Professional Documents

Culture Documents

Modeling and Position Control of Mobile Robot

Uploaded by

Amin EslamiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modeling and Position Control of Mobile Robot

Uploaded by

Amin EslamiCopyright:

Available Formats

Modeling and Position Control of Mobile Robot

P K Padhy, Takeshi Sasaki , Sousuke Nakamura and Hideki Hashimoto

Institute of Industrial Science, The University of Tokyo

4-6-1 Komaba, Meguro-ku, Tokyo, Japan, 153-8505

Abstract-This paper presents a new approach for stable

tracking of non-holonomic wheeled mobile robot using PID

controller. The major objective of the paper is to propose a

control rule to find out reasonable target linear and rotational

velocities of the mobile robot. The method requires the

information about the position (Cartesian space and orientation)

of the mobile robot which can be obtained by any kind of

positioning system. In the approach, the mobile robot, including

the actuator dynamics is identified by a linear model using

recursive least square method. The identified model is then used

to design the PID controller to set the target linear and rotational

velocities. Simulation and experimental studies are presented to

validate the theoretical findings.

I. INTRODUCTION

Despite the advanced controllers, PI/PID controllers are still

used for the path-tracking problem, which is concerned with

the ability to drive a mobile robot autonomously as close as

possible to a planed path. The controller should generate

commands to guide the robot to follow a desired path

accurately. Tracking errors of mobile robots cause collisions

with obstacles due to deviations from the planned path and also

cause the robot to fail to achieve the target successfully.

Tracking error can be reduced through feedback control. Many

control strategies has been proposed for the path tracking

problem based on kinematic model or dynamic model or the

integration of both [1-7]. Kanayama [8] presented the

decomposition of error between the reference and current

posture by PID filtering. Lingli Yu et al.[9] also proposed a

fuzzy immune based PID controller for non-holonomic mobile

robot. They focused on the error convergence and system

stability. But, the motion smoothness can be improved because

of robust controller design. Guerra et al. [10] proposed a

method for the linear modeling of the robot measuring linear

displacement and orientation of the robot. However, the

measurement of displacement may cause error.

In this work a linearized model for mobile robots is

identified from the knowledge of Cartesian coordinates and

orientation of mobile robot. The gains of the PID controller are

then tuned based on the identified model. Recursive least

square method [11] is used for the identification of the linear

model which will avoid the non-linearity, commonly adopted

for non-holonomic mobile robots.

This paper is organized as follows. Section II describes

about the position control used for mobile robot. The proposed

modeling of the considered robot and the control system design

are given in section III and IV, respectively. The method is

illustrated by simulation and experimental results in Section V.

Finally, conclusion is given in section VI.

II. POSITION CONTROL

The posture control loop tracks the flow of reference

postures from the path planner by generating the control

variables and v for the velocity control loop. The error

vector is computed from current posture (

c c c

y x and , ) and

the reference posture (

r r r

y x and , ) as shown in figure 1 by

=

=

+ =

) (

sin ) ( cos ) (

sin ) ( cos ) (

c r

c r c r y

c r c r x

e

x x y y e

y y x x e

(1)

This transformation generates the distances that vehicle

should travel in the forward, lateral and angular directions,

respectively. The control input to the mobile robot can be

represented as translational velocity ( v ) and rotational velocity

( ) that can be obtained by using PID controller as

x

x

dx x Ix x px

v

dt

de

k dt e k e k v = + + =

(2)

+ = + + +

+ + =

v v

dt

de

k dt e k e k

dt

de

k dt e k e k

y d I p

y

dy y Iy y py

(3)

In this case, it is assumed that mobile robot has three control

inputs

v v v

y x

and , and can be represented by

(

(

(

=

(

v

v

v

v

y

x

1 1 0

0 0 1

(4)

III. MODELS FOR DIFFERENTIAL DRIVE MOBILE ROBOT

The model of open-loop system in order to design a controller

is key factor to achieve a satisfactory closed loop performance.

The robot has, driven by two electric motors and the wheels are

placed at each side of the robot, in such a position that their

rotation axis is synchronized. The robot configuration is

represented by the position of the center of the axis between

the two wheels in the Cartesian space (x and y) and by its

orientation, .

