Professional Documents

Culture Documents

Chapter 5 2

Uploaded by

Arka Pravo BandyopadhyayOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 5 2

Uploaded by

Arka Pravo BandyopadhyayCopyright:

Available Formats

1

Chapter: 5

Approximate methods for multicomponent multistage separation

5.1 Design methods and simulation methods for multistage

contactor

In multi component distillation one usually comes across two kinds of problems:

a) Design problems: In this method, based on known values of feed flow rate, feed

temperature, pressure etc, the total number of plates is found out to bring about a

given desired separation of components.

b) Simulation or Rating problems: Such problems deal with calculating the flow

rates of distillate and residue with the product composition i.e. concentration

profile, as well as temperature profile as a function of the plate number along the

length of the column.

Thus from the nature of problems we see that the calculations for simulation methods

needs to be much more rigorous. The design methods are thus approximate methods

giving the initial parameter values that are to be checked further by the simulation

methods.

In design problem, the product split is specified and feed rate, feed composition, pressure

and feed temperature is also specified. The objective of the method is to find out the

reflux ratio, number of ideal plates and feed tray location.

For the specification of product split only two split can be specified and that will be

sufficient. This can be proved by the phase rule using degrees of freedom. If more than

two component split is specified, then the problem is over specified. Suppose that there

are five components in the mixture and it is specified that the second and the fourth

component should be present in the distillate by an amount equal to 90% of the feed and

5% of the feed respectively. Then the split for the second component is 0.90 and for the

fourth will be 0.05.

Design method is valid only for simple distillation column i.e. in case of only one feed

stream and distillate and bottom stream only. If there are more than one feed stream and

multiple side streams then the column is complex and there is no design method for this

type of column. Also it has to be noted that the design methods yield approximate results

and to get more accurate results, one has to ratify the results obtained from the design

methods by using much more rigorous simulation methods.

Fenske-Underwood-Gilliland (FUG) [ ] method is one design method where minimum

number of trays is found by Fenske method. Minimum reflux ratio is found by

2

Underwood method and the operating number of trays by Gilliland correlation of tray and

reflux.

Another well-known design method is the Lewis-Matheson method [ ] which is more

accurate than FUG method but due to substantial amount of computation effort and

inherent instability in the convergence, this method is not so much in use nowadays. It is

recommended to use FUG method to obtain the initial estimate, which are then further

ratified or corrected as needed, using some rigorous simulation methods.

In simulation problem the specified variables are:

- Number of equilibrium stages

- Number of components

- All feed and side stream locations

- All feed rates

- All feed compositions and temperatures

- Reflux ratio

- Top product rate

- Heat input to any stage and the corresponding stage number

- Type of condenser

- Column pressure

So this method assumes that a column exist which can be simple as well as complex and

then calculates the temperature profile in each tray, composition in liquid and vapor for

each component in each tray, liquid and vapor flow rate at each tray so that it matches the

requirement. This method is also rigorous method and much more accurate than design

methods.

5.2 Fenske Underwood Gilliland (FUG) method for

distillation

The FUG method utilizes Fenske equation to make an estimate of the number of

theoretical plates at total reflux; Underwoods method to roughly compute the minimum

reflux ratio and Gillilands method for approximately getting the operating number of

plates at operating reflux which is 1.2-1.5 times the minimum reflux. Kirkebride method

is used to locate the feed plate.

In this method splits of two components are specified in one of the product stream say in

the distillate. Let it be desired that distillate contain Pn% of the n

th

component of the feed

and Pm% of the m

th

component of the feed.

It is also conventional to define a light key and a heavy key component. A heavy

key component is one that is present in the distillate at important concentration while

component heavier than it are present in negligible amount. If all components are present

in the distillate in appreciable amount then the least volatile component will be the heavy

key. Similarly, a light key component is present in the residue at important concentration

3

while components lighter than it are present in very small amounts. If all components are

present in the residue at important concentrations then the most volatile component will

be the light key.

5.2.1 Estimation of key components by Shiras, Hanson and

Gibson equation

Let split of n

th

and m

th

component be P

n

and P

m

respectively.

Then P

n

= d

n

/f

n

where dn and fn is the n

th

component molar flow rate in the distillate and in the feed

respectively.

SHG equation gives for the ith component split

P

i

= d

i

/f

i

= ((

i

-1)/(

lk

-1)) (d

lk

/f

lk

) + ((

lk

-

i

)/(

lk

-1)) (d

hk

/f

hk

)

where

i

is the relative volatility of the i

th

component

lk is the light key, hk is the heavy key

Substituting i=n and i=m we get

P

n

= d

n

/f

n

= ((

n

-1)/(

lk

-1))x(d

lk

/f

lk

) + ((

lk

-

n

)/(

lk

-1))x(d

hk

/f

hk

)

P

m

= d

m

/f

m

= ((

m

-1)/(

lk

-1))x(d

lk

/f

lk

) + ((

lk

-

m

)/(

lk

-1))x(d

hk

/f

hk

)

Let these two equations be written like this:

P

n

=A

1

d

lk

+ B

1

d

hk

P

m

= A

2

d

lk

+ B

2

d

hk

Solving for d

lk

and d

hk

we get

d

hk

=(P

n

A

2

-P

m

A

1

)/(A

2

B

1

-A

1

B

2

)

d

lk

= (P

n

-B

1

d

hk

)/A

1

Then knowing d

lk

, d

hk

, f

lk

, f

hk

and all the relative volatilities one can calculate

P

i

= d

i

/f

i

= ((

i

-1)/(

lk

-1)) (d

lk

/f

lk

) + ((

lk

-

i

)/(

lk

-1)) (d

hk

/f

hk

)

Then it is required to test that

P

i

>= 1 for all i<lk

0<P

i

<1 for all lk<=i<=hk

P

i

<=0 for all i>hk

4

If all constrains are satisfied then the choice of key components are correct, else they are

to be re chosen.

