Professional Documents

Culture Documents

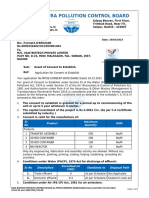

Chrome Hard

Uploaded by

pallavan.kOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chrome Hard

Uploaded by

pallavan.kCopyright:

Available Formats

CONSENT ORDER NO. : 22647/Dated: 21.08.2012 Proc No. : T4/TNPCB/F.No.21221/AMB/RS/W/2012 dated: 21.08.

2012 Consent for New discharge of sewage and trade effluent under section 25 of the

Water (Prevention and Control of Pollution) Act 1974, as amended. Sub: TAMIL NADU POLLUTION CONTROL BOARD CONSENT M/s. Chrome Hard, No.33A/15, SIDCO Industrial Estate, North Phase, Ambattur, Ambattur Taluk, Tiruvallur District for the

discharge of sewage and trade effluent under Section 25 of the Water (Prevention and Control of Pollution) Act, 1974, (Central Act, 6 of 1974) as amended.

Ref: 1. Your Application dated 20/05/2011, vide CARE Regn. No:CC12993. 2. IR No. F.AMB0174/RS/DEE/AMB/2012 dated 07/03/2012.

3. Minutes of CCC Meeting vide Item No. 134-12. ***** CONSENT is hereby granted under Section 25 of the Water (Prevention and Control of Pollution) Act, 1974, (Central Act, 6 of 1974) as amended (hereinafter to as The Act) and the rules and orders made there under to The Proprietor, M/s. Chrome Hard, No.33A/15, SIDCO Industrial Estate, North Phase, Ambattur, Ambattur Taluk, Tiruvallur District

(hereinafter referred to as The Applicant) Authorizing him to bring into make new discharge of sewage and trade effluent.

This is subject to the provision of the Act and the rules and orders made there under and further subject to the terms and conditions incorporated in the Special and General Conditions annexed. This CONSENT is valid for a period ending with the31/03/2013 ( Thirty first March two thousand thirteen) Sd./-xxxxxxx, Member Secretary To

The Proprietor, M/s. Chrome Hard, No.33A/15, SIDCO Industrial Estate, North Phase, Ambattur, Chennai - 600 098 Copy to : 1. The District Environmental Engineer, TamilNadu Pollution Control Board, Ambattur 2. 3. 4. The Commissioner, Corporation of Chennai BMS Technical File //Forwarded By Order// For Member Secretary.

SPECIAL CONDITIONS 1. Details of the products manufactured: Sl. No. a 1. Main Products manufactured: Hard Chrome Electroplating ( Dies & Industrial Components) b By/Intermediate products manufactured: NIL 600 Nos./Month Description Quantity

This Consent is valid for the manufacture of Products and the rate of Production mentioned above. Any change in the quantity or quality of products has to be brought to the notice of the Board and fresh consent has to be obtained. 2. Discharge of effluent is permitted from the following outlets. The quantity of effluent discharged shall not exceed the figures mentioned below.

4.

All units of the sewage / trade effluent treatment plant to achieve the quality of the effluent according to the tolerance limits prescribed above shall be completed along with the commissioning of production. Meters must be affixed at the entrance of the water supply connection so that such meters are easily accessible for inspection and maintenance and for other purposes of the Act, provided that the place where it is affixed shall in no case be at a point before which water has been tapped by the consumer for utilization for any purposes whatsoever

5.

6.

Separate Meters with necessary pipe-line for assessing the quantity of water used for each of the purposes mentioned below:

a. b. c. d. e. 7.

Industrial Cooling, Spraying in mine pits or boiler feed. Domestic purpose. Process. The applicant shall take immediate action to install mechanical composting sampling equipment and continuous flow measuring/recording devices on the effluent drains of trade as well as sewage effluent within three months from the date of this Consent Order. A record of daily effluent discharge shall be maintained.

8.

This Consent is given by the Board in consideration of the particulars given in the application. Any change or alteration or deviation made in actual practice from the particulars furnished in the application will also be ground for

review/variation/revocation of the Consent Order under Section 27 of the Act and to make such variation as deemed fit for the purpose of the Act 9. The Applicant shall not change or alter either the quality or quantity the rate of the discharge or temperature or the route of discharge without the previous written permission of the Board

10.

The applicant shall comply with the carryout directions/orders issued by the Board in this Consent Order and at all subsequent times without any negligence on his/her/their part. The applicant shall be liable for such legal action as per provisions of the Law/Act in case of non/compliance of any order/directions issued at any time and or violation of the terms and conditions of this Consent Order.

11.

The following information shall be forwarded to the Member Secretary/DEE/AEE regularly on or before 10th of every month:

a. b.

Progress on the installation of effluent treatment plant. Progress on the installation of Mechanical Compost sampling equipment and continuous flow recording/measuring devices Monthly statement of daily discharge of sewage as well as trade effluent. Any upset condition in any of the plant/plants of the factory which is, likely to result in increased effluent discharge and or result in violation of the standards mentioned above shall be reported to the Head Quarters and District Environmental Engineers Office/Regional telegraphically. Joint Chief Environmental Engineers Office of the Board

c. 12.

13.

The applicant shall furnish to the visiting officer of the Board any information regarding the construction installation or operation of the plant or effluent treatment plant and any other particulars as may be pertinent to preventing and controlling pollution of Water.

14.

