Professional Documents

Culture Documents

EN1591 Flange Design

Uploaded by

madodandembeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EN1591 Flange Design

Uploaded by

madodandembeCopyright:

Available Formats

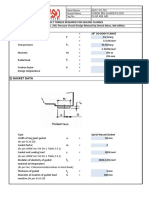

EN1591 version 1.

0 CALCULATION OF FLANGES AND THEIR JOINTS ACCORDING TO EN1591-1

Project summary

Project : Catliq Demo

ID No.

Flange

Date .....................................................

16-01-2009

Time ....................................................

16:39:45

Project No ...........................................

264

Calculated by .......................................

Revision ...............................................

Page ....................................................

1/9

References

European Standard .............................................................................................................................................................................

EN 1591-1

Standard title .......................................................................................................................................................................................

Flanges and their joints

Standard subtitle .................................................................................................................................................................................

Design rules for gasketed circular flange connections

Standard edition ..................................................................................................................................................................................

Issue 1

Standard dated ...................................................................................................................................................................................

April 2001

ICS number ........................................................................................................................................................................................

ICS 23.040.60

Program version .................................................................................................................................................................................

Version 1.0

Program build .....................................................................................................................................................................................

Build 015 12-01-2009

Program development ........................................................................................................................................................................

Danish Exergy Technology - DXT

Nomenclature, equation numbers and figure numbers are made with direct reference to the English printed

version of this European Standard.

Component type

Hubbed threaded flange

Hubbed threaded flange

Cylindrical Shell

Cylindrical Shell

Solid metal gaskets

Bolts - ISO M24

Component name

Shell flange 1

Shell flange 2

Compnent ID

Mat. code

Mat. grade

Status

EN10028-3

EN10028-3

VdTV 499

VdTV 499

P460NH

P460NH

NiCr22Mo9Nb (F)

NiCr22Mo9Nb (F)

EN10269

1.1181

OK

OK

--OK

OK

PlantWare A/S - Skovlytoften 4, DK-2840 - Holte - Phone: +45 4547 5101 - Fax: +45 4548 5101 - info@plantware.dk - www.plantware.dk Checked by :

EN1591 ver 1.0

Project

CALCULATION OF FLANGES AND THEIR JOINTS ACCORDING TO EN1591-1

Catliq Demo

Component : Flange

ID No.

Date ..................................................

16-01-2009

Time .................................................

16:39:45

Project No ........................................

264

Calculated by ....................................

Revision ............................................

Page .................................................

2/9

Main body design code .......................................................................................................................................................................

-EN13480

Medium ...............................................................................................................................................................................................

-Other

Fluid state ...........................................................................................................................................................................................

-Gas

Fluid gruppe ........................................................................................................................................................................................

-1

Maximum operation pressure (Po) .....................................................................................................................................................

barg

300,0

Maximum operation temperature (to) .................................................................................................................................................

C

250,0

Number of full load cycles ..................................................................................................................................................................

pcs

500

Temperature gradient during start-up .................................................................................................................................................

C/min

1,0

Component lifetime (T) .......................................................................................................................................................................

h

200000

Lifetime monitoring system provided ..................................................................................................................................................

-NO

Max allowable internal pressure (PSmax) ..........................................................................................................................................

barg

325,0

Internal calculation pressure (P) .........................................................................................................................................................

barg

325,0

Minimum allowable temperature (TSmin) ...........................................................................................................................................

C

20,0

Maximum allowable temperature (TSmax) .........................................................................................................................................

C

400,0

Calculation temperature (tc) ...............................................................................................................................................................

C

400,0

Max allowable external pressure (PSmax) ........................................................................................................................................

barg

0,0

External calculation pressure (P) ........................................................................................................................................................

barg

0,0

Minimum allowable temperature (TSmin) ...........................................................................................................................................

C

0,0

Maximum allowable temperature (TSmax) .........................................................................................................................................

C

50,0

Calculation temperature (tc) ...............................................................................................................................................................

C

30,0

PlantWare A/S - Skovlytoften 4, DK-2840 - Holte - Phone: +45 4547 5101 - Fax: +45 4548 5101 - info@plantware.dk - www.plantware.dk Checked by :

EN1591 ver 1.0

Project

CALCULATION OF FLANGES AND THEIR JOINTS ACCORDING TO EN1591-1

Catliq Demo

Component : Flange

ID No.

Date ..................................................

16-01-2009

Time .................................................

16:39:45

Project No ........................................

264

Calculated by ....................................

Revision ............................................

Page .................................................

3/9

Flange number ...................................................................................................................................................................................

First flange in joint

Flange type .........................................................................................................................................................................................

Hubbed threaded flange

Flange code ........................................................................................................................................................................................

NA

Flange serie ........................................................................................................................................................................................

NA

Flange material code ..........................................................................................................................................................................

EN10028-3

Flange material grade .........................................................................................................................................................................

