Professional Documents

Culture Documents

AC Heat Exchanger & Heater Sizing Calculation For Electrical Enclosures

Uploaded by

nooruddinkhan1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AC Heat Exchanger & Heater Sizing Calculation For Electrical Enclosures

Uploaded by

nooruddinkhan1Copyright:

Available Formats

Climate Control Products

Air Conditioner Sizing and Selection

Climate Control Cooling Electronic Control Cabinets

Most electronic control systems generate a substantial amount of heat during operation. This heat factor is intensified as electronic controls are made more compact, perform more functions and are placed in confined areas. Additional problems are encountered when the electronic process control system is located online in an industrial setting, rather than in a clean computer room. The factory environment can be hostile to the point that performance and effective life of the electronic components are materially reduced or the control system fails completely. Ambient temperature might be excessively high, as that found in a steel mill. Moisture-laden air and airborne particulate matter might be present to adversely affect the electronic components, as in the paper manufacturing industry. Air conditioners are designed to perform reliably under many of these harsh conditions and to provide the cooling and environmental protection required by sensitive electronic production control systems.

Resistance to Air Flow in the Enclosure

Air flow is measured in cubic feet per minute (CFM). To create an air flow of any desired velocity requires that pressure be produced by the blower. Resistance to this blower-produced air flow is created by obstructions within the cabinet in the air flow path. The resistance itself is called static pressure (SP) and is measured in inches of water column.The effect of significant restrictions in the cabinet air flow path are as follows: the obstructions cause static pressure. static pressure results in a pressure drop, or differential, from the air velocity produced by the blower. this reduction in cool air flow will decrease the effective capacity of the cooling unit. Allowance must be made for static pressure.

Heat Load from the Surroundings

Ambient conditions can cause a heat gain in the enclosure. The rated capacity of the cooling unit must be sufficient to handle this heat gain. When evaluating the additional heat load gained from the surroundings there are two possible conditions: the cabinet is insulated and well sealed the cabinet is not insulated. Cabinet Insulated - Normally, wellinsulated cabinets do not gain sufficient heat from the surroundings to affect the air conditioner operation. BTU/HR ratings for Kooltronic air conditioners have been established at the maximum ambient operating temperature of 125F. A substantial improvement in heat removal occurs when operating in ambient temperatures below 125F. Cabinet Not Insulated - Obviously, this design places more of a burden on the cooling unit. Heat is conducted to the cool side. Thus, high ambient heat will be readily transmitted into the

Factors Affecting Model Selection

This section is presented as a basic outline or checklist of the various application conditions to be considered when choosing a cooling unit. These are the factors which must be considered when selecting a cooling unit:

cooler enclosure. To determine the additional capacity required of an air conditioner installed in an uninsulated cabinet, the surface area of the enclosure must be calculated to obtain the total effective heat transfer area. For this calculation, use the surface area of the sides, plus the area of the top and omit the bottom area of the cabinet. Air movement outside the uninsulated cabinet will increase the heat conducted from the ambient into the enclosure. When there is little or no air circulation outside the cabinet, the layer of air immediately adjacent to the exterior cabinet walls acts as an insulating film. Exterior air movement dissipates this insulating layer of air in proportion to the velocity of the air flow. Substantial ambient air circulation will increase the transmitted heat load imposed on the cooling unit. If the cabinet being cooled is not air tight, high ambient relative humidity will adversely affect the cooling effectiveness of the air conditioner. When humid air infiltrates a poorly sealed enclosure, the air conditioner is required to use up valuable capacity just to condense the moisture from the internal air. Conversely, if the cabinet is well sealed, high ambient relative humidity has very little effect on the rated capacity of the air conditioner.

Climate Control

Internal Heat Load

This is the heat dissipated by the electronic controls. It is expressed in watts. One WATT equals 3.413 BTU/HR. Thus, to obtain the approximate cooling capacity required to remove a specific heat load, the following formula can be used: Watts x 3.413 - BTU/HR. For example, a heat load of 800 watts, require an air conditioner capable of removing at least 2,730 BTU/HR.

Notes: Dimensions are in inches. Millimeters shown are for reference only. Data subject to change without notice.