Notwithstanding anything contained in this conditional letter of Consent, the Board hereby reserves to it the right and power under Section 27(2) of the Water (Prevention and Control of Pollution) Act, 1974(as amended) to review any and/or all the conditions imposed herein above and to make such variation as deemed fit for the purpose of the Act by the Board

15.

The conditions imposed as above shall continue in force until revoked under Section 27(2) of the Act

16.

The industry has to ensure that minimum three varieties of trees (Eucalyptus, Subabul and any other suitable variety) are planted at the density of not less than 1,000 trees per acre of land. The trees may be planted along the boundaries of the industry or

industrial premises. This plantation is stipulated over and above the bulk plantation of trees in that area and maintains them. 17. 18 The unit shall adopt non cyanide acid/base zinc and Tin plating process only. The unit shall provide properly designed electroplating baths & rinse tanks in good layout for optimized process flow. 19 The unit shall provide drain boards between each process baths to recover drag out to minimize the chemicals lose in greater extent and also to control the effluent generation by way of spillages. 20 The unit shall provide multi rinse tanks in counter current system to reduce the effluent generation from the plating and rinse process. 21 The unit shall follow cleaner process techniques such as use of eco friendly degreasing agents, trivalent chromium passivation. 22 The unit shall adopt cleaner technology options, waste minimization techniques, reduce and recycle methods to minimize pollution output. 23 The unit shall operate and maintain the ETP provided efficiently and continuously so as to treat the effluent arising from pickling and plating sections and the effluent shall be discharged in to the solar evaporation pans provided so as to ensure zero discharge of effluent. 24 The unit shall follow cleaner process techniques such as use of eco friendly degreasing agents, non cyanide plating process, trivalent chromium passivation. 25 The hazardous sludge generated shall be disposed through land fill in the common hazardous waste TSDF located at Gummidipoondi with valid authorization from the Board under the Hazardous Wastes (Management, Handling and TransBoundary Movement) Rules,2008. 26 The unit shall provide pieziometric wells around the solar evaporation pan to monitor ground water. 27 The unit shall use DM water for all process water requirements.

28

The unit shall dispose the ETP sludge to TSDF, a common disposal facility at Gummudipoondi.

29

The unit shall co-operate with the Ambattur Electroplaters Association and CAAIIUC in formulating the proposal of setting a CETP and if formulated the effluent shall be treated and disposed through the common effluent treatment plant facility.

30

The unit shall remit balance amount of consent fee from the date of commissioning within fifteen days. Sd./-xxxxx, MEMBER SECRETARY. //Forwarded By Order// For Member Secretary

GENERAL CONDITIONS

1.

The applicant shall make an application for grant of fresh consent atleast 60 days before the date of expiry of this Consent Order.

2.

The applicant shall display suitable caution board at the place where the effluent is entering any water-body or any other place to be indicated by the Board indicating therein that the area into which the effluents are being discharged is not fit for the domestic use/bathing.

3. a.

The applicant shall either: Not later than 30 days from the date of issue of this Consent Order, Certify in writing to the Member-Secretary that the applicant has installed or provided for an alternate electric power source sufficient to operate all facilities installed by the maintain compliance with the terms and conditions of the Consent. applicant to

b.

Not later than 30 days from the date of this Consent, certify in writing to the Member Secretary that upon the reduction, loss or failure of any one or more of the primary sources of electric power to any facilities installed by the applicant to maintain compliance with the terms and conditions of this Consent, the applicant shall halt, reduce or otherwise control production and/or all discharges in order to maintain compliance with the terms and conditions of this Consent.

4.

The applicant shall not allow the discharge from other premises to mix with the discharges from his/her/their premises.

5.

Storm water shall not be allowed to mix the sewage and/or trade effluent on the upstream of the terminal manholes where the flow measuring devices will be installed

6.

All Solid Wastes arising in the premises shall be properly classified and disposed off to the satisfaction of the Board by:

i.

Landfill, in case of inert material, care being taken to ensure that the material does not

give rise to leachate which may percolate into ground water or carried away with storm runoff. ii. Controlled incineration, wherever possible in case of combustible organic material.

iii. Composting, in case of biodegradable material. 7. Any toxic material shall be detoxified otherwise be sealed in steel drums and buried in protected areas after obtaining approval of this Board in writing. The detoxification or sealing and burying shall be carried out in the presence of Boards authorized persons only. 8. The applicant shall maintain good house-keeping both within the factory and in the premises. All pipes, valves, sewers and drains shall be leak proof. Floor washings shall be admitted into the effluent collection system only and shall not be allowed to find their way in storm drains or open areas. 9. 10. The applicant shall provide all facilities to the Board staff for collection of samples. The applicant shall at all times maintain in good working order and operate efficiently all treatment or control facilities or systems installed or used by him to satisfy the terms and conditions of the Consent. 11. The issuance of this Consent does not convey any property right in either real personal property or any exclusive privileges, nor does it authorize any injury to private property or any invasion of personal rights nor any infringement of Central, State laws or regulation. 12. This Consent does not authorize or approve the construction of any physical structures or facilities or the undertaking of any work in any natural water course. 13. Non-compliance with effluent limitations: a.

If for any reason the applicant does not comply with or will be unable to comply with any effluent limitations specified in this Consent, the applicant, shall immediately notify the Consent issuing authority by telephone and provide the Consent issuing authority with the following in writing within 5 days of such notifications: i. Cause for Non compliance. ii. A description of the non complied discharge including its impact upon the receiving waters. iii. Anticipated time of continuance of non-compliance if expected to continue or if such condition has been corrected the duration of period of non-compliance.

iv. v.

