Professional Documents

Culture Documents

Used FOR: Methods I N Testing Masonry Specimens Bending, Tension, and Shear'

Uploaded by

zabrathkudOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Used FOR: Methods I N Testing Masonry Specimens Bending, Tension, and Shear'

Uploaded by

zabrathkudCopyright:

Available Formats

METHODS USED IN TESTING MASONRY SPECIMENS FOR BENDING, TENSION, AND SHEAR'

B Y h-ORMAN

W. KELCH

ABSTRACT

Twenty-four walls, 4 / feet wide, 5I/a feet high, some 8 inches and some 12 inches l2 thick, werr tested for bending alter aging sixty days and six months, respactively. It was shown that aging of lime mortar is essential. Failures in shearing stress were also due to immature mortar. Brick masonry withstands earthquake shocks when mortar is matured by aging. An outline o the more extensive tests is given. f

I. Purpose of the Investigation

Whether warranted or not, the Pacific Coast is considered by some as a district in which there is occasional earthquake activity of varying intensities and consequence. It has become the practice of some architects and engineers in certain localities to take this possible activity into consideration in the design and construction of buildings. A study of the nature of earthquake forces and their effect upon structures discloses the fact that the most damaging of the horizontal, vertical, and transverse earthquake waves is the direct horizontal wave which will be referred to herein as the earthquake. It is also found that the earthquake stress is not comparable to wind stress. In skeleton frame structures, analysis shows that the forces tending to distort the rectangular bents into rhomboids induce stresses into the walls contained within the bents which must be resisted either by shear or by compression or tension in a diagonal direction, as is accomplished in bridge or roof truss design. The earthquake stresses in the skeleton frame building are found to increase from the top story down in increments by the weights of the various stories, the earthquake stress being a function of mass times acceleration, or weight times the intensity of the earthquake. Thus in designing walls sufEciently strong to resist distortion their values must be known for compression, tension, and shear. In bearing wall buildings, the earthquake force may induce shear or direct bending in the first story, or secondary bending of the entire building as a unit. A great deal of work has been done at the Bureau of Standards and elsewhere in determining the compressive strengths of masonry. These, of course, were direct compression strengths and cannot safely be assigned to wall panels subjected to compression in a diagonal direction. Nor can the compression strengths be calculated into terms of horizontal shear

Presented at the Annual Meeting, AMERICAN CERAMIC SOCIETY, Toronto, Ont., February, 1930 (Terra Cotta Division).

125

126

KELCH

without knowing the tensile value of the masonry, or the cohesive and adhesive values of the mortar. It was for the purpose of determining the values of masonry composed of solid and hollow fired clay units in terms of bending (modulus of rupture), tension, adhesion, and cohesion of different mixtures of mortars and for values of cement-lime mortars t o steel bars, that this Institute undertook to program an elaborate series of experiments and tests in California.

11. Experiments

12 inches thick. The materials used were standard load-bearing tile, Heath cube load-bearing tile, wire-cut common brick, sand-mold common brick, laid in Arnerican bond and Flemish bond. The mortar used in the masonry was composed of 1 part Portland cement to 6 parts of a commercial ready-mixed lime mortar which supposedly contained 1 part lime to 3 parts sand according to the Los Angeles city ordinance. A contract was let for the construction of all of the walls t o be built in accordance with good job practice. They were constructed on the FIG. 1.-Transverse or bending test ground in a large room of a building apparatus. at the California Institute of Technology under the direction of Franklin Thomas and were allowed t o cure or dry in the open without protection for 60 days. The testing apparatus consisted of steel angle irons and I-beams in the shape of a yoke passing around the top and bottom of the walls at the back and loaded by pressing on bearings a t the third points of the face of the wall. The load was applied at the dead center of distributing b e a m by means of a calibrated hydraulic jack equipped with a load gage, as shown in Fig. 1. It was found that all of the walls tested, failed by the lack of adhesion of the mortar, as shown in Fig. 2. FIG.2.-Bending failure by mortar adhesion. There was little or no diffuencc between wire-cut and sand-mold brick and load-bearing tile walls of the same thickness. It was known from experience with this class of masonry a n d

