Professional Documents

Culture Documents

Tower Manufacturing Process

Uploaded by

mechajay2002Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tower Manufacturing Process

Uploaded by

mechajay2002Copyright:

Available Formats

Toolfab Engineering Industries (P) Ltd

(Heavy Engineering Fabrication)

Heavy Engineering Fabrication

Heavy Engineering Fabrication

Heavy Engineering Fabrication

Heavy Engineering Fabrication

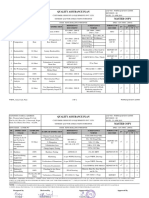

Material Unloading Material Stacking Handling to CNC Cutting Station Plate Cutting Edge Preparation Dimensional Inspection After E.P. Shell Rolling L-Seam Welding L-Seam Welding Inspection L-Seam BG L-Seam BG Welding L-Seam BG Welding Inspection Shell Rerolling Handling of Shells Shell to Shell Cir-Seam Fitup Cir-Seam Fitup Inspection Cir-Seam Welding Cir-Seam BG Cir-Seam BG Inspection Cir Seam BG Welding Flange to Section Fitup

Flange to Section Fitup Inspection FCS Welding FCS BG FCS BG Inspection FCS BG Welding FCS BG Welding Inspection NDT Easy Laser Inspection Internal Fittings Dimensional Inspection Blasting Blasting Inspection Painting Painting Inspection Internals / Electricals Assembly Packing Handling of finished product Dispatch of Finished Goods

Heavy Engineering Fabrication

Material Unloading with the help of Mobile Cranes Raw material inspection / reception control Visual, Verification of material with Mill TC

Heavy Engineering Fabrication

Plate Material Stocking

Heavy Engineering Fabrication

Material Stocking of Internal Items & Paint Materials

Heavy Engineering Fabrication

Loading to CNC Profile Cutting Machine

Heavy Engineering Fabrication

Plate Cutting at Profile Cutting Machine. MESSER 4Mtr/30Mtr Bay one 20Mtr x 80Mtr

Heavy Engineering Fabrication

Beveling & Smoothening by Grinding

Heavy Engineering Fabrication

Plate Rolling in Three Roll Plate Bending Machine 2.5 Mtr Width & 25mm / 40mm Thickness - Himalaya

Heavy Engineering Fabrication

Shell Profile Checking using Template

Heavy Engineering Fabrication

Maintaining required Circumference & Shell Height

Heavy Engineering Fabrication

Maintaining required Circumference & Shell Height by Checking the LS Fit up Shells

Heavy Engineering Fabrication

Back Gouging By Grinding

Heavy Engineering Fabrication

Back Gouging Area DP Test Check

Heavy Engineering Fabrication

Back Gouging Welding- SAW COLOUMN BOOM

Heavy Engineering Fabrication

Rerolling

Heavy Engineering Fabrication

CS Fit up Fit up on Roller Bed using Hydraulic Jack

Heavy Engineering Fabrication

End Ovality arresting, Straightness, Mismatch & Length Checking

Heavy Engineering Fabrication

CS Welding SAW Process with Rotator Bed Using Column Boom (5Mtr X 5Mtr)

Heavy Engineering Fabrication

During CS BG Welding Proper Current Parameters are Maintained using Traly SAW Machine

Heavy Engineering Fabrication

During Flange with Shell Fit up, Maintaining Face out & Plumb out, Verticality as well as Total Length of the Section.

Heavy Engineering Fabrication

Using SAW COLOUMN BOOM

Heavy Engineering Fabrication

Flange with Shell Welded area Back Gouge Grinding

Heavy Engineering Fabrication

Flange Back Gouging Area DP Test Checking

Heavy Engineering Fabrication

After DP Test Back Gouging Area Welding

Heavy Engineering Fabrication

Checking weld Defect by Ultrasonic Testing

Heavy Engineering Fabrication

Checking weld Defect by Radio Graphic Testing(Random)

Heavy Engineering Fabrication

Fixing Bushes and welding with Shells and Platforms

Heavy Engineering Fabrication

To Measure flatness and Tilting of Flanges using Easy Laser

Heavy Engineering Fabrication

Checking Face out & Plumb out, Verticality, Ovality, Total length, Internals locations, Mismatches & Scratches, Surface defects.

Heavy Engineering Fabrication

Fixing Bushes welding with Shells and Platforms

Heavy Engineering Fabrication

Shifting cleared section for blasting site

Heavy Engineering Fabrication

Blasting with Steel Shots in Blasting Chamber. Adherence to Pollution Control Norms.

Heavy Engineering Fabrication

After Blasting checking the surface roughness

Heavy Engineering Fabrication

Painting using with Airless Guns- Inside Painting Chamber.

