Professional Documents

Culture Documents

Inverted Pendulum Systems: Rotary and Arm-Driven A Mechatronic System Design Case Study

Uploaded by

Wan Nizam Wan SulaimanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inverted Pendulum Systems: Rotary and Arm-Driven A Mechatronic System Design Case Study

Uploaded by

Wan Nizam Wan SulaimanCopyright:

Available Formats

INVERTED PENDULUM SYSTEMS: ROTARY AND ARM-DRIVEN A MECHATRONIC SYSTEM DESIGN CASE STUDY Kevin Craig Shorya Awtar

Department of Mechanical Engineering, Aeronautical Engineering and Mechanics Rensselaer Polytechnic Institute, Troy, NY12180, USA

Abstract: The inverted pendulum, a popular mechatronic application, exists in many different forms. The common thread among these systems is their goal: to balance a link on end using feedback control. Two challenging inverted pendulum systems are the rotational and arm-driven systems. The system described in this paper can be transformed from the rotational to the arm-driven configuration by replacing the links and setting the base on its side. It was designed and built by students as part of the course Mechatronic System Design at Rensselaer. This paper presents a complete mechatronic system design case study for this inverted pendulum system.

1. INTRODUCTION: MECHATRONICS AT RENSSELEAR Mechatronics is the synergistic combination of mechanical engineering, electronics, control systems and computers. The key element in mechatronics is the integration of these areas through the design process. The essential characteristic of a mechatronics engineer and the key to success in mechatronics is a balance between two sets of skills: modeling / analysis skills and experimentation / hardware implementation skills. Synergism and integration in design set a mechatronic system apart from a traditional, multidisciplinary system. Mechanical engineers are expected to design with synergy and integration and professors must now teach design accordingly. Rensselaer - the nations first technological university - was founded in 1824. A nonsectarian, coeducational private university, it is home to five schools -- Architecture, Engineering, Humanities and Social Sciences, Lally School of Management and Technology, and Science -- as well as the interdisciplinary faculty of Information Technology. Rensselaer enrolls more than 9,600 undergraduates, graduate students, and working professionals at

campuses in Troy, New York and Hartford, Connecticut, and through distance learning opportunities around the world. With 2600 students, Rensselaer's School of Engineering offers one of the largest undergraduate engineering programs of any private university in the country. In recent years Rensselaer has been consistently ranked among the top 20 engineering teaching and research universities in the United States. Undergraduate engineering education at Rensselaer consists of two phases: an interdisciplinary core curriculum during the first two years, with instruction from various departments, followed by the disciplinary curriculum implemented by an individual department. The Department of Mechanical Engineering, Aeronautical Engineering & Mechanics (ME, AE & M) at Rensselaer offers bachelors, masters, and doctoral degrees in the three disciplines represented in the name. The department awards over 200 bachelor, 80 master, and 20 doctoral degrees per year, the major portion of which are mechanical engineering degrees. In the department there are presently two senior-elective courses in the field of mechatronics, which are also open to graduate students: Mechatronics, offered in the fall semester, and Mechatronic System Design, offered in

the spring semester. In both courses, emphasis is placed on a balance between physical understanding and mathematical formalities. The key areas of study covered in both courses are: 1. 2. 3. 4. 5. Mechatronic system design principles Modeling, analysis, and control of dynamic physical systems Selection and interfacing of sensors, actuators, and microcontrollers Analog and digital control electronics Real-time programming for control

