation

8 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Plasma Melter

Information on Waste Treatment Plants

Waste Conversion System 2 (Vitrification/Melter of Non-Fuel Waste) Total Non-Fuel Waste ton / yr 169,246 Non-Fuel Waste ton/yr Domiciles Small Business & Organizations Grain Production (Farm) Fruit & Vegetable Production (Farm) Animal Farms Aluminum Plant Assembly & Manufacturing Plant Steel Production Canning Plant Glass Production Bottling Plant Cement Plant Concrete Plant Construction Business Lime Plant Textile Production Solar System Plant Wind Power Production Wood Mill Pulping Process Paper Production Furniture Manufacturing Tree Farm Meat Processing Dairy Products Grain Processing Fruit & Vegetables Processing Waste Conversion Plant 1 Digester Electric Power Plant IMPORT from other Communities EXPORT to other Communities Total Non-Fuel Waste Specific Energy Usage Electric Power Usage Operation Ratio Water / Waste Water Usage Waste Water Ratio Waste Water Production Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Volatile Content Offgas Production Ratio Additives/Waste Additives (e.g. Glas Grid) Selectivity to Slag Slag (Product used in Construction) to Landfill (Residue) NG Usage Gasoline / Diesel Usage Staffing Requirements Staffing Category (e.g., Engineering) 1 Staffing Category 2 (e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff 6 32 12 15 65 ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr MW/ton MW/yr hrs / yr MWh / yr ton w./ton w. ton / yr ton / yr MWh / hr MWh / hr MWh / hr MWh / hr ton v. / ton w. ton / yr ton / yr ton / yr ton / yr MWh / yr MWh / yr 69,350 5,400 0 0 0 1,751 500 3,500 200 1,296 1,008 0 0 18,709 2,000 30 5 50 1,195 402 749 38 0 139 430 309 364 27,579 30,557 3,684 0 0 169,246 2.3 389,266 8,760 44 0.0% 0 2.0% 3,385 0 0 0 0 15.0% 25,387 50.0% 84,623 100.0% 228,482 0 0 0 25,387 84,623 228,482 0 389,266 Fraction % 41% 3% 0% 0% 0% 1% 0% 2% 0% 1% 1% 0% 0% 11% 1% 0% 0% 0% 1% 0% 0% 0% 0% 0% 0% 0% 0% 16% 18% 2% 0% 0%

Enter this value

27,578 5,820

0 3,385

Prepared for Walden 3 Foundation

9 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Waste Water Treatment Plant

Information on Waste Water Treatment Plant

Waste Water Treatment Plant (WWTP)

Total Waste Water to WWTP ton / yr 21,224,559 Waste Water ton/yr 11,616,261 1,474,701 0 0 14,756 51,000 88,442 5,000 37,980 102,816 623 8,370 38,977 20,000 2,000 5,000 50,000 5,974 1,995,021 37,441 568 0 32,272 2,145 1,546 1,821 42,980 3,385 585,480 0 5,000,000 0 21,224,559 2,423 0.010 212,246 8,760 24.2 0 0 0 0 5.0% 1,061,228 0.0% 0 0.0% 0 3.5% 742,860 19,420,471 0 0 Fraction % 54.7% 6.9% 0.0% 0.0% 0.1% 0.2% 0.4% 0.0% 0.2% 0.5% 0.0% 0.0% 0.2% 0.1% 0.0% 0.0% 0.2% 0.0% 9.4% 0.2% 0.0% 0.0% 0.2% 0.0% 0.0% 0.0% 0.2% 0.0% 2.8% 0.0% 23.6% 0.0%

Enter this value

Domiciles Small Business & Organizations Grain, Fruit, & Vegetable Farms Animal Farms Aluminum Plant Assembly & Manufacturing Plant Steel Production Canning Plant Glass Production Bottling Plant Concrete Plant Concrete Plant Construction Business Lime Plant Textile Plant Solar System Plant Wind Systems Production Wood Mill Pulping Process Paper Production Furniture Manufacturing Tree Farm Meat Processing Dairy Products Grain Processing Fruit & Vegetables Processing Waste Conversion System 1 Waste Conversion System 2 Digester Electric Power Plant IMPORT from other Communities EXPORT to other Communities Total Waste Water Specific Energy Usage Electric Power Usage Operation Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production

ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton/hr MW/ton MW/yr hrs / yr MW/hr MWh / hr MWh / hr MWh / hr MWh / hr

42,979

212,246

Evaporation Rate Evaporation ton / yr Waste Ratio 1 ton w. / ton w.w. Waste Production (Recyclables TBD) ton / yr Waste Ratio 2 ton w. / ton w.w. Waste Production (Non-Fuel Waste) ton / yr Waste Ratio 3 (Sludge/org. Solids) ton w. / ton w.w. Waste Production (Fuel Waste e.g. Sludge) ton / yr Balance (clean Water) ton / yr Clean Water Demand ton / yr NG Usage Gasoline / Diesel Usage Staffing Requirements Staffing Category 1(e.g., Engineering) Staffing Category 2 (e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff Note: R&D, manufacturing, and field servicing MWh / yr MWh / yr

5 20 8 12 45

Prepared for Walden 3 Foundation

10 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Digester System

Information on Digester Plant

Digester Plant (DP)

Total Waste (liquid Manure) to DP ton / yr 611,148 Organic Waste ton/yr 69,350 6,650 0 535,148 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 N/A 0 0 0 611,148 69.8 0.010 6,111 8,760 0.7 0 0 0 0 0.05% 306 5.0% 30,557 580,285 4.20% 24,372 100.0% 24,372 60.0% 14,623 1.7 9,749 585,480 0 0 5 20 8 12 45 306 30,557 Fraction % 11.3% 1.1% 0.0% 87.6% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0%

Domiciles Small Business & Organizations Grain, Fruit, & Vegetable Farms Animal Farms Aluminum Plant Assembly & Manufacturing Plant Metal Forming Plant Canning Plant Glass Production Bottling Plant Construction Business Cement Plant Concrete Plant Lime Plant Solar System Plant Wind Power Production Wood Mill Pulping Process Paper Production Furniture Manufacturing Tree Farm Meat Processing Dairy Products Grain Processing Fruit & Vegetables Processing Waste Conversion Plant 1 Waste Conversion Plant 2 Digester Electric Power Plant IMPORT from other Communities EXPORT to other Communities Total Organic Waste Specific Energy Usage Electric Power Usage Operation Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Evaporation Rate Evaporation Average Solid Content Solid Fuel Waste Balance Ratio for Biogas Production Biogas Conversion to CH4 and CO2 Total Gas Ratio CH4 in Biogas CH4 Gas CO2 Gas Residual Waste Water NG Usage Gasoline / Diesel Usage Staffing Requirements

ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / hr MW/ton MW/yr hrs / yr MW/hr MWh / hr MWh / hr MWh / hr MWh / hr ton / yr ton / yr ton / yr ton / yr ton / yr ton / yr ton / hr ton / yr ton / yr MWh / yr MWh / yr

6,111

14,623 9,749 585,480

Staffing Category 1(e.g., Engineering) Staffing Category 2 (e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff Note: R&D, manufacturing, and field servicing

Prepared for Walden 3 Foundation

11 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Materials & Recycle Overview

Materials (& Waste) Generated in planned Community - (A more detailed Overview)

Explicitly Recycle / accounted Reuse for in Model X NO X X X X X X TBD TBD Parts Parts X Yes No Yes Yes No No No Yes No No No No No Recycled in/at Treated at Metal Melter Gasifier Pulp/Paper Prod. Wood Mill Compost Farm Construction Compost Farm Glass Melter Gasifier Gasifier Plasma Melter (TBD) Export to Car Manufacturer Gasifier (or export to Tire Manufacturer) (X) Disass./ Sorting/ Cutting Separation X X X X X (X) (X) X (X) (X) X (X) X Residues Secondary Waste (By-)Product (potential) Metal Products Soundboards, Benches, Containments Pulp & Paper Products Wood Chips, Pulp Wood, Rock Wood, Rock Metal, Plastic Metal TBD Metal, Plastic Metal, Plastic, Glass, Leather, Fabric Filler in Tire Manuf., etc. Final Product from thermal Treatment Slag / Construction Fuel Gas Fuel Gas Fuel Gas Fuel Gas Slag / Construction Slag / Construction Slag / Construction Fuel Gas Fuel Gas Slag / Construction N/A Fuel Gas