Bending (Modulus wide by 5 feet 6 inches high; some 8 inches and some of Rupture)

Twenty-four walls were constructed 4 feet 6 inches

TESTING MASONRY FOR BENDING, TENSION, AND SHEAR

127

this mixture of mortar that when older buildings have been cut into it has been impossible to separate the mortar from the units as occurred in these tests. These specimens a t 60 days were therefore obviously underaged. At the age of six months sections of these walls were again tested, specimens were cut from them and an increase up to 100% for the brick walls and a higher percentage of increase for the load-bearing tile walls was found. These failures were partially by cohesion. This again confirmed the opinion that cement mortars containing lime require at least six months and undoubtedly longer for curing before being tested for values which may be considered approaching the ultimate. It is firmly believed that this will apply also to values in the direct compression strength of masonry walls wherein the tensile strength or cohesion of the mortar is an element. A number of samples were made up of three brick, one on top of Shear the other, thus having two mortar joints. After curing for two months these were tested by supporting the outer two brick and applying a load on the center brick endwise. These failures were in adhesion. Other specimens were made of six brick, being three courses high having two mortar joints which were tested similarly by supporting the two outer courses and applying a load on the center course of two brick. These failures likewise were by adhesion a t the end of two months. At the same time the walls were constructed, some specimens were assembled for direct and diagonal shear. The direct shear specimens were constructed as wallettes 21 inches long x 8 inches thick, 8 courses high. These were tested by turning the wallette on end and supporting the specimen on the 3 courses of brick each side of the center 2 courses. The load was applied on top of the 2 center courses a t the end of 2 months. The results of these tests were most erratic; some values were high and some were low, relatively speaking. The failures were by adhesion but were not confined to FIG.3.-Method of attempt to detert h e 2 m o r t a r j o i n t s in wh ich mine shear. the failure was supposed to occur. In some cases the failure stepped over as shown in Fig. 3. Upon close observation i t was determined that the failures of the specimens being tested for shear were successive failures rather than simultaneous failures. T h a t is, the failure first occurred in some local area which immediately and successively transferred to other small areas until the entire specimen failed. Tests of identical specimens a t the age o six months showed the same erf

12s

KELCH

ratic values which substantiated the fact that this method is erroneous for attempting to arrive a t the shearing value of masonry, because if the mortar behaved as i t did with the walls high shearing values a t the six months period should have been obtained. Such, however, was not the case. Shearing values can only be obtained truely through tests by torsion and such tests of masonry would be very difficult to make. When the proper values are assigned to masonry for compression and tension, shear can be calculated with sufficient accuracy.

111. Compression on Diagonal

In an attempt to assign a value to masonry for compression on a diagonal, specimens 17 x 17 inches x 8 inches thick were constructed and tested in a diagonal position in the testing machine by placing them on a steel angle and applying a load through a steel angle t o which was welded a flat plate, thus assuring the specimen in a true 45-degree position as shown in Fig. 4. Some of these specimens failed by tension, which occurred partially through the brick themselves but within the lines of compression between the top and bottom angles. Most of them, however, failed by adhesion. The FIG.4.--Method of attempt to d e t u specimen being so small in proportion mine compression on diagonal. t o the size of the angles used for applying the load, i t is difficult to form a conclusion as to what kind of a result was obtained. It was planned to calculate the failure value into terms of shear on the mortar joint but observation of the test method shows that such a procedure would be erroneous, besides being underaged. The numerical values obtained for the different specimens tested a t 2 and 6 months in this same manner were also most erratic showing again a fallacy in the test method.

IV.