P460NH

Inside diameter of flange (d0) .............................................................................................................................................................

mm

24,0

Average diameter of hub at thin end (d1) ...........................................................................................................................................

mm

NA

Average diameter if hub at thick end (d2) ...........................................................................................................................................

mm

NA

Bolt circle diameter (d3) ......................................................................................................................................................................

mm

80,0

Outside diameter of flange (d4) ..........................................................................................................................................................

mm

115,0

Diameter of bolt hole (d5) ...................................................................................................................................................................

mm

24,0

Inside diameter of loose flange (d6) ...................................................................................................................................................

mm

42,4

Diameter of reaction between flange and stub or collar (d7) ..............................................................................................................

mm

42,4

Outside diameter of collar (d8) ...........................................................................................................................................................

mm

42,4

Diameter of central hole in blank flange (d9) ......................................................................................................................................

mm

NA

Thickness of central plate of blank flange (e0) ...................................................................................................................................

mm

NA

Thickness of hub at thin end (e1) .......................................................................................................................................................

mm

NA

Thickness of hub at thick end (e2) .....................................................................................................................................................

mm

NA

Length of hub (lH) ...............................................................................................................................................................................

mm

NA

Effective axial thickness of flange (eF) ...............................................................................................................................................

mm

25,0

Thickness (ep) ....................................................................................................................................................................................

mm

25,0

Cross-section area of ring (AF) ..........................................................................................................................................................

mm

230,0

Shell material code .............................................................................................................................................................................

-VdTV 499

Shell material number .........................................................................................................................................................................

-- NiCr22Mo9Nb (F)

Shell form ...........................................................................................................................................................................................

-Cylindrical

Diameter of shell at junction (ds) ........................................................................................................................................................

mm

32,4

Thickness of shell (es) ........................................................................................................................................................................

mm

9,5

Angle of inclination of connected shell (PsiS) .....................................................................................................................................

0,0

Pitch between bolts (pB) .....................................................................................................................................................................

mm

31,4

Effective diameter of bolt holes (d5e) .................................................................................................................................................

mm

21,0

Effective bolt circle diameter (d3e) .....................................................................................................................................................

mm

77,5

Average diameter of flange (dF) .........................................................................................................................................................

mm

33,2

Effective width of flange (bF) ..............................................................................................................................................................

mm

9,2

Effective axial thickness of flange (eF) ...............................................................................................................................................

mm

25,0

Part of flange thickness with radial pressure loading (eP) ..................................................................................................................

mm

25,0

Part of flange thickness without radial pressure loading (eQ) ............................................................................................................

mm

0,0

Wall thickness of equivalent cylinder for load calculations (eE) .........................................................................................................

mm

9,5

Average diameter equivalent cylinder for load calculation (dE) ..........................................................................................................

mm

32,4

Lever arm correction (hP) ...................................................................................................................................................................

mm

30,59

Lever arm correction (hG) ..................................................................................................................................................................

mm

2,70

Calculation factor (Gamma) ...............................................................................................................................................................

-1,06

Calculation factor (Theta) ...................................................................................................................................................................

-0,39

Calculation factor (Lambda) ...............................................................................................................................................................

-0,00

Calculation factor (cF) ........................................................................................................................................................................

-0,35

Lever arm correction (hS) ...................................................................................................................................................................

mm

14,65

Lever arm correction (hT) ...................................................................................................................................................................

mm

14,95

Lever arm correction (hQ) ..................................................................................................................................................................

mm

27,68

Lever arm correction (hR) ...................................................................................................................................................................

mm

-2,20

Calculation factor (kQ) ........................................................................................................................................................................

-0,85

Calculation factor (kR) ........................................................................................................................................................................

--0,15

Rotational flexibility modulus of flange (ZF) *1,0E5 ............................................................................................................................

1/mm

0,00

PlantWare A/S - Skovlytoften 4, DK-2840 - Holte - Phone: +45 4547 5101 - Fax: +45 4548 5101 - info@plantware.dk - www.plantware.dk Checked by :

EN1591 ver 1.0

Project

CALCULATION OF FLANGES AND THEIR JOINTS ACCORDING TO EN1591-1

Catliq Demo

Component : Flange

ID No.

Date ..................................................

16-01-2009

Time .................................................

16:39:45

Project No ........................................

264

Calculated by ....................................

Revision ............................................

Page .................................................

4/9

Flange number ...................................................................................................................................................................................

Second flange in joint

Flange type .........................................................................................................................................................................................

Hubbed threaded flange

Flange code ........................................................................................................................................................................................

NA

Flange serie ........................................................................................................................................................................................

NA

Flange material code ..........................................................................................................................................................................

EN10028-3

Flange material grade .........................................................................................................................................................................

P460NH

Inside diameter of flange (d0) .............................................................................................................................................................

mm

24,0

Average diameter of hub at thin end (d1) ...........................................................................................................................................

mm

NA

Average diameter if hub at thick end (d2) ...........................................................................................................................................

mm

NA

Bolt circle diameter (d3) ......................................................................................................................................................................

mm

80,0

Outside diameter of flange (d4) ..........................................................................................................................................................

mm

115,0

Diameter of bolt hole (d5) ...................................................................................................................................................................

mm

24,0

Inside diameter of loose flange (d6) ...................................................................................................................................................

mm

42,4

Diameter of reaction between flange and stub or collar (d7) ..............................................................................................................

mm

42,4

Outside diameter of collar (d8) ...........................................................................................................................................................

mm

42,4

Diameter of central hole in blank flange (d9) ......................................................................................................................................

mm

NA

Thickness of central plate of blank flange (e0) ...................................................................................................................................

mm

NA

Thickness of hub at thin end (e1) .......................................................................................................................................................

mm

NA

Thickness of hub at thick end (e2) .....................................................................................................................................................

mm

NA

Length of hub (lH) ...............................................................................................................................................................................

mm

NA

Effective axial thickness of flange (eF) ...............................................................................................................................................

mm

25,0

Thickness (ep) ....................................................................................................................................................................................

mm

25,0

Cross-section area of ring (AF) ..........................................................................................................................................................

mm

230,0

Shell material code .............................................................................................................................................................................