Origin

Waste / Materials

Municipal

Metals Plastic Paper/Cardboard Wood Leaves / Yard Waste Rock Soil Glass Textile / Leather / Fabric Carpet Electronics / Computers Automobiles Tires

X X X (X) X

(X) (X) X X (X)

Municipal / Industrial

Oil Coolant Cleaning Liquids/Spray Insecticides Medicine Other Chemicals TBD TBD TBD TBD TBD TBD No No No No No No Gasifier Gasifier Gasifier Gasifier Gasifier Gasifier (TBD) (X) (X) (X) (X) (X) (X) (X) (X) (X) (X) (X) (X) Oil, Lubricants TBD TBD TBD TBD TBD Fuel Gas Fuel Gas Fuel Gas Fuel Gas Fuel Gas Fuel Gas Final Product from Treatment System Fuel Gas Fuel Gas Fuel Gas Fuel Gas Final Product from Treatment System Fuel Gas / Electric Power Fuel Gas / Electric Power Irrigation Water Irrigation & Process Water Irrigation & Process Water

(X) (X) (X)

Municipal / Farms

Corpses (Animals) Meat / Skin (Animals) Blood Bones No No No No Yes Yes No No Biomass Gasifier Biomass Gasifier Biomass Gasifier Biomass Gasifier NO NO NO NO

Waste Water / Sewage

Sewage/Manure (Municipal / Farms) Chicken Manure Grey Water / Run-off Municipal waste water Small business / industrial / Farm waste water NO NO YES (X) (X) YES YES No Yes Yes Digester Gasifier WWTP WWTP WWTP Waste Water to WWTP Solids to Plasma Melter Sludge (to Gasifier) Sludge (to Gasifier) Sludge (to Gasifier)

Prepared for Walden 3 Foundation

12 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Domiciles Inputs & Outputs

Information on Domiciles Inputs & Outputs (and Solar Systems)

Building Quantities & Population Demographics

Total Population People / family Families / Multi-family Home Single-family homes Multiple-family homes Apartment buildings Residential Total Small Businesses (ground floor in apartment buildings) Community Buildings, Schools, Hotels, Universities, etc. City Administrations etc. Industry Buildings11 Living Area / Person [m2] Aspect Ratio

Number of Buildings

Occupied Floors per Building

Building Configuration in Community

Population and Housing Occupancy 100,000 2.4 4.0 0.0 15,000 85,000

Individuals per Living Unit 1. 2. 3. 4. 5. 6. 7.

Notes / Assumptions

All domestic (potable) water is supplied from a central water supply system. Heat for domestic hot water is provided with solar heating via heat exchange (back-up w/ NG & electric Power). Space heating is provided from solar heatingvia heat exchange (back-up via NG & electric power). El. power is provided from city utility. Renewable energy (solar (PV) and wind) are part of the energy mix. Goal: minimization of use of fossil & nuclear fuels. Sophisticated recycling for: paper, plastic, aluminum/metal, glass. Organic mat'ls are fuel waste for gasification. Non-organics are non-fuel waste for melting. Sewage & manure are convered to biogas in digester. All businesses participate in solar energy/ warm water system. (Water and power requirements are assumed as % of domestic energy requirements.) 11% South wall surface area used for photovoltaic: 89%

0.0 1,563 625 2,188 625 57 20 83

160

1 2 4

0% 15% 85.0% 100.0% 15% 20% 5.0% 5.0%

2.4 9.6 136

1 2 2 2

15,000 20,000 5,000 5,000

24 350 250 60 57

8. South wall surface area used for solar heating: 9. Roof area used for solar heating: 0%

50 4

Families per Apartment Building Floor Height (m) 3.10

10. Roof-mounted flat plate collector - recommend tilt to match the latitude. 11. Water and electricity usage only considered for office heating and facilities, not for industrial processes. Cooling energy is assumed to be delivered via absorption refrigeration from industrial steam. (Concept improvements may be implemented later). 12. Industry buildings include office buildings and all other buildings for storage, processing, etc.. 13. Totals are only for peak load due to different on-line times: homes: 365 days/yr, small business, etc: 250 days/yr. Additional note: More comments are in cells with red flags.

Solar Energy Inputs Building Information

Floor Area per Occupant (m2) Roof Area usuable for Solar Wall Height (m) Panels 70% 70% 70% N/A 70% 70% 70% 2.5 3.0 3.0 3.5 4.0 4.0 4.5 Aspect Ratio (South Wall / East Wall) 2 3 4 4 3 3 3 Total Floor Area in Building (m2) 120 480 6800 1700 12250 8750 7200 Area per Floor (m2) South Facade Area per Building (m2) 39 161 990 289 1,084 917 935 Total South Active Roof Total Flat Roof Total Roof Solar Facade Areas Solar Area per Area (m2) Area (m2) (m2) Building (m2) 0 251,558 618,466 180,386 61,968 18,330 77,942 25,000 1,208,650 0 375,000 1,062,500 0 350,000 87,500 300,000 84 168 1,190 0 4,288 3,063 2,520 0 262,500 743,750 0 245,000 61,250 210,000 100,000 1,622,500 South Wall Length (m) 15.5 26.8 82.5 82.5 135.6 114.6 103.9 East Wall Length (m) 7.7 8.9 20.6 20.6 45.2 38.2 34.6

Building Footprint (m 2)

Single-family Multiple-family Apartment Building Small Businesses (below aptm'ts) Community Buildings Government Buildings Industry Buildings11, 12 Additional Structures for PV Energy

50 50 50 71 35 35 120

120 240 1,700 1,700 6,125 4,375 3,600

120 240 1700 1700 6125 4375 3600

TOTAL

2,175,000

Input Streams

Domestic Water (cold) per day (l / d) 228

Demand Applicability Factor

Hot water2 per Electric Power Demand day (l /day-person) (kWh/m2-yr) 90 17.0 kW-h/day 0 34,932 197,945 19,795 9,781 2,445 8,384

Heat Demand (kWh/m2-yr)

Solar Energy Calculation

Solar Energy (kW-h/m2-day)10

PV Cell Power on Roofs (kWh/day)

Portion of Faade used for PV Note

PV Cell Power on Facades (kWh/day)

PV Cell Power (sum) (kWh/day)

PV Cell Power (sum) (MWh/Yr)

Heat (Solar Energy) (kWh/day)

Heat (Solar Energy) (MWh/yr)

PV Cell Efficiency

Demand / Person (Domiciles)

15.0 kW-h/day 0 30,822 174,658 17,466 8,630 2,158 7,397

5.00

14.5% Correction Factor for PV on Roof 95% Correction Factor for PV on Faade 70.0% Collector Eff. for solar heating 40.0%

Single-family Multiple-family (All) Apartment Building(s) Small Businesses in Apartment Buildings Community Buildings Government Buildings Industry Buildings11, 12 Additional Structures for PV Energy Total13

0 3,424,462 19,405,285 1,369,785 1,369,785 342,446 342,446

100% 100% 100% 40% 30% 30% 30%

0 1,349,344 7,646,281 539,737 539,737 134,934 134,934 10,344,968

Single-family Multiple-family Apartment Building Small Businesses in Apartment Buildings Community Buildings Government Buildings Industry Buildings11, 12 Additional Structures for PV Energy Total averaged:

(kW-hr / day) (kW-hr / day) (kW-hr / day) (kW-hr / day) (kW-hr / day) (kW-hr / day) (kW-hr / day) (kW-hr / day) kW-h/day MW-h / hr