Steps taken by the applicant to reduce and eliminate the non-complying discharge and Steps to be taken by the applicant to prevent recurrence of condition of noncompliance.

b.

The applicant shall take all reasonable steps to minimize any adverse impact to natural waters resulting from non-compliance with any effluent limitation specified in this Consent including such accelerated or additional monitoring as necessary to determine the natural and impact of the non-complying discharge.

c.

Nothing in this Consent shall be construed to relieve the applicant from civil or criminal penalties for non-compliance whether or not such non compliance is due to factors beyond his/her control, such as break-down, electric failure, accident or natural disaster.

14.

The diversion or by-pass of any discharge from facilities utilized by the applicant to maintain compliance with the terms and conditions of this Consent is prohibited except. i. Where unavoidable to prevent loss of life or severe property damage or ii. Where excessive storm damage or run off would damage any facilities necessary for compliance with terms and conditions of this Consent.

The applicant shall immediately notify the Board in writing of each diversion or by-pass in accordance with procedure specified as under item No:14. 15. The applicant shall at his own cost get the effluent samples collected both before and after treatment and get them analysed at an approved laboratory of the Board every month for the parameters indicated in Special Condition No:3 and shall submit in duplicate the report there of to the Board. 16. The addition of various treatment chemicals should be done only with mechanical dosers and proper equipment for regulation of correct dosages determined daily and for proper uniform feeding. Crude practices such as dumping of chemicals in drains or sumps or trickling of acids or alkalies arbitrarily and utilizing poles for stirring etc., should not be resorted to.

17.

Care should be taken to keep the anaerobic lagoons, if any biologically active and not to utilize as mere stagnation ponds. The anaerobic lagoons should be fed with the required nutrients for effective digestion. Lagoons should be constructed with sides and bottom made impervious.

18.

The utilization of treated effluent on factorys own lands, if any, should be complete and there should be no possibility of the effluent gaining access into any drainage channel or other water courses either directly or by overflow.

19.

The effluent disposal on land, if any, should be done without creating any nuisance to the surroundings or inundation of the lands at any time.

20.

If at any time the disposal of treated effluent on land becomes incomplete or unsatisfactory or create any problem or becomes a matter of dispute, the industry must adopt alternate satisfactory treatment and disposal measures.

21.

The sludge from treatment units shall be dried in sludge drying beds and the drained liquid shall be taken to equalization tank.

22.

In the disposal of treated effluent on land for irrigation, the industry shall keep in view of the need for:

i. Rotation of crops. ii. Change of point of application of effluent on land. iii. A portion of land kept fallow. The adoption of these would avoid soil becoming sick or stale. The industry may ensure this is consultation with the Agricultural Department. 23. It is the sole responsibility of the industry to ensure that there are no complaints at any time from the ryots in the surrounding areas as a result of discharge of sewage or trade effluent. 24. The effluent treatment units and disposal measures shall become operative at the time of commencement of production.

25.

The fact of commissioning of the industry shall be intimated to this Office within One week of commissioning.

26.

The unit has to ensure that the agency to whom the disposal of solid waste/sludge arising from the process/treatment is entrusted, shall obtain the permission of TamilNadu Pollution Control Board under Section 24 of the Water (Prevention and Control of Pollution) Act, 1974 before the disposal.

27.

The unit has to put up Effluent Treatment Plant within the specified period indicated in Special Condition No.4 by engaging any one of the consultants approved by the Board and operate and maintain the Effluent Treatment Plant continuously and efficiently so that treated effluent satisfied the standards prescribed by the Board.

28.

The applicant shall display this consent granted to him in a prominent place for perusal of the inspecting Officers of this Board. Sd./-xxxxxxx, Member Secretary //Forwarded By Order// For Member Secretary.

CONSENT ORDER NO. : 18683/Dated: 21.08.2012 Proc No. : T4/TNPCB/F.No.21221/AMB/RS/A/2012 dated :21.08.2012 Consent for New operation of the plant under Section 21 of the Air (Prevention and Control of Pollution) Act, 1981 as amended. Sub: TAMIL NADU POLLUTION CONTROL BOARD CONSENT M/s. Chrome Hard, No.33A/15, SIDCO Industrial Estate, North Phase, Ambattur, Ambattur Taluk, Tiruvallur District - for the New operation of the plant under Section 21 of the Air (Prevention and Control of Pollution) Act, 1981 as amended. Ref: 1. Your Application dated 20/05/2011, vide CARE Regn. No:CC12993. 2. IR No. F.AMB0174/RS/DEE/AMB/2012 dated 07/03/2012. 3. Minutes of CCC Meeting vide Item No. 134-12. ********* CONSENT is hereby granted under Section 21 of the Air (Prevention and Control of Pollution) Act, 1981, (Central Act 14 of 1981) as amended (hereinafter referred to as The Act) and the rules and orders made there under to The Proprietor, M/s. Chrome Hard, No.33A/15, SIDCO Industrial Estate, North Phase, Ambattur, Ambattur Taluk, Tiruvallur District (hereinafter referred to as The Applicant) Authorizing him to operate his industrial plant in the Air Pollution Control Area as notified by the Government and make new discharge of emission from the stacks.

