Professional Documents

Culture Documents

Friction Loss Table

Uploaded by

Karthikeyan SankarrajanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Friction Loss Table

Uploaded by

Karthikeyan SankarrajanCopyright:

Available Formats

Pacific Pump and Power

91-503 Nukuawa Street

Kapolei, Hawaii 96707

Phone: (808) 672-8198 or (800) 975-5112

Fax:

(866) 424-0953

Email: sales@pacificpumpandpower.com

Web:

www.pacificpumpandpower.com

Pumps and Generators

Rentals * Sales * Service * Operations

(808) 672-8198

TableofContents

Friction Loss in Pipe

FrictionLossinPipe..

HeadLossper100FeetofPipeduetoFrictionLoss.

FrictionLossinPipeFittings

FrictionLossEstimatesbasedonPipeLengths.

ResistanceofFittingstoFlowofFluidsinEquivalentLengthofPipe...

Di l i

Disclaimer

Pacific Pump and Power Inc. accepts no responsibility for any losses or damage or

other matters arising from the use of this information. The use of information

and advice contained is used solely at the risk of the user.

Friction Loss in Pipe

Losses Due to Friction

As water moves through the pumping system, pressure losses occur due to water contact with

pipes, valves, and fittings. The four factors that determine friction losses in pipe are:

1. The velocity of the water: Water velocity is measured in feet per second. As velocity

increases, pressure losses increase. Velocity is directly related to flow rate. An increase or

decrease in flow rate will result in a corresponding increase or decrease in velocity.

2. The size (inside diameter) of the pipe: Smaller pipe causes a greater proportion of the

water to be in contact with the pipe, which creates friction. Pipe size also affects velocity.

Given a constant flow rate, decreasing pipe size increases the waters velocity, which

increases friction.

3. The roughness of the inside of the pipe: Pipe inside wall roughness is rated by a C

factor, which is provided by the manufacturer. The lower the C value, the rougher the inside

and the more pressure loss due to friction.

4. The length of the pipe: The friction losses are cumulative as the water travels through the

length of pipe. The greater the distance, the greater the friction losses will be.

Losses Due to Elevation Change

Water pressure can be expressed as either psi (pounds of pressure per square inch) or feet

of head. A column of water 1 foot high exerts 0.433 psi at the bottom and therefore 1 psi is

equivalent to 2.31 feet of head. This means that for every foot of elevation change from the

pump to the discharge point, the corresponding change in pressure will be 0.433 psi.

Fresh Water

1 foot of head = 0.433 psi

1.0 psi = 2.31 feet of head

Salt Water

1 foot of head = 0.444 psi

1.0 psi = 2.25 feet of head

Page 1

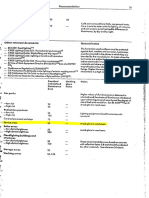

Friction Loss Table

Head Loss / 100 Feet Pipe Due to Friction (C = 150)

Flow (GPM)

0.5

1

2

3

4

5

10

15

20

30

40

50

60

70

80

90

100

150

200

250

300

400

500

600

700

800

900

1000

1200

1500

2000

3000

4000

5000

"

0.8

2.9

10.5

22.2

37.9

57.2

"

0.1

0.4

1.5

3.1

5.3

7.9

28.6

60.6

C = 150 for High Density Polyethylene Pipe (HDPE)

Pipe Diameter (Inch)

1"

1-" 1-"

2"

2-"

3"

4"

5"

0.1

0.4

0.8

1.3

2.0

7.1

14.9

25.4

53.8

91.7

0.1

0.3

0.4

0.7

2.4

5.0

8.6

18.2

30.9

46.7

65.5

87.1

0.1

0.2

0.3

1.0

2.1

3.5

7.5

12.7

19.2

26.9

35.8

45.9

57.0

69.3

0.1

0.2

0.5

0.9

1.8

3.1

4.7

6.6

8.8

11.3

14.1

17.1

36.1

61.6

93.0

0.1

0.2

0.3

0.6

1.1

1.6

2.2

3.0

3.8

4.7

5.8

12.2

20.8

31.4

44.0

74.8

0.1

0.1

0.3

0.4

0.7

0.9

1.2

1.6

2.0

2.4

5.0

8.5

12.9

18.1

30.8

46.5

65.2

86.7

0.1

0.1

0.2

0.2

0.3

0.4

0.5

0.6

1.2

2.1

3.2

4.5

7.6

11.5

16.1

21.4

27.4

34.0

41.3

57.9

87.5

0.1

0.1

0.1

0.1

0.2

0.2

0.4

0.7

1.1

1.5

2.6

3.9

5.4

7.2

9.2

11.5

13.9

19.5

29.5

50.3

6"