-VdTV 499

Shell material number .........................................................................................................................................................................

-- NiCr22Mo9Nb (F)

Shell form ...........................................................................................................................................................................................

-Cylindrical

Diameter of shell at junction (ds) ........................................................................................................................................................

mm

32,4

Thickness of shell (es) ........................................................................................................................................................................

mm

9,5

Angle of inclination of connected shell (PsiS) .....................................................................................................................................

0,0

Pitch between bolts (pB) .....................................................................................................................................................................

mm

31,4

Effective diameter of bolt holes (d5e) .................................................................................................................................................

mm

21,0

Effective bolt circle diameter (d3e) .....................................................................................................................................................

mm

77,5

Average diameter of flange (dF) .........................................................................................................................................................

mm

33,2

Effective width of flange (bF) ..............................................................................................................................................................

mm

9,2

Effective axial thickness of flange (eF) ...............................................................................................................................................

mm

25,0

Part of flange thickness with radial pressure loading (eP) ..................................................................................................................

mm

25,0

Part of flange thickness without radial pressure loading (eQ) ............................................................................................................

mm

0,0

Wall thickness of equivalent cylinder for load calculations (eE) .........................................................................................................

mm

9,5

Average diameter equivalent cylinder for load calculation (dE) ..........................................................................................................

mm

32,4

Lever arm correction (hP) ...................................................................................................................................................................

mm

30,59

Lever arm correction (hG) ..................................................................................................................................................................

mm

2,70

Calculation factor (Gamma) ...............................................................................................................................................................

-1,06

Calculation factor (Theta) ...................................................................................................................................................................

-0,39

Calculation factor (Lambda) ...............................................................................................................................................................

-0,00

Calculation factor (cF) ........................................................................................................................................................................

-0,35

Lever arm correction (hS) ...................................................................................................................................................................

mm

14,65

Lever arm correction (hT) ...................................................................................................................................................................

mm

14,95

Lever arm correction (hQ) ..................................................................................................................................................................

mm

27,68

Lever arm correction (hR) ...................................................................................................................................................................

mm

-2,20

Calculation factor (kQ) ........................................................................................................................................................................

-0,85

Calculation factor (kR) ........................................................................................................................................................................

--0,15

Rotational flexibility modulus of flange (ZF) *1,0E5 ............................................................................................................................

1/mm

0,00

PlantWare A/S - Skovlytoften 4, DK-2840 - Holte - Phone: +45 4547 5101 - Fax: +45 4548 5101 - info@plantware.dk - www.plantware.dk Checked by :

EN1591 ver 1.0

Project

CALCULATION OF FLANGES AND THEIR JOINTS ACCORDING TO EN1591-1

Catliq Demo

Component : Flange

ID No :

Date .............................

16-01-2009

Time .............................

16:39:45

Projekt No .................... 264

Calculated by ...............

Revision ......................

Page ............................. 5/9

Solid metal gaskets

Gasket group ...........................................................................................................................

Stainless steel, heat resistent

Gasket type .................................................................................................................................

Metal gasket with curved surface - figure 3c

Gasket form ..................................................................................................................................

Gasket material ................................................................................................................................

Inside diameter of gasket (dG1) ................................................................................................................

mm

Outside diameter of gasket (dG2) ........................................................................................................ mm

Gasket width (bGt) .............................................................................................................................................

mm

Gasket thickness (eGt) ..............................................................................................................

mm

Angle of inclination of sealing face (PsiG) ..................................................................................................................

Radius of curvature in cross.section (r2) ..........................................................................................................

mm

24,0

37,0

6,5

11,0

20,0

43,0

Maximum allowable operation temperature ........................................................................................................................

C

600,0

Minimum effective compressive stress in gasket for assembly conditions (Qmin) .....................................................

MPa

300,0

Maximum allowable compressive stress in gasket for reference gasket Qmax,ref (at 20C) ...............................................

MPa

660,0

Yield stress characteristic of gasket material (Qmax,y) (eq. 4a) ......................................................................................

MPa

660,0

Compressive modulus of elasticity of gasket at zero compressive stress at 20C (E0) .......................................................

MPa

210000,0

Rate of change of compressive modulus of elasticity of gasket with compressive stress at 20C (K1) ..................................

-0,00

Load - pressure ratio corresponding to reference conditions QI/P (20C) .......................................................................................

-2,00

Creep factor for gasket at 20C (gc) ...................................................................................................................................................

-1,00

Numerical constant c1 (eq. 4a) ................................................................................................................................................