This is subject to the provision of the Act and the rules and orders made there under and further subject to the terms and conditions incorporated in the Special and General Conditions annexed. This CONSENT is valid for a period ending with 31/03/2013 ( Thirty first March two thousand Thirteen) Sd./-xxxxxx, MEMBER SECRETARY. To

The Proprietor, M/s. Chrome Hard, No.33A/15, SIDCO Industrial Estate, North Phase, Ambattur, Chennai - 600 098

Copy to:

1. The District Environmental Engineer, TamilNadu Pollution Control Board, Ambattur

2. The Commissioner, Corporation of Chennai

3. BMS

4. Technical File

//Forwarded By Order//

For MEMBER SECRETARY.

SPECIAL CONDITIONS 1. Details of the products manufactured: Sl. No. Description Quantity a Main Products manufactured: 1. Hard Chrome Electroplating ( Dies & Industrial 600 Nos./Month Components) b By/Intermediate products manufactured: NIL This Consent is valid for the manufacture of Products and the rate of Production mentioned above. Any change in the quantity or quality of products has to be brought to the notice of the Board and fresh consent has to be obtained. 2. Emission is permitted through the following chimneys/stacks and shall not exceed the figures indicated : The emission shall not contain constituents in excess of the tolerance limits as laid down hereunder : Sl.No. Parameter Unit Tolerance limits in Chimney/ Stack number (1) 1 Acid Mist mg/Nm 50 3 mg/Nm 10 2 Lead 3 mg/Nm 5 3 Total 3 Cyanides 4 CO The unit shall adhere to the emission 5 6 SO2 NOx standards prescribed by the Board from time to time

3.a)

3.b)

7 SPM The Ambient Air in the industrial plant area shall not contain constituents in excess of the tolerance limits prescribed below :

Sl. POLLUTANT TIME No. WEIGHTED AVERAGE

UNIT55

1 Sulphur Dioxide (SO2) 2 Nitrogen Dioxide (NO2) 3 Particulate Matter (Size Less than 10 micro M) or PM10 4 Particulate Matter (Size Less than 2.5 micro M ) or PM2.5 5 Ozone (O3)

Annual 24 Hours Annual 24 Hours Annual 24 Hours

microgram/m3 microgram/m3 microgram/m3 microgram/m3 microgram/m3 microgram/m3 microgram/m3 microgram/m3 microgram/m3 microgram/m3 microgram/m3 microgram/m3 milligram/m3 milligram/m3 microgram/m3 microgram/m3 microgram/m3 nanogram/m3

TOLERANCE LIMITS Industrial, Ecologically Residential, Sensitive Rural and Area other area (notified by Central Govt.) 50 20 80 40 80 60 100 80 30 80 60 100

Annual 24 Hours

40 60

40 60

8 Hours 1 Hour Annual 24 Hours 8 Hours 1 Hour Annual 24 Hours Annual Annual

100 180 0.5 1.0 02 04 100 400 05 01

100 180 0.5 1.0 02 04 100 400 05 01

6 Lead (Pb)

7. Carbon Monoxide (CO) 8. Ammonia (NH3) 9. Benzene (C6H6) 10. Benzo(O) Pyrene (BaP) particulate phase only 11. Arsenic (As) 12. Nickel (Ni)

Annual Annual

nanogram/m3 nanogram/m3

06 20

06 20

3 (c)

The Ambient Noise Level in the industrial plant area shall not exceed the limits prescribed below:

Limits in dB(A) 4.

Day Time (6 A.M. to 10 P.M.) 75

Night Time (10 P.M. to 6 A.M.) 70

All units of the air pollution control equipment required to achieve the quality of the emissions to the tolerance limits prescribed above shall be completed along with the commissioning of production.

5.

The applicant shall provide port holes for sampling the emission and access-platform for carrying out stack sampling and provide electrical outlet points and other arrangements for Chimneys/stacks and other sources of emissions so as to collect samples of emission by the Board or the applicant at any time in accordance with the provisions of the Act or Rules made therein.

6.

The applicant shall at his own cost get the samples of emission collected and analyzed by the Tamilnadu Pollution Control Board Laboratory every month for the parameters indicated in condition No.3(a) and shall furnish in triplicate the report thereof to the Board by the 10th of succeeding month.

7.

This Consent is given by the Board in consideration of the particulars given in the application. Any change or alteration or deviation made in actual practice from the particulars furnished, in the application will also be ground for

review/variation/revocation of the Consent Order under Section 21 of the Act to make such deviation as deemed fit for the purpose of the Act. 8. The applicant shall not change or alter either the quality or quantity or rate of emission or install, replace or alter the air pollution control equipment or change the raw material or manufacturing process resulting in any change in quality and/or quantity of emissions, without the previous written permission of the Board. 9. The applicant shall provide and maintain at his own cost one ambient air quality monitoring stations for monitoring Suspended Particulate Matter, Sulphur Dioxide, Oxides of Nitrogen, Hydro-Carbon, Carbon-monoxide and monitor the same all in a

day, once in a month. The data collected shall be maintained in a register and a monthly extract furnished to the Board 10. The applicant shall provide and maintain at his own cost a meteorological station to collect the data on wind velocity, direction, temperature, humidity, rainfall, etc.,. and the daily readings shall be recorded and the extract sent to the Board once in a month. 11. The applicant shall forward the following information to the Member

Secretary/DEE/AEE, Tamil Nadu Pollution Control Board, Chennai/Concerned District Office regularly before 10th of every month. a. Progress on the installation of Air Pollution Control equipments. b. Progress on the procurement and installation of equipments for monitoring ambient air quality, stacks, chimneys and meteorological data. c. Monthly extract of daily discharge of emission through each chimney/stack. d. Report of Analysis of stack monitoring, ambient air quality monitoring, meteorological data as required under conditions. e. Progress on planting of trees and plants as referred to under General Conditions No.8 12. Any upset conditions if any of the plant/plants of the factory which is likely to result in increased emissions and/or result in violation of the standards mentioned above shall be reported to the Joint Head Chief Quarters and District Environmental Office of Engineers the Board

Office/Regional telegraphically. 13.