Present Testing Program

With these experiments as a background, this Institute has programmed a series of tests at the University of California a t Berkeley under the supervision of Raymond E. Davis, Professor of Civil Engineering. This program includes tests for modulus of rupture o specimens composed of stifff and soft-mud common brick, face brick, medium- and hard-fired loadbearing tile, with the different units laid wct and laid dry, some moistcured or 14 days and some cured in dry air. These specimens will be tested as beams, being of 2 sizes; solid brick 12 x 12 inches x 54 inches

TESTING MASONRY FOR BENDING, TENSION, AND SHEAR

129

FIG.5.-General view. Tests a t Univ. of California, 1929-30.

high, load-bearing tile 12 x 24 inches x 54 inches high and also a series of beams built up of unit on top of unit 24 to 36 inches high. Specimens were also crossed upon each other to ascertain the adhesive or cohesive value of the mortars laid wet and dry. Six different mixtures of mortars have been programmed. A set of brick specimens are also being used in which are embedded steel reenforcing rods to ascertain the adhesion bond between the cement-lime mortars and the steel. One set of 8 beams or piers have been manufactured for testing at the age of 6 months upon the top of which there was a load applied each day following their assembling. This load was applied in increments so as to

FIG.Ci.-Beams

and mortar adhesion-cohesion specimens.

130

KELCH

FIG.7.-solid

brick beams and load-bearing hollow tile beams.

simulate the first story masonry work of a $-story building in order to determine whether or not the additional weight of the superimposed brickwork applied to the masonry during its period of setting has any effect on its strength for modulus of rupture. The loads were applied by means of an apparatus of steel plates, rods, and springs which were previously calibrated to determine the amount of pressure applied, each day for 20 days. With the exception of the steel bond and of a few of the variables, these specimens have been made in triple triplicate so that 3 specimens will be tested a t each age of 2 months, 6 months, and 12 months. Mortar briquets and cylinders have been made which have been tested since the age of 7 days, 28 days, etc.

FIG. &-Brick beam after one break as cantilever.

TESTING MASONRY FOR BENDING, TENSION, AND SHEAR

131

FIG.S.-Brick in position for test on value of mortar in direct tension.

It is hoped that a t the end of 12 months there will be sufficient information so that with a given strength mortar, a given type of unit, and a given condition of assembly and curing, masonry true values for bending and shearing strengths can be accurately predicted. If these findings develop what it is believed they will, that cement mortars containing lime require a greater time than 2 months to attain their relatively final strength, then additional tests should be made on the compres-

132

KELCH

sive strengths of walls similar to those made a t the Bureau of Standards, for ages greater than 2 months. A full report and paper will be written on the subject of these tests when the present program is completed. Figures 5, 6, and 7 show a portion of the test specimens. Figure 8 shows a large brick beam having been broken in the testing machine. It will be noted th a t 2 cantilever brakes are made on each beam thus giving 6 results for each set of 3 specimens. Figure 9 shows a specimen in position for testing the adhesive or cohesive or tensile value of the mortar joint. The metal cylinder on top is a universal ball bearing. The first 2 months tests have already been made. Without attempting a discussion a t this time, it was nevertheless interesting to note that in the tests for modulus of rupture and for adhesion bond as shown in Figs. 8 and 9, the failures found were by adhesion between the lower surfaces of the joints and the upper surfaces of the units as laid by the mason. This was directly contrary to common supposition.

CLAYPRODUCTS IKSTITUTE CALIFORNIA OF Los ANGELES, CALIF.