391

Climate Control Products

Air Conditioners Sizing & Selection

Climate Control

The proper selection of an air conditioner is determined by the following criteria: 1) Required cooling capacity BTU/HR. 2) Mounting requirements (top, side or internal mounting) 3) Dimensions of air conditioner & enclosure

To determine air conditioner capacity required:

First

Second

W

Third

H D

Ti

To

1 Watt = 3.413 BTU/HR Determine the internal Watts of heat to be dissipated.

1 M2 = 10.76 ft2 Calculate the area of the enclosure which is exposed to the ambient air: 2H (W+ D) + (D x_W ) = Area (ft2) 144

1C T = 1.8F T Determine the temperature differential T ( F) by subtracting the maximum allowable internal cabinet temperature (Ti) from the maximum ambient temperature outside of the enclosure (T ): T - T = T o o i

Fourth: (Watts x 3.413) + [1.25 x Area ft.2 x

T (F)] = BTU/HR.

Calculations

Climate Control

Notes: Dimensions are in inches. Millimeters shown are for reference only. Data subject to change without notice.

392

Climate Control Products

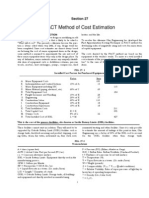

Heat Exchanger Sizing and Selection

Climate Control

The proper selection of a Heat Exchanger is determined by how many WATTS can be dissipated at a given temperature differential. Since a Heat Exchanger uses ambient air for cooling, the enclosure cannot be cooled below a temperature slightly above the surrounding air temperature. Therefore, the greater the temperature differential, the higher the capacity of the Heat Exchanger.

NOTE: This selection process applies only to indoor gasketed enclosures which are uninsulated.

To determine required Heat Exchanger performance in WATTS/F:

First Second Third W

Ti

To

H D

Climate Control

Determine the internal Watts of heat to be dissipated.

Determine the temperature differential by subtracting the maximum ambient temperature outside of the enclosure (To) from the maximum allowable internal cabinet temperature (Ti). (Ti) - (To) = T F Note: The maximum allowable internal cabinet temperature (Ti) should not exceed the heat tolerance specification of the most sensitive component in your system.

Calculate the area of the enclosure which is exposed to the ambient air. 2H (W + D) + (D x_ W ) = Area (ft2) 144

Fourth: (Watts / T F) - (0.22 x Area ft.2) = WATTS/F (Required Heat Exchanger Performance) To calculate the total internal enclosure temperature using the Heat Exchanger selected, add the temperature rise ( T) inside the cabinet to the maximum ambient temperature. Divide the internal heat load (WATTS) by the heat exchanger performance (WATTS/F + Area Ft.2 x .22) and add the maximum ambient temperature outside of the enclosure (To), as in the equation: Total Cabinet Temperature = Internal Heat Load (WATTS) + Heat Exchanger Performance (WATTS/F) + (Area Ft.2 x .22) To

Notes: Dimensions are in inches. Millimeters shown are for reference only. Data subject to change without notice.

406

Climate Control Products

Heater Calculation Sheet

Climate Control

Enclosure Heaters are used to maintain minimum operating temperatures and to help prevent failure of electronic components caused by condensation and corrosion. Follow steps 1-5 to determine the heating requirement of an enclosure (US units - left column, metric - right column) STEP 1: Determine Surface Area (A) exposed to open air Enclosure Dimensions: height = width = depth = feet feet feet meters meters meters

Assuming a free-standing enclosure A = 2 (Height x Width) + 2 (Height x Depth) + 2 (Width x Depth) A= ft2 or m2

STEP 2: Choose the Heat Transmission Coefficient (k) for your enclosure painted steel stainless steel aluminum plastic (or insulated stainless) = = = = 0.511 W/(ft2 K)5.5 W/(m2 K) 0.344 W/(ft2 K)3.7 W/(m2 K) 1.115 W/(ft2 K) 0.325 W/(ft2 K)3.5 W/(m2 K) W/(ft2 K) or

12 W/(m2 K)

k=

W/(m2 K)

STEP 3: Determine the Temperature Differential () Desired interior temperature = Lowest ambient temperature = Temperature differential = Climate Control Calculation requires to be in Kelvin (K) Divide T (F) by 1.8 for T = K or K F F F C C C = K