-0,0

Thermal conductivity (alphaG) at 20C ...............................................................................................................................

W/mK

0,0

Reference inside gasket diameter (dG1)ref .........................................................................................................................

mm

50,0

Reference outside diameter (dG2)ref .......................................................................................................................

mm

90,0

Reference gasket width (bGt)ref .........................................................................................................................................

mm

40,0

Reference gasket thickness (eG)ref ............................................................................................................................

mm

2,0

Reference pressure (Pref) ..................................................................................................................................................

barg

40,0

Nitrogen gas leak rate .................................................................................................................................

ml/min

1,0

PlantWare A/S - Skovlytoften 4, DK-2840 - Holte - Phone: +45 4547 5101 - Fax: +45 4548 5101 - info@plantware.dk - www.plantware.dk Checked by :

EN1591 ver 1.0

Project

CALCULATION OF FLANGES AND THEIR JOINTS ACCORDING TO EN 1591

Catliq Demo

Component : Flange

ID No.

Date ..................................................

16-01-2009

Time .................................................

16:39:45

Project No ........................................

264

Calculated by ....................................

Revision ............................................

Page .................................................

6/9

Bolt frabrication code .........................................................................................................................................................................

-EN/ISO 898

Bolt thread type ..................................................................................................................................................................................

-ISO M24

Number of bolts .................................................................................................................................................................................

pcs

8

Bolt nominal diameter ........................................................................................................................................................................

mm

24,00

Bolt outside diameter (dB0) ...............................................................................................................................................................

mm

24,00

Bolt effective diameter (dBe) .............................................................................................................................................................

mm

21,20

Bolt shank diameter (dBs) .................................................................................................................................................................

mm

22,10

Thread mean diameter (dB2) ............................................................................................................................................................

mm

22,05

Thread pitch (pt) ................................................................................................................................................................................

mm

3,00

Bolt axial dimension (LB - figure 2) ....................................................................................................................................................

mm

576,2

Bolt axial diemnsion (LS - figure 2) ....................................................................................................................................................

mm

100,0

Nominal stress area for single bolt (As) ............................................................................................................................................

mm

353,0

Nominal stress area for all bolt (AB) ..................................................................................................................................................

mm

2823,9

Plastic torsion modulus for single bolt (IB) ........................................................................................................................................

mm

2494,5

Flexibility modulus for all bolts (XB) ...................................................................................................................................................

1/mm

0,207

Bolt material code ..............................................................................................................................................................................

-EN10269

Bolt material class .............................................................................................................................................................................

-NA

Bolt material grade ............................................................................................................................................................................

-C35E +N

Bolt material number .........................................................................................................................................................................

-1.1181

Bolt material type ...............................................................................................................................................................................

-Other

Heat treatment ...................................................................................................................................................................................

-N

Minimum tensile strength at room temperature (Rm) ........................................................................................................................

N/mm

500,0

Proof strength at room temperature (Rp02) ......................................................................................................................................

N/mm

300,0

Elongation after fracture (A) ..............................................................................................................................................................

%

20,0

Reduction in area after fracture (Z) ...................................................................................................................................................

%

-Impact energy (ISO-V) (KV) ..............................................................................................................................................................

J

27,0

Material strength properties

Min

Max

500

C

Si

Mn

P

S

N

Cr

Cu

Mo

Nb

Ni

Ti

W

0,3200

0,0000

0,5000

0,0000

0,0000

0,0000

0,0000

0,0000

0,0000

0,0000

0,0000

0,0000

0,0000

0,3900

0,4000

0,8000

0,0350

0,0350

0,0000

0,4000

0,0000

0,1000

0,0000

0,4000

0,0000

0,0000

450

Stress value [N/mm]

Elements

Rm

Rp02

Ret

400

350

300

250

200

150

100

50

50

100 150

200 250 300 350 400

Tem perature [C]

450

500

PlantWare A/S - Skovlytoften 4, DK-2840 - Holte - Phone: +45 4547 5101 - Fax: +45 4548 5101 - info@plantware.dk - www.plantware.dk Checked by :

EN1591 ver 1.0

Project

CALCULATION OF FLANGES AND THEIR JOINTS ACCORDING TO EN 1591

Catliq Demo

Component : Flange

ID No.

Date ..................................................

16-01-2009

Time .................................................

16:39:45

Project No ........................................

264

Calculated by ....................................

Revision ............................................

Page .................................................

7/9

Bolting up method ..............................................................................................................................................................................

Wrench. Torque measuring

Bolting up model ................................................................................................................................................................................

General

Surface conditions ..............................................................................................................................................................................

Smooth lubricated surface (0,10 to 0,15)

Friction coefficient under nut or bolt head (myn) ................................................................................................................................

-0,130

Friction coefficient on thread (myt) .....................................................................................................................................................

-0,000

Mean contact diameter under nut or bolt head (dn) ...........................................................................................................................

mm

20,80

Mean contact diameter on thread (dt) ................................................................................................................................................

mm

14,40

Scatter of initial bolt load of a single bolt (eps1+) ...............................................................................................................................

-0,070

Scatter of initial bolt load of a single bolt (eps1-) ................................................................................................................................