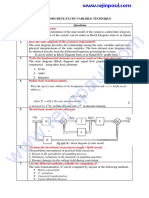

Figure 1 shows a diagram of the procedure for a dynamic system investigation which emphasizes this balance. Here the physical system can be an actual device or system that one needs to understand and possibly improve, or it can represent a concept being evaluated in the design process. Engineers can no longer evaluate each design concept by building and testing; it is too costly and time consuming. They must rely on modeling and analysis and previous hardware experience to evaluate each design concept with the goal of building choice prototypes only. This diagram serves as a guide for the study of the various mechatronic hardware systems in the courses taught at Rensselaer. When students perform a complete dynamic system investigation of a mechatronic system, they develop modeling / analysis skills and obtain knowledge of and experience with a wide variety of analog and digital sensors and actuators that will be indispensable as mechatronic design engineers in future years. 2. INVERTED PENDULUM SYSTEM: ROTARY AND ARM-DRIVEN The inverted pendulum is a popular mechatronic application that exists in many different forms. The common thread among these systems is their goal: to balance a link on end using feedback control. Two rather challenging inverted pendulum systems are the rotational and the arm-driven systems. These use a link rotating about an axis to balance a second link on end. In the rotary (horizontal) configuration, the first link, driven by a motor, rotates in the horizontal plane to balance a pendulum link, which rotates freely in the vertical plane. The arm-driven (vertical) or stick-on-a-stick configuration uses a driven link rotating in the vertical plane to balance the pendulum

Mechatronics covers the fundamentals in these areas through integrated lectures and laboratory exercises, while Mechatronic System Design focuses on the application and extension of the fundamentals through a design, build, and test experience. Throughout the coverage, the focus is kept on the role of the key mechatronic areas of study in the overall design process and how these key areas are integrated into a successful mechatronic system design. In mechatronics, balance is paramount. The essential characteristic of a mechatronics engineer and the key to success in mechatronics is a balance between two skill sets: 1. Modeling (physical and mathematical), analysis (closed-form and numerical simulation), and control design (analog and digital) of dynamic physical systems; and Experimental validation of models and analysis (for computer simulation without experimental verification is at best questionable, and at worst useless), and an understanding of the key issues in hardware implementation of designs.

2.

Measurements, Calculations, Manufacturer's Specifications

Model Parameter Identification

Which Parameters to Identify? What Tests to Perform?

Physical System

Physical Model

Mathematical Model

Physical Laws Equation Solution: Analytical and Numerical Solution

Experimental Analysis

Assumptions and Engineering Judgement

Model Inadequate: Modify

Actual Dynamic Behavior

Compare

Predicted Dynamic Behavior

Modify or Augment

Make Design Decisions

Model Adequate, Performance Inadequate

Model Adequate, Performance Adequate

Design Complete

Figure 1: Dynamics System Investigation Process

link, which also rotates in the vertical plane. The inverted pendulum system is unique in that it can be transformed from the horizontal to vertical configuration by replacing the links and setting the base on its side, as shown in Figure 2.

system investigation is presented at the Rensselear Mechatronics web site: http://www.meche.rpi.edu. 3.1 Physical System The subject of this investigation is the rotary inverted pendulum system. It consists of two links: a motordriven horizontal link and an un-actuated vertical pendulum link. The horizontal link is driven by a permanent-magnet, brushed DC motor. A DC power supply together with a pulse-width-modulated (PWM) servo-amplifier, operating in the current mode, supply power to the motor. Angular position and velocity of the two links are measured with two rotary incremental optical encoders having a resolution with quadrature decoding of 2048 pulses per revolution. A slip-ring assembly, mounted between the housing and the motor shaft, is used to connect power to the pendulum optical encoder and read the signal from the three channels of the encoder. The horizontal link is counter-weighted and there are leveling screws on the housing base. System testing for parameter identification and control system design is performed in a MatLab / Simulink / dSpace real-time control environment. This allows for rapid control system development and testing. 3.2 Physical Model Several simplifying assumptions were made in developing a physical model: 1. rigid links 2. two degrees of freedom 3. negligible sensor dynamics 3.3 Mathematical Model The Lagrange method was used to derive the equations of motion for the system. The generalized coordinates for the system are the angular displacements of the driven link () and the pendulum link (). When the pendulum is balanced and the driven link is centered, both and are zero. The nonlinear equations of motion are:

2 2 m1 11 + I1z1 + m 2 1 + m 2 2 2 + I2z 2 sin + I2y 2 cos [ m 2 1 21 cos ] + [ m 2 1