0 180,797 512,258 0 168,744 42,186 144,638 68,875 1,117,497 46.6

93% 93% 84.0% 100% 92% 92% 92% 100%

0 118,729 263,652 91,546 28,933 8,558 36,391 12,688 560,497 23.4

0 299,526 775,910 91,546 197,676 50,744 181,029 81,563 1,677,994 69.9

0 109,327 283,207 33,414 72,152 18,522 66,075 29,770 612,468 69.9

0 35,218 197,909 0 9,915 2,933 12,471 0 258,446 10.8

0 12,855 72,237 0 3,619 1,070 4,552 0 94,333 10.8

El. Power

273,281 11.4

2.33

Heat

241,130 10.0

26,254,210

kW-h/day MW-h / hr averaged: kW-h/day-person

Output Streams

Non-fuel waste (inorganic MSW) (Kg / d)5 1.6 0 24,000 136,000 7,200 9,600 2,400 2,400 181,600

Applicability Factor %

Fuel waste (organic MSW) (Kg / d)6 1 0 15,000 85,000 4,500 6,000 1,500 1,500 113,500

Applicability Factor %

Fuel waste Applicability (sewage) (Kg Factor % / d)6 1.9 0 28,500 161,500 11,400 7,600 3,800 3,800 216,600

Recycled Waste (Kg / d) 0.55 0 8,250 46,750 30,030 5,500 2,475 10,010 103,015

Applicability Factor %

Output / Person Single-family Multiple-family Apartment Building Small Businesses Community Buildings Government Buildings Industry Buildings11, 12 Total

100% 100% 100% 30% 30% 30% 30%

100% 100% 100% 30% 30% 30% 30%

100% 100% 100% 40% 20% 40% 40%

100% 100% 100% 364% 50% 90% 364%

ENERGY USAGE IN BUILDINGS Single-Family House (new) Multi-Family/Use House (new) Target Value (old & new) Low-Energy House (Germany) Minergie Standard (new) Minergie Standard (old) Passivhaus Standard (Germany) Zero-Energy House

Heating (rooms) kWh / m2a 92 83 78 70 45 90 15 0

Demand for Warm Water kWh / m2a 18

Electric Power kWh / m2a 21 Improvements at insulation for roof, windows, and walls 17 17 17 0 (or negative)

passive energy usage, controlled airflow w/ heat recovery based on solar heating and use of PV cells

Prepared for Walden 3 Foundation

13 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Domiciles & Small Businesses

Information on Domiciles and Small Businesses

Domiciles

Population Consumption Specific Energy Usage Energy Usage Operation Type of Energy NG Electricity Oil / Gasoline Usage of Energy NG Electricity Base load Factor Base Load Peak Load Oil / Gasoline Water (clean) Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Waste Generation (in Domiciles) Waste Ratio 1 Waste Production (Recyclable TBD) Waste Ratio 2 Waste Production (Non-Fuel Waste) Waste Ratio 3 Waste Production (Fuel Waste) Waste Ratio 4 Waste Production (Sewage) Waste Water Ratio Waste Water Recycling/Waste Separation (in Domiciles) Recycle Ratio 1 Recycle (Aluminum) Recycle Ratio 2 Recycle (other Metals) Recycle Ratio 3 Recycle (Paper/Board) Recycle Ratio 4 Recycle/Separation (Plastic) Recycle Ratio 5 Recycle (Glass) Total Recycle ton /person-day ton / yr MWh / hr MWh / hr MWh / hr MWh / hr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day 1.5 8.2 70% 5.8 2.5 0.0 0.228 8,332,858 0 0 0 0 see below see below 1.6 58,400 1.0 36,500 1.9 69,350 318.3 11,616,261 0.08 2,738 0.10 3,650 0.15 5,475 0.03 913 0.20 7,300 0.55 14% 2,738 18% 3,650 27% 5,475 5% 913 36% 7,300 1.5 8.2 5.8 2.5 0.0 15% 85% 0% 100,000 kW / person-day MWh / yr Hrs / Yr MWh / hr 2.33 85,000 8,760 9.7

85,000 Base load 10

8,332,858

58,400 36,500 69,350 11,616,261

Prepared for Walden 3 Foundation

14 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Domiciles & Small Businesses

Small Businesses

Persons in Small Businesses & other Organizations Consumption Specific Energy Usage (Human) kW / person-day Energy Usage MW / yr MW / hr Specific Energy Usage (Business) kW / person-day Energy Usage MW / yr Operation Hrs / Yr MW / hr Type of Energy NG Electricity Oil / Gasoline Usage of Energy NG Electricity Oil / Gasoline WATER for Human (clean) ton /person-day ton / yr Business Water (clean) ton /person-day ton / yr Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Waste Generation (small businesses & organ.) Waste Ratio 1 Waste Production (Recyclable TBD) Waste Ratio 2 Waste Production (Non-Fuel Waste) Waste Ratio 3 Waste Production (Fuel Waste) Waste Ratio 4 Waste Production (Sewage) (Human) Waste Water Ratio (Human) Waste Water (Business Specific) Waste Water Ratio (Specific) Waste Water Recycling/Waste Separation Recycle Ratio 1 Recycle (Aluminum) Recycle Ratio 2 Recycle (other Metals) Recycle Ratio 3 Recycle (Paper/Board) Recycle Ratio 4 Recycle/Separation (Plastic) Recycle Ratio 5 Recycle (Glass) Total Recycle Staffing Requirements (small Business) MWh / hr MWh / hr MWh / hr MWh / hr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day ton / yr kg/person-day 45,000 0.9 10,101 4.5 4.00 45,000 2,250 20.0 10% 80% 10% 2.4 19.6 2.4 0.106 1,193,451 0.10 1,125,000 0 0 2.4 19.6 2.4 39,150

10,101 4 45,000 20

sum

2,318,451

see below see below 0.48 5,400 0.30 3,375 0.6 6,650 106.1 1,193,451 25.0 281,250 0.150 3,750 0.250 6,250 0.80 20,000 0.10 2,500 0.50 12,500 1.80

5,400 3,375 6,650 1,193,451 281,250

3,750 6,250 20,000 2,500 12,500

Staffing Category 1 (e.g., Engineering) Staffing Category 2 (e.g., Technical) Staffing Category (e.g., Man'mt, Admin) 3 Staffing Category 4 (other) Total Staff

1500 6000 2000 5500 15000

Note: R&D, manufacturing, and field servicing Developed by TCC / NUVOTEC INC., Richland, WA

Prepared for Walden 3 Foundation

14 of 42

113844839.xls.ms_office / Staffing

Information on STAFFING in Community

Staffing Overview Total (Full-Time) Positions Category 1 Category 2 Category 3 Higher Degree Base Degree Managm't & (Eng., Physitian, etc.) (Technitian, etc.) Admin Support 7,032 16,575 4,243 16% 39% 10% 1,500 4 5 20 5 15 15 4 5 6 50 5 5 4 8 30 15 8 6 6 6 5 6 5 8 5 6 5 5 15 0 500 250 4,000 500 6,000 20 25 60 50 100 80 20 40 40 250 25 50 24 40 120 50 36 48 36 40 25 25 25 40 25 32 20 20 80 829 1500 800 4000 2000 2,000 8 10 12 10 20 20 8 10 15 50 10 10 8 8 15 10 10 10 12 10 10 10 10 10 8 12 8 8 20 81 350 250 800 400 Category 4 Other (Service, etc.) 15,079 35% 5,500 30 50 20 20 25 60 12 15 20 150 15 10 12 20 40 25 15 30 20 40 15 15 15 24 12 15 12 12 30 0 1200 600 2000 5000

Full-Time Positions 42,929 15,000 62 90 112 85 160 175 44 70 81 500 55 75 48 76 205 100 69 94 74 96 55 56 55 82 50 65 45 45 145 910 3,550 1,900 10,800 7,900

Fraction % 100% 34.9% 0.1% 0.2% 0.3% 0.2% 0.4% 0.4% 0.1% 0.2% 0.2% 1.2% 0.1% 0.2% 0.1% 0.2% 0.5% 0.2% 0.2% 0.2% 0.2% 0.2% 0.1% 0.1% 0.1% 0.2% 0.1% 0.2% 0.1% 0.1% 0.3% 2.1% 8.3% 4.4% 25.2% 18.4%