Heavy Engineering Fabrication

Coating Thickness checked with coat meter

Heavy Engineering Fabrication

Assembling of all Internals Like Ladder, Door Fittings, using recommended Fasteners & Electrical Fittings

Heavy Engineering Fabrication

Assembling of all Internals Like Ladder, Door Fittings, using recommended Fasteners & Electrical Fittings

Heavy Engineering Fabrication

Ends Covered with Plywood and Spider

Heavy Engineering Fabrication

Finished Goods are Ready for Getting Dispatch Clearance

Heavy Engineering Fabrication

Finished Goods Loaded on Trailer

Heavy Engineering Fabrication

After Completion of all Inspections Finished Goods are Dispatched

Heavy Engineering Fabrication

Work Shed 3 Bays 20Mtr x 80Mtr Each. 2 Nos EOT Cranes capacity 30MT.

Heavy Engineering Fabrication

THANK YOU

You might also like

- Painting Procedure 4288 Danem 28-04-13Document24 pagesPainting Procedure 4288 Danem 28-04-13Rejoy baby100% (1)

- List of Useful Materials StandardDocument6 pagesList of Useful Materials StandardStephen MontelepreNo ratings yet

- Analysis To Optimizing Inventory Management in Dies-Mold Making Factory by Partial Least Square (PLS) Case Study: ABC CompanyDocument3 pagesAnalysis To Optimizing Inventory Management in Dies-Mold Making Factory by Partial Least Square (PLS) Case Study: ABC CompanyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Preheating Procedure For Equipment Nozzle Modification (Cs and LTCS)Document6 pagesPreheating Procedure For Equipment Nozzle Modification (Cs and LTCS)Rakesh RanjanNo ratings yet

- Tower Manufacturing ProcessDocument30 pagesTower Manufacturing Processmechajay2002No ratings yet

- Greaseless Bushing PDFDocument122 pagesGreaseless Bushing PDFthavisiNo ratings yet

- Forging - The Process: Metal Forging Is A Metal Forming Process That Involves ApplyingDocument25 pagesForging - The Process: Metal Forging Is A Metal Forming Process That Involves ApplyingAdityasinh DesaiNo ratings yet

- A Project Report On: TMT Bar Bending MachineDocument46 pagesA Project Report On: TMT Bar Bending MachinePrajay BhavsarNo ratings yet

- Forgings PDFDocument23 pagesForgings PDFrrameshsmitNo ratings yet

- Plate BendingDocument5 pagesPlate Bendingnitesh2109No ratings yet

- Heat Treatment PDFDocument22 pagesHeat Treatment PDFravi00098No ratings yet

- Pran RFL (Factory Building-4) Olipur, SayestagonjDocument13 pagesPran RFL (Factory Building-4) Olipur, Sayestagonjshafiq_05No ratings yet

- Manufacturing Engineering Guide BookDocument2 pagesManufacturing Engineering Guide BookGiridharan SharmaNo ratings yet

- 1.4462 PropertiesDocument1 page1.4462 PropertiesutreshwarmiskinNo ratings yet

- ASTM A36/A36M Standard Specification For Carbon Structural SteelDocument4 pagesASTM A36/A36M Standard Specification For Carbon Structural SteeliuliamicutNo ratings yet

- Design of Machining Fixture For Turbine Rotor BladeDocument14 pagesDesign of Machining Fixture For Turbine Rotor BladeesatjournalsNo ratings yet

- BHEL SPEC Section D2 PDFDocument249 pagesBHEL SPEC Section D2 PDFelangorengaNo ratings yet

- ROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFDocument24 pagesROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFFayaz MohammedNo ratings yet

- Chapter 3B. Welded Connections: CE4: Design of Steel Structures - Prof. Dr. A. VarmaDocument14 pagesChapter 3B. Welded Connections: CE4: Design of Steel Structures - Prof. Dr. A. VarmaGNo ratings yet

- Hot Dip Galvanizing Design ConsiderationsDocument10 pagesHot Dip Galvanizing Design ConsiderationsAndreasNo ratings yet

- Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDocument2 pagesWifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDeipak HoleNo ratings yet

- Introduction To Materials: Principles of EngineeringDocument45 pagesIntroduction To Materials: Principles of EngineeringPrakharNo ratings yet

- Product Inspection Report: Results OverviewDocument8 pagesProduct Inspection Report: Results Overviewblackberry7130gNo ratings yet

- Sheet Metal Manufacturing ProcessDocument42 pagesSheet Metal Manufacturing ProcessThamizharasan SaranNo ratings yet

- Welding and Welder Performance 10 July 2015Document26 pagesWelding and Welder Performance 10 July 2015Achmad AffandyNo ratings yet

- Design For XDocument48 pagesDesign For XIvan ViewerNo ratings yet

- Progress Tracking Sheet-Steel FabricationDocument2 pagesProgress Tracking Sheet-Steel FabricationMohamed AtefNo ratings yet