Environmental

Engineers

The applicant shall furnish to the Visiting Officer of the Board any information regarding the stack monitoring system/or operation of the plant or any other particulars as may be pertinent in preventing and controlling of pollution of Air.

14.

The applicant shall submit process flow sheet and particulars of proposed control equipments, monitoring equipments and time schedule for completing the installation of the same so as to reach the Board within 30 days from the date of receipt of this Order.

15.

The conditions imposed as above shall continue in force until revoked under Section 21 of the Act.

16.

The unit shall operate and maintain the wet scrubber system with stack arrangement provided for the control of emissions from pickling & plating bath effectively so as to comply with Ambient Air Quality/Emission standards prescribed by the Board.

17.

The unit shall increase the height of the stacks at least to 10 meters above the Ground Level as required in G.S.R.266(E), dated 30.03.2012 issued by Ministry of Environment and Forests, Government of India, New Delhi.

18.

The unit shall develop adequate green belt in an area of 25% of total area at a rate of 400 samplings per hectares (minimum of 10 samplings) within the premises in consultation with Forest department on the selection of species/samplings.

19 .

The unit shall remit balance amount of consent fee from the date of commissioning within fifteen days. Sd./-xxxxx, MEMBER SECRETARY. //Forwarded By Order// For MEMBER SECRETARY.

GENERAL CONDITIONS 1. The applicant shall make an application for grant of fresh consent atleast 60 days before the date of expiry of this Consent Order. 2. The necessary fee, as prescribed for obtaining consent, shall be paid for by the applicant along with the application for consent.. 3. The industry shall immediately submit the revised application for Consent to this Board in the event of any change in the quantity/quality or raw material, manufacturing process, rate of emissions, air pollution control equipment, etc 4. The applicant shall either:

a. Not later than 30 days from the date of issue of this Consent Order, Certify in writing to the Member-Secretary that the applicant has installed or provided for an alternate electric power source sufficient to operate all facilities installed by the applicant to maintain compliance with the terms and conditions of the Consent. b. Not later than 30 days from the date of this Consent, certify in writing to the Member Secretary that upon the reduction, loss or failure of any one or more of the primary sources of electric power to any facilities installed by the applicant to maintain compliance with the terms and conditions of this Consent, the applicant shall halt, reduce or otherwise control production and/or all discharges in order to maintain compliance with the terms and conditions of this Consent. 5. No control equipments or chimney shall be altered or replaced or as the case may be erected or re-erected except with the previous approval of the Board. 6. The liquid effluent arising out of the operation of the air pollution control equipment shall also be treated in a manner and to the satisfaction of standards prescribed by the Board in accordance with the provisions of Water (Prevention and Control of Pollution) Act, 1974 as amended.

7.

The solid waste, such as sweepings, wastage, package, empty containers, residues, sludge including that from air pollution control equipments collected within the premises of the industrial plant shall be disposed off scientifically to the satisfaction of the Board, so as not to cause fugitive emission, dust problems, or water pollutions problem through leaching, etc., of any kind.

8.

The applicant shall plant a minimum of three varieties of trees (Eucalyptus, Subabul and any other suitable variety) at the density of not less than 1000 trees per acre of land. The plantation is stipulated over and above the bulk plantation of trees in that areas and maintain them.

9. 10.

The applicant shall provide all facilities for collection of sample to the Board staff. The stack monitoring system employed by the applicant shall be open for inspection of this Board at any time.

11. 12.

There shall not be any fugitive or episodal discharge from the premises. In case of such episodal discharge/emissions the industry shall take immediate action to bring down the emission within the limits prescribed by the Board in special conditions No.3(a).

13.

The applicant shall at all times maintain in good working order and operate as efficiently as possible all pollution control facilities to achieve the terms and conditions of the Consent.

14.

The issue of this Consent does not cover any property right in either real or personal property or any exclusive privileges nor does it authorize any injury to private property or any invasion of personal rights, or any infringement of Central, State Laws or regulations.

15.

The applicant shall keep the premises of the industrial plant and air pollution equipments clean and make all hoods, pipes, valves and stacks/chimneys leak proof. The air pollution control equipments, location inspection chambers, sampling port holes shall be made easily accessible at all time.

16.

The applicant shall display this Consent granted to him in a prominent place for perusal of the inspecting officers of this Board.

17.

An inspection book shall be opened and made available to the Boards Officers during their visit to the factory.

18.

If due to any technological improvements or otherwise this Board is of opinion that all or any of the conditions referred to above requires variation (including the change of any control equipment either in whole or in part) this Board shall, after giving the applicant an opportunity of being heard, vary all or any of such condition and thereupon the applicant shall be bound to comply with the conditions so varied.

19.

The applicant, his/her/their legal heirs/representatives or assignees shall have no claim whatsoever to the continuation or renewal of this Consent after the expiry of the period of this Consent.

20.

The Board reserves the right to review, impose additional conditions or conditions, revoke change or alter the terms and conditions of this Consent. Sd./-xxxxxx, MEMBER SECRETARY. //Forwarded By Order//

For MEMBER SECRETARY.