Small Business & Organizations Grain Production (Farm) Fruit & Vegetable Production (Farm) Animal Farms Aluminum Plant Assembly & Manufacturing Plant Steel Product Plant Canning Plant Glass Production Bottling Plant Construction Business Cement Plant Concrete Plant Lime Plant Textile Plant Solar System Plant Wind Power Systems Wood Mill Pulp & Paper Production Furniture Manufacturing Tree Farm Meat Processing Dairy Products Grain Processing Fruit & Vegetables Processing Gasification System Plasma Melter Waste Water Treatment Plant Digester Electric Power Plant Transportation Systems City Administration & Functions Arts & Entertainment Other Public Functions (Health Care, Schools, etc.) Other Service Business / Trade

Prepared for Walden 3 Foundation

8 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Consumption by Domiciles 1

Product & Utility Consumption by Domiciles

Year ENERGY / FUEL Energy US (Domic. & Indust.) 1999 Energy Europe (Dom. & Ind.) TOTAL ENERGY Electricity Household (Hot Water) Household / Yard (Other) Heating Cooling NG Household (Hot Water) Household / Yard (Other) Heating / Cooling Coal / Oil / Other Household / Yard (Hot Water) Household / Yard (Other) Heating / Cooling Transportation Fuels Private Uses WATER Drinking Water Cold Water Sink Filling Faucet Flow Bath Filling Showers Clotheswasher Dishwasher Toilets Yard / Other Hot Water Sink Filling Faucet Flow Bath Filling Showers Clotheswasher Dishwasher Toilets Yard / Other Forestry & Wood Products Paper & Paperboard Furniture 1993 2.0 0.719 628 0% 75% 0% 0% 0% 0% 0% 0% 0% 35% 0% 0% 0% 0% 0.0 1.5 0.0 0.0 0.0 0.00 0.0 0.0 0.0 0.2 0.0 0.0 0.0 0.0 per day liter/day 228.3 60% 60% 45% 40% 40% 0% 30% 15% 39% 40% 40% 40% 38% 38% 40% 0% 0% 50% 11.4 18.9 15.7 29.4 36.6 0.0 67.3 49.1 90.0 10.1 5.1 14.4 37.4 14.1 8.8 0.0 0.0 kg/day 0.46 32.8 3.7 1.9 5.3 13.7 5.1 3.2 0.0 0.0 kg/yr 167.5 ton / yr 16,750 YES NO 0.000 0.539 0.000 0.000 0.000 0.000 0.000 0.000 0.000 0.077 0.000 0.000 0.000 0.000 per year ton/yr 0.0 83.3 4.1 6.9 5.7 10.7 13.4 0.0 24.6 17.9 YES YES YES NO YES YES YES NO NO YES NO NO NO per day kWh/day 331.5 142.5 per year MWh/yr 121 52 Annual per Capita Consumption Per Capita (aver.) Planned Assum. % per year per day per year Trill. BTU /yr kWh/day MWh/yr 0% 0 0 0% 0 0 Accounted in Model

1993

6.3

2.302

2012

1993

0.6

0.220

192

per day liter/day

per year ton/yr 100% 211.8 5.0 8.3 9.2 19.4 24.2 0 59.3 86.4 61.2 6.7 3.4 9.5 26 9.8 5.8 0 0

1990 801.7 292.6 1990 18.9 6.9 1990 31.4 11.5 1990 34.8 12.7 1990 73.4 26.8 1990 91.6 33.4 1990 0.0 0.0 1990 224.5 81.9 1990 327.1 119.4 1990 231.7 84.6 1990 25.4 9.3 1990 12.9 4.7 1990 36.0 13.1 1990 98.4 35.9 1990 37.1 13.5 1990 22.0 8.0 1990 0.0 0.0 1990 0.0 0.0 kg/day kg/yr 1997 0.92 335.0 No Data

Prepared for Walden 3 Foundation

15 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Consumption by Domiciles 2

Product & Utility Consumption by Domiciles

Year per day gram/day 2386.9 per year kg/yr 871.2 Annual per Capita Consumption Assum. % Per US Capita (aver.) Planned per day per year gram/day kg/yr 82.9% 1978.0 722.0 82.5% 1945.1 61% 150.0 54.7 56% 78.7 28.7 32% 60% 47 17.3 25% 50% 31 11.1 1% 50% 1 0.3 60% 51.1 18.6 28% 60% 41 14.8 7% 60% 11 3.8 8% 110% 20 7.4 50% 0.3 124.5 53% 50% 50% 40% 50% 50% 50% 60% 60% 60% 50% 100% 111% 105% 115% 50% 58% 50% 50% 30% 100% 100% 103% 109% 110% 110% 216.1 110% 100% 100% 110% 98% 115% 115% 243.8 90% 90% 90% 90% 80% 80% 60% 80% 155% 150% 150% 200% 150% 50% 50% 50% 50% 50% 50% 100% 100% 100% 100% 385.1 279 43 48 15 95.7 41 53.5 39 12 2 1 34.9 15.1 19.5 14.2 4.5 0.9 0.3 #VALUE! #VALUE! #VALUE! #VALUE! YES YES YES YES NO NO NO NO YES 118 81 37 91 59 22 26 8 140.6 101.9 15.7 17.7 5.3 YES YES YES YES 5 13 25 172 509.0 265.2 68 197 89.0 43.2 29.7 13.6 33.3 21.4 8.2 9.4 3.1 YES YES YES YES YES YES YES YES 185.8 96.8 25.0 71.8 YES YES 390.8 18 2 16.1 8 5 1 3 3 3 5 11 12 32.8 11 22 0.9 0.9 1.8 3.9 4.2 12.0 142.6 6.4 0.6 5.9 2.9 1.7 0.3 1.0 YES YES YES YES YES YES YES YES YES YES YES YES YES Accounted in Model

FOOD BASIS Meats/Eggs Total Meat / Fish Red Meat Beef Pork Veal & Lamb Poultry Chicken Turkey Fish/Shellfish Eggs [numbers] Dairy Products Total Dairy Products Cheese Cottage Cheese Frozen dairy Products Ice Cream Lowfat ice cream Sherbet Other Nonfat dry milk Dry whey Condensed & evapor. Milks Cream Products Yogurt Beverage milk Whole Lower Fat Other Dairy Products Fats & Oils Total added fats and oils Salad & cooking oils Baking & Frying fats Shortening Lard & beef tallow Table spreads Butter Margarine Fruits & Vegetables Total Fruits & Vegetables Total Fruit Fresh Fruit Citrus Non-citrus Processed Fruit Frozen Fruit, non-citrus Dried, Fruit, non-citrus Canned Fruit, non-citrus Fruit Juices Total Vegetables Fresh Vegetables Potatoes Other Processing Vegetables Vegetables for Canning Tomatoes Other Vegetables for Freezing Potatoes Other Dehydrated Veg's & Chips Pulses Grain Products Total Grain Products Wheat Flour Corn Products Rice Other Caloric Sweeteners Total caloric Sweeteners Cane & Beet Sugar Corn Sweeteners High Fructose Corn Syrup Glucose Dextrose Other Caloric Sweeteners Beverages Malt Products Wine Products Liquor Other

1999

1999 245.1 89.4 1999 141.5 51.7 1999 79 28.8 1999 61 22.3 1999 2 0.6 1999 85.1 31.1 1999 68 24.7 1999 18 6.4 1999 18 6.7 1999 0.7 249.0 1998 734.5 268.1 1998 35 12.9 1998 3 1.2 1998 36.3 13.2 1998 20 7.3 1998 9 3.4 1998 2 0.6 1998 5 2.0 1998 4 1.5 1998 4 1.5 1998 8 3.0 1998 21 7.8 1998 12 4.2 1998 29.5 10.8 1998 10 3.8 1998 19 7.0 1998 580 211.8 gram/day kg/yr 1997 84.8 30.9 1997 37 13.5 1997 31.8 11.6 1997 26 9.5 1997 6 2.1 1997 15.9 5.8 1997 5 1.9 1997 11 3.9 1997 882.5 322.1 1997 365.5 133.4 1997 165.5 60.4 1997 33 12.2 1997 132 48.3 1997 200.0 73.0 1997 4 1.6 1997 13 4.9 1997 25 9.3 1997 157 57.2 1997 517.0 188.7 1997 230.7 84.2 1997 60 21.7 1997 171 62.5 1997 286.3 104.5 1997 132 48.0 1997 90 33.0 1997 41 15.1 1997 101 37.0 1997 73 26.8 1997 28 10.2 1997 43 15.6 1997 11 3.9 1997 248.7 90.8 1997 186 1997 29 1997 24 1997 10 67.9 10.5 8.8 3.5

