Professional Documents

Culture Documents

CB 7cu

Uploaded by

Thomas SamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CB 7cu

Uploaded by

Thomas SamCopyright:

Available Formats

25 Commerce Road, Orillia, Ontario, Canada L3V 6L6 Phone (705) 325-2781 Fax (705) 325-5887

ALLOY DATA SHEET

CORROSION RESISTANT ALLOY REVISION: 01/90

CB-7Cu-1

DESCRIPTION CB-7Cu-1 is a precipitation hardening, martensitic stainless steel, known in the wrought form as 17-4PH. Resistance to atmospheric corrosion, organic compounds, sea water and paper mill liquors is intermediate between that of the hardenable CA alloys and the non-hardenable CF alloy grades. The alloy is particularly suited to service combining corrosion resistance and high strength at temperatures up to 700oF. Machining is frequently conducted on castings in the solution annealed condition, followed by hardening at a low temperature thus alleviating distortion and scaling. Service at temperatures below -40oF should be avoided due to poor impact properties at this temperature. COMPOSITION C Min % Max % Notes: Cr Ni P S Cu(i) 15.5 3.6 2.5 0.07 0.7 1.0 17.7 4.6 0.035 0.03 3.2 (i) Copper should be less than 3% if the castings require welding. (ii) Niobium should be omitted if the castings are hardened at 900oF. Mn Si Nb(ii) 0.20 0.35 N2 0.05

APPLICATIONS Centrifuge components, food mixers and processing machinery, pump and compressor impellers, pump shafts and sleeves, screw conveyors,valve bodies and trim, propeller shafts,and hydraulic cylinders PRODUCT FORMS Horizontal and vertical centrifugal castings; static castings. PHYSICAL PROPERTIES Density (lbs/in3) Liquidus( oF) Thermal Conductivity (Btu/h/ft2/ft/oF)

0.280 2750 9.9 @ 212oF 11.3 @ 500oF 13.0 13.1 @ 860oF @ 900oF Aged at Aged at 900oF 1100oF

Thermal Expansion (10-6in/in oF)

70-200oF 70-400oF 70-600oF 70-800oF

6.0 6.1 6.3 6.5

6.6 6.9 7.1 7.2

Magnetic Permeability

Ferromagnetic

C0RR0SION RESISTANT ALLOY CB 7Cu 1 Page 2

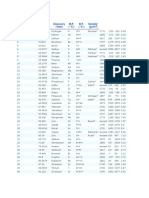

MECHANICAL PROPERTIES Typical Values at Room Temperature - Solution Annealed 1925oF Air Cooled. Aging Temperature oF 900 925 1025 1075 1100 1150 U.T.S. Y.S. Elong. R.A. Brinell Charpy key' K.S.I. K.S.I. % % HB ft-lbs 187 161 10 21 412 7 189 165 11 26 412 12 165 158 14 35 350 22 155 141 14 35 319 27 145 132 15 39 315 30 140 120 16 42 307 37

Typical Values at Elevated Temperatures - Solution Annealed at 1925oF, Air Cooled,.and Aged at 900oF Aging Temperature oF 200 400 600 700 800 900 U.T.S. Y.S. Elong. R.A. K.S.I. K.S.I. % % 181 152 9 21 173 140 8 19 162 128 6 17 158 121 5 15 148 115 6 12 130 100 8 19

WELDABILITY CB-Cu7-1 may be welded by the SMAW, GTAW or GMAW processes. Electrodes Same composition or 308 Preheat Not required for section less than 0.75" thick. Heavier sections with substantial welding may be preheated to 500oF. Post weld heat treatment 900 to 1100oF, Air Cool. Procedures for welding CB-Cu7-1 alloy are available from Kubota Metal Corporation RELATED SPECIFICATIONS ASTM: A747(CB7Cu-1 and CB7Cu-2). Nearest wrought grade: 17-4PH, 15-5PH.