STEP 4: Determine Heating Power (PV), if any PV = components in the enclosure which generates heat (i.e. transformers, power supplies, etc.) PV = STEP 5: Calculating the Required Heating Power (PH) If enclosure is located inside: If enclosure is located outside: PH = (A x k x T) - PV = PH = 2 x (A x k x T) - PV = W W W or W

412

You might also like

- AC FAN CalculationDocument6 pagesAC FAN CalculationSubramanyaNo ratings yet

- VArticle - Thermal Design of APFC PanelsDocument4 pagesVArticle - Thermal Design of APFC PanelsChandru RangarajNo ratings yet

- Cooling Load1111 PDFDocument43 pagesCooling Load1111 PDFJason PaquibulanNo ratings yet

- Heating Load Calculation ExampleDocument1 pageHeating Load Calculation Examplemuhd.qasimNo ratings yet

- Presentation HVACDocument45 pagesPresentation HVACMistyNo ratings yet

- STULZ Complete Precision Cooling BrochureDocument36 pagesSTULZ Complete Precision Cooling Brochurejun005100% (2)

- Establishing Thermal ComfortDocument12 pagesEstablishing Thermal ComfortShahruzi MahadzirNo ratings yet

- OTTVDocument61 pagesOTTVmaxwalkerdreamNo ratings yet

- Engineering Design PhilosophyDocument1 pageEngineering Design PhilosophyMH BappyNo ratings yet

- Mep Hvac 3Document133 pagesMep Hvac 3Muhammad Musa100% (1)

- The Good Ventilation of Switchgear and Transformer RoomsDocument7 pagesThe Good Ventilation of Switchgear and Transformer RoomsJosé SánchezNo ratings yet

- BUSBARDocument8 pagesBUSBARRachit KhannaNo ratings yet

- Condenser Product ManualDocument24 pagesCondenser Product ManualAdnanNo ratings yet

- Air ConditioningDocument19 pagesAir ConditioningNurul AkmamNo ratings yet

- Therm NFRCSim7 Jan2016Document3 pagesTherm NFRCSim7 Jan2016Tony RobbinsNo ratings yet

- Presented By: Aishwarya Deopujari Prerana Das Nishtha Duggal Vasundhra Singh SrideviDocument110 pagesPresented By: Aishwarya Deopujari Prerana Das Nishtha Duggal Vasundhra Singh Sridevikothat82No ratings yet

- LEED Application GuideDocument40 pagesLEED Application GuidejonathandacumosNo ratings yet

- Cooling Load Calc PBL PDFDocument14 pagesCooling Load Calc PBL PDFkunal jatharNo ratings yet

- Section 01 Electrical Design CriteriaDocument18 pagesSection 01 Electrical Design Criteriabakien-canNo ratings yet

- 19 - Heating and Ventilating Systems - HVACDocument6 pages19 - Heating and Ventilating Systems - HVACJoshua EvansNo ratings yet

- Heat Load Calculation of CabinetDocument4 pagesHeat Load Calculation of Cabinethemant kumar0% (1)

- Central Chiller PlantDocument2 pagesCentral Chiller PlantatiqulaNo ratings yet

- Energy Audit InstrumentsDocument74 pagesEnergy Audit InstrumentsANIL KUMARNo ratings yet

- HVAC Design For Healthcare Facilities: Course No: M06-011 Credit: 6 PDHDocument60 pagesHVAC Design For Healthcare Facilities: Course No: M06-011 Credit: 6 PDHNelson VargasNo ratings yet

- DEWA UserManualDocument42 pagesDEWA UserManualUnni Krishnan100% (1)

- Heatload Calculation 2Document44 pagesHeatload Calculation 2Mustansir Pancha50% (2)

- Project On ACDocument82 pagesProject On ACMahesh DondapatiNo ratings yet

- Fulltext01 PDFDocument64 pagesFulltext01 PDFdexiNo ratings yet

- Climate Control 1.1 General Consideration (HVAC, Heating Ventilation Air Conditioning)Document12 pagesClimate Control 1.1 General Consideration (HVAC, Heating Ventilation Air Conditioning)Naresh KumaarNo ratings yet