The 11th IEEE International Workshop on

Advanced Motion Control

March 21-24, 2010, Nagaoka, Japan

978-1-4244-6669-6/10/$26.00 2010 IEEE 100

Figure 1: Coordinate system of the mobile robot

The kinematic model relates the derivatives of robot position

(x and y) and orientation ( ) with the robot linear and angular

speeds, and v , without taking its movement into

consideration:

(

(

(

(

=

(

(

(

v

y

x

.

1 0

0 sin

0 cos

&

&

&

(5)

Using [12], the dynamic model of the mobile robot that

includes the actuator dynamics (electric and mechanical

characteristics of the motors), friction and robot dynamics

(movement equations) can be expressed as

BU AV V + =

&

(6)

where R M A

1

= , K M B

1

= and [ ]

T

v V = .

[ ]

r l

e e U = contains the input signals applied to the left

and right motors, K is the matrix which transforms the

electrical signals U into forces to be generated by the robot

wheels, M is the inertia matrix and R is the damping matrix.

The complete robot model, obtained from the union of (5) and

(6), can be represented by the following state equation:

(

(

(

(

+

(

(

(

(

(

(

(

(

(

(

(

(

(

(

=

(

(

(

(

(

(

r

L

e

e

y

x

v

y

x

v

0

B

0

0 A

.....

.

1 0

0 sin

0 cos

.... .......... ..........

&

&

&

&

&

(7)

(

(

(

(

(

(

(

(

(

=

(

(

(

y

x

v

y

x

y

1 0 0 0 0

0 1 0 0 0

0 0 1 0 0

(8)

The armature tension to the mobile robot depends on the

velocity command given. Hence, one can assume

)

`

r r

l l

v e

v e

(9)

where

r l

v v and are the velocities given to left and right

wheels, respectively. For a non-holonomic mobile robot, it

gives

d

v v v v

v

r L r L

=

+

= and

2

where d is the

distance between the wheels and rearranged as

(

=

(

v

d

d

v

v

r

L

2 / 1

2 / 1

(10)

Use of (4), (9) and (10) gives

(

(

(

=

(

v

v

v

d d

d d

e

e

y

x

r

L

2 / 2 / 1

2 / 2 / 1

(11)

Substituting (11) in (7), the state equation can be represented

as

(

(

(

(

(

(

+

(

(

(

(

(

(

(

(

(

(

(

(

(

(

=

(

(

(

(

(

(

v

v

v

y

x

v

y

x

v

y

x

0

B

0

0 A

.....

~

.

1 0

0 sin

0 cos

.... .......... ..........

&

&

&

&

&

(12)

Equations (8) and (12) give the state space model of the mobile

robot. It is clear from (12) that, the model is non-linear in

nature because of sin and cosine terms. However, for small arc,

the non-linear terms can be approximated as

= sin and 1 cos . Therefore, the model (8) and (12)

became linear with outputs , , y x and inputs

v v v

y x

, , as

shown in figure 2. The choice velocities as inputs helps to

retune the controller parameters online when required. Three

decentralizes controller can be designed based on the model

identified.

reference path

current position

reference position

x

e y

e

e

c

x

r

x

r

y

c

y

r

X

r

Y

X

Y

101

Fig.2 System block diagram

For estimation, the state space model can be converted to linear

transfer function model. The continuous transfer matrix of the

model can be found as

(

(

(

(

(

(

=

(

(

(

) (

) (

) (

) ( ) ( ) (

) ( ) ( ) (

) ( ) ( ) (

) (

) (

) (

33 32 31

23 22 21

13 12 11

s V

s V

s V

s G s G s G

s G s G s G

s G s G s G

s

s Y

s X

y

x

(13)

The above model is a three input three output system and can

be identified the equivalent diagonal transfer matrix to design

three decentralized controller for three loops. The model

structure is

(

(

(

(

(

(

=

(

(

(

) (

) (

) (

) ( 0 0

0 ) ( 0

0 0 ) (

) (

) (

) (

3

2

1

s V

s V

s V

s G

s G

s G

s

s Y

s X

y

x

(14)

where

) ( ) (

) (

) (

i i

s

p

i

i

i

b s a s

e K

s U

s O

s G

i

+

= =

3 , 2 , 1 = i (15)

At first, three discrete transfer functions for three loops are

identified using least square recursive algorithm [11]. The form

of the transfer function is assumed as

) )( 1 ( ) (

) (

) (

i i

i i

i

i

i

l z k z

e z d

z U

z O

z G

+

+

= = (16)

Thereafter, the discrete transfer function is converted to

continuous form as given in (15) to design three PID

controllers for three loops using internal model based PID

controller.

