Professional Documents

Culture Documents

Uploaded by

sandragiaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uploaded by

sandragiaCopyright:

Available Formats

Cleaning Validation: Did you make the right choice of techniques?

Y. Ikezawa, M. Tanaka, Shimadzu Corporation, Japan

Introduction

A TOC Analyzer has been used for the following applications in the pharmaceutical field. 1. Control of quality for the water that is used in pharmaceutical production 2. Cleaning validation for pharmaceutical facilities Cleaning Validation Ensure that the quantity of residue substances collected from the surfaces of the equipment is within permissible limit. Pharmaceutical company should conduct it! And a high recovery rate is needed for cleaning validation.

Instrument

Shimadzu TOC-L Total Organic Carbon analyzer.

(2) Swab sampling - aqueous extraction - TOC measurement method

Step 1: Apply the pure water (low TOC water) to the fibrous swab material. Step 2: Wipe off in specified dimension of the stainless steel pot. Step 3: Place the swab material in a glass jar containing 100mL of pure water and stir with stirrer for 1 hour. Step 4: Measure TOC value of the water in the container.

TOC Concentration [mgC/L] 0.059 2.19 2.23 1.90 1.86 0.093 0.208 Recovery Rate, [( TOC Conc. Blank / Theoretical Conc.] 107 % 109 % 92.2 % 89.9 % 1.70 % 7.45 %

Results Water-soluble samples had high recovery rate (as expected). Evaluation of recovery rates of substances which are not readily water-soluble is hard by this method. This may be due to the difference in the rate of extraction. Recovery ratio of this method = Recovery of the swab sampling x Extraction rate to the rinse water

SSM-5000A Solid Sample Combustion Unit

Cleaning Validation by TOC Analyzer

3 types of cleaning validation methods are available. (1) Rinse sampling TOC measurement method (2) Swab sampling aqueous extraction TOC measurement method

TOC analyzer can adopt all type of methods [(1), (2), (3)] for cleaning validation and be upgraded with the SSM-5000A

(1) Rinse sampling TOC measurement method.

(3) Swab sampling direct combustion carbon measurement method Step 1: Apply the solution (100mL pure water) into the stainless steel pot. Step 2: Stir with stirrer for 15 minutes. Step 3: Measure TOC value of the rinse solution.

TOC Concentration [mgC/L] Recovery Rate, [( TOC Conc. Blank / Theoretical Conc.] 105 % 108 % 109 % 107 % 4.35 % 15.2 %

(3) Swab sampling - direct combustion carbon measurement method

Step 1: Apply the pure water (low TOC water) to the quartz glass filter. Step 2: Wipe off in specified dimension of the stainless steel pot. Step 3: Place the quartz glass filter in the ceramic boat. Step 4: Measure TC value with SSM-5000A.

TC Value [gC] 0.00 202 201 210 212 200 209 Recovery Rate, [( TC Value Blank / Theoretical Value] 101 % 100 % 105 % 106 % 100 % 104 %

Which is the right choice to get a high recovery rate ?

0.030 2.14 2.19 2.20 2.17 0.117 0.333

Results High recovery rates were obtained for all the substances regardless of their water-solubility or water-insolubility. Recovery ratio of this method = Recovery of the swab sampling Merits Enable to wipe off completely Easily conduct analysis without the need for any pretreatment, such as sample extraction

Sample

Applying various types of pharmaceutical products to stainless steel pots. Water-soluble and water-insoluble substances were used.

Substance Name Tranexamic acid Anhydrous caffeine Isopropylantipyrine Nifedipine Gentacin ointment Rinderon ointment Solubility in Water Soluble Soluble Insoluble Insoluble Insoluble Insoluble

Results Water-soluble samples had high recovery rate (as expected). Water-insoluble samples had different results depending on the substances. This may be due to the differences in the strength which the substances adhere to the stainless steel. Recovery ratio of this method = Extraction rate to the rinse water

Measure and compare the results of analysis for these samples by 3 types of methods for cleaning validation.

Conclusion

(3) Swab sampling direct combustion method is considered to be an effective measurement method for conducting cleaning validation.