In this context one needs to remember that the relative volatility is defined as

i

= K

i

/ K

hk

where K

i

and K

hk

are the equilibrium constant of the i

th

component and heavy key

respectively. Another thing this is important is that the components are to be ordered in

order of decreasing relative volatility. To do this one first need to check which K value is

the least and then relative volatility is calculated for all the components based on the least

K value and then ordered in decreasing order. This is done because FUG method

supposes that the components are input in order of decreasing relative volatility but user

may not be aware of the order and may input the components haphazardly.

5

a

b

c

d

e

f

lk

hk

Distillate

Bottoms

Distributed

Components

a

b

c

d

e

f

lk

hk

Distillate

Bottoms

Distributed

Components

4 1 3

o u o s s

4 1 3

o u o s s

and

a

b

c

d

e

f

Component o

i

d

i

f

i

lk

hk

o

1

o

2

o

3

o

4

o

5

o

6

u

1

u

2

d

1

= f

1

d

2

= f

2

d

3

d

4

d

5

0

f

1

f

2

f

3

f

4

f

5

f

6

b

i

0

0

b

3

b

4

b

5

b

6

= f

6

D d

c

i

i

=

=1

B b

c

i

i

=

=1

In general

1 1 +

s s

lk lk

o u o

2 2 1 + +

s s

lk lk

o u o

and i lk i i lk + +

s s o u o

1

4 1 3

o u o s s

4 1 3

o u o s s

and 4 1 3

o u o s s

4 1 3

o u o s s

and

a

b

c

d

e

f

Component o

i

d

i

f

i

lk

hk

o

1

o

2

o

3

o

4

o

5

o

6

u

1

u

2

d

1

= f

1

d

2

= f

2

d

3

d

4

d

5

0

f

1

f

2

f

3

f

4

f

5

f

6

b

i

0

0

b

3

b

4

b

5

b

6

= f

6

D d

c

i

i

=

=1

B b

c

i

i

=

=1

In general

1 1 +

s s

lk lk

o u o

2 2 1 + +

s s

lk lk

o u o

and i lk i i lk + +

s s o u o

1

a

b

c

d

e

f

Component o

i

d

i

f

i

lk

hk

o

1

o

2

o

3

o

4

o

5

o

6

u

1

u

2

d

1

= f

1

d

2

= f

2

d

3

d

4

d

5

0

f

1

f

2

f

3

f

4

f

5

f

6

b

i

0

0

b

3

b

4

b

5

b

6

= f

6

D d

c

i

i

=

=1

B b

c

i

i

=

=1

a

b

c

d

e

f

Component o

i

d

i

f

i

lk

hk

o

1

o

2

o

3

o

4

o

5

o

6

u

1

u

2

d

1

= f

1

d

2

= f

2

d

3

d

4

d

5

0

f

1

f

2

f

3

f

4

f

5

f

6

b

i

0

0

b

3

b

4

b

5

b

6

= f

6

Component o

i

d

i

f

i

lk

hk

o

1

o

2

o

3

o

4

o

5

o

6

u

1

u

2

d

1

= f

1

d

2

= f

2

d

3

d

4

d

5

0

f

1

f

2

f

3

f

4

f

5

f

6

b

i

0

0

b

3

b

4

b

5

b

6

= f

6

D d

c

i

i

=

=1

B b

c

i

i

=

=1

In general

1 1 +

s s

lk lk

o u o

2 2 1 + +

s s

lk lk

o u o

and i lk i i lk + +

s s o u o

1

6

5.2.2 Calculation of minimum reflux by Underwood equation

After calculating the right key components Underwood method is used for finding out the

minimum reflux ratio.

There are two equations of Underwood.

1. (

i

fi)/(

i

-)=F(1-q)

2. (

i

di)/(

i

-)=D(Rm+1)

where the terms have their usual meanings and q is the fraction of the feed going into the

liquid state which can be determined from isothermal flash calculation discussed earlier.

Rm is the minimum reflux.

So in the first equation the unknown variable is . From the equation we also can see that

there will be C number of roots where C is the number of components. What we are

intending is to use these values in the second equation to get simultaneous equations to

get the unknown variables di and Rm. But we know two di values d

lk

and d

hk

from SHG

equation. Also as per definition of light and heavy key and di for i<lk will be equal to the

feed component flow rate fi and di for i>lk will be zero. So after all we have to find out

hk-lk-1 number of di values and one Rm value i.e. total hk-lk unknowns.

One can also see that if heavy and light key are two adjacent components then hk-lk-1

equals to zero. In that case there will be only one unknown Rm and only one equation, so

it can be directly obtained. But for non adjacent keys we have to solve the simultaneous

equations by any suitable numerical method. Gauss-Jordan method was used in the

program.

only has mathematical significance. And any i lies between

lk+i-1

and

lk+i

where i

lies between lk and hk.