0.1

0.1

0.1

0.2

0.3

0.4

0.6

1.1

1.6

2.2

3.0

3.8

4.7

5.7

8.0

12.1

20.7

43.8

74.6

8"

10"

12"

0.1

0.1

0.2

0.3

0.4

0.5

0.7

0.9

1.2

1.4

2.0

3.0

5.1

10.8

18.4

27.8

0.1

0.1

0.1

0.2

0.2

0.3

0.4

0.5

0.7

1.0

1.7

3.6

6.2

9.4

0.1

0.1

0.1

0.1

0.2

0.2

0.3

0.4

0.7

1.5

2.6

3.9

Notes:

1. Values shown above are used in the Hazen-Williams Equation for flow in pipes.

Feet of head loss values shown in the tables were developed using the

Hazen-Williams equation.

2. Feet of head loss values are subject to the following conditions:

a) Pipes carrying clear water at approximately 60 F (15.6 C).

b) Pipes are flowing full.

c) Velocities of water are generally less than 10 feet per second.

Note: HDPE is commonly sized by outside diameter. If in doubt, use the next smaller pipe size.

Page 2

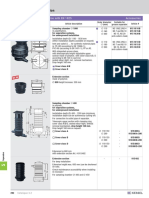

Friction Loss in Pipe Fittings

Steel/Copper

Equivalent feet of pipe caused by joint @ diam. Inch

Fitting

1

1- 1-

2

2-

90 Std Elbow

1.6

2.1

2.6

3.5

4.0

5.5

6.2

90 Long Elbow

1.0

1.4

1.7

2.3

2.7

4.3

5.1

90 Street Elbow

3.0

3.4

4.4

5.8

6.7

8.6

10.3

45 Std Elbow

0.8

1.1

1.4

1.8

2.1

2.8

3.3

45 Street Elbow

1.0

1.8

2.3

3.0

3.5

4.5

5.4

Square Elbow

3.0

3.9

5.0

6.5

7.6

9.8

11.7

Std T Flow Run

1.0

1.4

1.7

2.3

2.7

4.3

5.1

Std T Flow Branch

4.0

5.1

6.0

6.9

8.1

12.0 14.3

Gate Valve - Open

0.7

0.9

1.1

1.5

1.7

2.2

2.7

Equivalent feet of pipe caused by joint @ diam. Inch

Plastic

Fitting

1

1- 1-

2

90 Std Elbow

4

5

6

7

8

9

Std T Flow Run

4

4

4

5

6

7

Std T Flow Branch

7

8

9

12

13

17

Page 3

2-

10

8

20

Friction Loss Estimates based on Pipe Lengths

Note: Determine total run of hose/pipe in pumping system and calculate friction loss

at a given flow rate. Add Friction Loss in head feet to vertical elevation from suction

point to discharge point to determine total dynamic head.

Flow

100

200

300

400

400

500

600

700

800

800

900

900

1000

1000

1100

1200

1300

1400

1500

1600

1800

1800

2000

2000

2500

3000

3500

4000

Hose Size

4"

4"

4"

4"

6"

6"

6

6"

6"

6"

8"

6"

8"

6"

8"

8"

8"

8"

8"

8"

8"

8"

12"

8"

12"

12"

12"

12

12"

12"

Velocity

2.5' / sec

5.0' / sec

7.6' / sec

10.1' / sec

4.4' / sec

5 6' / sec

5.6

6.7' / sec

7.8' / sec

8.9' / sec

5.1' / sec

10.0' / sec

5.8' / sec

11.1'

11 1' / sec

6.4' / sec

7.0' / sec

7.7' / sec

8.3' / sec

9.0' / sec

9.6' / sec

10.3' / sec

11.5' / sec

5.1' / sec

12.8' / sec

5.7' / sec

7.1' / sec

8.5'

8.5 / sec

9.9' / sec

11.4' / sec

100'

0.8'

2.9'

6.1'

10.4'

1.4'

2 2'

2.2

3.1'

4.1'

5.2'

1.3'

6.6'

1.6'

7.8'

7 8'

2.0'

2.3'

2.7'

3.1'

3.6'

4.1'

4.7'

5.6'

0.8'

7.0'

0.9'

1.5'

2.1'

2.1

2.7'