- Laser Mig - Hybrid - WeldinggDocument26 pagesLaser Mig - Hybrid - WeldinggFeratNo ratings yet

- 1) Unfilled Section:: ForgingDocument1 page1) Unfilled Section:: ForgingdillipNo ratings yet

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- Purpose of Heat TreatmentDocument4 pagesPurpose of Heat TreatmentVenkateshYadavCivarlaNo ratings yet

- Solidification Analysis of Investment Cast Knee Joint ImplantDocument7 pagesSolidification Analysis of Investment Cast Knee Joint ImplantijsretNo ratings yet

- Nippon Steel PDFDocument13 pagesNippon Steel PDFhbookNo ratings yet

- IZO Appliances (PVT) LTD: Quality Management System Procedure For System of ProductionDocument7 pagesIZO Appliances (PVT) LTD: Quality Management System Procedure For System of ProductionS M Arif HussainNo ratings yet

- M2 U7 Plasma Arc CuttingDocument29 pagesM2 U7 Plasma Arc CuttingKenan MuhamedagicNo ratings yet

- Hollow Structural Sections Column Load TablesDocument128 pagesHollow Structural Sections Column Load TablesPedro PereiraNo ratings yet

- New Operator Training ManualDocument35 pagesNew Operator Training ManualBharat ChakravartinNo ratings yet

- Sintered Metal BushDocument5 pagesSintered Metal Bush124swadeshiNo ratings yet

- Design and Stress Analysis of Multi-Purpose Power Tiller: B Tech Pursuer Abin ThomasDocument7 pagesDesign and Stress Analysis of Multi-Purpose Power Tiller: B Tech Pursuer Abin ThomasArunNo ratings yet

- FSH TigDocument105 pagesFSH TigChee WeiNo ratings yet

- Flux Cored Arc WeldingDocument147 pagesFlux Cored Arc WeldingArnel MoralesNo ratings yet

- ISO - TC 44 - SC 10 - Quality Management in The Field of WeldingDocument5 pagesISO - TC 44 - SC 10 - Quality Management in The Field of WeldingNilesh MistryNo ratings yet

- Counter Top SpecsDocument12 pagesCounter Top Specsapi-3797031100% (3)

- Steel Selection CriteriaDocument34 pagesSteel Selection CriteriaAcharya KrishnanandaNo ratings yet

- CV of Ramoni Saidi A. Piping EngrDocument8 pagesCV of Ramoni Saidi A. Piping EngrAnonymous qaI31HNo ratings yet

- Metal Fabrication - WikipediaDocument4 pagesMetal Fabrication - WikipediaSanthan SalaiNo ratings yet

- Transamerican Manufacturing Group: Document Title: Weld Standards, SteelDocument16 pagesTransamerican Manufacturing Group: Document Title: Weld Standards, SteelQuoc VinhNo ratings yet

- Forging SDocument93 pagesForging SrichardchiamNo ratings yet

- Ss Pipe WeldingDocument3 pagesSs Pipe WeldingshridharbshenoyNo ratings yet

- HSFG BoltsDocument4 pagesHSFG BoltspajipitarNo ratings yet

- Standard QAPDocument9 pagesStandard QAPsivaNo ratings yet

- Manufacturing Process IDocument144 pagesManufacturing Process IHari Prasad100% (1)

- Organization Method Procedure FinanceDocument74 pagesOrganization Method Procedure FinanceTAMILNo ratings yet

- Working Procedure For Pipes and GatesDocument29 pagesWorking Procedure For Pipes and GatesAdvance Hydro Power Works Pvt. Ltd.No ratings yet

- Quality Control in FabricationDocument7 pagesQuality Control in FabricationradhakrishnangNo ratings yet

- 01 Cital KPW Sea Presentation r3Document31 pages01 Cital KPW Sea Presentation r3daveNo ratings yet

- Shell Plate Dimension CheckDocument7 pagesShell Plate Dimension Checksetak0% (1)

- Welcome: Good Engineering PracticesDocument64 pagesWelcome: Good Engineering PracticesSaswata Chakraborty100% (3)

- Fabrication Sequence PDFDocument38 pagesFabrication Sequence PDFharry_1981100% (7)

- TPL - Iav Voj CPRR JV: Construction of Chennai Peripheral Ring Road (Phase-I)Document1 pageTPL - Iav Voj CPRR JV: Construction of Chennai Peripheral Ring Road (Phase-I)mechajay2002No ratings yet

- Risk - Batching Plant OperationsDocument6 pagesRisk - Batching Plant Operationsmechajay2002100% (1)

- Method Statement of Gantry Crane Dismantling - DIFD 20-09-18Document8 pagesMethod Statement of Gantry Crane Dismantling - DIFD 20-09-18mechajay2002No ratings yet