- Compare ExcelDocument21 pagesCompare ExcelHariharan2994No ratings yet

- Natural VentilationDocument6 pagesNatural VentilationSumit Raina100% (1)

- Advantage Disadvangtage of Suspended Vs Open CeilingDocument5 pagesAdvantage Disadvangtage of Suspended Vs Open CeilingAre OnezNo ratings yet

- Smart Innovation Systems For Indoor Environmental Quality (IEQ)Document13 pagesSmart Innovation Systems For Indoor Environmental Quality (IEQ)shahriz amriNo ratings yet

- High Performance BuildingDocument21 pagesHigh Performance BuildingPallab MukherjeeNo ratings yet

- Review of Dimming Techniques For Solid-State LED LightsDocument7 pagesReview of Dimming Techniques For Solid-State LED LightsijaertNo ratings yet

- Building Load Calculations Building Load CalculationsDocument60 pagesBuilding Load Calculations Building Load CalculationsHarinder Goel100% (1)

- Lecture 1-2 - Heat ConductionDocument29 pagesLecture 1-2 - Heat ConductionBilal AhmedNo ratings yet

- ThermodynamicsDocument42 pagesThermodynamicsBuild AteddyNo ratings yet

- Hap Free CoolingDocument2 pagesHap Free CoolingHnin PwintNo ratings yet

- HVAC Module 04 Cooling Load 2020Document29 pagesHVAC Module 04 Cooling Load 2020Ziad El SamadNo ratings yet

- PNNL 25218 PDFDocument76 pagesPNNL 25218 PDFShekar AjmeeraNo ratings yet

- Cable SelectionDocument4 pagesCable SelectionMuhammadThoriqAzmiNo ratings yet

- Vav SystemsDocument4 pagesVav SystemsJesus RoldanNo ratings yet

- Substation DesigningDocument11 pagesSubstation DesigningBeto HerrenoNo ratings yet

- Building EnvelopDocument213 pagesBuilding Envelopسامح الجاسمNo ratings yet

- Current Transformers Theory & SelectionDocument7 pagesCurrent Transformers Theory & Selectionkyawswarpm100% (1)

- Steady Heat ConductionDocument25 pagesSteady Heat ConductionMohd Azhari Mohd RodziNo ratings yet

- Heat Recovery System in AhuDocument6 pagesHeat Recovery System in AhuManmeet KumarNo ratings yet

- 4 ACMV SystemsDocument293 pages4 ACMV SystemsMorgan HengNo ratings yet

- Chapter 2 - Losses in Piping SystemsDocument30 pagesChapter 2 - Losses in Piping SystemsNicholas EmildasNo ratings yet

- Materaial For Question 3. - Cooling Load CLTD Example Ashrae PDFDocument5 pagesMateraial For Question 3. - Cooling Load CLTD Example Ashrae PDFkumarNo ratings yet

- Heat TransferDocument1 pageHeat TransferhuangjlNo ratings yet

- Energy Conservation: ASHRAE Standard 90.1. Each New BuildingDocument4 pagesEnergy Conservation: ASHRAE Standard 90.1. Each New BuildingdemuthuNo ratings yet

- ME5521 Chapter1 1 2011Document77 pagesME5521 Chapter1 1 2011Sebastián EspinozaNo ratings yet

- Fundamental of Building PhysicsDocument52 pagesFundamental of Building PhysicssyafixNo ratings yet

- Panel Heat Dissipation Hoffman Stream - DocumentDocument6 pagesPanel Heat Dissipation Hoffman Stream - Documentreality88No ratings yet

- Hoffman Heat Dissipation Document PDFDocument6 pagesHoffman Heat Dissipation Document PDFbilgipaylasimNo ratings yet

- How to Dissipate Excess Heat - Understanding ΔT and CFM: Thermal ManagementDocument8 pagesHow to Dissipate Excess Heat - Understanding ΔT and CFM: Thermal ManagementDiego HinojosaNo ratings yet

- Enclosure Cooling DesignDocument9 pagesEnclosure Cooling Designrajpre1213No ratings yet

- Heating Selection GuideDocument3 pagesHeating Selection GuideAdam Thong Chee HungNo ratings yet