You might also like

- The Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationFrom EverandThe Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationNo ratings yet

- Form Pressure Generated by Fresh ConcretDocument15 pagesForm Pressure Generated by Fresh ConcretDarren ThoonNo ratings yet

- Concrete Encased Duct Bank PDFDocument8 pagesConcrete Encased Duct Bank PDF101079No ratings yet

- Weld AbilityDocument34 pagesWeld AbilityGauthamSarangNo ratings yet

- Amem201 Group1 Multiple Choice Q&A Amem201Document4 pagesAmem201 Group1 Multiple Choice Q&A Amem201Aero NaveenNo ratings yet

- Shay Murtag Precast BeamsDocument49 pagesShay Murtag Precast BeamsMilind GuptaNo ratings yet

- SS316 - Comparison With SS316LDocument3 pagesSS316 - Comparison With SS316LAdrianus PrimaNo ratings yet

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966From EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullRating: 5 out of 5 stars5/5 (1)

- Plastic FormingDocument11 pagesPlastic FormingAngeloLorenzoSalvadorTamayoNo ratings yet

- Deaerators: Technical BackgroundDocument8 pagesDeaerators: Technical Backgroundกี๋ แต่งงามNo ratings yet

- Metallurgy - Chapter (5) - Steels and Cast IronsDocument79 pagesMetallurgy - Chapter (5) - Steels and Cast IronsKarim Mamdouh100% (1)

- Sample Questions For Practice Fiber LengthDocument0 pagesSample Questions For Practice Fiber LengthShailendra Mishra100% (4)

- Yanbu Refinery Corrosion Prevention SummaryDocument25 pagesYanbu Refinery Corrosion Prevention SummaryJanakiraman MalligaNo ratings yet

- Seismic Performance of An Unreinforced Masonry Building - An Experimental InvestigationDocument24 pagesSeismic Performance of An Unreinforced Masonry Building - An Experimental InvestigationProshutBlogNo ratings yet

- Centrifugally Cast Inserted Grinding Rollers SpecificationDocument6 pagesCentrifugally Cast Inserted Grinding Rollers Specificationsiva100% (1)

- Large Diameter Diaphragm Wall ShaftsDocument7 pagesLarge Diameter Diaphragm Wall ShaftsmeñoxNo ratings yet

- Slender Walls (James E. Amrhein)Document3 pagesSlender Walls (James E. Amrhein)Cesar RjszvlNo ratings yet

- Non Destructive Test On ConcreteDocument6 pagesNon Destructive Test On ConcreteOpany JuliusNo ratings yet

- GabionsDocument2 pagesGabionsFrancois-No ratings yet

- Silicon CarbideDocument10 pagesSilicon CarbideTushar AneyraoNo ratings yet

- RC Masonry Shear Wall DuctilityDocument8 pagesRC Masonry Shear Wall DuctilityArieska HermastiadiNo ratings yet

- Tests of Reinforced Concrete Beams at the University of IllinoisDocument70 pagesTests of Reinforced Concrete Beams at the University of Illinoisfukuro2kNo ratings yet

- Dry-Stacked Masonry - Present Scenario: Upadhyay Tejas JDocument9 pagesDry-Stacked Masonry - Present Scenario: Upadhyay Tejas Jharnishtanna212No ratings yet

- RPV Dawe Out of PlaneDocument11 pagesRPV Dawe Out of PlaneppppsecNo ratings yet

- Shake-Table Tests of Partially Grouted Reinforced Masonry BuildingsDocument12 pagesShake-Table Tests of Partially Grouted Reinforced Masonry BuildingstonyNo ratings yet

- Dry Stacked Masonry-Present Scenario - 2 Harshad M. Patel Tejas J. Upadhyay Dr. N. K. AroraDocument3 pagesDry Stacked Masonry-Present Scenario - 2 Harshad M. Patel Tejas J. Upadhyay Dr. N. K. Aroraharnishtanna212No ratings yet

- Seismic Resistance of Brick Masonry WallsDocument21 pagesSeismic Resistance of Brick Masonry WallsLucas ScartonNo ratings yet

- Earthquake Performance of High-Strength Concrete Structural Walls With Boundary ElementsDocument18 pagesEarthquake Performance of High-Strength Concrete Structural Walls With Boundary ElementsAbi Ilamvazhuthi100% (1)

- CRACK PREDICTIONDocument12 pagesCRACK PREDICTIONAnonymous XVEucVMsENo ratings yet

