Professional Documents

Culture Documents

Untitled

Uploaded by

Anil KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Untitled

Uploaded by

Anil KumarCopyright:

Available Formats

SIKKIM MANIPAL UNIVERSITY OF DISTANCE EDUCATION PROJECT REPORT N OPERATIONS MANAGEMENT IN CAD DESIG

[Type the author name] [Pick the date]

[Type the abstract of the document here. The abstract is typically a short summa ry of the contents of the document. Type the abstract of the document here. The abstract is typically a short summary of the contents of the document.] Operations Management in CAD Design Introduction: Design is a roadmap or a strategic approach for someone to achieve a uni que expectation. It defines the specifications, plans, parameters, costs, activi ties, processes and how and what to do within legal, political, social, environm ental, safety and economic constraints in achieving that objective. Design includes Analysis, research, specification, conceptualising and p resentation. Computer-aided design (CAD), is the use of computer technology for the process of design and design-documentation. CAD is an important industrial a rt extensively used in many applications, including automotive, shipbuilding and aerospace industries, industrial and architectural design, prosthetics, and man y more. Objectives: The objective of optimal design is to satisfy the customer requirements and the basic principles/standards of engineering or Rules. There are Rules to b e followed during design, specified by the International classification societie s. These Rules form the basis for assessing the design and construction of new projects and the integrity of existing ones. Rules are derived from basic pr inciples of engineering and associated disciplines. The design has to be perform ed as per the customer requirements. Methedology: Design softwares are useful Tools used to implement the design. These s oftwares were imbibed with Rules and basic principles of Design. The software d esigner and implementer can get valuable feedback from the users early in the pr oject. These softwares are very useful in prototyping, comparing the results bef ore manufacturing. The client and the contractor can compare if the software made matches t he software specification, according to which the software program is built. It also allows the engineer some insight into the accuracy of initial project esti mates and whether the deadlines and milestones proposed can be successfully met. Conclusion: The customer specifications and the concerned rules are the basis of des ign. Design softwares are the tools used for optimal design. Future designs can be easily performed using these softwares and suggest new designs to the custom ers.

Synopsis

Introduction Objectives Methodology Conclusion Chapter 1 Introduction One of the first processes in the manufacturing task is designing a prod uct or service that has been identified by the marketing department as important to existing or potential customers. In either case computer aided design is an important tool in this process. Computer-aided design (CAD) is the use of computer technology for the process o f design and design-documentation. Computer Aided Drafting describes the process of drafting with a computer. CAD software provides the user with input-tools fo r the purpose of streamlining design processes; drafting, documentation, and man ufacturing processes. CAD output is often in the form of electronic files for pr int or machining operations. CAD software uses either vector based graphics to d epict the objects of traditional drafting, or may also produce raster graphics s howing the overall appearance of designed objects. 1.1 General Overview CAD often involves more than just shapes. As in the manual drafting of technical and engineering drawings, the output of CAD must convey information, such as ma terials, processes, dimensions, and tolerances, according to application-specifi c conventions. CAD may be used to design curves and figures in two-dimensional (2D) space; or c urves, surfaces, and solids in three-dimensional (3D) space. CAD is an important industrial art extensively used in many applications, includ ing automotive, shipbuilding, and aerospace industries, industrial and architect ural design, prosthetics, and many more. CAD is also widely used to produce comp uter animation for special effects in movies, advertising and technical manuals. The modern ubiquity and power of computers means that even perfume bottles and shampoo dispensers are designed using techniques unheard of by engineers of the 1960s. Because of its enormous economic importance, CAD has been a major driving force for research in computational geometry, computer graphics (both hardware and software), and discrete differential geometry. The design of geometric models for object shapes, in particular, is occasionally called computer-aided geometric design (CAGD).

1.2 Scope of the project The scope of the project encompasses Study and Analysing the design specificatio ns received from the Customer, preparing 3D Model in CAD Software, Analysing the model against the given loads and constraints, preparation of Detailed Design d rawings for manufacturing, Bill of material and Work breakdown sequence for manu facturing. 1.3 Objectives of the study The objectives of the study are scope of the project encompasses Study and Analy sing the design specifications received from the Customer, preparing 3D Model in CAD Software, Analysing the model against the given loads and constraints, prep aration of Detailed Design drawings for manufacturing, Bill of material and Work breakdown sequence for manufacturing. 1.4 Methodology Methodology 1.5 Overview of CAD Design 1.6 Conclusion Chapter 2 Related work

2.1 Existing studies related to our work 2.2 Proposed Project 2.3 Advantages of the work 2.4 Limitations of the study Chapter 3 Operation Management 3.1 Management Life cycle 3.2 Services offered 3.3 Technologies used 3.4 Design Documentation 3.5 Applications Chapter 4 Case Study 4.1 Problem description 4.2 Design Issues 4.3 Implementation 4.4 Reports 4.5 Performance Review Chapter 5 Conclusion 5.1 Conclusion 5.2 Future enhancements

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Advt No 13 2017 Engl 0Document40 pagesAdvt No 13 2017 Engl 0Anil KumarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Jyothi Rling AsDocument2 pagesJyothi Rling AsAnil KumarNo ratings yet