Bisection or Regula-Falsi method can be used to solve the nonlinear equation of . As

initial guesses for i,

lk+i-1

and

lk+i

values are supplied. So by invoking hk-lk times this

routine and incrementing i from 1 to hk-lk one can get all values needed.

Once all the values are calculated, second Underwood equation is used two get Rm and

the unknown di values. Since total distillate flow rate D is not known before knowing all

component distillate flow rate di so D(Rm+1) as a whole is taken as one variable. After

getting all di values D is calculated by summing up all di and then Rm is obtained.

After calculating di and Rm distillate composition can be calculated from

Z

Di

=di/D i=1, 2 C

and bottom composition using the following equation

X

Bi

= (fi-di)/(F-D) i=1,2C

7

The relative volatilities in the two equations can be calculated as usual but a closer look

will give that relative volatility is temperature dependent, but the dependency is not so

pronounced as the equilibrium constant. Nevertheless, since the relative volatility values

have been taken as constant throughout the column for each component a rational

approach is to calculate it at the average temperature of the column top and bottom

temperature. But column top temperature can be calculated from the dew point

temperature of the distillate and bottom temperature from the bubble point temperature of

the bottom mixture. In order to do that one needs to know the compositions. So as a first

trial Tavg is taken equal to the feed temperature and then two Underwood equations are

solved and the compositions of both the streams are obtained. Then the respective dew

point and bubble point temperatures are calculated. Then average temperature is

calculated as (Ttop+Tbot)/2. Then this temperature is checked with the earlier

assumption. If the difference is tolerable then calculated di values and Rm is correct

otherwise one needs to replace the previous average with the new average and

recalculate.

5.2.3 Calculation of minimum number of plates by Fenskes

equation

Fenske method is used to calculate the minimum number of trays at the total reflux.

When the column operates at total reflux no feed is introduce and no distillate and bottom

is taken out. So in this case a column is charged with the feed and then the feed flow is

stopped, distillate and bottom outlets are closed. The entire condenser outlet is returned to

the top tray. Eventually the column comes to steady state shown by no fluctuation in the

tray temperatures. Then the column is said to operate at total reflux.

Fenske equation at total reflux is given by:

di/d

hk

=(

i

)

Nm

(bi/b

hk

)

where di is the i

th

component distillate flow rate and bi is the i

th

component bottom flow

rate.

Replacing i with lk one gets

d

lk

/d

hk

=(

lk

)

Nm

(b

l k

/b

hk

)

For the first trial temperature is assumed equal to that comes out from the Underwood

method and at this temperature relative volatility of the light key is calculated. And the

flow rates are taken from the Underwood method. Though the flow rates are not at total

reflux but as an initial guess it is quite handy.

Then Nm is calculated from the second equation. Once Nm is calculated then all bi

values can be calculated by the equation

8

bi=fi/(1+(dhk/bhk)(

i

)

Nm

)

The equation is obtained by substituting di=fi-bi in the first form of the Fenske equation.

After calculating all bi values all di values are obtained using di=fi-bi. Then distillate and

bottom compositions are calculated using

Z

di

=di/D

X

Bi

=bi/B i=1, 2C

Then the distillates dew point and bottoms bubble point temperature is calculated and

the average temperature is obtained. If this average temperature is not quite different than

the previous temperature then convergence is achieved otherwise the entire calculation is

repeated.

5.2.4 Determination of equilibrium number of plates by

Gilliland correlation

Gilliland correlation is used to calculate the number of ideal trays at operating reflux.

Nonlinear regression technique is used to correlate operating reflux with the operating

number of trays.

The equation is:

(N-Nm)/(N+1)= 1-exp[{(1+54.4K)/(11+117.2K)}{(K-1)/sqrt(K)}]

where N is the number of theoretical plates at operating reflux and

K=(R-Rm)/(R+1)

R=1.2-2.0 times the minimum reflux (Rm).

If (N-Nm)/(N+1) be plotted against K in log-log scale then the curve will look like the

following:

9

Distillate and bottom compositions at operating reflux can be calculated by linear

interpolation.

(di

op

-di

tot

)/(di

m

-di

tot

)=(R/(R+1)-1)/(Rm/(Rm+1)-1) i=1, 2C

where di

op

, di

tot

, di

m

is i

th

component distillate flow rate at operating reflux, total reflux

and minimum reflux respectively.

After calculating di

op

we have to calculate the following:

di

op

=fi- di

op

D= di

op

B=F-D

Z

di

=di/D

X

bi

=bi/B i=1, 2C

Column top and bottom temperatures are calculated from the distillate dew point and

bottoms bubble point temperature using compositions calculated.

5.2.5 Feed plate location by Kirkbride correlation

Kirtebride correlation is used to determine the feed tray location.

log(N

R

/N

s

)=0.206log[(B/D)(Z

Fhk

/Z

Flk

)(X

Blk

/Z

Dhk

)

2

]

where N

R

is the number of trays in the rectifying section

10

N

s

is the number of trays in the stripping section

B,D are bottom and distillate flow rate respectively

Z

Fhk

, Z

Flk

, Z

Dhk

, X

Blk

are compositions of the key components in the feed or

distillate or bottom

From the equation N

R

/N

s

can be obtained.

Also N

R

+N

s

=N total number of trays

So from the two equations N

R

and N

s

can be separately calculated. So the feed tray

location will be the N

R

th

plate from the top.