Figure 2: Inverted Pendulum System Configurations: (a) Horizontal and (b) Vertical The complete mechatronic system design includes design concept generation, mechanical / electromechanical dynamic analysis, simulation of system dynamics, component selection and fabrication, electronic hardware and transducer selection and interfacing, circuit design and wiring, software design, system parameter identification and verification, and finally, controller design, swing-up and balance, and implementation. 3. ROTARY INVERTED PENDULUM DYNAMIC SYSTEM INVESTIGATION Highlights of the complete dynamic system investigation are presented. The complete dynamic

2 21

sin 2 + sin ] 2 + 21

+ I2 + m 2 z2

2 21

I2y 2 ( 2 cos sin ) = T Tf

m2 + m2

2 21 2 21

+ I2x 2 [ m 2

1 21

cos ]

I2y 2 + I2z 2 ( cos sin ) 2 + m 2g 21 sin = Tf

The linearized equations of motion (about the operating point = = 0) are given by:

m1

2 11

+ I1z1 + m 2

2 21

2 1

+ I2y 2 + [ m 2

1 21

1 21

] + = T B

21

q1 =

q2 = 1

q3 =

q4 = 0 0 q C3 0 1 q2 C1C3 C 2 2 + [T] 1 q3 0 q C 2 0 4 2 C1C3 C 2

m2

+ I2x 2 [ m 2

] + m2g

2 1

= B

Define:

C1 = m1 C2 = m2 C3 = m 2

2 11

+ I1z1 + m 2 + I2x 2

+ I2y 2

1 21 2 21

C4 = m2 g

0 q1 q 0 2 = q3 0 q 4 0

0 C 2 C 4 0 C1C3 C2 2

0 C1C4 0 C1C3 C2 2

21

The linearized equations of motion can then be written as:

C1 + C 2 + = T B C 3 + C 2 C 4 = B

3.4 Control System Design: Balancing and Swing-Up A MatLab / Simulink block diagram of the control system design is shown in Figures 3 and 4. The swing-up control is based on the work of Astrom and Furuta (1996) and the balancing controller is a fullstate-feedback regulator. The swing up controller calculates the total system energy based on the kinetic energy of both links, and the potential energy of the pendulum. This calculated value is compared to a defined quantity of energy when the pendulum is balanced. The difference between desired energy and actual energy is multiplied by an "aggressivity" gain and applied to the motor.

The transfer functions (neglecting damping terms) are: C3 s 2 C 4 = 2 2 T s ( C1C3 C2 ) s 2 C1C4 C 2 s 2 = 2 T s 2 ( C1C3 C 2 ) s 2 C1C 4 The state-space equations (neglecting damping terms) are:

Rotary Inverted Pendulum: Swing-Up Control and Balancing Control

alpha alpha theta theta

theta

Arm Angle

Normalized Arm Angle

theta_N theta_N Mux Demux theta_dot theta_dot alpha_N alpha_N Mux Demux1 alpha_dot alpha_dot control_torque

Normalization - Arm Angle

theta_dot Torque alpha Pendulum Angle Normalized Pendulum Angle

alpha_dot

Normalization - Pendulum Angle

Rotary IP Nonlinear Model

Pendulum Angle Normalized Sw ing-Up Control Control Torque

control_torque Torque Sat

States Total System Energy

K Matrix Gain1

-1

Balancing Control

Control Selection: Swing-up vs. Balance

System Energy energy

0.1 Desired System Energy Sum cos cos (alpha)

5 Gain Multiply Clock Multiply Sign

system energy time time

Figure 3. MatLab / Simulink Block Diagram of Control System Design

1 Pendulum Angle Normalized

0.43633 -0.43632

0.34907 -0.34907 1 Control Torque

0 Zero 2 Swing-Up Control Limit Switch + or - 25 degrees 3 Balancing Control Limit Switch + or - 20 degrees

Control Selection: Swing-up vs. Balance

Figure 4. MatLab / Simulink Block Diagram of the Control Selection Subsystem

To simplify the calculations, the balanced, stationary position of the inverted pendulum is defined to be at zero energy level. The objective of the swing-up control exercise is to move the system from the stable equilibrium position to the unstable equilibrium position. Hence, energy has to be added to the system to achieve this swing-up action. The manipulated input to realize the above idea is given by the following control law:

V = K A ( E EO ) sign ( cos )