YES YES YES YES YES YES YES

4.0 8.0 290 105.9 gram/day-pers. kg/yr-person 49.2 17.9 19 6.8 14.7 5.4 13 4.7 2 0.6 15.9 5.8 5 1.9 11 3.9 907.2 398.1 182.1 37 145 78.9 1.7 4.9 9.3 62.9 331.1 145.3 66.5 13.4 53.1

YES YES YES YES YES

YES YES YES YES YES YES

1997 191.5 69.9 1997 83 30.2 1997 107.1 39.1 1997 78 28.3 1997 25 9.0 1997 5 1.7 1997 2 0.6

Prepared for Walden 3 Foundation

16 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Energy Consumption

Energy Consumption per Capita

All Consumption per Country (including Households, Industries, Transportation, etc.) Country US Germany France Switzerland S. Africa China Thailand Africa (aver.) India Year 1990 1990 1990 1990 1990 1990 1990 1990 1990 ton-oil/ personyr 7.75 4.56 3.93 3.4 2.59 0.57 0.53 0.34 0.21 Country US Germany China Bangladesh Tansania Goal for W. Europe Year n/a n/a n/a n/a n/a MW-h/ person-yr 95 52 7 0.7 0.4 39 (121 in 1999) kW-h/ person-day 260 142 19 2 1 107 55% 7% 1% 0% 41% Link to Model NO NO NO NO NO NO

Value for this community: 55 150 for comparison Note: The above values are for all electricity used per person within the country. Note: For information on el. Power usage per person in households, see Sheet "Domiciles Inputs & Outputs"

Consumption by Europeans (in a City with 1 Million Persons; Source: EEA) Country Europe Europe Europe Year 2000 2000 2000 Type Fossil Fuel Water Food Qty. 11.5 320 2 Unit kg/person-day kg/person-day kg/person-day NO NO NO

Waste Production by Europeans (in 1 Million City; Source: EEA) Europe Europe Europe 2000 Waste water 2000 CO2 2000 Solid Waste 300 25 1.6 kg/person-day kg/person-day kg/person-day YES YES YES

Prepared for Walden 3 Foundation

17 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Consumption Overview

Consumption/Demand in 100,000 Person City (INFORMATION ONLY, NO LINKS TO OTHER SHEETS) Category Fossil Fuel Oil NG Other incl. coal Gasoline/Diesel Biodiesel Methanol Hydrogen Electric Power Water for households for industry Other (Yard w/o Farming) Food Meats Fish Eggs Dairy Products Added Fats & Oils Fruits & Vegetables Grain Products Caloric Sweeteners Beverages Beverage Milk Wine Malt Products 100% 0.033 liter/d 3.3 ton/day 1,199 ton/yr

(EEA/USDA)

Subcategory

% of US in 1999

Qty. Per Capita - Daily 11.5 kg/d

Qty. Community - Daily 1,150 ton/day

Qty. Community - Yearly 419,750 ton/yr

Source

EEA

269 49 83% 57% 110% 50% 53% 58% 103% 155% 50% 1.945 0.130 0.020 0.34 0.358 0.049 0.907 0.385 0.096

l/d l/d l/d kg/d kg/d kg/d pc./day kg/d kg/d kg/d kg/d kg/d

EEA

26,919 4,906 195 13 2 34,110 36 5 91 39 10

m3/day m3/day

9,825,615 1,790,646

m3/yr m3/yr ton/yr ton/yr ton/yr pc./yr ton/yr ton/yr ton/yr ton/yr ton/yr

(EEA/USDA)

ton/day 70,997 ton/day 4,736 ton/day 738 pc./day 12,450,000 ton/day 13,065 ton/day 1,794 ton/day 33,112 ton/day 14,057 ton/day 3,495

Waste Production in 100,000 Person City Category Waste water CO2 Solid Waste Subcategory Qty. Per Capita - Daily 300 25 1.6 l/d kg/d kg/d Qty. Community - Daily 30,000 2,500 160 Qty. Community - Yearly ton/yr ton/yr ton/yr

Source

ton/day 10,950,000 ton/day 912,500 ton/day 58,400

EEA EEA EEA

Prepared for Walden 3 Foundation

18 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / ENERGY USAGE

ENERGY USAGE & WASTE PRODUCTION FOR SIC CODE 20

SIC CODE INDUSTRY Total Energy Year Consumption Energy Usage Product Ratio kg fin. Prod/ kg raw Mat'l 0.56 0.76 0.19 0.9 0.93 1.37 0.63 0.77 Major Type of Fuel Consumption Type of Heat used Total Waste Million m3/yr 424 106 204 22 2763 Volatile Solids ,000 ton (metric) /yr Fuel Waste ,000 ton (metric) /yr NonFuel Waste Applicable Waste

GWh (1977) 2011 2016 2022 2023 2026 2033 2037 Meat Packing Plants Poultry Dressing Plants Cheese, Natural & Processed Condensed & Evaporated Milk Fluid Milk Canned Fruits & Vegetables Frozen Fruits & Vegetables Potatoes Tomatoes Citrus Fruit Corn Peaches Rice Milling Wet Corn Milling Cane Sugar Refining Beet Sugar Soybean Oil Mills Malt Beverages / Malt Distilled Liquor (except Brandy) 18,869 5,919 6,944 7,471 10,167 13,859 9,786 1977 1977 1977 1977 1977 1977 1977

kW/ kg finished product 1.68 kW/kg 1.16 kW/kg 3.04 kW/kg 1.55 kW/kg raw 0.37 kW/kg 0.97 kW/kg raw 1.07 kW/kg raw 2.03

NG

Electricity

Coal

(Resid.) Steam [DEG C] Fuel Oil

Direct Heat [DEG C]

TBD Catch basin and slaughter All waste water (solids per 1000 birds) Whey All wastes Cottage cheese whey

49% 33% 18% 35% 28% 49% 33% 59% 31% 37% 29% 59% 28% 13% 10% 75% 52.8% 46.8% 0.0%

60, 188 C 60 C 37% 49, 71-93 C 18% 10% 71 C 177 - 204 C 34% 72 - 77 C 0% 82-100C, 100-121C 82 - 93 C 15% 0.4%

321 6.8

321 6.8

121 57 189 22 16 1.1 34 220 352 1.5 227 49

Mill. ton hulls/yr

Peel (wet caustic peeling) Clean and peel Peel Centrifuging Cut and blanch (frozen) Clean and cut (canned)

Mill. ton hulls/yr

2044 2046 2062 2063 2075 2082/83 2085

1,113 24,729 9,522 22,004 13,273 14,679 4,541

1977 1977 1977 1977 1977 1977

0.26 3.75 1.42 7.75 0.52

kW/kg kW/kg kW/kg kW/kg kW/kg kW/liter

0.73 0.70 0.86 0.13 0.92

70% 40% 55% 37%

30% 60% 5%

0% 0% 40% n/a 182, 315 C 129 C 132-138 C 315-482 C 85 - 91 C 110-138 C

23.6

23.6

50.0% 20.0% 0.0% 30.0% 45% 33% 33% 56% 22% 11%

82 - 93 C 100 C 100, 110, 149-204 C

1977 17.63 1977

7.95 kW/kg raw

Hulls Starch modifying, syrup refining Process water Bagasse Flume water, process water, Steffans waste Hulls Equipment wash water, waste beer, cooling H2O, sanitary wastes Feed Recovery

TBD TBD TBD TBD TBD

Forrest Business (Tree Farm) Wood Mills Paper Production Crop Production Other Businesses Electronics/El. Products Assembly Bakery Grocery Store Entertainment Business Drugstore Beauty Store Coffeshop TBD