-0,070

Systematic error due to inaccuracy of bolt tightening (Ks) .................................................................................................................

-0,018

Scatter for the global load of all bolts (eps+) ......................................................................................................................................

-0,036

Scatter for the global load of all bolts (eps-) .......................................................................................................................................

-0,036

Nominal torque applied to tighten bolt (Mt,nom) .................................................................................................................................

Nm

45725

Nominal twisting moment on bolt shanks (MtB,nom) .........................................................................................................................

Nm

11925

Nominal bolt assembly force (FB0nom) .............................................................................................................................................

N

200000

Minimum bolt assembly force inclusive scatter (FB0min) ..................................................................................................................

N

192788

Maximum bolt assembly force inclusive scatter (FB0max) ................................................................................................................

N

207212

Required bolt assembly force (FB0req) ..............................................................................................................................................

N

145223

Max allowable assembly force (FB0all) ..............................................................................................................................................

N

282391

PlantWare A/S - Skovlytoften 4, DK-2840 - Holte - Phone: +45 4547 5101 - Fax: +45 4548 5101 - info@plantware.dk - www.plantware.dk Checked by :

EN1591 ver 1.0

Project

CALCULATION OF FLANGES AND THEIR JOINT ACCORDING TO EN 1591

Catliq Demo

Component : Flange

ID No.

First flange

Date ..................................................

16-01-2009

Time .................................................

16:39:45

Project No ........................................

264

Calculated by ....................................

Revision ............................................

Page .................................................

8/9

Load point ..........................................................................................................................................................................................

0

1

2

3

4

Load description ................................................................................................................................................................................

-Bolting Up Operation

Test

Load condition ...................................................................................................................................................................................

-Assembly Operation

Test

Internal pressure (Pi) .........................................................................................................................................................................

barg

1,0

325,0

550,0

External pressure (Pe) .......................................................................................................................................................................

barg

0,0

0,0

0,0

Temperature (T) ................................................................................................................................................................................

C

20,0

400,0

20,0

Additional external axial force (FA) ....................................................................................................................................................

N

0,0

0,0

0,0

Additional external moment (MA) ......................................................................................................................................................

Nm

0,0

0,0

0,0

Bolt temperature (TB) ........................................................................................................................................................................

C

20,0

400,0

20,0

Flange temperature (TF) ...................................................................................................................................................................

C

20,0

400,0

20,0

Temperature loose flange (TL) ..........................................................................................................................................................

C

20,0

400,0

20,0

Gasket temperature (TG) ..................................................................................................................................................................

C

20,0

400,0

20,0

Min. tensile strength at 20C (RmS) ..................................................................................................................................................

N/mm

760,0

760,0

760,0

Min tensile strength at design temp (RetS) .......................................................................................................................................

N/mm

0,0

0,0

0,0

0,2% yield stress at design temp. (Rp02S) .......................................................................................................................................

N/mm

380,0

260,0

380,0

Safety factor for shell material (SS) ...................................................................................................................................................

-1,5

1,5

1,5

Nominal stress for shell material (fS) ................................................................................................................................................

N/mm

253,3

173,3

253,3

Min. tensile strength at 20C (RmF) ..................................................................................................................................................

N/mm

570,0

570,0

570,0

Min tensile strength at design temp. (RetF) .......................................................................................................................................

N/mm

0,0

0,0

0,0

0,2% yield stress at design temp. (Rp02F) ........................................................................................................................................

N/mm

445,0

253,0

445,0

Safety factor for flange material (SF) ................................................................................................................................................

-2,4

1,5

2,4

Nominal stress for flange material (fF) ..............................................................................................................................................

N/mm

253,3

173,3

253,3

Min tensile strength at 20C (RmB) ...................................................................................................................................................

N/mm

500,0

500,0

500,0

Min tensile strength at design temp. (RetB) ......................................................................................................................................

N/mm

0,0

0,0

0,0

0,2% yield stress at design temp (Rp02B) ........................................................................................................................................

N/mm

300,0

173,0

300,0

Safety factor for bolt material (SB) ....................................................................................................................................................

-3,0

3,0

2,0

Nominal stress for bolt material (fB) ..................................................................................................................................................

N/mm

100,0

57,7

150,0

Axial compliance YG (eq. 46) ............................................................................................................................................................

-9,57E-06

1,14E-05

9,57E-06

Axial compliance YQ (eq. 47) ............................................................................................................................................................

-1,76E-06

2,04E-06

1,76E-06

Axial complianceYR (eq. 48) .............................................................................................................................................................

-1,76E-06

2,04E-06

1,76E-06

Min gasket force FGmin (eq. 49/50) .................................................................................................................................................

N

78169

96203

78169

Min gasket force FGd (eq. 51) ...........................................................................................................................................................

N

78188

145223

89038

Bolt assembly force (FG0) .................................................................................................................................................................

N

145209

145209

145209

Req. assembly force (FG0req) ..........................................................................................................................................................

N

145223

145223

145223

Nominal assembly force (FB0nom) ...................................................................................................................................................

N

200000

200000

200000

Minimum assembly force (FB0min) ...................................................................................................................................................