A

"Horizon"

motion

Vo

Vo

The first two terms in the above control law are the "agressivity" gain and the difference between actual and desired system energy. These two terms provide the magnitude of energy that has to be added to the system at any given time. The "agressivity" gain determines what proportion of the available input will be used to increase or decrease the system energy. This gain could be the difference in swinging the pendulum up in 5 or 50 oscillations. The second half of the energy swing up equation determines the direction the input should be applied to increase the energy of the system. The velocity term causes the input to change directions when the pendulum stops and begins to swing in the opposite direction. The cosine term is negative when the pendulum is below horizontal and positive above horizontal. This helps the driven link to get under the pendulum and catch it as shown in Figure 5. By controlling on energy feedback, the system automatically stops inputting excess energy and allows the system to coast to a balanced position. From Figure 6, when the remaining potential energy required is equal to the kinetic energy, the feedback will become very small and the pendulum will coast to vertical position.

"Horizon"

motion

Figure 5. Sign function effect on swing up

motion

Figure 6. Swing up diagram

By setting the desired energy to a value greater than zero, unmodeled energy dissipation effects can be overcome as the pendulum is approaching its balanced point. If this is too much, the pendulum will overshoot and the driven link will not be able to catch it. The switching between the controllers has a dead-band of 5. When the pendulum is within 25 of vertical, the swing up controller will turn off. If the pendulum coasts to within 20 of vertical, the balance controller will be activated and the driven link will attempt to catch the pendulum. If the balance controller is not successful, the pendulum will fall and the swing up algorithm will automatically engage. Figures 5 and 6 show the simulation results for the swing-up and balance controllers. The angles plotted are normalized angles.

2. Development of a commercial smaller version of the rotary inverted pendulum system including microcontroller control implementation. The commercial prototype is shown in Figure 7.

Rotary IP Swing-Up + Balance Control: Pendulum Angle vs. Time 4 3 2 1 0 -1 -2 -3 -4

Figure 7. Commercial Version of the Rotary Inverted Pendulum System

REFERENCES Astrom, K.J. and K. Furuta (1996). Swinging Up A pendulum By Energy Control. IFAC 13th World Congress, San Francisco, California.

0.5

1.5

2.5 3 Time (sec)

3.5

4.5

Figure 5. Normalized pendulum angle versus time

Rotary IP Swing-Up + Balance Control: Driven Link Angle vs. Time 4 3 2 1 0 -1 -2 -3 -4

0.5

1.5

2.5 3 Time (sec)

3.5

4.5

Figure 6. Normalized driven link angle versus time

4. CONTINUING WORK There are two ongoing projects that are continuations of this work: 1. Development of the swing-up and balancing controller for the arm-driven inverted pendulum system.

You might also like

- Inverted PendulumDocument18 pagesInverted PendulumLingxi HuangNo ratings yet

- Inverted PendulumDocument4 pagesInverted PendulumFerbNo ratings yet

- Modeling An Inverted PendulumDocument45 pagesModeling An Inverted Pendulumjunaid_honey83896770% (1)

- Abstract. The Balancing of An Inverted Pendulum byDocument5 pagesAbstract. The Balancing of An Inverted Pendulum byFariz AhdiatamaNo ratings yet

- Sliding Mode Control Strategy For A 6 DOF Quadrotor HelicopterDocument7 pagesSliding Mode Control Strategy For A 6 DOF Quadrotor HelicopternaderjsaNo ratings yet

- Arpita Thesis 1Document186 pagesArpita Thesis 1Aparajita SenguptaNo ratings yet

- A Robust Optimal Sliding-Mode Control Approach For Magnetic Levitation SystemsDocument8 pagesA Robust Optimal Sliding-Mode Control Approach For Magnetic Levitation Systemsankurgoel1975No ratings yet

- Attitude Control of A QuadrotorDocument6 pagesAttitude Control of A QuadrotorGhada BeydounNo ratings yet

- System Simulation Using Matlab, State Plane PlotsDocument7 pagesSystem Simulation Using Matlab, State Plane PlotsmosictrlNo ratings yet

- Inverted PendulumDocument71 pagesInverted PendulumShruti100% (1)