- Shear and Tensile Test of Brick Masonry Unit For Earthquake SafetyDocument5 pagesShear and Tensile Test of Brick Masonry Unit For Earthquake SafetyIngeniero Emmanuel RodriguezNo ratings yet

- Interaction of Reinforced Embankment and Retaining WallDocument6 pagesInteraction of Reinforced Embankment and Retaining WallSidharth MahajanNo ratings yet

- Strength Characteristics of Brick Masonry Wall Before and After Encasing With FerrocementDocument9 pagesStrength Characteristics of Brick Masonry Wall Before and After Encasing With FerrocementaminNo ratings yet

- Seismic Retrofitting of Unreinforced Masonry Walls by Cable SystemDocument15 pagesSeismic Retrofitting of Unreinforced Masonry Walls by Cable SystemDamit SuranaNo ratings yet

- Sayed Rahman - Cyclic In-Plane Behavior of Unreinforced and Confined Masonry Walls Retrofitted by Shotcrete Experimental InvestigationDocument13 pagesSayed Rahman - Cyclic In-Plane Behavior of Unreinforced and Confined Masonry Walls Retrofitted by Shotcrete Experimental InvestigationSergio Alonso SunleyNo ratings yet

- MS - Unit 4Document9 pagesMS - Unit 4sushant metriNo ratings yet

- Bamboo Reinforced Soil WallDocument5 pagesBamboo Reinforced Soil Walllokesh_bhangale100% (1)

- Seismic Behavior of Hollow Masonry WallsDocument11 pagesSeismic Behavior of Hollow Masonry WallsCarlos NBNo ratings yet

- 21 Seismic Behaviour of Confined Masonry WallsDocument13 pages21 Seismic Behaviour of Confined Masonry WallsFouad KehilaNo ratings yet

- Structural Materials LAB REPORTDocument10 pagesStructural Materials LAB REPORTmusiomi2005No ratings yet

- Sp36-07 Cardenas Magura AciDocument32 pagesSp36-07 Cardenas Magura Acihcastelblancor100% (1)

- Bonded Steel Plating For Strengthening Concrete Structures: M.D. Macdonald and A.J.J. CalderDocument9 pagesBonded Steel Plating For Strengthening Concrete Structures: M.D. Macdonald and A.J.J. CalderpaulkohanNo ratings yet

- Rehabilitation of Brick Walls With Openings Using Steel Wire MeshDocument13 pagesRehabilitation of Brick Walls With Openings Using Steel Wire MeshturkuazulNo ratings yet

- Field Measurements of Lateral Earth Pressures and Movements On Retaining WallsDocument11 pagesField Measurements of Lateral Earth Pressures and Movements On Retaining WallsjamNo ratings yet

- Behavior o Welded Plate Connections in Precast Concrete Panels Under Simulated Seismic LoadsDocument13 pagesBehavior o Welded Plate Connections in Precast Concrete Panels Under Simulated Seismic Loadslil_starNo ratings yet

- Greifenhagen Lestuzzi Eng Struct 2005Document28 pagesGreifenhagen Lestuzzi Eng Struct 2005Killian WismanNo ratings yet

- Thin-Walled Structures: Full Length ArticleDocument17 pagesThin-Walled Structures: Full Length ArticleSeban ACNo ratings yet

- Retrofitting The Shear Capacity of The Masonry Walls Using CFRP Composite OverlaysDocument6 pagesRetrofitting The Shear Capacity of The Masonry Walls Using CFRP Composite OverlaysTaulantKarriqiNo ratings yet

- Taylor and Wallace - Design of Slender Reinforced Concrete Walls With OpeningsDocument15 pagesTaylor and Wallace - Design of Slender Reinforced Concrete Walls With OpeningsALEXANDER BECERRANo ratings yet

- Experimental Investigation of Confined Masonry Infill WallsDocument8 pagesExperimental Investigation of Confined Masonry Infill WallsGalal El-DarratNo ratings yet