IV. CONTROLLER DESIGN

The IMC principle relies on the internal model principle

where the control scheme is developed based on the exact

model of the process. However, process model mismatch is

common in practice due to unknown disturbance and

measurement noise. The structure of IMC scheme is shown in

figure 3.

The closed loop transfer function for IMC structure is

( )

( )

)] ( ) ( ) ( [

) ( ) ( ) ( 1

) ( 1

) (

) ( ) ( ) ( 1

) (

) (

2 1

s d s d s G

s G s G s G

s G G

s R

s G s G s G

s G G

s Y

IMC

IMC

IMC

IMC

+

+

+

+

=

(18)

Therefore, perfect set-point tracking and disturbance

rejection can be achieved if ) ( ) ( s G s G = . However, the

robustness can be improved if the effect of model mismatch is

minimized. Since the discrepancies between the process and

the model behavior usually occur at the high frequency, a low

pass filter is used along with IMC controller to reduce the

effect of process-model mismatch. So, the IMC controller is

designed as

) ( ) ( ) (

1

s G s f s G

IMC

= (19)

where, ) 1 /( 1 ) ( + = s s f is a low pass filter that reduces

the effect of process-model mismatch with proper design of

. Using first order Tylor series for the approximation of

delay and [13], the identified process model given in (15) can

be written as

) )( (

) 1 (

) (

b as s

s K

s G

i p

+ +

+

=

(20)

where, is very small. In this work, 01 . 0 = is chosen. As

per the principle of IMC controller design, the process model is

represented by invertible and non-invertible components

) )( (

) (

b as s

K

s G

p

I

+ +

=

(21)

1 + = s G

i NI

(22)

where, the non-invertible component

NI

G contains the

terms (positive zeros and time delays) which if inverted, will

lead to instability and realisable problem. Then the IMC

controller is

) 1 (

) )( (

) ( ) ( ) (

1

+

+ +

= =

s K

b as s

s G s f s G

p

I IMC

(23)

Mobile

robot

Cx

Cy

C

X

Y

-

-

-

v

e

x

e

y

e

v

x

v

y

v

Xr

Yr

r

+

Fig. 3 Structure for IMC scheme

) (s G

+

+

r

+

-

e

u

) (s G

y

+

-

2

d

) (s G

IMC

+

+

1

d

102

Now the IMC controller structure (figure 3) is redrawn in

figure 4 to design a PID controller. The form of the PID

controller is assumed as

|

|

\

|

+

+

+ =

|

|

\

|

+

+

+ =

s

K

s T

s K

K

s T s T

s T

K C

I

f

d

c

I f

d

c PID

1

1

1

1 (24)

Where s T T

d f

1 . 0 = is the derivative filter constant and

neglected during analysis. Referring to Fig. 4, the IMC

controller is transform to PID controller

[ ] ) 1 ( ) 1 (

) )( (

) ( 1

) (

+ +

+ +

=

=

s s K

b as s

s G G G

s G

C

i p NI I IMC

IMC

PID

Rearranging, it gives

|

|

\

|

+

+

+

+

+

+

=

s K

b

s

K

a

K

b a

s C

i p i p i p

PID

) ( ) ( ) (

) (

) (

(25)

Comparison of (24) and (25) gives

) ( ) ( ) (

) (

i p

I

i p

d

i p

c

K

b

K

K

a

K

K

b a

K

+

=

+

=

+

+

= (26)

The only unknown in the last equation is the filter constant,

. The optimal value of is chosen based on the system

response.

V. RESULTS

The results presented in this section were obtained using the

mobile robot (Black Ship) with two wheels driven by two

independent DC motors in the experimental room. The inputs

signals

v v v

y x

and , are the velocities given to mobile robot.

The system output

T

c c c

y x y ] [ = is measured by dead

reckoning technique. The Recursive Least Squares method [11]

is utilized for the estimation of the parameters of the models

given in (16) and then converted into continuous transfer

function models. Three transfer function models are identified

for three loops (x, y and -loop). Table 1 shows the identified

models and the corresponding PID controller for 1 = .