3.5'

500'

4'

14.5'

30.5'

52'

11

11'

15.5'

20.5'

26'

1000'

8'

29'

61'

104'

14'

22'

22

31'

41'

52'

1500'

12'

43.5'

91.5'

156'

21'

33'

33

46.5'

61.5'

78'

33'

66'

99'

39'

78'

11.5'

13.5'

15.5'

18'

20.5'

23.5'

28'

23'

27'

31'

36'

41'

47'

56'

117'

30'

34.5'

40.5'

46.5'

54'

61.5'

70.5'

84'

35'

70'

7.5'

10.5'

10.5

13.5'

17.5'

15'

21'

21

27'

35'

105'

13.5'

22.5'

31.5'

31.5

40.5'

52.5'

Note:

Numbers in bold and italics represent dynamic head levels that exceed pump

pump capabilities at that flow.

Page 4

2000'

16'

58'

122'

208'

28'

44'

44

62'

82'

104'

26'

132'

32'

156'

40'

46'

54'

62'

72'

82'

94'

112'

16'

140'

18'

30'

42'

42

54'

70'

Page 5

You might also like

- Water Flow Based On Pipe SizeDocument7 pagesWater Flow Based On Pipe SizeGeorge KyawNo ratings yet

- B:::: Liquid:: - :: I""gtll: FrictionDocument2 pagesB:::: Liquid:: - :: I""gtll: FrictionAnonymous T32l1RNo ratings yet

- Minimum Thickness of MetalDocument15 pagesMinimum Thickness of MetalswatiNo ratings yet

- Pipe WorkDocument12 pagesPipe WorkSudheepNo ratings yet

- Pump SizingDocument4 pagesPump SizingRodolfo RodriguezNo ratings yet

- Beam Design Constants and Reinforcement Details for Two BeamsDocument1 pageBeam Design Constants and Reinforcement Details for Two BeamsrajedmaglinteNo ratings yet

- Water Hammers PDI PDFDocument38 pagesWater Hammers PDI PDFkarthickNo ratings yet

- Motor Data CalculatorDocument6 pagesMotor Data CalculatorSebastian R.No ratings yet

- Water Demand CalculationDocument6 pagesWater Demand CalculationValium MorphineNo ratings yet

- ResourcesFrictionLossData PDFDocument4 pagesResourcesFrictionLossData PDFhmid007No ratings yet

- Wire Sizing EngineerdogDocument23 pagesWire Sizing EngineerdogRobin Andres Quezada SanhuezaNo ratings yet

- Manning Equation Calculator Open Channel Flow Software: Lmno Engineering Home Page (More Calculations)Document2 pagesManning Equation Calculator Open Channel Flow Software: Lmno Engineering Home Page (More Calculations)Chris van RensburgNo ratings yet

- 22146410-A02-DOC-LI-001-Master Document Register - V1.0 PDFDocument5 pages22146410-A02-DOC-LI-001-Master Document Register - V1.0 PDFBalasoobramaniam CarooppunnenNo ratings yet

- Test Track - Pluming Boq Final-GDocument12 pagesTest Track - Pluming Boq Final-Gsmathy68100% (2)

- Pump Sizing Calculation (Photo)Document25 pagesPump Sizing Calculation (Photo)anto3harrish3fdoNo ratings yet

- Pump Calc ExampleDocument21 pagesPump Calc ExampleMohammad Usman HabibNo ratings yet

- Booster PDSDocument3 pagesBooster PDSsunii19847908No ratings yet

- Final - Report Hydroelectric Power PlantDocument39 pagesFinal - Report Hydroelectric Power PlantnisarNo ratings yet

- LOT-5 Akaki I WWTP BOQ FinalDocument95 pagesLOT-5 Akaki I WWTP BOQ FinalMesfin100% (1)

- TRIPLEX WATER BOOSTERDocument1 pageTRIPLEX WATER BOOSTERSharon LambertNo ratings yet

- Neutrik CatalogueDocument119 pagesNeutrik CatalogueAnonymous kKYg8kcNo ratings yet

- Pump MathsDocument10 pagesPump MathsSakib RafeeNo ratings yet

- Deep Well Submersible Pump - HydraulicsDocument1 pageDeep Well Submersible Pump - HydraulicsImran AzizNo ratings yet

- HyTran Training Hill ChartDocument31 pagesHyTran Training Hill ChartAyanilNo ratings yet

- Perfect Chloro Systems - Gas ..Document6 pagesPerfect Chloro Systems - Gas ..nazar750No ratings yet