You might also like

- Urban Wastewater Management in Indonesia: Key Principles and Issues in Drafting Local RegulationsFrom EverandUrban Wastewater Management in Indonesia: Key Principles and Issues in Drafting Local RegulationsNo ratings yet

- CertiFicate For Water - NEWDocument6 pagesCertiFicate For Water - NEWMohan RajNo ratings yet

- A Model Environmental Code: The Dubai Environment LawFrom EverandA Model Environmental Code: The Dubai Environment LawNo ratings yet

- Regional Office:: Guntur D.No:4-5-4/5C, 4/3 - Navabharath Nagar, Ring Road, Guntur - 522 006Document6 pagesRegional Office:: Guntur D.No:4-5-4/5C, 4/3 - Navabharath Nagar, Ring Road, Guntur - 522 006ROOPDIP MUKHOPADHYAYNo ratings yet

- Alkyl Amines KurkumbhDocument9 pagesAlkyl Amines KurkumbhVishvajit PatilNo ratings yet

- R K CashewsDocument5 pagesR K CashewsVijay SethupathiNo ratings yet

- Slaughter House by Eluru Municipality, ELR (1) - 221029 - 174130Document4 pagesSlaughter House by Eluru Municipality, ELR (1) - 221029 - 174130Rao GNo ratings yet

- Allegro Speciality Cfo OrderDocument5 pagesAllegro Speciality Cfo Orderap26n1389No ratings yet

- BHEL Bhandara MPCB FileDocument9 pagesBHEL Bhandara MPCB FileVishvajit PatilNo ratings yet

- Vineet Tex FabDocument7 pagesVineet Tex FabSharon SusmithaNo ratings yet

- New CFO PHASE VI LANDFILL EXPANSIONDocument6 pagesNew CFO PHASE VI LANDFILL EXPANSIONShiva SunuNo ratings yet

- AOV Agro Foods Private Limited: Consent of Pollution Control Board - Naresh KadianDocument3 pagesAOV Agro Foods Private Limited: Consent of Pollution Control Board - Naresh KadianNaresh KadyanNo ratings yet

- Haryana State Pollution Control Board Near The Orion Banquet, Naraingarh Road, BaldevDocument4 pagesHaryana State Pollution Control Board Near The Orion Banquet, Naraingarh Road, BaldevHaryana Water AuthorityNo ratings yet

- Consent Order: J&K Pollution Control Committee Jammu/Kashmir (WWW - Jkspcb.nicDocument3 pagesConsent Order: J&K Pollution Control Committee Jammu/Kashmir (WWW - Jkspcb.nickrish659No ratings yet

- Siting Criteria and Consent Conditions Notification PDFDocument20 pagesSiting Criteria and Consent Conditions Notification PDFPrince JoseNo ratings yet

- Walta ActDocument15 pagesWalta ActRaghu RamNo ratings yet

- Haryana State Pollution Control Board C-11, Sector-6, PanchkulaDocument3 pagesHaryana State Pollution Control Board C-11, Sector-6, PanchkulaRaj KumarNo ratings yet

- Ardex Endura - CFODocument5 pagesArdex Endura - CFOAPIIC EENo ratings yet

- cnacasDocument5 pagescnacasrajeshkannaa1986No ratings yet

- Water - DAO 2003-39Document12 pagesWater - DAO 2003-39HjktdmhmNo ratings yet

- Renewal Consent Green Packaging IndustryDocument3 pagesRenewal Consent Green Packaging IndustryVijay SethupathiNo ratings yet

- Walta Act 2002Document15 pagesWalta Act 2002dileepreddy220No ratings yet

- Technical InstrumentationDocument209 pagesTechnical Instrumentationrenjithv_40% (1)

- Certi Ficate 1Document4 pagesCerti Ficate 1rajeshkannaa1986No ratings yet

- NOV TemplateDocument3 pagesNOV TemplateEman OsorioNo ratings yet

- Hazardous WateDocument2 pagesHazardous WateMuthuswamyNo ratings yet

- Water Pollution Cess Rules SummaryDocument11 pagesWater Pollution Cess Rules SummarySathish KumarNo ratings yet

- Pollution NOCDocument3 pagesPollution NOCdda yamuna nagarNo ratings yet

- Certi Ficate 1Document5 pagesCerti Ficate 1Vinoth SenthilNo ratings yet

- Water (Prevention and Control of Pollution) Cess Rules, 1978Document12 pagesWater (Prevention and Control of Pollution) Cess Rules, 1978Balu Mahendra SusarlaNo ratings yet

- Maharashtra Pollution Board grants consentDocument7 pagesMaharashtra Pollution Board grants consentSharon SusmithaNo ratings yet

- The Water Supply Regulations 2009Document22 pagesThe Water Supply Regulations 2009triggs1971No ratings yet

- Cdphe Reg. 84 - Reclaimed Water Control RegulationDocument27 pagesCdphe Reg. 84 - Reclaimed Water Control RegulationGeraldTrumbuleNo ratings yet

- Lesson 2 Philippine Environmental LawsDocument44 pagesLesson 2 Philippine Environmental LawsGlen Mangali100% (21)

- Water Supply Regulation 1991 EnglishDocument9 pagesWater Supply Regulation 1991 EnglishArun BakshiNo ratings yet

- Florida BLDG Code Appendix FDocument17 pagesFlorida BLDG Code Appendix FSarah GlennNo ratings yet

- Trade Effluent Regulations GuideDocument58 pagesTrade Effluent Regulations Guidetriggs1971No ratings yet