- CONTROL THEORY EXERCISES AND SOLUTIONSDocument183 pagesCONTROL THEORY EXERCISES AND SOLUTIONSFrancesco Vasturzo100% (1)

- Inverted PendulumDocument25 pagesInverted PendulumNassim DoukhiNo ratings yet

- Reaction Wheel Pendulum ProjectDocument85 pagesReaction Wheel Pendulum ProjectAnanth Vishwanath100% (1)

- 1 Flexible Link ProjectDocument15 pages1 Flexible Link Projectprasaad08No ratings yet

- Nonlinear Model & Controller Design For Magnetic Levitation System-IsPRADocument5 pagesNonlinear Model & Controller Design For Magnetic Levitation System-IsPRAIshtiaq AhmadNo ratings yet

- Estimate ARX model parametersDocument14 pagesEstimate ARX model parametersJoãoEdgarNo ratings yet

- Modeling and Simulation of Sensorless Control of PMSM With Luenberger Rotor Position Observer and Sui Pid ControllerDocument8 pagesModeling and Simulation of Sensorless Control of PMSM With Luenberger Rotor Position Observer and Sui Pid ControllerYassine MbzNo ratings yet

- Inverted PendulamDocument34 pagesInverted PendulamVi JayNo ratings yet

- Installation LeviDocument32 pagesInstallation Levihenrry342No ratings yet

- OUFTI-1 - ADCS - Attitude Control System PDFDocument101 pagesOUFTI-1 - ADCS - Attitude Control System PDFRobin CookNo ratings yet

- Inverted Pendulum On Cart SolutionDocument8 pagesInverted Pendulum On Cart SolutionMario R. KallabNo ratings yet

- Designing A Neuro PD With Gravity Compensation For Six Legged RobotDocument8 pagesDesigning A Neuro PD With Gravity Compensation For Six Legged RobotVishwanath KetkarNo ratings yet

- ECE1647 NonlinearControlDocument138 pagesECE1647 NonlinearControlfyahyaie100% (1)

- Inverted PendulumDocument73 pagesInverted PendulumDheeraj GaddiNo ratings yet

- Fuzzy Controller Design Using LQR Fusion For Magnetic Levitation SystemDocument6 pagesFuzzy Controller Design Using LQR Fusion For Magnetic Levitation Systemijsret100% (1)

- Modeling, Implementation, Simulation and Comparison of Different Control Theories On A Two Wheel Self Balancing Robot Model in SimulinkDocument5 pagesModeling, Implementation, Simulation and Comparison of Different Control Theories On A Two Wheel Self Balancing Robot Model in SimulinkMario CavazosNo ratings yet

- Lyapunov Stability Theory - LTI SystemsDocument19 pagesLyapunov Stability Theory - LTI SystemsAnith KrishnanNo ratings yet

- 3 Inverted Pendulum ProjectDocument26 pages3 Inverted Pendulum ProjectJoshua D JohnNo ratings yet

- 03 LagrangianDynamics 1Document28 pages03 LagrangianDynamics 1Terence DengNo ratings yet

- 1978 - Stable Adaptive Controller Design-Direct Control (Narendra)Document14 pages1978 - Stable Adaptive Controller Design-Direct Control (Narendra)ademargcjuniorNo ratings yet

- Modeling and Position Control of Mobile RobotDocument6 pagesModeling and Position Control of Mobile RobotAmin EslamiNo ratings yet

- Fuzzy Logic Automatic Braking System in TrainsDocument10 pagesFuzzy Logic Automatic Braking System in Trainsvaalgatamilram100% (1)

- Inverted Pendulum Control System DesignDocument36 pagesInverted Pendulum Control System Designstephanie-tabe-1593No ratings yet

- DYNAMIC MODELLING AND CONTROL OF A 3-DOF PLANAR PARALLEL ROBOTIC (XYthetaZ MOTION) PLATFORMDocument10 pagesDYNAMIC MODELLING AND CONTROL OF A 3-DOF PLANAR PARALLEL ROBOTIC (XYthetaZ MOTION) PLATFORMVinoth VenkatesanNo ratings yet