1998 1997 kW/kg raw TBD TBD Usage in the NW: Pulp & boards Fuel 54% 31% Sawdust, wood chips, bark, slabs, edging, trim Logging Residue Crop Waste

TBD TBD TBD TBD TBD TBD TBD

Misc. Unused

8% 7% MSW Sewage

Prepared for Walden 3 Foundation

19 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Grain Production

Information on Grain Production

Grain Production Demand by Community (Grain) Export of raw Grain Export of processed Grain ton / yr ton / yr 14,057 0 10% 1,406 Wheat Flour Fractions Product Ratio (Yield) Production Specific Energy Usage Energy Usage Operation Type of Energy NG Electricity Oil / Gasoline Usage of Energy NG Electricity Oil / Gasoline Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Waste Generation (in Production) Waste Ratio 1 Waste Production (Recyclable Metal) Waste Ratio 2 Waste Production (Non-Fuel Waste TBD) Waste Ratio 3.1 Waste Production (Grain Waste) Waste Ratio 3.2 (Straw) Waste Production (Straw) Waste Ratio 3.3 (all other Fuel Waste) Waste Production (Fuel Waste other) Waste Production (Fuel Waste total) ton w./ton pr. ton / yr ton w./ton pr. ton / yr ton w./ton pr. ton / yr ton w./ton pr. ton / yr ton w./ton pr. ton / yr ton / yr 0% 0 0% 0 5.0% 590 110% 12,973 25% 2,948 16,511 0% 0 0% 0 0% 0 5.0% 91 50% 910 30% 546 1,547 0% 0 0% 0 0% 0 5.0% 102 50% 1,024 30% 615 1,741 0% 0 0% 0 0% 0 5.0% 31 50% 307 20% 123 461 0% 0 0.8 0.2 3.4 0.3 0.0 0.5 0.6 0.1 0.0 0.0 0.0 0.3 1.7 0.3 4.2 17% 5% 78% 37% 4% 59% 84% 12% 4% 6% 1% 93% 36% 6% 59% 72% 95% 11,794 1.17 11,917 2,700 4.4 Corn Products 11% 95% 1,820 1.39 2,185 2,700 0.8 Rice 13% 95% 2,048 1.17 2,070 2,700 0.8 Other 4% 95% 615 1.49 791 2,700 0.3 100% 16,276 16,962 2700 6.3 14,057

ton / yr MW / ton MWh / yr hrs / yr MW / hr

MWh / hr MWh / hr MWh / hr MWh / hr

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0.0 0.0 0.0 0.0

0 0

814 15,215 4,232 20,260

Waste Water Ratio ton w.w./ton pr. Waste Water ton / yr Staffing Requirements Staffing Category (e.g., Engineering) 1 Staffing Category 2 (e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff

4 20 8 30 62

Prepared for Walden 3 Foundation

20 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Fruit & Vegetable Farm

Information on Fruit, & Vegetable Farming

Fruit & Vegetables Production Demand by Community (Fruit & Vegetables) Export of unprocessed Fruit & Veget. Export of processed Fruit & Veget.

ton / yr ton / yr ton / yr

33,112 0 10% 3,311 Fruit (fresh) Vegetables (fresh) 56% 85% 24,044 0.50 9,290 2,700 3.4 25% 25% 50% 0.9 0.9 1.7

33,112

Type of Processing Product Ratio (Yield) Production Specific Energy Usage Energy Usage Operation Type of Energy

ton / yr MW / ton MW / yr hrs / yr MWh / hr NG Electricity Oil / Gasoline

44% 85% 18,807 0.50 7,266 2,700 2.7 25% 25% 50% 0.7 0.7 1.3

100% 42,850 16,556 2700 6.1 13% 13% 25% 1.5 1.5 3.1

Usage of Energy NG Electricity Oil / Gasoline Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Waste Generation (in Production) Waste Ratio 1 Waste Production (Recyclable Metal) Waste Ratio 2 Waste Production (Non-Fuel Waste TBD) Waste Ratio 3.1 Waste Production (Fruit & Vegetable Waste) Waste Ratio 3.2 (Leaves, Branches) Waste Production (Leaves, Branches) Waste Ratio 3.3 (all other Fuel Waste) Waste Production (Fuel Waste other) Waste Production (Fuel Waste total)

MWh / hr MWh / hr MWh / hr MWh / hr

0 0 0 0

0 0 0 0

0.0 0.0 0.0 0.0

ton w./ton pr. ton / yr ton w./ton pr. ton / yr ton w./ton pr. ton / yr ton w./ton pr. ton / yr ton w./ton pr. ton / yr ton / yr

0% 0 0% 0 15.0% 2,821 80% 15,045 15% 2,821 20,687 0% 0 0

0% 0 0% 0 15.0% 3,607 150% 36,066 15% 3,607 43,279 0% 0

0 0

6,428 51,111 6,428 63,966

Waste Water Ratio ton w.w./ton pr. Waste Water ton / yr Export of Fruit & Vegetable ton / yr

Staffing Requirements Staffing Category (e.g., Engineering) 1 Staffing Category 2 (e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff 5 25 10 50 90

Prepared for Walden 3 Foundation

21 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Animal Farms 1

Information on Animal Farming (1)

MILK from COWS Production per Animal Endprod./Prod. Ratio Consumption Animals Stock (min.) Life Expectancy Reproduction Time Stock for Reprod. Stock for Prod. Export Stock for Exp. of Goods Stock for Reprod. of Exp. Total Stock Cows Animals dying/yr Animals reproduced/yr CATTLE for Meat Weight Gain Meat for Consumption Product Ratio Total Animal Meat Animal Waste Feed Time Animal Weight (Birth) Animal Weight (Slaughter) Animals killed for Meat Animals Stock (min.) Reproduction Rate Stock (for Reprod.) Stock for Prod. Export For Export Stock for Export Exp. Stock (for Reprod.) Total Animal Count Animals killed/dying per yr Animals reproduced/yr SWINE for Meat Weight Gain Meat for Consumption Product Ratio Total Animal Meat Animal Waste Feed Time Life Expectancy Reproduction Time Animal Weight (Birth) Animal Weight (Slaughter) Animals killed for Meat Animals Stock (min.) Reproduction Rate Stock (for Reprod.) Stock for Prod. Export For Export Stock for Export Exp. Stock (for Reprod.) Total Animal Count Animals killed/dying per yr Animals reproduced/yr FISH for Meat Weight Gain For Consumption Product Ratio Total Animal Meat Animal Waste Lifetime Life Expectancy Reproduction Time Animal Weight (Birth) Animal Weight (Slaughter) Animals killed for Meat Animals Stock (min.) Reproduction Rate Stock (for Reprod.) Stock for Prod. Export For Export Stock for Export Exp. Stock (for Reprod.) Total Animal Count Animals killed/dying per yr Animals reproduced/yr ton/day 0.00120 4.7 2.7 2.1 ton/day 0.0298 39.2 ton/yr 10.89 90% 14,301 1,314 4.5 3.5 525 657 263 2,758 613 613 ton/yr 0.44 1,728 56% 3086 1,358 0.78 0.020 0.362 8,534 6,656 1 15,360 853 666 1,536 24,218 13,142 13,142 ton/day 0.00073 3.1 1.7 1.3 ton/yr 0.27 1,114 56% 1989 875 1.5 4.5 3.5 0.005 0.40 4,914 7,371 2.3 3,137 2,457 3,685 1,568 15,761 8,416 8,416 ton/day 0.000015 2.0 0.9 1.1 ton/yr 0.01 738 45% 1641 903 2.0 4.0 3.5 0.00000 0.011 149,864 299,728 500 343 149,864 299,728 343 600,142 299,900 299,900 TURKEY for Meat Weight Gain Meat for Consumption Product Ratio Total Animal Meat Animal Waste Feed Time Life Expectancy Reproduction Time Animal Weight (Birth) Animal Weight (Slaughter) Animals killed for Meat Animals Stock (min.) Reproduction Rate Stock (Reprod.) Stock for Prod. Export For Export Stock for Export Exp. Stock (for Reprod.) Total Animal Count Animals killed/dying per yr Animals reproduced/yr CHICKEN for Meat Weight Gain Meat for Consumption Product Ratio Total Animal Meat Animal Waste Feed Time Animal Weight (Birth) Animal Weight (Slaughter) Animals killed for Meat Animals Stock (min.) Reproduction Rate Stock (Reprod.) Stock for Prod. Export For Export Stock for Export Exp. Stock (for Reprod.) Total Animal Count Animals killed/dying per yr Animals reproduced/yr EGGS from CHICKEN Production per Animal Endprod./Prod. Ratio Consumption Weight (kg / egg) Animals Stock (min.) Life Expectancy Reproduction Time Stock for Reprod. Stock for Prod. Export Stock for Exp. of Goods Stock for Reprod. of Exp. Total Stock Chicken Animals dying/yr Animals reproduced/yr eggs/day 0.8 35,905 eggs/yr 293 95% 13,105,263 0.070 44,728 3.5 2.75 2,130 11,182 532 58,572 16,735 16,735 ton/day 0.000048 4.1 3.1 1.0 ton/yr 0.02 1,481 76% 1948 468 0.132 0.00010 0.0024 810,349 106,566 8 135,058 324,140 42,627 54,023 338,275 1,188,512 1,188,512 ton/day 0.000050 1.1 0.8 0.3 ton/yr 0.02 384 76% 505 121 0.4 3.5 2.75 0.0002 0.0075 67,323 26,929 6 15,202 20,197 8,079 4,561 54,771 93,167 93,167