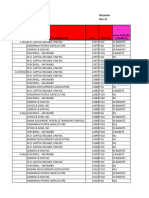

Table1: Model and controller parameters

) (

1

s G

) 22 . 0 53 . 0 (

) 1 02 . 0 ( 451 . 1

+

+

s s

s

s s

s 0015 . 0

035 . 0 1

35 . 0

152 . 0 +

+

+

) (

2

s G

) 192 . 0 68 . 0 (

) 1 023 . 0 ( 551 . 1

+

+

s s

s

s s

s 0012 . 0

042 . 0 1

42 . 0

125 . 0 +

+

+

) (

3

s G

) 3052 . 0 44 . 0 (

) 1 021 . 0 ( 52 . 1

+

+

s s

s

s s

s 002 . 0

028 . 0 1

28 . 0

199 . 0 +

+

+

The true and estimated parameters and estimation errors of

model identification for x-loop, y-loop and -loop are shown

in figures 5, 6 and 7, respectively.

Fig 5(a): True and estimated parameters for x-loop

Fig 5(b): Error curve for x-loop

0 10 20 30 40 50 60

10

-4

10

-3

10

-2

10

-1

10

0

Error curvex

Samples

E

r

r

o

r

v

a

l

u

e

5 10 15 20 25 30 35 40 45 50 55 60

-0.8

-0.7

-0.6

-0.5

-0.4

-0.3

-0.2

-0.1

System outputx

Samples

T

r

u

e

a

n

d

e

s

t

i

m

a

t

e

d

o

u

t

p

u

t

y

) (s G

r

+

-

e u

) (s G

IMC

d

+

+ +

+

) (s G G

NI I

C

PID

(s)

Fig. 4 IMC-PID structure

103

Fig 6(a): True and estimated parameters for y-loop

Fig 6(b): Error curve for y-loop

Fig 7(a): True and estimated parameters for -loop

Fig 7(b): Error curve for -loop

0 10 20 30 40 50 60 70 80

-1

-0.5

0

0.5

1

1.5

2

Time in seconds

E

r

r

o

r

s

xerror

yerror

therror

Fig 8(a): path errors of the mobile robot

-0.5 0 0.5 1 1.5 2 2.5 3 3.5

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

x-coordinate

y

-

c

o

o

r

d

in

a

t

e

measured

reerencef

Fig 8(b): Mobile robot tracking

It is observed from figures 5(b), 6(b) and 7(b) that the

model estimation errors for each loop are in acceptable range

indicating the accuracy of the identification. The proposed

algorithm is applied to an elliptical path. In the beginning, the

reference and current position of mobile robot are

( 2 / 0 0 ) and ( 0 0 0 ), respectively. The experimental

results of the mobile robot are shown in figure 8. It is

0 10 20 30 40 50 60 70 80

10

-3

10

-2

10

-1

10

0

Error curver

Samples

E

r

r

o

r

v

a

l

u

e

20 30 40 50 60 70 80

-0.6

-0.5

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

System outputr

Samples

T

r

u

e

a

n

d

e

s

t

i

m

a

t

e

d

o

u

t

p

u

t

0 10 20 30 40 50 60

10

-4

10

-3

10

-2

10

-1

10

0

Error curvey

Samples

E

r

r

o

r

v

a

l

u

e

5 10 15 20 25 30 35 40 45 50 55 60

0.35

0.4

0.45

0.5

0.55

0.6

0.65

0.7

System outputy

Samples

T

r

u

e

a

n

d

e

s

t

i

m

a

t

e

d

o

u

t

p

u

t

104

observed that the robot starts with offset from the desired

path. However, the errors are converging to zero quickly.

VI. CONCLUSIONS

A new approach for the path tracking of a non-holonomic

mobile robot is proposed. The linear modeling of the mobile

robot considering

v v v

y x

and , as inputs helps to adjust the

PID controller gains in a simple way. The controller gains can

also be adjusted adaptively during the path tracking of the

mobile robot. So, the algorithm can improve the controller

quality by eliminating the error using only the Cartesian space

and orientation of mobile robot. The proposed approach has

been verified using the mobile robot (Black Ship).