- Stability: Control Engineering and Signal Processing Michala Srnová 2009/2010Document12 pagesStability: Control Engineering and Signal Processing Michala Srnová 2009/2010srnkaNo ratings yet

- HW1Document11 pagesHW1Tao Liu YuNo ratings yet

- Updated Self Balancing Report (F16mte28)Document25 pagesUpdated Self Balancing Report (F16mte28)Shahrukh Aleem JhatialNo ratings yet

- DC Motor State Space ModelDocument5 pagesDC Motor State Space ModelSelaRajNo ratings yet

- Bibliography Report Quadrotor Control MethodsDocument47 pagesBibliography Report Quadrotor Control MethodsPablo Fernández de la Granja100% (2)

- Spatial Mechanisms Lecture NotesDocument77 pagesSpatial Mechanisms Lecture NotesErico Eric100% (1)

- 06 UkfDocument40 pages06 UkfAmit ParasharNo ratings yet

- Mathematical Model of Inverted Pendulum SystemDocument18 pagesMathematical Model of Inverted Pendulum SystemMajid Mehmood100% (1)

- Two-degree-of-freedom mass-damper-spring system linear dynamicsDocument2 pagesTwo-degree-of-freedom mass-damper-spring system linear dynamicsReinaldy MaslimNo ratings yet

- Extended State Observer Based ControllerDocument5 pagesExtended State Observer Based ControllerD.Viswanath50% (2)

- Unit I - Discrete State-Variable Technique Q.No Questions: Scalar Adder IntegratorDocument184 pagesUnit I - Discrete State-Variable Technique Q.No Questions: Scalar Adder IntegratorAgatha ChristieNo ratings yet

- Control System Development For Small UAV GimbalDocument113 pagesControl System Development For Small UAV GimbalJulian Camilo Alba GilNo ratings yet

- Control of Magnetic Levitation SystemDocument15 pagesControl of Magnetic Levitation SystemordekNo ratings yet

- Self Balancing With Pid ControlDocument7 pagesSelf Balancing With Pid Controlengrumar100% (1)

- Guidance, Navigation and Control of Fixed-Wing Unmanned Aerial VehiclesDocument13 pagesGuidance, Navigation and Control of Fixed-Wing Unmanned Aerial VehiclesBHAVESH JOSHINo ratings yet

- PLL - Thesis Final VersionDocument50 pagesPLL - Thesis Final VersionDjameleddine BougrineNo ratings yet

- Spacecraft Attitude Control: A Linear Matrix Inequality ApproachFrom EverandSpacecraft Attitude Control: A Linear Matrix Inequality ApproachNo ratings yet

- System Modeling: PRESSENTED BY:-Er. Saurabh MalpotraDocument36 pagesSystem Modeling: PRESSENTED BY:-Er. Saurabh MalpotraCr ZyNo ratings yet

- A Framework For Integrated Design of Mechatronic SystemsDocument34 pagesA Framework For Integrated Design of Mechatronic SystemsSaulo FigliuoloNo ratings yet

- Mechatronics Course SyllabusDocument17 pagesMechatronics Course Syllabusnikhilrane91_7522800No ratings yet

- Mechatronics WikiDocument4 pagesMechatronics WikibekkuNo ratings yet

- 6565 Ijmme Ijens PDFDocument17 pages6565 Ijmme Ijens PDFعلي كامل الاسديNo ratings yet

- RIET Student's Mechatronics AbstractDocument2 pagesRIET Student's Mechatronics AbstractChandan AgarwalNo ratings yet

- Mechatronics Lecture on Classification and Design Flow of Mechatronic SystemsDocument9 pagesMechatronics Lecture on Classification and Design Flow of Mechatronic SystemsRosiana RahmaNo ratings yet

- PUP Mechanical Engineering Quiz on Machine Elements ConceptsDocument15 pagesPUP Mechanical Engineering Quiz on Machine Elements ConceptsQuen CuestaNo ratings yet

- AKG00346Document12 pagesAKG00346Akshaya AgarwalNo ratings yet

- 322439480MVR Single Page Single Page Booklet - OPTDocument12 pages322439480MVR Single Page Single Page Booklet - OPTlarry vargas bautistaNo ratings yet

