Professional Documents

Culture Documents

Saved Recs

Uploaded by

Rashedul IslamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saved Recs

Uploaded by

Rashedul IslamCopyright:

Available Formats

FN Thomson Reuters Web of Knowledge VR 1.0 PT J AU Robinson, PJ Luyben, WL AF Robinson, Patrick J. Luyben, William L.

TI Integrated Gasification Combined Cycle Dynamic Model: H2\S Absorption/Stripping, Water-Gas Shift Reactors, and CO2 Absorption/Stripping SO INDUSTRIAL & ENGINEERING CHEMISTRY RESEARCH LA English DT Article AB Gasification could potentially emerge as the premier unit operation in the en ergy and chemical industries. In the future, plants are predicted to be a hybrid between power and chemical with the ability to handle unavoidable swings in bot h power demand and biomass feed composition without a loss of efficiency. The co upling of a power plant with a chemical plant provides an additional control deg ree of freedom, which fundamentally improves the controllability of the process. The coupling of an integrated gasification combined cycle (IGCC) power plant wi th a methanol chemical plant handles swings in power demand by diverting hydroge n gas from a combustion turbine and syn gas from the gasifier to a methanol plan t for the production of an easily stored, hydrogen-consuming liquid product. Thi s paper presents an extension of the dynamic gasifier model, which uses a high-m olecular weight hydrocarbon (with a 1 : 1 hydrogen to carbon ratio) as a pseudobiomass feed stock. Using this gasifier model, the downstream units of a typical IGCC can be modeled in the widely used process simulator Aspen Dynamics. Dynami c simulations of the H2S absorption/stripping unit, water gas shift (WGS) reacto rs, and CO2 absorption/stripping unit are essential for the development of stabl e and agile plantwide control structures of this hybrid power/chemical plant. Be cause of the high pressure of the system, hydrogen sulfide is removed by means o f physical absorption. SELEXOL (a mixture of the dimethyl ethers of polyethylene glycol) is used to achieve a gas purity of less than 5 ppm H2S. This desulfuriz ed synthesis gas is sent to two water gas shift reactors that convert a total of 99% of carbon monoxide to hydrogen. Physical absorption of carbon dioxide with Selexol produces a hydrogen-rich stream (90 mol % H-2) to be fed into combustion turbines or to a methanol plant. Steady-state economic designs and plantwide co ntrol structures are developed in this paper. C1 [Robinson, Patrick J.; Luyben, William L.] Lehigh Univ, Dept Chem Engn, Bethl ehem, PA 18015 USA. RP Luyben, WL (reprint author), Lehigh Univ, Dept Chem Engn, Bethlehem, PA 18015 USA EM WLL0@Lehigh.edu FU Zisman Family Foundation FX Financial support for this work provided by the Zisman Family Foundation is greatly appreciated. NR 17 TC 4 Z9 4 PU AMER CHEMICAL SOC PI WASHINGTON PA 1155 16TH ST, NW, WASHINGTON, DC 20036 USA SN 0888-5885 J9 IND ENG CHEM RES JI Ind. Eng. Chem. Res. PD MAY 19 PY 2010 VL 49 IS 10 BP 4766

EP DI PG WC SC GA UT ER EF

4781 10.1021/ie901549s 16 Engineering, Chemical Engineering 593HH WOS:000277443100035

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 2022 - Hyd 443 - 1Document201 pages2022 - Hyd 443 - 1api-620585842No ratings yet

- API NotesDocument9 pagesAPI Notesking4lifeNo ratings yet

- Houston Ugm Phase Change ModelingDocument45 pagesHouston Ugm Phase Change Modelingsunilpatil.043827No ratings yet

- Medical Gas Pipeline SystemsDocument202 pagesMedical Gas Pipeline Systemsshahrul aiman100% (2)

- Fortran 77 Tutorial PDFDocument38 pagesFortran 77 Tutorial PDFDheeraj VermaNo ratings yet

- 0420 - 118T3440 - Cooling WaterDocument2 pages0420 - 118T3440 - Cooling WaterfaisalnadimNo ratings yet

- Flare Sizing Rel 1 - 1Document50 pagesFlare Sizing Rel 1 - 1Andreea AntohiNo ratings yet

- On Water Conservation by Vishwajit MitraDocument18 pagesOn Water Conservation by Vishwajit Mitravmitra8575% (12)

- Estructuras Químicas en LatexDocument84 pagesEstructuras Químicas en LatexMiguel Angel Mosquera MolinaNo ratings yet

- Basics of X-Ray Powder DiffractionDocument97 pagesBasics of X-Ray Powder DiffractionGeorgia ManikaNo ratings yet

- Basics of X-Ray Powder DiffractionDocument97 pagesBasics of X-Ray Powder DiffractionGeorgia ManikaNo ratings yet

- Basics of X-Ray Powder DiffractionDocument97 pagesBasics of X-Ray Powder DiffractionGeorgia ManikaNo ratings yet

- Solid Oxide Fuel Cell System Control in MatlabDocument54 pagesSolid Oxide Fuel Cell System Control in MatlabRashedul IslamNo ratings yet

- IIE Six Sigma Green Belt Certification Event PDFDocument1 pageIIE Six Sigma Green Belt Certification Event PDFRashedul IslamNo ratings yet

- AIChE 2013 Abstract1 May 08Document1 pageAIChE 2013 Abstract1 May 08Rashedul IslamNo ratings yet