REFERENCES

[1] J. E.Normey-Rico, I. Alcal!a, J. G!omez-Ortega and E. F. Camacho,

Mobile robot path tracking using a robust PID controller Control

Engineering Practice,vol.9, pp. 1209-1214, 2001.

[2] W. Weiguo, C. Huitang; W Yuejuan; Back stepping design for path

tracking of mobile robots, Proc. of IEEE/RSJ International Conference

on Intelligent Robots and Systems, vol 3, pp: 1822 1827, Oct. 1999.

[3] J. P. Hwang and E. Kim, Robot tracking control of an electrically

Driven robot: Adaptive fuzzy logic approach, IEEE transaction on fuzzy

system, vol.14,No.2, pp232-247, Apr. 2006.

[4] C. Hua, X. Guan, and P. Shi, robot output feedback tracking control for

time-delay nonlinear systems using neural network, IEEE transactions

on neural networks, vol.18, no.2, pp. 495-505, March, 2007.

[5] C. Lin, Q. G Wang, and T. H. Lee, Output tracking control for nonlinear

systems via T-S Fuzzy model approach, IEEE transaction on system,

man and cybernetics-part B: Cybernetics vol. 36, No.2, pp. 450-457,

April 2006.

[6] R. Fierro, F. L. Lewis, Control of a Nonholonomic mobile Robot Using

Neural Networks, IEEE transactions on neutral network, vol. .9, no.4,

pp. 589-590, July, 1998.

[7] T. Fukao, H Nakagawa, N. Adachi, adaptive tracking control of

nonholonomic mobile robot, IEEE transitions on robotics and

automation, vol. 16, no.5, pp. 609-615, Oct.2000.

[8] Y. Kanayama, A locomotion control method for autonomous vehicles,

Proc. IEEE Intl. Conf. on Robotics and Automation, pp. 1315-1317,

1988.

[9] L. Yu, Z. Cai, Z. Jiang and Q. Hu, An Advanced Fuzzy Immune PID-

type Tracking Controller of a Nonholonomic Mobile Robot,

Proceedings of the IEEE International Conference on Automation and

Logistics, pp 18 - 21, 2007.

[10] P N. Guerra, P. J. Alsina, A. A. D. Medeiros, and A. P. Araujo. Linear

modelling and identification of a mobile robot with differential drive,

International Conference on Informatics in Control, Automation and

Robotics, 2004.

[11] R Johansson, System Modeling and Identification, Prentice Hall, Inc.,

Englewood Cliffs, NJ,1993.

[12] M. M. Yamamoto, D. P. F. Pedrosa, and A. A. D. Medeiros, Um

simulador dinamico para mini robos moveis com modelagem de colises,

SBAI -Simposio Brasileiro de Automacao Inteligente, Brazil, 2003.

[13] M. Shamsuzzoha, and M. Lee. PID controller design for integrating

processes with time delay, Korean J. Chem. Eng., vol. 25, no. 4, pp.

637-645, 2008.

105

You might also like

- Spacecraft Attitude Control: A Linear Matrix Inequality ApproachFrom EverandSpacecraft Attitude Control: A Linear Matrix Inequality ApproachNo ratings yet

- Designing A Neuro PD With Gravity Compensation For Six Legged RobotDocument8 pagesDesigning A Neuro PD With Gravity Compensation For Six Legged RobotVishwanath KetkarNo ratings yet

- Dynamic Mobile Robot Paper 1Document6 pagesDynamic Mobile Robot Paper 1pgamasterNo ratings yet

- LQR FeedforwardDocument20 pagesLQR Feedforwardsri248No ratings yet

- Inverted Pendulum On Cart SolutionDocument8 pagesInverted Pendulum On Cart SolutionMario R. KallabNo ratings yet

- A Motion ControlDocument6 pagesA Motion ControlRonald CaravacaNo ratings yet

- Model Predictive Control For UAVsDocument24 pagesModel Predictive Control For UAVsJulio BVNo ratings yet

- Understanding and Applying Kalman FilterDocument34 pagesUnderstanding and Applying Kalman FilterNahom GirmaNo ratings yet

- MEE1045 - MECHATRONICS-SYSTEMS-DESIGN - EPJ - 1.0 - 49 - MEE1045 Mechatronics Systems Design PDFDocument2 pagesMEE1045 - MECHATRONICS-SYSTEMS-DESIGN - EPJ - 1.0 - 49 - MEE1045 Mechatronics Systems Design PDFSathish SatNo ratings yet