The following code finds out the feed tray location:

5.2.6 Complete algorithm of the FUG method

1. Light key and heavy key component are specified

2. Relative volatilities of all the components are calculated based on the heavy key

take Tavg = Tfeed for the first trial

3. d

lk

and d

hk

are computed from SHG equation

4. Substituting d

lk

and d

hk

in the SHG equation all Pi values are calculated

5. The required constrain is checked:

Pi>=1 for i<lk

0<Pi<1 for lk<=i<=hk

Pi<=0 for i>hk

6. If all the constrains are true then choice of key component is correct else key

components are re chosen and calculations repeated from step 2

7. Find q by solving the flash equation

8. Solve the first Underwood equation for hk-lk values of by calling hk-lk times

the routine of bisection or regula-falsi

9. Solve the second Underwood equation by writing it for all values by Gauss

Jordan method to find hk-lk-1 values of di and D(Rm+1)

10. Find D,B,Z

Di

,X

Bi

and Rm

11. Find distillate dew point and bottom bubble point temperature and calculate

Tavg=(Td+Tb)/2

12. If this Tavg is not closely equal to the previous Tavg then repeat from step1 using

the latest Tavg until convergence is achieved

13. Starting with the latest values of Tb,Td and Tavg find the relative volatilities and

then apply Fenskes equation to calculate Nm

14. Find the non key product distribution (bi and di) at total reflux

15. Find D,B,Z

Di

and X

Bi

at total reflux

16. Find distillate dew point and bottom bubble point temperature and calculate

Tavg=(Td+Tb)/2

11

17. If this Tavg is not closely equal to the previous Tavg then repeat from step13

using the latest Tavg until convergence is achieved

18. After convergence D,B,Z

Di

,X

Bi

are all defined at total reflux

19. Select operating reflux ratio

20. Find product distribution at operating reflux ratio by linear interpolation

21. Find D,B,Z

Di

,X

Bi

at operating reflux

22. Find distillate dew point and bottom bubble point temperature. Then Td will be

column top temperature and Tb will be bottom temperature at operating reflux

23. Use Gilliland correlation to find out number of theoretical plates at operating

reflux

24. Use Kirtebride correlation to find out the feed tray location

Question:

The feed mixture having the following composition enters a

distillation column at a flow rate 100 k mole/hr with feed temperature 107.2

deg C. The pressure inside the distillation column may be taken as 1.72

Mpa. Use ideal mixture assumption & Antoines constants to evaluate K

values.

i Component Composition (Zi)

1 C2 0.03

2 C3 0.20

3 n-C4 0.37

4 n-C5 0.35

5 n-C6 0.05

It is specified that 90% of C3 and n-C4 is required in the distillate. It has been proposed

that 2

nd

and 3

rd

component may be assumed as lk and hk.

i) Use Shiras-Hanson-Gibson (SHG) equation to check the validity of the proposition.

ii) Find minimum reflux ratio by Underwood method if q=0.88(given). Write any

assumptions that you have made in your solution.

Solution:

i) Given:

Flow rate: 100 K mole/ hr

Feed Temperature: 107.2 deg C

Pressure inside the distillation column: 1.72 Mpa

90% of C3: p2 = d2/f2=0.9 =split of lk

2% of n-C4: p3 = d3/f3=0.02 =split of hk

12

Let us assume

2

nd

Component: Light key (lk)

3

rd

Component: Heavy key (hk)

Antoines Constants:

Sl no. Component A B C

1 C2 15.6637 1511.92 -17.16

2 C3 15.7260 1872.49 -25.16

3 n-C4 15.6782 2154.90 -34.42

4 n-C5 15.8333 2477.07 -39.94

5 n-C5 15.8366 2697.55 -48.78

Antoines Equation:

ln P

i

=A

i

B

i

/(C

i

+ T)

Now,

Ki= P

i

/P (P= 1.72Mpa)

and o=K

i

/K

hk

Sample Calculation:

ln P1 =15.6637 1511.42/(-17.16+380.35)

or, P1 = 98931.87 mm of Hg = 13.1898 Mpa

therefore,

K1 =13.1898/1.72=7.67

o1= 7.67/0.98 = 7.83 (where K

hk

= 0.98)

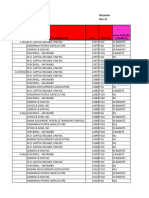

ith component Component Composition (Zi) Pressure

Pi (Mpa)

Ki oi

1 C2 0.03 13.1898 7.67 7.83

2 C3 (lk) 0.20 4.6250 2.69 2.74

3 n-C4(hk) 0.37 1.6920 0.98 1.0

4 n-C5 0.35 0.6930 0.403 0.41

5 n-C6 0.05 0.2950 0.17 0.17

Now,

13

Split, p

i

= d

i

/f

i

= [{(o

i

-1)/(o

lk

-1)} * {(d

lk

/f

lk

)} * {(o

lk

-o

i

)/(o

lk

-1)} * {(d

lk

/f

lk

)}]

putting the values of the terms from the table of the above equation, we get,

p

1

= 1.08

p

4

= -0.008

p

5

= -0.013

Conditions:

p

i

>1.0 for i<lh

p

i

<=0 for i>hk

The above condition are satisfied,

So the proposition is correct.

ii) Given q=0.88

Now,

) /( *

1

u o o

=

i i Z

c

i

= (1-q)