- Flexible & Rigid PVC Pipe Size IdentificationDocument4 pagesFlexible & Rigid PVC Pipe Size IdentificationAziz Khan KakarNo ratings yet

- Screening Equipments TrainingDocument74 pagesScreening Equipments TrainingSindhuja RaghunathanNo ratings yet

- Section 11 Sanitary Sewer Pump Station Design StandardsDocument9 pagesSection 11 Sanitary Sewer Pump Station Design StandardsKVRamananNo ratings yet

- Akar Clarifier CatalogueDocument6 pagesAkar Clarifier CatalogueAnonymous O0lyGOShYGNo ratings yet

- Lift Pump CalculationDocument10 pagesLift Pump CalculationMaxmore KarumamupiyoNo ratings yet

- CE308 - Ch2 - Pipe Flow v2 PDFDocument97 pagesCE308 - Ch2 - Pipe Flow v2 PDFKhuram ShahzadNo ratings yet

- Reducer Fittings Decrease Pipe Size To Avoid FailureDocument7 pagesReducer Fittings Decrease Pipe Size To Avoid Failurefarshan296015100% (1)

- Head Loss CalculationDocument7 pagesHead Loss CalculationCuong VuNo ratings yet

- Water and Sewerage AuthorityDocument43 pagesWater and Sewerage AuthorityCarl Crow100% (1)

- CEM - April 2015 A Primer On Rectangular TanksDocument7 pagesCEM - April 2015 A Primer On Rectangular TanksT. LimNo ratings yet

- Design Guidelines Electromagnetic Flow MetersDocument7 pagesDesign Guidelines Electromagnetic Flow Metersaugur8866124No ratings yet

- How To Calculate Septic Tank Size - CivilologyDocument5 pagesHow To Calculate Septic Tank Size - CivilologyHang ChethaNo ratings yet

- Hazen Williams CoefficientsDocument1 pageHazen Williams CoefficientsAshish GulrandheNo ratings yet

- Design Guidelines Water Supply Booster Pump StationDocument12 pagesDesign Guidelines Water Supply Booster Pump Stationrodriguez.gaytan100% (1)

- ResourcesFrictionLossData PDFDocument4 pagesResourcesFrictionLossData PDFEduardo MirandaNo ratings yet

- Kerala State Electricity Board: Form of Application For Supply of ElectricityDocument43 pagesKerala State Electricity Board: Form of Application For Supply of ElectricityManisha DubeyNo ratings yet

- Bell and Gossett Sump DesignDocument8 pagesBell and Gossett Sump DesignVelpandian ManiNo ratings yet

- WHA Water Hammer ArrestorsDocument5 pagesWHA Water Hammer ArrestorsvitgahiNo ratings yet

- D. Design Load D.1. Loading DataDocument14 pagesD. Design Load D.1. Loading DataEdNo ratings yet

- Ato Abdulkader Residence Plumbing DesignDocument15 pagesAto Abdulkader Residence Plumbing Designdawitggg0% (1)

- Multiple Pump OperationDocument2 pagesMultiple Pump OperationChingapooh2008No ratings yet

- UPGRADE CONNECTION POINTS PRODUCTION TRANSMISSION MEET DESALINATION CODEDocument166 pagesUPGRADE CONNECTION POINTS PRODUCTION TRANSMISSION MEET DESALINATION CODEDeepak RajanNo ratings yet

- Hydropneumatic TanksDocument7 pagesHydropneumatic Tankstimka1910No ratings yet

- 230313-MEP Client RequirementDocument19 pages230313-MEP Client RequirementSelcen yeniçeriNo ratings yet

- Plumbing PIpe SizingDocument12 pagesPlumbing PIpe SizingAwokeNo ratings yet

- GEM Series - Fire Fighting Booster Sets in Egypt, Technical Catalog Part 1Document114 pagesGEM Series - Fire Fighting Booster Sets in Egypt, Technical Catalog Part 1Rheoserve Industrial SolutionsNo ratings yet

- LEC-8 Water Hammer and Penstock DesignDocument37 pagesLEC-8 Water Hammer and Penstock DesignAziz ul HakeemNo ratings yet

- Sectional WeightsDocument1 pageSectional WeightsradhakrishnangNo ratings yet

- Water Hammer Report 1Document74 pagesWater Hammer Report 1Ah Leng LauNo ratings yet