- Dynamic System Modelling and ControlDocument761 pagesDynamic System Modelling and ControlDr-Nancy Ahmed100% (1)

- ECE1647 NonlinearControlDocument138 pagesECE1647 NonlinearControlfyahyaie100% (1)

- Fundamentals of Mechatronics Short CourseDocument3 pagesFundamentals of Mechatronics Short CourseAamir Hasan KhanNo ratings yet

- Mo Phong Matlab Ball and BeamDocument52 pagesMo Phong Matlab Ball and BeamHuong NguyenNo ratings yet

- Advance Control SystemDocument3 pagesAdvance Control Systemcoep05100% (1)

- Practical guide to solving real-life optimal control problemsDocument39 pagesPractical guide to solving real-life optimal control problemschaitanya_awast9336No ratings yet

- T7 - State Feedback Analysis and Design - 2021Document35 pagesT7 - State Feedback Analysis and Design - 2021James ChanNo ratings yet

- ESO Based LQR Controller For Ball and Beam System PDFDocument4 pagesESO Based LQR Controller For Ball and Beam System PDFRemus PopescuNo ratings yet

- Advanced State Observer DesignDocument11 pagesAdvanced State Observer DesignNileshNo ratings yet

- Fuzzy Logic - Controls Concepts Theories and ApplicationsDocument428 pagesFuzzy Logic - Controls Concepts Theories and ApplicationsSchreiber_Dieses100% (3)

- Tutorial of The Bond GraphDocument22 pagesTutorial of The Bond Graphsf111No ratings yet

- 2012 Book RobotMotionAndControl2011Document425 pages2012 Book RobotMotionAndControl2011鄭至峻No ratings yet

- Abstract. The Balancing of An Inverted Pendulum byDocument5 pagesAbstract. The Balancing of An Inverted Pendulum byFariz AhdiatamaNo ratings yet

- Fundamentals of Lyapunov TheoryDocument9 pagesFundamentals of Lyapunov Theorygoitom01No ratings yet

- (Peter Van Overschee, Bart de Moor (Auth.) ) SubsDocument262 pages(Peter Van Overschee, Bart de Moor (Auth.) ) SubsMarcos HenriqueNo ratings yet

- Thesis - Robust Control of Power Electronic ConvertersDocument172 pagesThesis - Robust Control of Power Electronic ConvertersDhananjayNo ratings yet

- Balancing RobotDocument5 pagesBalancing RobotMilton MuñozNo ratings yet

- Swarm Intelligence PSO and ACODocument69 pagesSwarm Intelligence PSO and ACOKrishna Reddy KondaNo ratings yet

- 1978 - Stable Adaptive Controller Design-Direct Control (Narendra)Document14 pages1978 - Stable Adaptive Controller Design-Direct Control (Narendra)ademargcjuniorNo ratings yet

- 1.control Systems NotesDocument59 pages1.control Systems NotesmuhammadNo ratings yet

- Sliding Mode Control of DC MotorDocument5 pagesSliding Mode Control of DC MotorPham Quoc ThienNo ratings yet

- Advanced Topics in Control Systems Theory IIDocument294 pagesAdvanced Topics in Control Systems Theory IICarlosNo ratings yet

- Total NotesDocument442 pagesTotal NotesArmando MaloneNo ratings yet

- System Modelling CourseDocument15 pagesSystem Modelling CoursevinhxuannNo ratings yet

- System Simulation Using Matlab, State Plane PlotsDocument7 pagesSystem Simulation Using Matlab, State Plane PlotsmosictrlNo ratings yet

- CISE 316 Control Systems Design Lab ManualDocument78 pagesCISE 316 Control Systems Design Lab Manualnirmal_inbox100% (1)

- Sensitization Workshop On The Single Spine Pay Policy Organised by Civil Servants' AssociationDocument16 pagesSensitization Workshop On The Single Spine Pay Policy Organised by Civil Servants' Associationdugbarsteve40100% (1)

- Basic of Kalman FilterDocument20 pagesBasic of Kalman FilterWaseem AsifNo ratings yet