N

192788

192788

192788

Maximum assembly force (FB0max) .................................................................................................................................................

N

207212

207212

207212

Bolt load ratio B (eq.71) ..................................................................................................................................................................

-0,522

0,805

0,324

Gasket load ratio G (eq.72) ............................................................................................................................................................

-0,353

0,303

0,190

Flange load ratio F (eq 73) .............................................................................................................................................................

-0,000

0,000

0,000

Blank flange load ratio F (eq.85) .....................................................................................................................................................

----Blank flange load ratio x (eq.87) .....................................................................................................................................................

----Loose flange load ratio L (eq.89) ....................................................................................................................................................

----Allowable load ratio max .................................................................................................................................................................

-0,950

0,950

0,950

Minimum value of eF (eq. A.1) ..........................................................................................................................................................

mm

12,99

13,15

12,99

Load point admissibility valid .............................................................................................................................................................

-OK

OK

OK

PlantWare A/S - Skovlytoften 4, DK-2840 - Holte - Phone: +45 4547 5101 - Fax: +45 4548 5101 - info@plantware.dk - www.plantware.dk Checked by :

EN1591 ver 1.0

Project

CALCULATION OF FLANGES AND THEIR JOINT ACCORDING TO EN 1591

Catliq Demo

Component : Flange

ID No.

Second flange

Date ..................................................

16-01-2009

Time .................................................

16:39:45

Project No ........................................

264

Calculated by ....................................

Revision ............................................

Page .................................................

9/9

Load point ..........................................................................................................................................................................................

0

1

2

3

4

Load description ................................................................................................................................................................................

-Bolting Up Operation

Test

Load condition ...................................................................................................................................................................................

-Assembly Operation

Test

Internal pressure (Pi) .........................................................................................................................................................................

barg

1,0

325,0

550,0

External pressure (Pe) .......................................................................................................................................................................

barg

0,0

0,0

0,0

Temperature (T) ................................................................................................................................................................................

C

20,0

400,0

20,0

Additional external axial force (FA) ....................................................................................................................................................

N

0,0

0,0

0,0

Additional external moment (MA) ......................................................................................................................................................

Nm

0,0

0,0

0,0

Bolt temperature (TB) ........................................................................................................................................................................

C

20,0

400,0

20,0

Flange temperature (TF) ...................................................................................................................................................................

C

20,0

400,0

20,0

Temperature loose flange (TL) ..........................................................................................................................................................

C

20,0

400,0

20,0

Gasket temperature (TG) ..................................................................................................................................................................

C

20,0

400,0

20,0

Min. tensile strength at 20C (RmS) ..................................................................................................................................................

N/mm

760,0

760,0

760,0

Min tensile strength at design temp (RetS) .......................................................................................................................................

N/mm

0,0

0,0

0,0

0,2% yield stress at design temp. (Rp02S) .......................................................................................................................................

N/mm

380,0

260,0

380,0

Safety factor for shell material (SS) ...................................................................................................................................................

-1,5

1,5

1,5

Nominal stress for shell material (fS) ................................................................................................................................................

N/mm

253,3

173,3

253,3

Min. tensile strength at 20C (RmF) ..................................................................................................................................................

N/mm

570,0

570,0

570,0

Min tensile strength at design temp. (RetF) .......................................................................................................................................

N/mm

0,0

0,0

0,0

0,2% yield stress at design temp. (Rp02F) ........................................................................................................................................

N/mm

445,0

253,0

445,0

Safety factor for flange material (SF) ................................................................................................................................................

-2,4

1,5

2,4

Nominal stress for flange material (fF) ..............................................................................................................................................

N/mm

253,3

173,3

253,3

Min tensile strength at 20C (RmB) ...................................................................................................................................................

N/mm

500,0

500,0

500,0

Min tensile strength at design temp. (RetB) ......................................................................................................................................

N/mm

0,0

0,0

0,0

0,2% yield stress at design temp (Rp02B) ........................................................................................................................................

N/mm

300,0

173,0

300,0

Safety factor for bolt material (SB) ....................................................................................................................................................

-3,0

3,0

2,0

Nominal stress for bolt material (fB) ..................................................................................................................................................

N/mm

100,0

57,7

150,0

Axial compliance YG (eq. 46) ............................................................................................................................................................

-9,57E-06

1,14E-05

9,57E-06

Axial compliance YQ (eq. 47) ............................................................................................................................................................

-1,76E-06

2,04E-06

1,76E-06

Axial complianceYR (eq. 48) .............................................................................................................................................................

-1,76E-06

2,04E-06

1,76E-06

Min gasket force FGmin (eq. 49/50) .................................................................................................................................................

N

78169

96203

78169

Min gasket force FGd (eq. 51) ...........................................................................................................................................................

N

78188

145223

89038

Bolt assembly force (FG0) .................................................................................................................................................................

N

145209

145209

145209

Req. assembly force (FG0req) ..........................................................................................................................................................

N

145223

145223

145223

Nominal assembly force (FB0nom) ...................................................................................................................................................

N

200000

200000

200000

Minimum assembly force (FB0min) ...................................................................................................................................................

N

192788

192788

192788

Maximum assembly force (FB0max) .................................................................................................................................................