- Maharashtra Pollution Control Board grants consent to V&W BiotechDocument8 pagesMaharashtra Pollution Control Board grants consent to V&W BiotechSharon SusmithaNo ratings yet

- Regulations for Safe Recycled Water and BiosolidsDocument62 pagesRegulations for Safe Recycled Water and Biosolidskevinning51No ratings yet

- Certi Ficate 1Document5 pagesCerti Ficate 1rajeshkannaa1986No ratings yet

- Consent Order - MPPCBDocument4 pagesConsent Order - MPPCBNational HospitalNo ratings yet

- Certi Ficate 1Document4 pagesCerti Ficate 1rajeshkannaa1986No ratings yet

- Haryana State Pollution Control Board Near The Orion Banquet, Naraingarh Road, BaldevDocument3 pagesHaryana State Pollution Control Board Near The Orion Banquet, Naraingarh Road, BaldevHaryana Water AuthorityNo ratings yet

- Kejriwal Geotech Pvt. LTDDocument4 pagesKejriwal Geotech Pvt. LTDTerapanth Yuvak Parishad VapiNo ratings yet

- ANDHRA PRADESH POLLUTION CONTROL BOARD CONSENT ORDERDocument4 pagesANDHRA PRADESH POLLUTION CONTROL BOARD CONSENT ORDERPRAVEEN KUMARNo ratings yet

- Letter To EngrDocument5 pagesLetter To EngrMeycauayan DialysisNo ratings yet

- State Pollution Control Board, Odisha: No. Date Office MemorandumDocument3 pagesState Pollution Control Board, Odisha: No. Date Office Memorandumkrish659No ratings yet

- Supplemental Rules and Regulations On The Nationwide Implementation of The Wastewater Charge System Under Rules 13 and 14 of DAO 2005 10Document15 pagesSupplemental Rules and Regulations On The Nationwide Implementation of The Wastewater Charge System Under Rules 13 and 14 of DAO 2005 10AllanNo ratings yet

- Ozzi+Kleen Owners+ManualLRev LDocument24 pagesOzzi+Kleen Owners+ManualLRev LmutazsalihNo ratings yet

- Maharashtra Pollution Control Board: Consent No. SRO-SANGLI/CONSENT/1 70 7001353/ Date: 31-07-2017Document4 pagesMaharashtra Pollution Control Board: Consent No. SRO-SANGLI/CONSENT/1 70 7001353/ Date: 31-07-2017PRAVEEN KUMARNo ratings yet

- DhandapaniCementTryConsents PDFDocument4 pagesDhandapaniCementTryConsents PDFmurali manogarNo ratings yet

- Water Pollution Prevention ActDocument26 pagesWater Pollution Prevention ActAmita SinwarNo ratings yet

- Dao 2004-26 (Ra 8749)Document5 pagesDao 2004-26 (Ra 8749)Paul ValerosNo ratings yet

- Application Filed by The Applicant/organization On: LocationDocument5 pagesApplication Filed by The Applicant/organization On: Locationkrish659No ratings yet

- LEGAL AND REGULATORY REQUIREMENTSDocument21 pagesLEGAL AND REGULATORY REQUIREMENTSNishit RupaparaNo ratings yet

- Waste Water Standards For Discharge of Industrial Effluent Into A Waste Water System RegulationsDocument12 pagesWaste Water Standards For Discharge of Industrial Effluent Into A Waste Water System RegulationsHeshika BeeharryNo ratings yet

- Module-V: Environmental Acts and Sustainable Development in IndiaDocument72 pagesModule-V: Environmental Acts and Sustainable Development in IndiaSavya JaiswalNo ratings yet

- Certified Mail 7018 1830 0001 8036 5232 Return Receipt RequestedDocument5 pagesCertified Mail 7018 1830 0001 8036 5232 Return Receipt RequestedBen SchachtmanNo ratings yet

- Certification Study Guide For Water Treatment Operators: The Training Station ©2002Document0 pagesCertification Study Guide For Water Treatment Operators: The Training Station ©2002Mubarik AliNo ratings yet

- Provisional Consent Order (CCA) : Consent No. AWH-39922 Valid Upto: 31/03/2020Document1 pageProvisional Consent Order (CCA) : Consent No. AWH-39922 Valid Upto: 31/03/2020Ks SainiNo ratings yet

- Hindustan Hot FrontDocument2 pagesHindustan Hot Frontpallavan.kNo ratings yet

- Fluent Comprehensive BrochureDocument6 pagesFluent Comprehensive Brochurepallavan.kNo ratings yet

- Renewal ParticularsDocument1 pageRenewal ParticularsManikandan SelvamNo ratings yet

- Hindustan Hei BackDocument2 pagesHindustan Hei Backpallavan.kNo ratings yet

- 10 Six SigmaDocument25 pages10 Six Sigmapharmashri5399No ratings yet

- Tamil Samayal - 30 Different Dosa VaritiesDocument24 pagesTamil Samayal - 30 Different Dosa VaritiesSakthivel100% (8)

- 415V System Voltage Tower Crane Motor Load DataDocument1 page415V System Voltage Tower Crane Motor Load Datapallavan.kNo ratings yet

- Cable Size Design (10.6.13)Document95 pagesCable Size Design (10.6.13)TigrilloNo ratings yet

- Filtermist Full CatalogDocument30 pagesFiltermist Full Catalogpallavan.kNo ratings yet

- 01 Preventative Maintenance Procedure 1 P04Document1 page01 Preventative Maintenance Procedure 1 P04pallavan.k100% (1)