- Linear Matrix Inequalities in System and Control Theory - Stephen BoydDocument205 pagesLinear Matrix Inequalities in System and Control Theory - Stephen BoydMarco Antonio LealNo ratings yet

- Modeling, Implementation, Simulation and Comparison of Different Control Theories On A Two Wheel Self Balancing Robot Model in SimulinkDocument5 pagesModeling, Implementation, Simulation and Comparison of Different Control Theories On A Two Wheel Self Balancing Robot Model in SimulinkMario CavazosNo ratings yet

- LMI-Linear Matrix InequalityDocument34 pagesLMI-Linear Matrix InequalitySangramjit SarkarNo ratings yet

- Inverse Kinematic Analysis of Robot ManipulatorsDocument336 pagesInverse Kinematic Analysis of Robot ManipulatorsDebabrata PaulNo ratings yet

- Self-Balancing Robot DesignDocument39 pagesSelf-Balancing Robot DesignFatima BaigNo ratings yet

- Advances in PID ControlDocument286 pagesAdvances in PID ControlDavid GonzalezNo ratings yet

- ECE402 Quadcopter Final PaperDocument41 pagesECE402 Quadcopter Final Papernoumanscorpion100% (1)

- Extended State Observer Based ControllerDocument5 pagesExtended State Observer Based ControllerD.Viswanath50% (2)

- Adaptive ControlDocument382 pagesAdaptive ControlAnonymous QakmLc3kTINo ratings yet

- Modeling An Inverted PendulumDocument45 pagesModeling An Inverted Pendulumjunaid_honey83896770% (1)

- DC Motor State Space ModelDocument5 pagesDC Motor State Space ModelSelaRajNo ratings yet

- Nonlinear Zero Dynamics in Control SystemsDocument12 pagesNonlinear Zero Dynamics in Control SystemsAshik AhmedNo ratings yet

- MSC Thesis Comparison and Analysis of Attitude Control Systems of A Satellite Using Reaction Wheel ActuatorsDocument117 pagesMSC Thesis Comparison and Analysis of Attitude Control Systems of A Satellite Using Reaction Wheel Actuatorsnab05No ratings yet

- Adaptive Control: Presented by Harikrishna Satish.TDocument22 pagesAdaptive Control: Presented by Harikrishna Satish.THari ThotaNo ratings yet

- Introduction To Control SystemsDocument28 pagesIntroduction To Control SystemsAK MizanNo ratings yet

- Nonlinear Internal Model Control With Automotive ApplicationsDocument243 pagesNonlinear Internal Model Control With Automotive ApplicationsDieter SchwarzmannNo ratings yet

- Simulation of electric machines and drive systemsDocument17 pagesSimulation of electric machines and drive systemsSamuel Alves de SouzaNo ratings yet

- Factorization Methods for Discrete Sequential EstimationFrom EverandFactorization Methods for Discrete Sequential EstimationNo ratings yet

- Stability of Nonlinear Control SystemsFrom EverandStability of Nonlinear Control SystemsRating: 5 out of 5 stars5/5 (1)

- Engineering Optimization: An Introduction with Metaheuristic ApplicationsFrom EverandEngineering Optimization: An Introduction with Metaheuristic ApplicationsNo ratings yet

- Preventative Maintenance V1.1Document6 pagesPreventative Maintenance V1.1Amin EslamiNo ratings yet

- TCP Wireline CorrelationDocument1 pageTCP Wireline CorrelationAmin EslamiNo ratings yet

- BackOff - String Shot Schedule PDFDocument4 pagesBackOff - String Shot Schedule PDFAmin EslamiNo ratings yet

- Using The WinQSB Software in Critical Path AnalysisDocument8 pagesUsing The WinQSB Software in Critical Path AnalysisAmin EslamiNo ratings yet

- Zamin Shenasi NaftDocument6 pagesZamin Shenasi NaftAmin EslamiNo ratings yet

- Modeling and Position Control of Mobile RobotDocument6 pagesModeling and Position Control of Mobile RobotAmin EslamiNo ratings yet

- NiazeMarkazi Article 2 10000577Document5 pagesNiazeMarkazi Article 2 10000577Amin EslamiNo ratings yet

- Grade 6 Term1 Properties of 2-D Shapes Lesson 7Document4 pagesGrade 6 Term1 Properties of 2-D Shapes Lesson 7Ayanda Siphesihle NdlovuNo ratings yet