- Shear Capacity Prediction of Confined Masonry Walls Subjected To Cyclic Lateral LoadingDocument14 pagesShear Capacity Prediction of Confined Masonry Walls Subjected To Cyclic Lateral LoadingJalal KeNo ratings yet

- Strength and Stiffness of Masonry Shear Walls With OpeningsDocument12 pagesStrength and Stiffness of Masonry Shear Walls With OpeningsAhmad NaqiNo ratings yet

- Compressive Strength Testing For CEBDocument7 pagesCompressive Strength Testing For CEBSyndy AlvarezNo ratings yet

- Energy Efficient Node Deployment Scheme in Wireless Sensor NetworkDocument18 pagesEnergy Efficient Node Deployment Scheme in Wireless Sensor NetworkInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Rat Trap Bond StructuresDocument8 pagesRat Trap Bond Structuresprozoam21No ratings yet

- Test of High-Rise Core Wall: Effective Stiffness For Seismic AnalysisDocument23 pagesTest of High-Rise Core Wall: Effective Stiffness For Seismic AnalysisMirellaNo ratings yet

- Properties of Anchor Grouts in A Confined State A D Barley Ice Conference London March 1997Document10 pagesProperties of Anchor Grouts in A Confined State A D Barley Ice Conference London March 1997Kenny CasillaNo ratings yet

- Use of Maturity Method To Estimate Compressive Strength of Mass ConcreteDocument11 pagesUse of Maturity Method To Estimate Compressive Strength of Mass ConcreteEdicson Gabriel Garcia MateusNo ratings yet

- Shear Capacity Prediction of Confined Masonry Walls Subjected To Cyclic Lateral LoadingDocument13 pagesShear Capacity Prediction of Confined Masonry Walls Subjected To Cyclic Lateral LoadingAdel AdelNo ratings yet

- Finite Element Analysis of Cantilever and Counterfort Retaining Wall BehaviorDocument15 pagesFinite Element Analysis of Cantilever and Counterfort Retaining Wall BehaviorKhalid AljanabiNo ratings yet

- Membrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperDocument10 pagesMembrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperpicottNo ratings yet

- Distortion of Steel Tanks Due To Settlement of Their WallsDocument20 pagesDistortion of Steel Tanks Due To Settlement of Their WallsMiguel BenítezNo ratings yet

- Comparing Effects of Openings in Concrete Shear WallsDocument10 pagesComparing Effects of Openings in Concrete Shear WallsIrshadAhmedNo ratings yet

- 2010 SEAOC Convention ProceedingsDocument9 pages2010 SEAOC Convention ProceedingsPE EngNo ratings yet

- Research On Different Types of Cracks in Plain and Reinforced ConcreteDocument3 pagesResearch On Different Types of Cracks in Plain and Reinforced ConcreteSnehal AbhyankarNo ratings yet

- Experimental investigation of lateral load response of confined masonry wallsDocument14 pagesExperimental investigation of lateral load response of confined masonry wallsdhakal.binaya07No ratings yet

- CV311 - Final Assignment#2Document11 pagesCV311 - Final Assignment#2Inoke LiutoloNo ratings yet

- Local Media4337401909846594209Document12 pagesLocal Media4337401909846594209Anonymous ANo ratings yet

- Pile Behavior Due To Excavation-Induced Soil Movement in Clay. II: Collapsed WallDocument9 pagesPile Behavior Due To Excavation-Induced Soil Movement in Clay. II: Collapsed WallDaanyal Ibn UmarNo ratings yet

- Study on Vertical Dowel Connections in Precast WallsDocument14 pagesStudy on Vertical Dowel Connections in Precast WallsroshidNo ratings yet

- Masonry 1Document3 pagesMasonry 1kenyan trends liveNo ratings yet

- Diagonal Tension Strength of Vintage Unr PDFDocument27 pagesDiagonal Tension Strength of Vintage Unr PDFEduardo ArdonNo ratings yet