- Method Statement 3Document12 pagesMethod Statement 3mechajay2002No ratings yet

- Batching of Concrete Method StatementDocument4 pagesBatching of Concrete Method Statementmechajay2002100% (1)

- ActivitiesDocument1 pageActivitiesmechajay2002No ratings yet

- Batching Plant LBPD22142035 A00Document1 pageBatching Plant LBPD22142035 A00mechajay2002No ratings yet

- Procedures of Plant Layout N Piping-RILDocument123 pagesProcedures of Plant Layout N Piping-RILfacebookshopNo ratings yet

- My Roses: Jovie PunzalanDocument4 pagesMy Roses: Jovie PunzalanJziki LokovaniakNo ratings yet

- Mrichchakatika - A Chronicle of Its MilieuDocument8 pagesMrichchakatika - A Chronicle of Its MilieuSehajdeep kaurNo ratings yet

- Islands Magazine 19th Photo ContestDocument5 pagesIslands Magazine 19th Photo Contestjjaguirr6434No ratings yet

- Đề KTHK I -TA 10 -ma de 303 doneDocument3 pagesĐề KTHK I -TA 10 -ma de 303 doneDương VũNo ratings yet

- Public ArtDocument16 pagesPublic ArtPia Hephzibah Abelita Panganiban100% (1)

- Borivali Course Calendar 13-01-2023Document10 pagesBorivali Course Calendar 13-01-2023abhicwatNo ratings yet

- Beaded ShoesDocument20 pagesBeaded ShoesJanice EclairNo ratings yet

- Institutte Medium Dom Bosco: TETEDocument7 pagesInstitutte Medium Dom Bosco: TETENovaz SliveNo ratings yet

- Case Study Doha TowerDocument11 pagesCase Study Doha TowerJALPA0% (2)

- MUSIC 2 Sing, Act and PlayDocument23 pagesMUSIC 2 Sing, Act and PlayJoice Ann PolinarNo ratings yet

- ManpowerDocument18 pagesManpowerCarlo Orgula Andal100% (2)

- The Last Metaphor NaeemDocument11 pagesThe Last Metaphor NaeemNaeem MuhammadNo ratings yet

- Drama and Its KadramahanDocument15 pagesDrama and Its KadramahanRichard Etil Jr.No ratings yet

- The Road Not Taken by Robert Frost Activities With Music Songs Nursery Rhymes Writing 115408Document5 pagesThe Road Not Taken by Robert Frost Activities With Music Songs Nursery Rhymes Writing 115408Eddie EddieNo ratings yet

- Micro-Utopias: Anthropological Perspectives On Art, Relationality, and CreativityDocument17 pagesMicro-Utopias: Anthropological Perspectives On Art, Relationality, and CreativityMartina AhlertNo ratings yet

- Bottle Lid ProjectDocument5 pagesBottle Lid ProjectAbdul JabbarNo ratings yet

- What Is A Definition of Short Story?Document8 pagesWhat Is A Definition of Short Story?Nimra Khalid100% (1)

- Offis Textile - Company ProfileDocument18 pagesOffis Textile - Company ProfileIsrael ExporterNo ratings yet

- Block PrintingDocument10 pagesBlock Printingila03No ratings yet

- M Butterfly Final FinalDocument8 pagesM Butterfly Final FinalTakuma OkadaNo ratings yet

- Pune 2024Document3 pagesPune 2024designerNo ratings yet

- Spring 2020 Laurence King CatalogDocument76 pagesSpring 2020 Laurence King CatalogChronicleBooks80% (5)

- Man Ray's Paris Portraits 1921-39 (Art Photography)Document140 pagesMan Ray's Paris Portraits 1921-39 (Art Photography)Vinit Gupta100% (1)

- Fernan DO Amorso LODocument2 pagesFernan DO Amorso LOMargie ManzanoNo ratings yet

- Fire Engine19Document11 pagesFire Engine19Kataa Mészáros75% (4)

- Game Design Workshop-A Playcentric Approach To Creating Innovative Games-2nd Edition (001-038) PDFDocument38 pagesGame Design Workshop-A Playcentric Approach To Creating Innovative Games-2nd Edition (001-038) PDFpepe12340100% (3)

- Karaoke ListDocument30 pagesKaraoke Listinef111No ratings yet

- Company Profile Slide Show 2017-1Document15 pagesCompany Profile Slide Show 2017-1Franky Bobby Juntak100% (1)

- Brittany (Eyewitness Travel Guides) PDFDocument290 pagesBrittany (Eyewitness Travel Guides) PDFionut nicolaeNo ratings yet

- Kelowna Fan Experience ItineraryDocument13 pagesKelowna Fan Experience ItineraryCarli BerryNo ratings yet