- BS 2995-1966 PDFDocument15 pagesBS 2995-1966 PDF윤규섭No ratings yet

- Wi Cswip 3.1 Part 13Document7 pagesWi Cswip 3.1 Part 13Ramakrishnan AmbiSubbiahNo ratings yet

- NCERT: Why Is Steel More Elastic Than Rubber?Document7 pagesNCERT: Why Is Steel More Elastic Than Rubber?Satyam RaiNo ratings yet

- AMCP 706-185, Military Pyrotechnics - Theory and ApplicationDocument270 pagesAMCP 706-185, Military Pyrotechnics - Theory and ApplicationASDAFF ASADNo ratings yet

- Catalogo Carbones Helwig GDE-006Document17 pagesCatalogo Carbones Helwig GDE-006Sergio HernandezNo ratings yet

- A Git Cheat Sheet (Git Command Reference) - A Git Cheat Sheet and Command ReferenceDocument14 pagesA Git Cheat Sheet (Git Command Reference) - A Git Cheat Sheet and Command ReferenceMohd AzahariNo ratings yet

- Requirements Elicitation and AnalysisDocument74 pagesRequirements Elicitation and AnalysisSadam GebiNo ratings yet

- Accelerate your career with online coursesDocument22 pagesAccelerate your career with online coursesAYEDITAN AYOMIDENo ratings yet

- Chapter 3 Step Wise An Approach To Planning Software Projects 976242065Document31 pagesChapter 3 Step Wise An Approach To Planning Software Projects 976242065RiajiminNo ratings yet

- Full Paper Template IRC 2020Document3 pagesFull Paper Template IRC 2020Mobina AbdulRaufNo ratings yet

- Energy Criteria in GRIHA PDFDocument71 pagesEnergy Criteria in GRIHA PDFAnisha Prakash100% (1)

- Ansoff Matrix Template User GuideDocument6 pagesAnsoff Matrix Template User Guidebernardo95No ratings yet

- Maintenance Recommendations: Operation and Maintenance ManualDocument10 pagesMaintenance Recommendations: Operation and Maintenance ManualAmy Nur SNo ratings yet

- Proportional Chopper Amplifier VB-3A: Min MaxDocument5 pagesProportional Chopper Amplifier VB-3A: Min MaxryujoniNo ratings yet

- Compressed Air Operated Vacuum Waste Removal: Systems and ComponentsDocument20 pagesCompressed Air Operated Vacuum Waste Removal: Systems and ComponentsDaniel RukawaNo ratings yet

- ASME - Performance Test CodesDocument1 pageASME - Performance Test CodesanoopkntpcNo ratings yet

- Operation & Service Manual For Cable Tensiometer: SeriesDocument28 pagesOperation & Service Manual For Cable Tensiometer: SeriesJonatan BernalNo ratings yet

- IMS2 Manual EngDocument61 pagesIMS2 Manual EngJhonatan BuenoNo ratings yet

- Homework1 PDFDocument3 pagesHomework1 PDFYuanhao LiuNo ratings yet

- B 2Document12 pagesB 2Mohamed Sayed Abdel GaffarNo ratings yet

- Modular Forms Exam - Homework RewriteDocument2 pagesModular Forms Exam - Homework RewritejhqwhgadsNo ratings yet

- Cork Properties Capabilities and ApplicationsDocument22 pagesCork Properties Capabilities and ApplicationsVijay AnandNo ratings yet

- Ch01Document33 pagesCh01sakali aliNo ratings yet

- No.1 PrestressedDocument10 pagesNo.1 PrestressedKristin ArgosinoNo ratings yet

- Abstract (Lab 2) Ionization ConstantDocument12 pagesAbstract (Lab 2) Ionization Constantmirdza94No ratings yet

- Analysis of Structure of C Type Hydraulic PressDocument10 pagesAnalysis of Structure of C Type Hydraulic PressShubhamNo ratings yet

- Nov. AbwDocument50 pagesNov. Abwjbyarkpawolo70No ratings yet

- Chapter 6 Basic Heat TransferDocument7 pagesChapter 6 Basic Heat TransferGabo MarquezNo ratings yet

- Brake SystemDocument19 pagesBrake SystemSudarshan NepalNo ratings yet