HEAD OFFICE, FOUNDRY & INTERNATIONAL SALES Kubota Metal Corporation, Fahramet Division 25 Commerce Road, P.O. Box 1700, Orillia, Ontario, Canada, L3V 6L6. Phone (705) 325-2781 Fax (705) 325 5887

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Welding MachinesDocument53 pagesWelding MachinesDeepak Kumar Kant Kesri100% (2)

- SB 221Document9 pagesSB 221Siva PrasadNo ratings yet

- CottonDocument16 pagesCottonKushagradhi DebnathNo ratings yet

- Dentin Biomodification AgentsDocument56 pagesDentin Biomodification AgentsRevathy M Nair100% (1)

- Metallurgy Answer KeyDocument44 pagesMetallurgy Answer Keymalsttar82% (11)

- METALLODRUGSDocument21 pagesMETALLODRUGSAditya Verma100% (1)

- 11 Chemistry Notes ch12 Organic Chemistry PDFDocument3 pages11 Chemistry Notes ch12 Organic Chemistry PDFRangbaaz DA FIRENZENo ratings yet

- PPH 4069Document1 pagePPH 4069tranoNo ratings yet

- Manufacturing Processes: by Premchand Kumar Deoghar (Jharkhand)Document49 pagesManufacturing Processes: by Premchand Kumar Deoghar (Jharkhand)PremKumarNo ratings yet

- Ds Rewomid Ipp 240 eDocument3 pagesDs Rewomid Ipp 240 eEleany Antonieta Loayza MendocillaNo ratings yet

- Mp4f01 Ceramics 1 Khor 2011Document40 pagesMp4f01 Ceramics 1 Khor 2011Vincent KohNo ratings yet

- MACDEMIDDocument55 pagesMACDEMIDSetyohdWNo ratings yet

- Essential Competencies for MatterDocument8 pagesEssential Competencies for MatterMerry Chris TabliganNo ratings yet

- Structures and Properties of CeramicsDocument38 pagesStructures and Properties of CeramicsArjayNo ratings yet

- Symbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Document79 pagesSymbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Kameswar MandhataNo ratings yet

- Atp InvetigationDocument6 pagesAtp InvetigationHussain IbrahimNo ratings yet

- Chrome Yellow Experiment-1Document3 pagesChrome Yellow Experiment-1Roushan RoyNo ratings yet

- Aluminum Mill Products: Aluminum Angle, Channel, Pipe Fittings, Pipe, Rod, Bar, Sheet, Plate, Coil & TubingDocument44 pagesAluminum Mill Products: Aluminum Angle, Channel, Pipe Fittings, Pipe, Rod, Bar, Sheet, Plate, Coil & TubingVANo ratings yet

- Mil DTL 81706BDocument20 pagesMil DTL 81706BwcwtnuiNo ratings yet

- Subject: Chemistry Student Name: Grade: 9 Date: Worksheet-2: Atoms, Elements, and Compounds. MarksDocument25 pagesSubject: Chemistry Student Name: Grade: 9 Date: Worksheet-2: Atoms, Elements, and Compounds. Markssaeeda shoaibNo ratings yet

- Energy: Haifeng Liu, Xin Wang, Zunqing Zheng, Jingbo Gu, Hu Wang, Mingfa YaoDocument12 pagesEnergy: Haifeng Liu, Xin Wang, Zunqing Zheng, Jingbo Gu, Hu Wang, Mingfa YaoBắc Phạm LêNo ratings yet

- College BFA 2021Document35 pagesCollege BFA 2021Dinesh WaranNo ratings yet

- Organic Chemistry Some Basic Principles and Techniques - WatermarkDocument29 pagesOrganic Chemistry Some Basic Principles and Techniques - WatermarkPrathviraj SinghNo ratings yet

- Jiacheng Yang, Tianbo Tang, Yu Jiang, Georgios Karavalakis, Thomas D. Durbin, J. Wayne Miller, David R. Cocker III, Kent C. JohnsonDocument9 pagesJiacheng Yang, Tianbo Tang, Yu Jiang, Georgios Karavalakis, Thomas D. Durbin, J. Wayne Miller, David R. Cocker III, Kent C. JohnsonMohamed TaalbiNo ratings yet

- Vegetable Oils Grading and Marking RulesDocument34 pagesVegetable Oils Grading and Marking RulesRasheed BlackNo ratings yet

- Pasar PDFDocument70 pagesPasar PDFRalph Carlo EvidenteNo ratings yet

- Project Topics For CL 10Document8 pagesProject Topics For CL 10Nihaas Reddy KoppulaNo ratings yet

- US4450090Document6 pagesUS4450090Abdulrahman HamdanNo ratings yet

- Research 2 Mind Map Draft Q1Document1 pageResearch 2 Mind Map Draft Q1Danielle CastilloNo ratings yet

- Wiki ZirconiumDocument9 pagesWiki Zirconiumtruth.sayerNo ratings yet