- Plumbing Data SheetDocument2 pagesPlumbing Data SheetzhobeysNo ratings yet

- Brassengineeringinternational 151112220903 Lva1 App6891Document92 pagesBrassengineeringinternational 151112220903 Lva1 App6891cbt_71No ratings yet

- Hydro Design & ConstructionDocument81 pagesHydro Design & ConstructionSamNo ratings yet

- Pipe Friction Loss TableDocument5 pagesPipe Friction Loss TableGan Penton100% (1)

- Piping Systems Srac 1994Document6 pagesPiping Systems Srac 1994maheshNo ratings yet

- Machines DesignDocument7 pagesMachines DesignKarthikeyan SankarrajanNo ratings yet

- Stress DesignDocument11 pagesStress DesignKarthikeyan SankarrajanNo ratings yet

- Shaft DesignDocument13 pagesShaft DesignKarthikeyan SankarrajanNo ratings yet

- SMACNA - HVAC-Systems-Duct-Design1990 260Document1 pageSMACNA - HVAC-Systems-Duct-Design1990 260Karthikeyan Sankarrajan100% (1)

- Seasonal Energy Efficien..Document6 pagesSeasonal Energy Efficien..Karthikeyan SankarrajanNo ratings yet

- Method statement for testing and commissioningDocument1 pageMethod statement for testing and commissioningKarthikeyan SankarrajanNo ratings yet

- Smacna Duct Fitting Loss TableDocument2 pagesSmacna Duct Fitting Loss TableKarthikeyan Sankarrajan75% (4)

- Brake DesignDocument2 pagesBrake DesignKarthikeyan SankarrajanNo ratings yet

- Water Regulations Advisory Scheme Ltd. (Wras) Material ApprovalDocument2 pagesWater Regulations Advisory Scheme Ltd. (Wras) Material ApprovalKarthikeyan SankarrajanNo ratings yet

- Refrigerant Dehumidification Technology: Technical Bulletin 1Document12 pagesRefrigerant Dehumidification Technology: Technical Bulletin 1Karthikeyan SankarrajanNo ratings yet

- Health Facility GuidelinesDocument51 pagesHealth Facility GuidelinesAshok Kumar Pillai100% (1)

- Lux LevelDocument1 pageLux LevelKarthikeyan SankarrajanNo ratings yet

- F.A.Q. Picv: General Valve QuestionsDocument9 pagesF.A.Q. Picv: General Valve QuestionsKarthikeyan SankarrajanNo ratings yet

- Air Flow Velocity in DuctsDocument2 pagesAir Flow Velocity in DuctsKarthikeyan SankarrajanNo ratings yet

- Led Bollard Light: Item Code: EL-S-BOL-LEDDocument1 pageLed Bollard Light: Item Code: EL-S-BOL-LEDKarthikeyan SankarrajanNo ratings yet

- IPC Loading UnitsDocument3 pagesIPC Loading UnitsTaqui Mubeen67% (3)

- Led Top Pole Light: Item Code: LL-POLETOP-LEDDocument1 pageLed Top Pole Light: Item Code: LL-POLETOP-LEDKarthikeyan SankarrajanNo ratings yet

- Grease Trap TypesDocument1 pageGrease Trap TypesKarthikeyan SankarrajanNo ratings yet

- Typical Kv valve sizing chartDocument1 pageTypical Kv valve sizing chartKarthikeyan SankarrajanNo ratings yet

- 00 HVAC CalcDocument52 pages00 HVAC Calcibson045001256No ratings yet

- Air Duct Design Friction Loss ChartDocument1 pageAir Duct Design Friction Loss ChartKarthikeyan SankarrajanNo ratings yet

- Underground coalescence separatorDocument1 pageUnderground coalescence separatorKarthikeyan SankarrajanNo ratings yet

- Fittings - K ValueDocument2 pagesFittings - K ValueKarthikeyan SankarrajanNo ratings yet

- Sewerage CalculatorDocument5 pagesSewerage CalculatorKarthikeyan SankarrajanNo ratings yet

- For Underground Installation: Grease SeparatorsDocument1 pageFor Underground Installation: Grease SeparatorsKarthikeyan SankarrajanNo ratings yet

- Part 11. Air-Water System - Chapter 1. Induction Unit SystemDocument1 pagePart 11. Air-Water System - Chapter 1. Induction Unit SystemKarthikeyan SankarrajanNo ratings yet

- Halton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Document4 pagesHalton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Karthikeyan SankarrajanNo ratings yet