- FHM Espana 2010 12 PDFDocument2 pagesFHM Espana 2010 12 PDFBrandenNo ratings yet

- Niryana Shoola DasaDocument7 pagesNiryana Shoola DasaSuryasukraNo ratings yet

- Lession Plan - MIDocument21 pagesLession Plan - MINithya SannidhiNo ratings yet

- 1B Cosmos-Standard - Technical - Guide - v40Document45 pages1B Cosmos-Standard - Technical - Guide - v40carla deiddaNo ratings yet

- Tiger 690 Conversion PDFDocument8 pagesTiger 690 Conversion PDFGerardo Esteban Lagos RojasNo ratings yet

- INChO 2008 Question PaperDocument23 pagesINChO 2008 Question PaperChaitanya GaurNo ratings yet

- Diff Types of Transmission Lines Used in CommsDocument9 pagesDiff Types of Transmission Lines Used in CommsLe AndroNo ratings yet

- Prom 2Document3 pagesProm 2arvindNo ratings yet

- Hydraulic Power Steering System Design PDFDocument16 pagesHydraulic Power Steering System Design PDFAdrianBirsan100% (1)

- Diabetic Safe - One Pager - Version 1.0 - Oct 20Document2 pagesDiabetic Safe - One Pager - Version 1.0 - Oct 20naval730107No ratings yet

- The LM393Document2 pagesThe LM393mayron vasquezNo ratings yet

- 10 01 Breather Filters GBDocument8 pages10 01 Breather Filters GBosuengNo ratings yet

- Kathleen Langreo Notes FB (Feb6)Document27 pagesKathleen Langreo Notes FB (Feb6)Kaycee Ayo100% (4)

- Service Manual: EQ1030T47D-820 Light Commercial TruckDocument175 pagesService Manual: EQ1030T47D-820 Light Commercial TruckYonny ColqueNo ratings yet

- Ficha Tecnica Cat. Bard 36kbtu Act.Document15 pagesFicha Tecnica Cat. Bard 36kbtu Act.Jehison M Patiño TenorioNo ratings yet

- Margot's Cafe MenuDocument1 pageMargot's Cafe Menumichael_burns_24No ratings yet

- Type 2 Diabetes MellitusDocument6 pagesType 2 Diabetes MellitusJoy NisoladaNo ratings yet

- Motor Cat 924HZDocument6 pagesMotor Cat 924HZAdemilson Rangelvieira100% (1)

- Ex Ophtalmo Eng 1Document4 pagesEx Ophtalmo Eng 1Roxana PascalNo ratings yet

- Makalah Bahasa Inggris - Narrative TextDocument21 pagesMakalah Bahasa Inggris - Narrative TextFenny KartikaNo ratings yet

- Dell Precision Workstations: The #1 Workstations in The WorldDocument7 pagesDell Precision Workstations: The #1 Workstations in The WorldDiego RodriguezNo ratings yet

- Polycab HT XlpeDocument33 pagesPolycab HT Xlpezafrikhan875No ratings yet

- Reconsilation of Major Materials Steel SDA Lattice Ribs Rockbolts Admixture Etc.Document99 pagesReconsilation of Major Materials Steel SDA Lattice Ribs Rockbolts Admixture Etc.Rajat SharmaNo ratings yet

- Pd3c CV Swa (22kv)Document2 pagesPd3c CV Swa (22kv)เต่า วีไอNo ratings yet

- Terminal BlockDocument12 pagesTerminal BlockAlmaforNo ratings yet

- 1296169395JH 122310 - WebDocument12 pages1296169395JH 122310 - WebCoolerAdsNo ratings yet

- 1 s2.0 S2214860417301148 Main PDFDocument16 pages1 s2.0 S2214860417301148 Main PDFQuy Hoang KimNo ratings yet

- Data Sheet ID FanDocument5 pagesData Sheet ID FanrudiawanNo ratings yet

- Delay-Tolerant NetworksDocument66 pagesDelay-Tolerant NetworksMegi YantoNo ratings yet