Putting the values of the terms in the above equation, we get

u = 1.8539

Again,

a) d1=f1

d1/F=Z1

d1=Z1*F= 0.03 * 100 = 3 K mole/hr = 3000 mole/hr

b) d2/f2=0.9

d2/Z2*F=0.9

d2= 0.9*0.20*100*1000 mole/hr

14

d2= 18000 mole/hr

c) d3/f3=0.02

d3/Z3*F=0.02

d3=0.02*0.37*100*1000

d3=740 mole/hr

d) d4=0

e) d5=0

therefore,

D=3000+18000+740=21740

xd1=3000/21740=0.138

xd2=18000/21740=0.828

xd3=740/21740

Now,

=

hk

i

ai di i

1

) /( * u o = D * (Rm+1) (where, Rm= Minimum reflux ratio)

or,

=

hk

i

i xdi i

1

) /( * u o o = (Rm+1)

Putting the values of the above terms, we get

Minimum reflux ratio, Rm = 1.701

Assumptions:

1) The mixture is a ideal mixture.

2) Inlet temperature is equal to inside column temperature.

15

Question:

A ternary mixture containing 40% n-C

4

, 25 % n- C

5

and rest n-C

6

are subjected to

distillation. The feed enters the column as saturated liquid at 100 kmols/s and the

pressure at the feed plate location may be assumed to be 1 atm. It is specified that the

split of n-C

4

and n- C

6

should be 90% and 5% respectively. Find the minimum reflux

ratio and products compositions at minimum reflux ratio using underwood method.

The values of the Antoines constant are as given below

Components A B C

n-C

4

15.6782 2154.9 -34.42

n-C

5

15.8333 2477.07 -39.94

n-C

6

15.8366 2697.55 -48.78

Let us take n-C

4,

n-C

5

, n-C

6

as componets no. 1 ,2 and 3 respectively

From the given feed flow rate and splits of n-C

4

and n-C

6

we find the distillate flow rates

of 1 and 3 as 40 kmols/s and 35 kmols/s respectively using the equation

P

i

= d

i

/ f

i

Now from Antoines equation (like previous problem) we find the average normal boiling

points (NBP) of the given components as (T

nbp

)

avg

=308.02

Now we evaluate the K

i

values at this temperature

The K values are found as follows

K

i

= (1/P) exp(A

i

B

i

/ (C

i

+ T))

K

1

=3.21

K

2

= 0.96

K

3

= 0.3

Now assuming component 3 as the reference component we find out the relative

volatilities of the components as

o

i

= K

i

/ K

j

Thus the relative volatilities of the components are

o

1

= 10.7

o

2

= 3.2

o

3

= 1

16

Now we know that

o

i

x

i

= 1/ K

b

from this relation 1/K

b

is found to be equal to 5.43 where K

b

denotes the equilibrium

distribution coefficient for the base component.

Now

1/K

b

= (1/Pt) exp(A

3

(B

3

/(C

3

+ T))

from this relation T is found as T

BP

T

BP

= 407.65K

Now we calculate actual values o

1

,o

2,

o

3

For this we have to re-calculate the values of K

i

s at T

BP

So

K

1

= 26.36

K

2

= 11.74

K3=5.4

o

1

= (K

1

/ K

3

) = 4.88

o

2

= (K

2

/ K

3

) = 2.17

o

3

= 1

Now we apply SHG equation to find out the hk and lk compounds.

Let us assume lk = component 1

hk = component 3

the SHG equation is given by

P

n

= A

1

d

lk

+ B

1

d

hk

..(1)

P

m

= A

2

d

lk

+ B

2

d

hk

.(2)

Where A1= (o

n

1)/( o

lk

1) (1/f

lk

) = (4.88 1) / (4.88 1) (1/ f

lk

) = 1 / f

lk

B1 = (o

lk -

o

n

)/ (o

lk

1)(1/ f

hk

) = (4.88 4.88)/(4.88 1) (1/ f

hk

) = 0

17

A

2

= (o

m

1)/( o

lk

1) (1/f

lk

) = (1-1)/ (4.88 -1)(1/f

lk

) = 0

B2 = (o

lk -

o

m

)/ (o

lk

1)(1/ f

hk

) = (4.88 1) / (4.88 1) (1/ f

hk

) = 1/ f

hk

After substituting these values in the equations we have

P

n

= d

lk

/f

lk

P

m

= d

hk

/f

hk

The split of the distributed component is given by

P

2

= ((o

2

1)/( o

lk

1)) (d

lk

/f

lk

) + ((o

lk

- o

2

)/ ( o

lk

1))( d

hk

/f

hk

)

From this relation P

2

is found as 0.3068

So for lk<i<hk we have 0<P

2

<1 . so the condition is satisfied and this implies that our

choice of lk and hk has been correct.