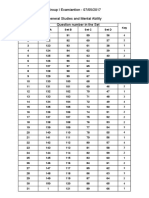

- Group I Examiantion - 07/05/2017 General Studies and Mental Ability Question Number in The SetDocument5 pagesGroup I Examiantion - 07/05/2017 General Studies and Mental Ability Question Number in The SetAnil KumarNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Pressure VesselsDocument2 pagesPressure VesselsAnil KumarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- UntitledDocument3 pagesUntitledAnil KumarNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- SMU 2nd Semester Assignment MB0048 - Operation Research Set - 1 (Per Subject at Rs.50 Only) This Is Just A Sample. :)Document8 pagesSMU 2nd Semester Assignment MB0048 - Operation Research Set - 1 (Per Subject at Rs.50 Only) This Is Just A Sample. :)सुवाल सेरिज़No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- MB0052-Strategic Management and Business Policy (Assignment-1)Document9 pagesMB0052-Strategic Management and Business Policy (Assignment-1)Anil KumarNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- MB0052-Strategic Management and Business Policy (Assignment-2)Document10 pagesMB0052-Strategic Management and Business Policy (Assignment-2)Anil KumarNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Unit 15 Uses of Computers in Production and Operations: StructureDocument18 pagesUnit 15 Uses of Computers in Production and Operations: StructureAnil KumarNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Redox TitrationDocument5 pagesRedox TitrationchristinaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Life Processes: Science Unit 1Document19 pagesLife Processes: Science Unit 1patil pratikNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- KD-131 Asme Viii Div3Document2 pagesKD-131 Asme Viii Div3comar85No ratings yet

- Cópia de Teste Excel - Intermediário (5166) .XLS: BIM Technology For EngineersDocument6 pagesCópia de Teste Excel - Intermediário (5166) .XLS: BIM Technology For EngineersFernanda AzevedoNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Budget of Work Sci5Document1 pageBudget of Work Sci5Jhoy Angeles PinlacNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- EXP.2 Enzyme Extraction From BacteriaDocument3 pagesEXP.2 Enzyme Extraction From BacteriaLinhNguyeNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Lab 6Document12 pagesLab 6Sujan HeujuNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Cep MPDocument1 pageCep MPAzmat HabeebNo ratings yet

- Epson WorkForce Pro WF-C878-879RDocument8 pagesEpson WorkForce Pro WF-C878-879Rsales2 HARMONYSISTEMNo ratings yet

- SpaceClaim - Developers Guide-5-6Document2 pagesSpaceClaim - Developers Guide-5-6Alexgh1993No ratings yet

- Articles On SidisDocument146 pagesArticles On SidisMircea492003100% (1)

- Chem 17 Exp 3 RDR Chemical KineticsDocument4 pagesChem 17 Exp 3 RDR Chemical KineticscrazypatrishNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Checklist For Conreting WorkDocument13 pagesChecklist For Conreting WorkMin Khant AungNo ratings yet

- Chapter 6 AssignmentDocument6 pagesChapter 6 AssignmentRohit RajeevNo ratings yet

- API2000 Tank Venting CalcsDocument5 pagesAPI2000 Tank Venting Calcsruhul01No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 2023-1509 TopSolid'Design Library Designer's GuideDocument21 pages2023-1509 TopSolid'Design Library Designer's GuideMáy TiệnNo ratings yet

- Testing, Adjusting, and Balancing - TabDocument19 pagesTesting, Adjusting, and Balancing - TabAmal Ka100% (1)

- FI Printing Guide Vinyl-303Document1 pageFI Printing Guide Vinyl-303tomasykNo ratings yet

- Product Specifications: Handheld Termination AidDocument1 pageProduct Specifications: Handheld Termination AidnormNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- ADO NET Tutorial - 16Document18 pagesADO NET Tutorial - 16Fenil Desai100% (1)

- SC Perthub Single Cell OmicsDocument34 pagesSC Perthub Single Cell OmicsGANYA U 2022 Batch,PES UniversityNo ratings yet

- Parts Manual Z-45Document240 pagesParts Manual Z-45John Forero PinzonNo ratings yet

- Review Skills 1-8Document1 pageReview Skills 1-8TegarNo ratings yet

- Teaching Tactics and Teaching Strategy: Arthur W. Foshay'Document4 pagesTeaching Tactics and Teaching Strategy: Arthur W. Foshay'Ahmed DaibecheNo ratings yet

- RRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftDocument55 pagesRRB JE CBT-2 Electronics Tech Paper With Key 31-8-2019 1st ShiftKuldeep SinghNo ratings yet

- Ethoxy 1Document77 pagesEthoxy 1HoshiNo ratings yet

- GTG - TFA Belt DrivenDocument2 pagesGTG - TFA Belt Drivensuan170No ratings yet

- RespiratorypptDocument69 pagesRespiratorypptMichelle RotairoNo ratings yet

- Projector Spec 8040Document1 pageProjector Spec 8040Radient MushfikNo ratings yet

- Chord Tone Improvisation Part IDocument38 pagesChord Tone Improvisation Part I2018 01097No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)