- NTi Audio AppNote XL2 Noise CurvesDocument13 pagesNTi Audio AppNote XL2 Noise CurvesdjossNo ratings yet

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Document1 pagePart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanNo ratings yet

- Recommended Duct VelocitiesDocument1 pageRecommended Duct VelocitiesKarthikeyan Sankarrajan100% (1)

- Amul India Case Study: Product Portfolio and SWOT AnalysisDocument10 pagesAmul India Case Study: Product Portfolio and SWOT AnalysisShruti NagmoteNo ratings yet

- DL420 15c SpecificationsDocument4 pagesDL420 15c Specificationsesteban muñozNo ratings yet

- Water Hammer PDFDocument30 pagesWater Hammer PDFbhavesh shuklaNo ratings yet

- REMOTE Calculator Tool May 21 2013Document77 pagesREMOTE Calculator Tool May 21 2013Leyner Garcia MezquitaNo ratings yet

- UNSG Report On Safety Security Humanitarian PersonnelDocument25 pagesUNSG Report On Safety Security Humanitarian PersonnelInterAction100% (1)

- 03 - 03 Product Index PDFDocument5 pages03 - 03 Product Index PDFWilder Fernando Vilca OreNo ratings yet

- Girl Scouts ActivitiesDocument5 pagesGirl Scouts ActivitiessluttybitchNo ratings yet

- SIX A Filthy Christmas Miracl JamesDocument55 pagesSIX A Filthy Christmas Miracl JamescarinaNo ratings yet

- EXU EN 2017-12 Manual Web PDFDocument126 pagesEXU EN 2017-12 Manual Web PDFИльнур ТагировNo ratings yet

- Ufara QasrinDocument14 pagesUfara Qasrinroni setiawanNo ratings yet

- Chery Amulet 1,6 Engine Service ManualDocument76 pagesChery Amulet 1,6 Engine Service ManualG x HxhNo ratings yet

- Bibliometric Handbook For Karolinska InstitutetDocument41 pagesBibliometric Handbook For Karolinska InstitutetCamila Araya G100% (1)

- Appointment Letter Staff Nurse Job DescriptionDocument3 pagesAppointment Letter Staff Nurse Job DescriptionRenita ChrisNo ratings yet

- BiostastisticDocument2 pagesBiostastisticاحمد ماجد زبنNo ratings yet

- Types of ProcurementDocument7 pagesTypes of ProcurementrahulNo ratings yet

- Commercial Law Review Midterm - Without AnswersDocument1 pageCommercial Law Review Midterm - Without AnswersTorni JoNo ratings yet

- 6-Step Guide to Crushing Imposter SyndromeDocument10 pages6-Step Guide to Crushing Imposter SyndromeMark KestNo ratings yet

- Dutch FarmDocument104 pagesDutch Farmdoc_abdullahNo ratings yet

- Analysis of Drinking Water Quality Parameters (A Case Study of Hanumangarh Town)Document8 pagesAnalysis of Drinking Water Quality Parameters (A Case Study of Hanumangarh Town)Editor IJTSRDNo ratings yet

- Track A Beast ManualDocument21 pagesTrack A Beast ManualboltojamNo ratings yet

- Test A: Reading - Passage 1Document29 pagesTest A: Reading - Passage 1barishyayNo ratings yet

- Trilon C Types TI enDocument11 pagesTrilon C Types TI enjuanfelipehincapieNo ratings yet

- Quiz Integumentary SystemDocument23 pagesQuiz Integumentary SystemLemuel CunananNo ratings yet

- LC Used in ProteimicsDocument15 pagesLC Used in ProteimicsMandu ManNo ratings yet

- A 1116Document15 pagesA 1116Rama S. SinghNo ratings yet

- Plane Bearings: Material Indicator Shape or SeriesDocument4 pagesPlane Bearings: Material Indicator Shape or SeriesJuan LoaizaNo ratings yet

- Round-The-clock Acid Control of Rabeprazole On Acid Related DisorderDocument8 pagesRound-The-clock Acid Control of Rabeprazole On Acid Related DisorderRabeprazole SodiumNo ratings yet

- Appendix VIII - Civil and Structural Scope of WorkDocument140 pagesAppendix VIII - Civil and Structural Scope of WorkjaganrajNo ratings yet

- Aiesha Edward Resume2Document2 pagesAiesha Edward Resume2api-491571342No ratings yet

- Pre-Final Exam in Audit 2-3Document5 pagesPre-Final Exam in Audit 2-3Shr BnNo ratings yet