N

207212

207212

207212

Bolt load ratio B (eq.71) ..................................................................................................................................................................

-0,522

0,805

0,324

Gasket load ratio G (eq.72) ............................................................................................................................................................

-0,353

0,303

0,190

Flange load ratio F (eq 73) .............................................................................................................................................................

-0,000

0,000

0,000

Blank flange load ratio F (eq.85) .....................................................................................................................................................

----Blank flange load ratio x (eq.87) .....................................................................................................................................................

----Loose flange load ratio L (eq.89) ....................................................................................................................................................

----Allowable load ratio max .................................................................................................................................................................

-0,950

0,950

0,950

Minimum value of eF (eq. A.1) ..........................................................................................................................................................

mm

12,99

13,15

12,99

Load point admissibility valid .............................................................................................................................................................

-OK

OK

OK

PlantWare A/S - Skovlytoften 4, DK-2840 - Holte - Phone: +45 4547 5101 - Fax: +45 4548 5101 - info@plantware.dk - www.plantware.dk Checked by :

You might also like

- Generic QMS TemplateDocument62 pagesGeneric QMS Templatemadodandembe100% (1)

- CAESAR II Flange CalcDocument8 pagesCAESAR II Flange CalcDavid Fonseca100% (1)

- Asme B 31J SifDocument6 pagesAsme B 31J SifVineesh Vs100% (1)

- TH255C Engine CAT PartsDocument134 pagesTH255C Engine CAT PartsKevine KhaledNo ratings yet

- Pratical Physics by DR Giasuddin Ahmed and MD Shahabuddin WWW Euelibrary ComDocument74 pagesPratical Physics by DR Giasuddin Ahmed and MD Shahabuddin WWW Euelibrary ComAntony George80% (15)

- Catalogo AGMADocument52 pagesCatalogo AGMAAndres Yentleman100% (1)

- New Standard For FRP PipingDocument37 pagesNew Standard For FRP PipingKamatchi NathanNo ratings yet

- X2 2100 Ar X2 2500 Ar PDFDocument113 pagesX2 2100 Ar X2 2500 Ar PDFtepys9112No ratings yet

- Flange Leakage CheckingDocument25 pagesFlange Leakage CheckingAMRUTA PATIL100% (1)

- Kellogg Equivalent Pressure Method For Piping FlangesDocument4 pagesKellogg Equivalent Pressure Method For Piping FlangesLucky Jaswal0% (1)

- ASME Section I and Section VIII-FundamentalsDocument52 pagesASME Section I and Section VIII-Fundamentalsmirzacogo100% (1)

- Flange Leakage - NC 3658.3Document4 pagesFlange Leakage - NC 3658.3gharsallah mounaNo ratings yet

- ASME Code Calculations For Companion FlangesDocument9 pagesASME Code Calculations For Companion FlangesKamlesh DalavadiNo ratings yet

- Air Cooler Piping Stress Analysis Using Caesar IIDocument5 pagesAir Cooler Piping Stress Analysis Using Caesar IIsemin prsesNo ratings yet

- GE Adv Gas Turb Mats and Coatings Ger3569gDocument30 pagesGE Adv Gas Turb Mats and Coatings Ger3569gjcarella_1No ratings yet

- 1) Design Data: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4rd EditionDocument6 pages1) Design Data: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4rd Editionsouren1975No ratings yet

- API 617 - E8 PADocument5 pagesAPI 617 - E8 PADavidGomezNo ratings yet

- (Welding) MIG-MAG Welding Guide - Lincoln Electric (Ebook, 48 Pages)Document48 pages(Welding) MIG-MAG Welding Guide - Lincoln Electric (Ebook, 48 Pages)Ahmad Arafa100% (10)

- AutoPipe Sustained Stress Calc B31.3Document2 pagesAutoPipe Sustained Stress Calc B31.3curvedbrainNo ratings yet

- Stress Sample Calculation On Base EllDocument1 pageStress Sample Calculation On Base EllLionel TorradoNo ratings yet

- Sisu 320-420-620-634 ManualDocument114 pagesSisu 320-420-620-634 ManualAlex100% (6)

- AGMADocument58 pagesAGMAsandeep580% (5)

- Senior Flexonics Expansion JointsDocument93 pagesSenior Flexonics Expansion JointssunethbabuNo ratings yet

- Loads On FlangesDocument16 pagesLoads On Flangesccoollest100% (3)

- Synthesis of Alum LabDocument6 pagesSynthesis of Alum LabAshraar DuaNo ratings yet

- Power Plant BasicsDocument80 pagesPower Plant Basicssandipchavan1280% (25)

- Taylor Forge - Modern Flange Design Bulletin 502Document53 pagesTaylor Forge - Modern Flange Design Bulletin 502bobnms86% (7)

- Thermosiphon ReboilersDocument7 pagesThermosiphon Reboilerssj_scribd100% (1)

- 04 - Local Coordinate SystemDocument18 pages04 - Local Coordinate Systemerikoh100% (2)

- Flange Leakage Evaluation Based On NC 3658 PDFDocument3 pagesFlange Leakage Evaluation Based On NC 3658 PDFkaruna346No ratings yet