From the first Underwood equation we have

o

i

f

i

/ (o

i

- u) = F (1 q)

here the liquid is saturated liquid so q=1 and this makes the right hand side of the first

underwood equation equal to zero. This leaves us with a quadratic equation of u

solving this equation we get u

1

= 2.86

u

2

= 1.3

we can see here that o

1

> u

1

> o

2

o

2

> u

2

> o

3

from the second underwood equation we have

o

i

d

i

/ (o

i

- u) = D (R

m

+ 1)

let us assume D (R

m

+ 1) = X and we know d

1

and d

3

. Thus we will obtain two

simultaneous equations in d

2

and X.

the equations obtained, are

3.14 d

2

+ X =86.03 (a)

- 2.49 d

2

+ X = 43.24 .(b)

solving these equations we get d

2

= 7.72 kmols /s

18

Therefore the amount of distillate is D = d

1

+ d

2

+d

3

= 36 + 7.72 + 1.75 = 45.47

Putting the value of d

2

in (a) we get

R

m

= 0.35

So the minimum reflux ratio should be 0.35

You might also like

- Working Guide to Vapor-Liquid Phase Equilibria CalculationsFrom EverandWorking Guide to Vapor-Liquid Phase Equilibria CalculationsRating: 5 out of 5 stars5/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsRating: 4 out of 5 stars4/5 (9)

- Chapter1 Design of Multicomponent Distillation Column................................................. 2Document12 pagesChapter1 Design of Multicomponent Distillation Column................................................. 2waleed ur rehmanNo ratings yet

- ProjectDocument65 pagesProjectshashank_kakadeNo ratings yet

- Multi Component DistillationDocument71 pagesMulti Component DistillationManu Jain83% (6)

- Material BalancesDocument24 pagesMaterial Balancesnael94No ratings yet

- Another New Look at Polytropic Calculations Methods For Turbomachinery PerformanceDocument24 pagesAnother New Look at Polytropic Calculations Methods For Turbomachinery PerformanceHoozefa J. ShaikhNo ratings yet

- Dehydration of Alcohols-Gas Chromatography: ObjectiveDocument6 pagesDehydration of Alcohols-Gas Chromatography: Objectiveamel saadNo ratings yet

- Multicomponent Distillation V ImpDocument94 pagesMulticomponent Distillation V Impsunami666No ratings yet

- Batch Distillation W 10Document6 pagesBatch Distillation W 10Junaid AhmadNo ratings yet

- Sensitivity Analysis in Linear ProgrammingDocument9 pagesSensitivity Analysis in Linear ProgrammingPratik PatilNo ratings yet

- CS 3612 CCMV3Document8 pagesCS 3612 CCMV3Wilhelm ThorleyNo ratings yet

- Process Control & Instrumentation Lab BKF 4791 Title of Experiment: Measurement and Control Air Flow System Lecturer's Name Group of Member: Name IDDocument12 pagesProcess Control & Instrumentation Lab BKF 4791 Title of Experiment: Measurement and Control Air Flow System Lecturer's Name Group of Member: Name IDTan Yong ChaiNo ratings yet

- Bhavishya Gupta Che251 Labreport4Document14 pagesBhavishya Gupta Che251 Labreport4Bhavishya GuptaNo ratings yet

- Preliminary Design of a Distillation ColumnDocument14 pagesPreliminary Design of a Distillation ColumnChandni SeelochanNo ratings yet

- ACT 5 SheetDocument5 pagesACT 5 SheetshaiNo ratings yet

- A simple design method for multicomponent distillation columnsDocument8 pagesA simple design method for multicomponent distillation columnsramantal5No ratings yet

- Chapter 5Document23 pagesChapter 5Ghaya Bani RushaidNo ratings yet

- Distillation 4Document13 pagesDistillation 4Renu SekaranNo ratings yet

- Prediction of physical properties of hydrocarbons and petroleum fractionsDocument6 pagesPrediction of physical properties of hydrocarbons and petroleum fractionsJosé Blanco MosqueraNo ratings yet

- Air Cooled Heat Exchanger SizingDocument12 pagesAir Cooled Heat Exchanger Sizingkhagahu100% (3)

- Factorial Design Excel AnalysisDocument30 pagesFactorial Design Excel Analysismaria10018012No ratings yet

- Distillation Column EfficiencyDocument33 pagesDistillation Column EfficiencyAldi StefanusNo ratings yet

- User's Guide 12-02-2009 TLSDDocument45 pagesUser's Guide 12-02-2009 TLSDDavid Bautista GonzálezNo ratings yet

- Multicomponent distillation shortcut methodsDocument4 pagesMulticomponent distillation shortcut methodsNguyễn Tiến DũngNo ratings yet

- Laboratory Exercise 5.1Document10 pagesLaboratory Exercise 5.1EUNICE JOI SARCONNo ratings yet

- Freezing Point DepressionDocument7 pagesFreezing Point DepressionpintuchemtechNo ratings yet

- Solving Equations of StateDocument12 pagesSolving Equations of StateMia Beatrice Benavidez Mawili100% (1)

- Vle, Lle and Vlle in Aspen Plus Mohammad Ali Fanaei, Ferdowsi University of MashhadDocument23 pagesVle, Lle and Vlle in Aspen Plus Mohammad Ali Fanaei, Ferdowsi University of MashhadTae Vorachit UmnuaypornNo ratings yet

- Pressure-Temperature Diagram Analysis of Liquefied PDFDocument5 pagesPressure-Temperature Diagram Analysis of Liquefied PDFneversig100% (1)

- Prediction of Temperature Drop Accompanying A Given Pressure Drop For Natural Gas WellstreamsDocument5 pagesPrediction of Temperature Drop Accompanying A Given Pressure Drop For Natural Gas Wellstreamsmisterno2No ratings yet

- Binary Distillation in A Bubble Cap Tray ColumnDocument3 pagesBinary Distillation in A Bubble Cap Tray ColumnShelly Theresse Catian NovoNo ratings yet