kg Yrs Yrs 25%

Yrs Yrs 50%

23

Yrs ton ton animals/yr animals births/cow-yr 10%

2220

Yrs ton ton animals/yr animals births/chic-yr 40%

13

Yrs Yrs Yrs ton ton animals/yr animals births/cow-yr 50%

184

Yrs Yrs Yrs ton ton animals/yr animals births/turkey-yr 30%

411

Yrs Yrs Yrs ton ton animals/yr animals births/fish-yr 100%

Prepared for Walden 3 Foundation

22 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Animal Farms 2

Information on Animal Farming (2)

Total Animal Count Total Living Animal Weight [ ton ] Animals slaughtered or killed / Yr Meat Production (ton/yr) Ton / yr For Consumption by Community (y) Export Other Production For Consumption by Community Export Waste (ton/yr) Ton / yr Fuel Waste (Type 1: Dead Animals only) Other Fuel Waste (Milk, Eggs, etc.) Manure Production (ton/yr-grown animal) Manure ton/yr kg manure/yr-kg living animal Non-Fuel Waste Energy usage (in Production) Specific Energy Usage MWh/ton Meat Energy Usage MWh/ yr Operation Hrs / Yr MWh/hr Type of Energy NG Electricity Oil / Gasoline Usage of Energy NG Electricity Oil / Gasoline Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production 2.4 0.5 1.0 1.2 0.7 0.0 0.1 0.8 0.0 0.0 0.2 0.0 0.0 0.02 0.0 3.7 2.2 1.1 61.7% 11.7% 26.6% 62.0% 36.5% 1.5% 12.2% 83.7% 4.1% 12.2% 83.7% 4.1% 5% 90% 5.0% Cattle 26,976 9,756 13,755 2,592 1,728 864 Milk (ton/yr) 14,301 7,151 21,452 1,580 1,430 22.3 8.3 499,068 51.2 Cattle 13.20 34218 8760 3.9 Swine 15,761 6,378 8,416 1,670 1,114 557 N/A Chicken 396,847 954 1,205,247 2,073 1481 592 Eggs (pc/yr) 13,105,263 3,276,316 16,381,579 170 46 0.024 9,524 10.0 Chicken 4.10 8498 8760 1.0 Turkey 54,771 411 93,167 499 384 115 Eggs (ton/yr) 917 229 1,147 42 0.112 6,134 14.9 Turkey 4.10 2045 8760 0.2 Fish 0.10 148 8760 0.0 Fish 600,142 6,572 299,900 1,477 738 738 N/A 8,311 5,445 2,867

423 1.9 29,946 4.7 Swine 10.08 16837 8760 1.9

1.9 N/A

2,217 1,476

544,672 0

61,747 8,760

MWh / hr MWh / hr MWh / hr MWh / hr

0 0 0 0 Milk 1.00 14301 8760 3.9 36.1% 34.0% 29.9% 1.4 1.3 1.2

0 0 0 0

0 0 0 0 Eggs 1.00 917 8760 0.1 25% 40% 35% 0.0 0.0 0.0

0 0 0 0

0 0 0 0

0.0 0.0 0.0 0.0

Specific Energy Usage MWh/ton Prod. Energy Usage MWh/ yr Operation Hrs / Yr MWh/hr Type of Energy NG Electricity Oil / Gasoline Usage of Energy NG Electricity Oil / Gasoline Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Staffing Requirements Staffing Category (e.g., Engineering) 1 Staffing Category 2 (e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff

ton/yr 8,760

1.4 1.4 1.2

MWh / hr MWh / hr MWh / hr MWh / hr

0 0 0 0

0 0 0 0

0.0 0.0 0.0 0.0

20 60 12 20 112

Prepared for Walden 3 Foundation

23 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Meat Processing

Information on Food Processing Industry (1)

Cows Pigs Chicken Turkey Fish Total

Meat Processing

Meat Processing / Dressing / Packaging Total Meat Product ton / yr Specific Energy Usage MW / ton Energy Usage MW / yr Operation hrs / yr MW / hr Energy Mix (assumed) Type of Energy NG Electricity Oil / Gasoline Usage of Energy NG Electricity Oil / Gasoline Use of STEAM Steam (LQ)/Heat Demand MWh / hr Steam (HQ) Demand MWh / hr Steam (LQ)/Heat Production MWh / hr Steam (HQ) Production MWh / hr Waste Generation (in Processing) Waste Ratio 1 Waste Production (Recyclable TBD) Waste Ratio 2 Waste Production (Non-Fuel Waste TBD) Waste Ratio 3 Waste Production (Fuel Waste) Waste Water Ratio Waste Water 2,592 1.68 4,354 8,760 0.5 1,670 1.68 2,805 8,760 0.3 2,073 1.16 2,410 8,760 0.3 499 1.16 580 8,760 0.1 1,477 0.22 328 8,760 0.0 8,311 1.26 10,477 8,760 1.2

49% 33% 49% 0.2 0.2 0.2 0 0 0 0

49% 33% 49% 0.2 0.1 0.2 0 0 0 0

35% 28% 37% 0.1 0.1 0.1 0 0 0 0

35% 28% 37% 0.0 0.0 0.0 0 0 0 0

35% 28% 37% 0.0 0.0 0.0 0 0 0 0

41% 30% 42% 0.5 0.4 0.5 0.0 0.0 0.0 0.0

ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr

0% 0 2% 53 44% 2,037 40% 1037

0% 0 2% 34 44% 1,312 40% 668

0% 0 2% 42 24% 655 40% 829

0% 0 2% 10 24% 158 40% 200

0% 0 0% 0 55% 1,805 2000% 29,538

0% 0 2% 139 38% 5,966 432% 32,272

Staffing Requirements Staffing Category 1 Engineering) (e.g., Staffing Category (e.g., Technical) 2 Staffing Category 3 (e.g., Man'mt, Admin) Staffing Category 4 (other) Total Staff 5 25 10 15 55

Prepared for Walden 3 Foundation

24 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Dairy Food Processing

Information on Food Processing Industry (2)