- Seismic Reinforcement of Existing Walls Made of Horizontally Hollow BricksDocument11 pagesSeismic Reinforcement of Existing Walls Made of Horizontally Hollow Bricksfartigas180No ratings yet

- The Retrofitting of Reinforced Concrete Column-To-Beam ConnectionsDocument9 pagesThe Retrofitting of Reinforced Concrete Column-To-Beam ConnectionssakthistructNo ratings yet

- Formwork Cop 2016 PDFDocument54 pagesFormwork Cop 2016 PDFAnil PyakurelNo ratings yet

- 1973 - Behaviour of Masonry Walls Under Lateral Loads - MeliDocument10 pages1973 - Behaviour of Masonry Walls Under Lateral Loads - Melizabrathkud100% (1)

- Ce470bolts s14 PDFDocument47 pagesCe470bolts s14 PDFzabrathkudNo ratings yet

- Singapore Downloads Student Handbook Exams IeltsDocument24 pagesSingapore Downloads Student Handbook Exams Ieltsuthomas_babuNo ratings yet

- Singapore Downloads Student Handbook Exams IeltsDocument24 pagesSingapore Downloads Student Handbook Exams Ieltsuthomas_babuNo ratings yet

- Singapore Downloads Student Handbook Exams IeltsDocument24 pagesSingapore Downloads Student Handbook Exams Ieltsuthomas_babuNo ratings yet

- Accelerating AdmixturesDocument5 pagesAccelerating AdmixturesFaraz TariqNo ratings yet

- Orientação ISO 11600Document6 pagesOrientação ISO 11600sahcristine3968No ratings yet

- 1 Cutting ToolDocument27 pages1 Cutting ToolKemalMalovcicNo ratings yet

- S 1300 Pene Krete Product Data 347250Document3 pagesS 1300 Pene Krete Product Data 347250uocmogiandi_aNo ratings yet

- Technical Specs CladdingDocument4 pagesTechnical Specs Claddingmgupta72No ratings yet

- SGG Reflectasol: 1. SGG Albarino: Extra Clear Patternned Glass (Photo-Voltaic Applications)Document5 pagesSGG Reflectasol: 1. SGG Albarino: Extra Clear Patternned Glass (Photo-Voltaic Applications)Abhimanyu GoelNo ratings yet

- 03 - TDS - Concresive 1414Document3 pages03 - TDS - Concresive 1414aahtagoNo ratings yet

- Traffic Signs, Markings and Other Road AppurtenancesDocument91 pagesTraffic Signs, Markings and Other Road Appurtenanceskumarnram50% (2)

- Bamboo Leaf Ash As Supplementary Cementitious MaterialDocument8 pagesBamboo Leaf Ash As Supplementary Cementitious MaterialAJER JOURNALNo ratings yet

- Scyon™ Matrix™ Installation Manual LR July 2013Document8 pagesScyon™ Matrix™ Installation Manual LR July 2013Roslyn L.No ratings yet

- Linear Coefficients of ExpansionDocument12 pagesLinear Coefficients of ExpansionVBT1No ratings yet

- TDS - Concresive 2020Document2 pagesTDS - Concresive 2020Venkata RaoNo ratings yet

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDocument24 pagesPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishNo ratings yet

- Mil STD 171FDocument65 pagesMil STD 171FMAI_QualityNo ratings yet

- ASTM D 16-03 Standard Terminology For Paint, Related Coatings, Materials, and Applications1Document8 pagesASTM D 16-03 Standard Terminology For Paint, Related Coatings, Materials, and Applications1Jorge ToribioNo ratings yet

- Material Science ManualDocument7 pagesMaterial Science ManualaoguNo ratings yet

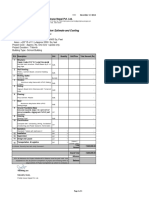

- Prefab School Cost EstimateDocument1 pagePrefab School Cost EstimatespellbindguyNo ratings yet