- OECD/OCDE Guideline for the testing of chemicals Partition Coefficient (n-octanol/water) by High Performance Liquid Chromatography (HPLC) MethodDocument11 pagesOECD/OCDE Guideline for the testing of chemicals Partition Coefficient (n-octanol/water) by High Performance Liquid Chromatography (HPLC) MethodGauri Toley MuleyNo ratings yet

- Termodinamica de Hidrocarburos: Generalized Phase EquilibriaDocument109 pagesTermodinamica de Hidrocarburos: Generalized Phase Equilibria13670319No ratings yet

- Detailed Notes Topic 5 Formulae Equations and Amounts of Substance Edexcel Chemistry A LevelDocument7 pagesDetailed Notes Topic 5 Formulae Equations and Amounts of Substance Edexcel Chemistry A LevelttjjjNo ratings yet

- Transcript - Multicomponent Flash Calculations VideoDocument3 pagesTranscript - Multicomponent Flash Calculations VideoChristopher RileyNo ratings yet

- CPE603 GuideDocument6 pagesCPE603 GuideainmnrhNo ratings yet

- Experiment: Reactive Distillation ColumnDocument14 pagesExperiment: Reactive Distillation ColumnchaitanyaNo ratings yet

- Matlab - Equations of StateDocument23 pagesMatlab - Equations of StateMia Beatrice Benavidez MawiliNo ratings yet

- Recycle Bypass and PurgeDocument8 pagesRecycle Bypass and PurgeMuhammadAliRajaieNo ratings yet

- Psych ProcessDocument9 pagesPsych Processmdalt9180No ratings yet

- Handout 2Document22 pagesHandout 2aaa206No ratings yet

- Differential DistillationDocument36 pagesDifferential DistillationShruti100% (1)

- 2 Stage CompressionDocument18 pages2 Stage CompressionSyed Muzamil Ahmed100% (3)

- Module 03Document10 pagesModule 03tdvisserservicesNo ratings yet

- Identification and Optimization of Pi Parameters Based On Genetic Algorithm For Non Linear System Using MatlabDocument51 pagesIdentification and Optimization of Pi Parameters Based On Genetic Algorithm For Non Linear System Using Matlabjagateesan50% (2)

- 2007 ANTEC Mold DesignDocument6 pages2007 ANTEC Mold DesignRupesh PillaiNo ratings yet

- Last Class: Classifying Process TypesDocument43 pagesLast Class: Classifying Process TypesStevenNo ratings yet

- Tutorial: Partially Premixed Combustion in A Co-Axial CombustorDocument13 pagesTutorial: Partially Premixed Combustion in A Co-Axial CombustorGaurav SinglaNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument27 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsSebastian PinzonNo ratings yet

- Mass Transfer Design: DR Sintayehu Mekuria Hailegiorgis Department of Chemical EngineeringDocument37 pagesMass Transfer Design: DR Sintayehu Mekuria Hailegiorgis Department of Chemical EngineeringAman RizanNo ratings yet

- Module-4: by Pandurangan.K Assistant Professor Senior VIT VelloreDocument51 pagesModule-4: by Pandurangan.K Assistant Professor Senior VIT VelloreUrvaNo ratings yet

- Liquid Holdup, MODELS PDFDocument14 pagesLiquid Holdup, MODELS PDFjoreliNo ratings yet

- Chemical Equilibrium NotesDocument11 pagesChemical Equilibrium NotesNeha Kaur SinhaNo ratings yet

- SPE Canada Unconventional Resources Conference CGR NormalizationDocument20 pagesSPE Canada Unconventional Resources Conference CGR NormalizationPedroNo ratings yet

- Pressure Drop Calculations in Boiling SystemsDocument4 pagesPressure Drop Calculations in Boiling Systemsw2381ftNo ratings yet

- Technological Institute of the Philippines Unit Operations Laboratory ExperimentsDocument35 pagesTechnological Institute of the Philippines Unit Operations Laboratory ExperimentsNoella NatividadNo ratings yet

- Final Exposition - CFDDocument21 pagesFinal Exposition - CFDDaniel Casas-OrozcoNo ratings yet

- Essentials of Multiphase Flow and Transport in Porous MediaFrom EverandEssentials of Multiphase Flow and Transport in Porous MediaNo ratings yet

- MQE2013Document13 pagesMQE2013Sanket AroraNo ratings yet

- Emerson-Valve Sizing Calculations (Traditional Method)Document21 pagesEmerson-Valve Sizing Calculations (Traditional Method)iqtorresNo ratings yet

- UOP Career Development Program For Chemical Engineers BrochureDocument8 pagesUOP Career Development Program For Chemical Engineers BrochureArka Pravo BandyopadhyayNo ratings yet

- APLUS 2004 Getting Started Petroleum PDFDocument103 pagesAPLUS 2004 Getting Started Petroleum PDFArka Pravo BandyopadhyayNo ratings yet

- Unit Operation ModelsDocument380 pagesUnit Operation Modelsvsraochemical1979100% (1)

- Steam TablesDocument16 pagesSteam TablesSantosh KumarNo ratings yet

- Unit Operation ModelsDocument380 pagesUnit Operation Modelsvsraochemical1979100% (1)

- FM200 MsdsDocument4 pagesFM200 MsdsArka Pravo BandyopadhyayNo ratings yet

- Steam TablesDocument16 pagesSteam TablesSantosh KumarNo ratings yet

- Ultra Frac TraysDocument4 pagesUltra Frac TraysAhmed Al-HashmiNo ratings yet

- Xat 2014Document1 pageXat 2014Arka Pravo BandyopadhyayNo ratings yet

- Pressure Drop in Reactors Calc.Document22 pagesPressure Drop in Reactors Calc.Arka Pravo BandyopadhyayNo ratings yet