- Omega PID TunningDocument4 pagesOmega PID TunningOwaisNo ratings yet

- Solid Oxide Fuel Cell System Control in MatlabDocument54 pagesSolid Oxide Fuel Cell System Control in MatlabRashedul IslamNo ratings yet

- Madhyajuger Bangla O BangaliDocument64 pagesMadhyajuger Bangla O BangaliRashedul IslamNo ratings yet

- RubaiyatDocument64 pagesRubaiyatRashedul IslamNo ratings yet

- How To Estimate Reid Vapor Pressure (RVP) of A BlendDocument10 pagesHow To Estimate Reid Vapor Pressure (RVP) of A BlendRashedul IslamNo ratings yet

- Cosmosac Regression PresentationDocument27 pagesCosmosac Regression PresentationRashedul IslamNo ratings yet

- PcaDocument22 pagesPcaRashedul IslamNo ratings yet

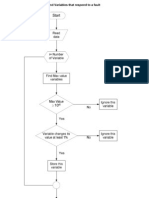

- Data Screening AlgorithmDocument1 pageData Screening AlgorithmRashedul IslamNo ratings yet

- Principal Component AnalysisDocument25 pagesPrincipal Component AnalysisRashedul IslamNo ratings yet

- PCA BiologyDocument45 pagesPCA BiologyRashedul IslamNo ratings yet

- HW 2 F 2011Document3 pagesHW 2 F 2011Rashedul IslamNo ratings yet

- ResultsDocument110 pagesResultsRashedul IslamNo ratings yet

- BCBS Health InsuranceDocument1 pageBCBS Health InsuranceRashedul IslamNo ratings yet

- Shell Standard Control ProblemDocument8 pagesShell Standard Control ProblemRashedul IslamNo ratings yet

- CS 312: Algorithm Analysis: ObjectivesDocument8 pagesCS 312: Algorithm Analysis: ObjectivesRashedul IslamNo ratings yet

- HW 8 InputDocument5 pagesHW 8 InputRashedul IslamNo ratings yet

- Z-Transforms and Transfer FunctionsDocument85 pagesZ-Transforms and Transfer FunctionsRashedul IslamNo ratings yet

- 1 States of Matter Changing States PowerpointDocument23 pages1 States of Matter Changing States PowerpointJoshua BermoyNo ratings yet

- Introduction To Manufacturing: Case Study: Thermometers-By: Bitisa KandelDocument3 pagesIntroduction To Manufacturing: Case Study: Thermometers-By: Bitisa Kandelapi-548943629No ratings yet

- Fundamentals of Refrigeration Part 1Document7 pagesFundamentals of Refrigeration Part 1Sanjay MalhotraNo ratings yet

- Cve 240-Assignment 5 - Chapter 4Document3 pagesCve 240-Assignment 5 - Chapter 4Ehab Wilson0% (1)

- CV Prop - Termof PG 518-19-20Document3 pagesCV Prop - Termof PG 518-19-20MargaritaNo ratings yet

- Ea 101Document2 pagesEa 101Najmul SaqibNo ratings yet

- Blue Book With Solution VIPDocument2 pagesBlue Book With Solution VIPMarvin MarianoNo ratings yet

- Bernoulli Chapter 3Document45 pagesBernoulli Chapter 3Izzudin HusseinNo ratings yet

- 6 QuestionDocument4 pages6 Questionمحمد مسعدNo ratings yet

- Gas Velocity CalculatorDocument10 pagesGas Velocity CalculatorTran Van ThanhNo ratings yet

- C4-State of MatterDocument171 pagesC4-State of MatterLan FazlanNo ratings yet

- BY Tamil Selvam 2282ADocument11 pagesBY Tamil Selvam 2282AKarthickNo ratings yet

- Tutorial 6Document2 pagesTutorial 6LeoThomas0% (1)

- Purified Water PDFDocument38 pagesPurified Water PDFRudi PurnamaNo ratings yet

- JP2001054556A - Atmospheric Pressure Low-Temperature Plasma Sterilization Method - Google PatentsDocument8 pagesJP2001054556A - Atmospheric Pressure Low-Temperature Plasma Sterilization Method - Google PatentsHosein HashemianNo ratings yet

- N2+o2 01.03.2023Document83 pagesN2+o2 01.03.2023anNo ratings yet

- Wellpoint: Horizontal WellpointsDocument6 pagesWellpoint: Horizontal WellpointsAbok AduogoNo ratings yet

- H408 Handout 2013 Spring Updated 07 Apr 2015wDocument11 pagesH408 Handout 2013 Spring Updated 07 Apr 2015wAbid AnuarNo ratings yet

- Hydrodynamic Simulation For Floodplain ModellingDocument34 pagesHydrodynamic Simulation For Floodplain Modellingchetan topreNo ratings yet

- Fluid and BMCDocument3 pagesFluid and BMChitkcivilNo ratings yet

- Group2 Viscosity QuestionsDocument2 pagesGroup2 Viscosity QuestionsShenlhee GesmundoNo ratings yet

- Cec 102 Lectures NoteDocument38 pagesCec 102 Lectures NoteMohammed AbdulazeezNo ratings yet

- Derivacion de La Ley de Los Gases Ideales PDFDocument2 pagesDerivacion de La Ley de Los Gases Ideales PDFDomingo KarrascalNo ratings yet