- Stainless Steel Enclosure Brochure-2017Document8 pagesStainless Steel Enclosure Brochure-2017nooruddinkhan1No ratings yet

- Altistart Brochure 2016Document9 pagesAltistart Brochure 2016nooruddinkhan1No ratings yet

- TeSys Brochure 2016Document8 pagesTeSys Brochure 2016nooruddinkhan1No ratings yet

- Zelio Relay Brochure-2016Document6 pagesZelio Relay Brochure-2016nooruddinkhan1No ratings yet

- STI Fuse BrochureDocument4 pagesSTI Fuse Brochurenooruddinkhan1No ratings yet

- Varset Brochure 2012Document12 pagesVarset Brochure 2012nooruddinkhan1No ratings yet

- Compact Ns Brochure enDocument12 pagesCompact Ns Brochure enLeonardo CarvalhoNo ratings yet

- Prisma P Brochure 2013Document8 pagesPrisma P Brochure 2013nooruddinkhan1No ratings yet

- SFP Enclosure Brochure-2011Document8 pagesSFP Enclosure Brochure-2011nooruddinkhan1No ratings yet

- NW & NT Brochure-2012Document8 pagesNW & NT Brochure-2012nooruddinkhan1No ratings yet

- Okken Brochure 2016Document14 pagesOkken Brochure 2016nooruddinkhan1No ratings yet

- EasyCan Brochure 2013Document14 pagesEasyCan Brochure 2013nooruddinkhan1No ratings yet

- Prisma G Brochure 2013Document8 pagesPrisma G Brochure 2013nooruddinkhan1No ratings yet

- NSX Brochure 2009Document8 pagesNSX Brochure 2009nooruddinkhan1No ratings yet

- EasyPact EZC Brochure-2012Document4 pagesEasyPact EZC Brochure-2012nooruddinkhan1No ratings yet

- Linergy TR Terminal Blocks Brochure-2016Document4 pagesLinergy TR Terminal Blocks Brochure-2016nooruddinkhan1No ratings yet

- Micrologic Brochure 2012Document6 pagesMicrologic Brochure 2012nooruddinkhan1No ratings yet

- Harmony XB4 XB5 XB7 Brochure 2016Document8 pagesHarmony XB4 XB5 XB7 Brochure 2016nooruddinkhan1No ratings yet

- Harmony XB4 XB5 XB6 Brochure 2013Document8 pagesHarmony XB4 XB5 XB6 Brochure 2013nooruddinkhan1No ratings yet

- ICT Brochure 2019Document18 pagesICT Brochure 2019nooruddinkhan1No ratings yet

- EasyPact EXE Brochure-2016Document13 pagesEasyPact EXE Brochure-2016nooruddinkhan1No ratings yet

- EasyPact CVS Brochure-2013Document9 pagesEasyPact CVS Brochure-2013nooruddinkhan1No ratings yet

- EasyLogic Brochure 2018Document4 pagesEasyLogic Brochure 2018nooruddinkhan1No ratings yet

- Linergy Brochure 2013Document12 pagesLinergy Brochure 2013nooruddinkhan1No ratings yet

- EasyPact MVS Brochure-2013Document9 pagesEasyPact MVS Brochure-2013nooruddinkhan1No ratings yet

- Acti9 Brochure 2011Document8 pagesActi9 Brochure 2011nooruddinkhan1No ratings yet

- Blokset Brochure 2015Document13 pagesBlokset Brochure 2015nooruddinkhan1No ratings yet

- Cable Sizing Short GuideDocument4 pagesCable Sizing Short Guidenooruddinkhan1100% (1)

- 4.4 Utilization Categories: Utilization Category Application With Respect To SelectivityDocument1 page4.4 Utilization Categories: Utilization Category Application With Respect To SelectivityNikhil Singh100% (1)

- 2019Document1 page2019nooruddinkhan1No ratings yet

- Analysis of The Gpu-3 Stirling EngineDocument28 pagesAnalysis of The Gpu-3 Stirling EnginesbregoNo ratings yet

- FALLSEM2019-20 ECE1006 ETH VL2019201001488 Reference Material I 22-Jul-2019 Lecture-7 Properties at NanoscaleDocument25 pagesFALLSEM2019-20 ECE1006 ETH VL2019201001488 Reference Material I 22-Jul-2019 Lecture-7 Properties at NanoscaleSuhil IrshadNo ratings yet