- Ac LeafletDocument2 pagesAc LeafletNaveen PadmanabanNo ratings yet

- Compressed Air Source BookDocument128 pagesCompressed Air Source Bookgfollert100% (1)

- Workplace Resources: Visual Systems Supplies That Help Deliver Results Fast!Document6 pagesWorkplace Resources: Visual Systems Supplies That Help Deliver Results Fast!pallavan.kNo ratings yet

- WP04 Ad3008Document19 pagesWP04 Ad3008pallavan.kNo ratings yet

- ISLG Cummins PDFDocument2 pagesISLG Cummins PDFNuman CalisNo ratings yet

- APERAM-Automotive Structural Components OfferDocument12 pagesAPERAM-Automotive Structural Components OfferJOVANY ACEVEDONo ratings yet

- Clean Air Act - LGU Quezon, Bukidnon PresentationDocument24 pagesClean Air Act - LGU Quezon, Bukidnon PresentationalfiedeckNo ratings yet

- LDVDocument101 pagesLDVIonut StavaracheNo ratings yet

- DENSO Common Rail Fuso Fighter 6M60 Service Manual PagesDocument12 pagesDENSO Common Rail Fuso Fighter 6M60 Service Manual PagesAlex Renne Chambi100% (3)

- RA 8749-Philippine Clean Air Act of 1999Document36 pagesRA 8749-Philippine Clean Air Act of 1999Rizalee J. PerezNo ratings yet

- Philippine Clean Air Act of 1999Document27 pagesPhilippine Clean Air Act of 1999Ram Migue SaintNo ratings yet

- Presidential Decree Establishes Philippine Environmental CodeDocument11 pagesPresidential Decree Establishes Philippine Environmental CodeMarky RamoneNo ratings yet

- Royce CullinanDocument6 pagesRoyce CullinanYashovardhan KothariNo ratings yet

- CPCB Industry Standards Effluent EmissionDocument2 pagesCPCB Industry Standards Effluent EmissionVaishnavi JayakumarNo ratings yet

- Constant Volume Vs Pressure ReactorDocument88 pagesConstant Volume Vs Pressure Reactorfogler833No ratings yet

- SEAT Leon Range - Model Year 2012Document44 pagesSEAT Leon Range - Model Year 2012Mihai SchmidtNo ratings yet

- 2012 Adv Combustion Engine PDFDocument396 pages2012 Adv Combustion Engine PDFdavid0775100% (2)

- Ebook Characteristics and Control of Low Temperature Combustion Engines PDFDocument553 pagesEbook Characteristics and Control of Low Temperature Combustion Engines PDFCao Đào Nam100% (1)

- RA 8749 - Clean Air ActDocument24 pagesRA 8749 - Clean Air ActRay Adrian P. DitonaNo ratings yet

- DPF Sizing Approaches for Large Diesel EnginesDocument11 pagesDPF Sizing Approaches for Large Diesel EnginesWeeIngNo ratings yet

- AutomobileDocument33 pagesAutomobilemarinerajesh3022No ratings yet

- RVP Related ArticleDocument31 pagesRVP Related ArticleJayakumar SankaranNo ratings yet

- Federal Motor Vehicle Safety Standards and RegulationsDocument23 pagesFederal Motor Vehicle Safety Standards and RegulationsKazi MehdiNo ratings yet

- Transport System in BangladeshDocument18 pagesTransport System in BangladeshSimantoPreeom100% (1)

- W Brochure TCM95-TCM180i-World 0119 V1 enDocument24 pagesW Brochure TCM95-TCM180i-World 0119 V1 enVamsiKrishna100% (1)

- Philippine Environmental Code Sets StandardsDocument9 pagesPhilippine Environmental Code Sets StandardsFaye Cience BoholNo ratings yet

- Jeep ModernizationDocument10 pagesJeep ModernizationErlle AvllnsaNo ratings yet

- Module 1 Part 1 Engine DynamicsDocument57 pagesModule 1 Part 1 Engine DynamicsTara GerdingNo ratings yet

- Exhaust Emission and TestingDocument36 pagesExhaust Emission and Testingherbert_thiva_82100% (3)

- Briggs & Stratton Owners ManualDocument20 pagesBriggs & Stratton Owners ManualgyrfalconNo ratings yet

- History of Emission Standards in India - A Critical Review: Elavarasan.G, Kannan.M, Karthikeyan.DDocument8 pagesHistory of Emission Standards in India - A Critical Review: Elavarasan.G, Kannan.M, Karthikeyan.DKannan MuthuNo ratings yet

- Mobility of E-Rickshaws in DelhiDocument9 pagesMobility of E-Rickshaws in DelhiSurajitBhattacharyaNo ratings yet

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- The Natural vs. Human Causes of Air Pollution : Environment Textbooks | Children's Environment BooksFrom EverandThe Natural vs. Human Causes of Air Pollution : Environment Textbooks | Children's Environment BooksRating: 4 out of 5 stars4/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- The Monsanto Papers: Corruption of Science and Grievous Harm to Public HealthFrom EverandThe Monsanto Papers: Corruption of Science and Grievous Harm to Public HealthRating: 5 out of 5 stars5/5 (1)

- Stand Up That Mountain: The Battle to Save One Small Community in the Wilderness Along the Appalachian TrailFrom EverandStand Up That Mountain: The Battle to Save One Small Community in the Wilderness Along the Appalachian TrailRating: 3 out of 5 stars3/5 (3)