- Innovative Catalyst Solutions For (Ultra) Low Sulphur DieselDocument24 pagesInnovative Catalyst Solutions For (Ultra) Low Sulphur DieselArka Pravo BandyopadhyayNo ratings yet

- CpmPlus Energy Manager (PRS128a)Document2 pagesCpmPlus Energy Manager (PRS128a)Arka Pravo BandyopadhyayNo ratings yet

- Valve PositionersDocument56 pagesValve PositionersArka Pravo BandyopadhyayNo ratings yet

- FM200 MsdsDocument4 pagesFM200 MsdsArka Pravo BandyopadhyayNo ratings yet

- API Plans FlowserveDocument56 pagesAPI Plans Flowservewwast72100% (5)

- Fiziks: Basic Properties and Tools of ThermodynamicsDocument28 pagesFiziks: Basic Properties and Tools of ThermodynamicsSURAJ PRATAP SINGHNo ratings yet

- Activity No. 5 Capacitive Circuit ObjectivesDocument4 pagesActivity No. 5 Capacitive Circuit ObjectivesJohn Paul BaquiranNo ratings yet

- Alcohols, Phenols and Ethers Worksheet Answer Grade 12Document6 pagesAlcohols, Phenols and Ethers Worksheet Answer Grade 12sethu100% (1)

- Fault Report - Inventory Cpf1 Vs Caño LimomDocument37 pagesFault Report - Inventory Cpf1 Vs Caño LimomJessica RiveraNo ratings yet

- Dental Material Final ReportDocument7 pagesDental Material Final ReportAbdullah Muhammed khaleel HassanNo ratings yet

- p-4500 Technical InformationDocument13 pagesp-4500 Technical InformationElhoiNo ratings yet

- Ukur KadasterDocument21 pagesUkur KadasterMuhammad NajmiNo ratings yet

- Effect of Temperature on Chemical ReactionDocument8 pagesEffect of Temperature on Chemical ReactionnajihahNo ratings yet

- Hazardous Area Hazardous Area ClassificaDocument106 pagesHazardous Area Hazardous Area ClassificaHedi Ben MohamedNo ratings yet

- Timer Counter ArduinoDocument8 pagesTimer Counter ArduinoKietDangNo ratings yet

- Abstract (Lab 2) Ionization ConstantDocument12 pagesAbstract (Lab 2) Ionization Constantmirdza94No ratings yet

- TDT4171 Artificial Intelligence Methods Task 5 Creating A Decision Support SystemDocument12 pagesTDT4171 Artificial Intelligence Methods Task 5 Creating A Decision Support SystemKermess McNo ratings yet

- Cambridge Learning Academy Physics - Sound and WavesDocument7 pagesCambridge Learning Academy Physics - Sound and WavesRubab BajwaNo ratings yet

- Digital Image Processing TechniquesDocument34 pagesDigital Image Processing Techniquesaishuvc1822No ratings yet

- Si™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Document23 pagesSi™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Agenor CarvalhoNo ratings yet

- Open Hole Logs Introduction GR SP CALDocument21 pagesOpen Hole Logs Introduction GR SP CALmagedNo ratings yet

- Maintenance Recommendations: Operation and Maintenance ManualDocument10 pagesMaintenance Recommendations: Operation and Maintenance ManualAmy Nur SNo ratings yet

- TR2400 HF SSB Transceiver FeaturesDocument4 pagesTR2400 HF SSB Transceiver FeaturesAravind VinduNo ratings yet

- H15B PLUS-2 Parts ManualDocument158 pagesH15B PLUS-2 Parts ManualАлексей50% (2)

- GBE Version 3: API: New API SpecificationDocument44 pagesGBE Version 3: API: New API SpecificationAdi BauNo ratings yet

- Nov. AbwDocument50 pagesNov. Abwjbyarkpawolo70No ratings yet

- Product Catalogue Chemical IndicatorsDocument28 pagesProduct Catalogue Chemical IndicatorsscribdddcNo ratings yet

- Multi-Band Booster With HRLB - In-Band Routed DCN Solution GuideDocument26 pagesMulti-Band Booster With HRLB - In-Band Routed DCN Solution GuideAchintha AluthmanageNo ratings yet

- 3 - Molecules and Compounds: Practice TestDocument2 pages3 - Molecules and Compounds: Practice Testfamily_jvcNo ratings yet

- Time Signature - WikipediaDocument17 pagesTime Signature - WikipediaDiana GhiusNo ratings yet

- Ductile deformation finite strain analysisDocument27 pagesDuctile deformation finite strain analysisJorgeBarriosMurielNo ratings yet

- Prepare and Interpret Technical DrawingDocument5 pagesPrepare and Interpret Technical DrawingDwin Rosco75% (4)

- Formulas For Thermodynamics 1Document2 pagesFormulas For Thermodynamics 1Stefani Ann CabalzaNo ratings yet

- Energy Criteria in GRIHA PDFDocument71 pagesEnergy Criteria in GRIHA PDFAnisha Prakash100% (1)

- Homework1 PDFDocument3 pagesHomework1 PDFYuanhao LiuNo ratings yet