- Pipe Stress Analysis by Computer CAESAR II PDFDocument11 pagesPipe Stress Analysis by Computer CAESAR II PDFAbhijeetNo ratings yet

- ASME VIII Flange CalculationDocument15 pagesASME VIII Flange Calculationmadodandembe100% (2)

- Heat Input CalculationDocument2 pagesHeat Input CalculationmadodandembeNo ratings yet

- QSI & QSB, 15, 20, 25, 30, 40, & 50 HP Version N Parts ManualDocument73 pagesQSI & QSB, 15, 20, 25, 30, 40, & 50 HP Version N Parts Manualgsinkovich100% (5)

- Virtual Anchor Length - KBRDocument22 pagesVirtual Anchor Length - KBRSammar Adhikari100% (2)

- Piping Stress Analysis Pipeline System in Offshore PlatformDocument2 pagesPiping Stress Analysis Pipeline System in Offshore Platformgpskumar22100% (1)

- GRP Stress AnalysisDocument13 pagesGRP Stress AnalysisCarlos Luis Esquerdo MarcanoNo ratings yet

- Powertrak 750 Illustrated Parts Catalog Revision 1.6Document188 pagesPowertrak 750 Illustrated Parts Catalog Revision 1.6andrew stables100% (1)

- Concrete Making MaterialsDocument55 pagesConcrete Making Materialsjaffna100% (1)

- Local Stress Analysis by Chris HinnantDocument52 pagesLocal Stress Analysis by Chris Hinnantjohnnyr_5100% (4)

- SMI - World Market For Clad Plate - Contents and Sample PagesDocument29 pagesSMI - World Market For Clad Plate - Contents and Sample PagesDurjoy ChakrabortyNo ratings yet

- Manual Skoda Octavia 1,9 96kW ASZDocument68 pagesManual Skoda Octavia 1,9 96kW ASZCornea Horatiu Sebastian100% (1)

- Load Case CAESAR IIDocument6 pagesLoad Case CAESAR IIshakasspNo ratings yet

- Forged Steel Gate Valve CalculationsDocument20 pagesForged Steel Gate Valve CalculationsMahendra PatilNo ratings yet

- Flange Calculations As Per en 1591.Document44 pagesFlange Calculations As Per en 1591.Shijumon Kp100% (3)

- Engine PartsTH414C GC, TH417C GC 4.4 Engine - CAT - Parts Nov2016Document160 pagesEngine PartsTH414C GC, TH417C GC 4.4 Engine - CAT - Parts Nov2016Malinda100% (1)

- Static Analysis of Piping SystemsDocument37 pagesStatic Analysis of Piping SystemsLeandro Vargas100% (1)

- Chapter 17 - Spontaneity, Entropy, and Free Energy: Answer: CDocument34 pagesChapter 17 - Spontaneity, Entropy, and Free Energy: Answer: C鄭子玄No ratings yet

- CT3 44 - CT3 37 Maquina DieselDocument67 pagesCT3 44 - CT3 37 Maquina DieselSaMos AdRiian100% (1)

- Work Instruction - Expansion Joint Modelling in CAESAR IIDocument11 pagesWork Instruction - Expansion Joint Modelling in CAESAR IIChanNo ratings yet

- Taller3 Modeling Concepts in Buried Pipe AnalysisDocument29 pagesTaller3 Modeling Concepts in Buried Pipe AnalysisFSAAVEDRAF100% (1)

- Carrier Parts CatalogDocument72 pagesCarrier Parts CatalogfjaristizabalNo ratings yet

- Analysis of Bolted JointDocument9 pagesAnalysis of Bolted Jointmario_gNo ratings yet

- Stress Analysis of GRP-GRE-FRP PipingDocument4 pagesStress Analysis of GRP-GRE-FRP PipingHmd MokhtariNo ratings yet

- NC3658 Flange CheckDocument2 pagesNC3658 Flange CheckvsvineeshNo ratings yet

- Calculation Bases of EN 1591-1 MethodDocument8 pagesCalculation Bases of EN 1591-1 Methodmechengg01100% (1)

- 2stress ManualDocument259 pages2stress ManualArup Mahanta100% (2)

- Mechanical Engineering News: For The Power, Petrochemical and Related Industries December, 1997Document24 pagesMechanical Engineering News: For The Power, Petrochemical and Related Industries December, 1997AnkithNo ratings yet

- Product Catalogue SomefluDocument20 pagesProduct Catalogue SomefluIlkuNo ratings yet

- A Finite Element-Based InvestigationDocument7 pagesA Finite Element-Based InvestigationSteve IpNo ratings yet

- Flange Leakage L&TDocument48 pagesFlange Leakage L&Tmidnightcowboy100% (1)

- Multi Layer Pressure VesselsDocument8 pagesMulti Layer Pressure VesselsprivatehomeNo ratings yet

- 13B-2 E5 PADocument4 pages13B-2 E5 PAMichel Dorian VargasNo ratings yet

- AGMA - Catalog of Technical Publications 1990 - 2003Document50 pagesAGMA - Catalog of Technical Publications 1990 - 2003danieloq1No ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 135292-0169-02Document65 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 135292-0169-02Alejandro UllesNo ratings yet