Dairy Products Processing

Total Milk Production ton / yr 21,452 Cheese (nat. & processed) Fraction of Dairy Products Milk Usage for Product Usage of Milk (assumed) Specific Energy Usage Energy Usage Operation Type of Energy NG Electricity Oil / Gasoline Usage of Energy NG Electricity Oil / Gasoline Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Waste Generation (in Processing) Waste Ratio 1 Waste Production (Recyclable TBD) Waste Ratio 2 Waste Production (Non-Fuel Waste TBD) Waste Ratio 3 Waste Production (Fuel Waste TBD) Waste Water Ratio Waste Water Total Production Consumption within Community Export of Dairy Products MWh / hr MWh / hr MWh / hr MWh / hr 0.7 0.5 0.3 0 0 0 0 0.0 0.0 0.0 0 0 0 0 0.0 0.0 0.0 0 0 0 0 1.3 0.8 0.5 0 0 0 0 2.1 1.3 0.8 0.0 0.0 0.0 0.0 49% 33% 18% 59% 31% 10% 37% 29% 34% 48% 31% 21% 48% 31% 21% ton / yr 4.9% 1,061 20.3% 3.04 13,260 8,760 1.5 Milk (cond. & evapor.) 1.3% 270 1.1% 1.55 352 8,760 0.0 Milk ( fluid) 8.4% 1,803 7.1% 0.37 560 8,760 0.1 Other (frozen, yoghurt, etc.) 85.4% 18,318 71.7% 1.50 23,082 8,760 2.6 100% 21,452 100% 1.74 37,254 8,760 4.3

MW / ton MW / yr hrs / yr MW / hr

ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr ton / yr ton / yr ton / yr

0% 0 2% 87 81% 3,533 10% 106 202 134 67

0% 0 2% 5 7% 16 10% 27 251 167 84

0% 0 2% 30 7% 106 10% 180 1,676 1,118 559

0% 0 2% 308 7% 1,077 10% 1,832 17,036 11,357 5,679

0% 0 2% 430 26% 4,732 2,145 19,165 12,777 6,388

Staffing Requirements Staffing Category 1 Engineering) (e.g., Staffing Category 2(e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff 6 25 10 15 56

Prepared for Walden 3 Foundation

25 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Grain Processing

Information on Food Processing Industry (3)

Grain Processing

Total Production for Community Production for Export Purpose Direct Export (of raw Grain) ton / yr ton / yr ton / yr 14,057 1,406 0 Wheat Flour Type of Products Type of Products Specific Energy Usage Energy Usage Operation Type of Energy NG Electricity Oil / Gasoline Usage of Energy NG Electricity Oil / Gasoline Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Waste Generation (in Processing) Waste Ratio 1 Waste Production (Recyclable TBD) Waste Ratio 2 Waste Production (Non-Fuel Waste TBD) Waste Ratio 3 Waste Production (Fuel Waste TBD) Waste Water Ratio Waste Water Export of Grain Products MWh / hr MWh / hr MWh / hr MWh / hr 0.1 0.1 0.0 0 0 0 0 0.5 0.4 0.0 0 0 0 0 0.0 0.0 0.0 0 0 0 0 0.1 0.0 0.0 0 0 0 0 0.8 0.5 0.0 0.0 0.0 0.0 0.0 50% 40% 10% 60% 40% 0% 70% 30% 0% 50% 40% 10% 58% 38% 5% ton / yr MW / ton MW / yr hrs / yr MW / hr 72% 11,204 0.15 1,528 6,600 0.2 Corn Products 11% 1,729 3.75 5,894 6,600 0.9 Rice 13% 1,946 0.26 460 6,600 0.1 Other 4% 584 1.50 796 6,600 0.1 100% 15,463 8,678 6,600 1.3 14,057

ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr ton / yr

0% 0 2% 224 25% 2,801 10% 1,120 1,019

0% 0 2% 35 30% 519 10% 173 157

0% 0 2% 39 27% 525 10% 195 177

0% 0 2% 12 25% 146 10% 58 53

0% 0 2% 309 27% 3,991 1,546 1,406

Staffing Requirements Staffing Category (e.g., Engineering) 1 Staffing Category 2 (e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff 5 25 10 15 55

Prepared for Walden 3 Foundation

26 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Fruit & Vegetable Processing

Information on Food Processing Industry (4)

Fruit & Vegetables Processing

Total Production for Community ton / yr 36423 Fruit (fresh) Type of Processing Production (fresh) Production (processed) Specific Energy Usage Energy Usage Operation Type of Energy NG Electricity Oil / Gasoline Usage of Energy NG Electricity Oil / Gasoline Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Waste Generation (in Processing) Waste Ratio 1 Waste Production (Recyclable e.g. TBD) Waste Ratio 2 Waste Production (Non-Fuel Waste TBD) Waste Ratio 3 Waste Production (Fuel Waste TBD) Waste Water Ratio Waste Water MWh / hr MWh / hr MWh / hr MWh / hr 2.2 1.9 0.0 0 0 0 0 1.0 1.2 0.4 0 0 0 0 3.2 2.8 0.0 0 0 0 0 1.1 1.4 0.4 0 0 0 0 7.4 7.4 0.8 0.0 0.0 0.0 0.0 53% 47% 0.4% 38% 48% 14% 53% 47% 0.4% 38% 48% 14% 45% 48% 7% ton / yr MW / ton MW / yr hrs / yr MW / hr 20% 7,311 2.03 14,841 3,600 4.1 Fruit (processed) 24% 8,675 1.07 9,302 3,600 2.6 Vegetables (fresh) 29% 10,650 2.03 21,619 3,600 6.0 Vegetables (processed) 27% 9,788 1.07 10,495 3,600 2.9 36,423

100% 17,960 18,462 56,256 15.6

ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr ton w./ ton pr. ton / yr

1% 73 1% 73 15% 1,097 5% 366

1% 87 1% 87 37% 3,210 5% 434

1% 106 1% 106 15% 1,597 5% 532

1% 98 1% 98 37% 3,621 5% 489

1% 364 1% 364 26% 9,525 1,821

Staffing Requirements Staffing Category 1(e.g., Engineering) Staffing Category 2 (e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff 8 40 10 24 82

Prepared for Walden 3 Foundation

27 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Tree Farm

Information on Tree Farming

Wood Production Wood Product Demand by Community Export of Trees (unprocessed) Export of Wood Products Total Wood Product Demand Trees per Ton of Paper Production Trees to be grown for Paper Production (alone) Tree Density Area for Paper Production (alone) ton / yr 29,500 0 35% 10,325 39,825 17 318,250 618 5.2 Hardwood 50% 95% 20,961 0.10 1,475 8,760 0.2 25% 25% 50% 0.0 0.0 0.1 0 0 0 0 111.8%

ton / yr tr. / ton Paper tr. / hectar km2

Fractions Product Ratio Production Specific Energy Usage Energy Usage Operation Type of Energy

ton / yr MWh / ton MWh / yr Hrs / Yr MWh / hr NG Electricity Oil / Gasoline

Softwood 50% 95% 20,961 0.10 1,475 8,760 0.2 25% 25% 50% 0.0 0.0 0.1 0 0 0 0

100% 41,921 2,950 4,380 0.3

Usage of Energy NG Electricity Oil / Gasoline Use of STEAM Steam (LQ)/Heat Demand Steam (HQ) Demand Steam (LQ)/Heat Production Steam (HQ) Production Waste Generation (in Production) Waste Ratio 1 Waste Production (Recyclable TBD) Waste Ratio 2 Waste Production (Non-Fuel Waste TBD) Waste Ratio 3 Waste Production (Fuel Waste Branches, etc.) Waste Water Ratio Waste Water Export of Trees (raw) MWh / hr MWh / hr MWh / hr MWh / hr 0.1 0.1 0.2 0.0 0.0 0.0 0.0

ton / ton pr. ton / yr ton / ton pr. ton / yr ton / ton pr. ton / yr ton w./ ton pr. ton / yr ton / yr

0% 0 0% 0 5% 1,048 0% 0 10,325

0% 0 0% 0 5% 1,048 0% 0

0 0 2,096 0

Staffing Requirements Staffing Category (e.g., Engineering) 1 Staffing Category 2 (e.g., Technical) Staffing Category 3 Man'mt, Admin) (e.g., Staffing Category 4 (other) Total Staff 6 40 10 40 96

Prepared for Walden 3 Foundation

28 of 42

Developed by TCC / NUVOTEC INC., Richland, WA

113844839.xls.ms_office / Wood Mill

Information on Wood Processing Industry (1)

Total Raw Wood Production (including for Export) ton / yr 39,825 Lumber & Wood Products 30% 11,948 Pulp, Paper & Paperboard 65% 25,886 Furniture & Fixtures 5% 1,991 Other 0% 0 100%

Use of the Wood Product