- CHEM F111 (Handout Revised)Document3 pagesCHEM F111 (Handout Revised)shrey shahNo ratings yet

- Lesson PlanDocument3 pagesLesson PlanCatherine yapeNo ratings yet

- Rates of ReactionsDocument54 pagesRates of ReactionsjohnyeapNo ratings yet

- End Term ALLDocument31 pagesEnd Term ALLJulie Anne CristalesNo ratings yet

- 2 Ig (Q&a)Document17 pages2 Ig (Q&a)EaintNo ratings yet

- Introduction To The Phenomenology of Hitc Superconductors. Patrick Lee and T. Senthil MitDocument54 pagesIntroduction To The Phenomenology of Hitc Superconductors. Patrick Lee and T. Senthil MitBrandon StephensNo ratings yet

- The Consep AcaciaDocument7 pagesThe Consep AcaciaPrincess Ruwarashe Courteney MunyoroNo ratings yet

- Lab Report Softeing Point G1Document7 pagesLab Report Softeing Point G1Zak HeroNo ratings yet

- Solids Liquids and GasesDocument25 pagesSolids Liquids and GasesJane Seymour100% (1)

- Post-Etch Residue Removal Using Choline Chloride-Malonic Acid Deep Eutectic Solvent (DES)Document6 pagesPost-Etch Residue Removal Using Choline Chloride-Malonic Acid Deep Eutectic Solvent (DES)JohnSmithNo ratings yet

- 161 Lab Experiment 7 CalorimetryDocument14 pages161 Lab Experiment 7 CalorimetryInês LapaNo ratings yet

- 029 3105 Bunga Rombel1 Tugaske01Document81 pages029 3105 Bunga Rombel1 Tugaske01Corinne SandersNo ratings yet

- General Chemistry IIDocument10 pagesGeneral Chemistry IIAravindan NatarajanNo ratings yet

- Laboratory Manual in ES 15ADocument2 pagesLaboratory Manual in ES 15AJay KayeNo ratings yet

- Scientific and OEM Diffraction Gratings Catalog 2017 PDFDocument44 pagesScientific and OEM Diffraction Gratings Catalog 2017 PDFmolmedchemNo ratings yet

- Kesetimbangan Uap CairDocument37 pagesKesetimbangan Uap Cairmanarul91No ratings yet

- Use of The HLB System in Selecting Emulsifiers For Emulsion PolymerizationDocument14 pagesUse of The HLB System in Selecting Emulsifiers For Emulsion PolymerizationdiegojrendonbNo ratings yet

- Nitro BenzeneDocument7 pagesNitro Benzenewasay0% (1)

- Oran 2Document263 pagesOran 2KerimberdiNo ratings yet

- Fact MethodDocument5 pagesFact MethodgenergiaNo ratings yet

- Approved Few P&Bits R&Taassj: Disirlbböesi UsDocument231 pagesApproved Few P&Bits R&Taassj: Disirlbböesi UsEne FlorinNo ratings yet

- Acid Gas Removal From Natural Gas With Alkanolamines:: A Modeling and Experimental StudyDocument292 pagesAcid Gas Removal From Natural Gas With Alkanolamines:: A Modeling and Experimental StudyMonel LenomNo ratings yet

- Heat Transfer Detailed Lesson PlanDocument20 pagesHeat Transfer Detailed Lesson PlanAiah Rica Sumalinog50% (2)

- AITS 2122 FT VIII JEEM SolDocument16 pagesAITS 2122 FT VIII JEEM SolSreejay BommineniNo ratings yet

- Heat Transfer: Revision - ExamplesDocument37 pagesHeat Transfer: Revision - ExamplesYasser HendyNo ratings yet

- Artikel PDFDocument20 pagesArtikel PDFJanuar AnharNo ratings yet

- Chemistry Made Easy 10-12Document236 pagesChemistry Made Easy 10-12Lloyd ChansaNo ratings yet

- Lesson Pure SubstanceDocument25 pagesLesson Pure SubstanceCreamverly ArroyoNo ratings yet