You might also like

- Micronization of Active Pharmaceutical Ingredients (API) From R&D To The Production ScaleDocument1 pageMicronization of Active Pharmaceutical Ingredients (API) From R&D To The Production ScalesandragiaNo ratings yet

- Shi Mad Zu Poster ResizedDocument1 pageShi Mad Zu Poster ResizedsandragiaNo ratings yet

- Poster Ctad 2013 Pethcv VmriDocument1 pagePoster Ctad 2013 Pethcv VmrisandragiaNo ratings yet

- Poster ACCP2013 v5 60x42Document1 pagePoster ACCP2013 v5 60x42sandragiaNo ratings yet

- AAIC2013 Gouttard Accel Vs NonAccelDocument1 pageAAIC2013 Gouttard Accel Vs NonAccelsandragiaNo ratings yet

- Poster ACCP2013 v5 60x42Document1 pagePoster ACCP2013 v5 60x42sandragiaNo ratings yet

- Application of QWBA and Short-Lived Isotopes in The Drug Development ParadigmDocument2 pagesApplication of QWBA and Short-Lived Isotopes in The Drug Development ParadigmsandragiaNo ratings yet

- Characterization of Assay Performance in An Electrochemiluminescence-Based Ligand Binding Method For Detection of A Therapeutic Monoclonal Antibody Utilizing Various Detection ReagentsDocument2 pagesCharacterization of Assay Performance in An Electrochemiluminescence-Based Ligand Binding Method For Detection of A Therapeutic Monoclonal Antibody Utilizing Various Detection ReagentssandragiaNo ratings yet

- Maximizing Protein Expression in CHO Suspension Cells Through Transient TransfectionDocument1 pageMaximizing Protein Expression in CHO Suspension Cells Through Transient TransfectionsandragiaNo ratings yet

- PEG Tube Placement in PigletsDocument2 pagesPEG Tube Placement in PigletssandragiaNo ratings yet

- Poster AntipsychoticsDocument1 pagePoster AntipsychoticssandragiaNo ratings yet

- Measuring The Pharmacokinetics of 123I-Albumin and 18F-FDG in Rats Administered Via Intrathecal Injection at Different VolumesDocument1 pageMeasuring The Pharmacokinetics of 123I-Albumin and 18F-FDG in Rats Administered Via Intrathecal Injection at Different VolumessandragiaNo ratings yet

- Near Infrared (NIR) Analysis of Tablets Containing Two Active IngredientsDocument1 pageNear Infrared (NIR) Analysis of Tablets Containing Two Active IngredientssandragiaNo ratings yet

- Poster AntipsychoticsDocument1 pagePoster AntipsychoticssandragiaNo ratings yet

- Enablement of Accurate Dose Administration For A Pre-Filled Syringe Drug ProductDocument1 pageEnablement of Accurate Dose Administration For A Pre-Filled Syringe Drug ProductsandragiaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CH10 CFLDocument11 pagesCH10 CFLNoman KhanNo ratings yet

- Punching, Perforating, Blanking, NibblingDocument2 pagesPunching, Perforating, Blanking, NibblingTtrraanneeOonneeNo ratings yet

- FLOWTITE - Installation Guide For Buried Pipes - AWWA - Abbr. Version - enDocument31 pagesFLOWTITE - Installation Guide For Buried Pipes - AWWA - Abbr. Version - envuqar0979No ratings yet

- SP-P-005 - Rev 1 - Specification For Underground PipingDocument12 pagesSP-P-005 - Rev 1 - Specification For Underground Pipingvishal bhamreNo ratings yet

- 2 Medición Correcta de Flujo en Biogas Húmedo - B200Document45 pages2 Medición Correcta de Flujo en Biogas Húmedo - B200ChemicalProgrammerNo ratings yet

- 1995 R129-Owners-Manual PDFDocument148 pages1995 R129-Owners-Manual PDFMarvin ChuaNo ratings yet

- Artigo - Contribuição em Estudos Reológicos de Autonivelante Com Adição de Resíduo Rocha OrnamentalDocument12 pagesArtigo - Contribuição em Estudos Reológicos de Autonivelante Com Adição de Resíduo Rocha OrnamentalDjalma NetoNo ratings yet

- 88 m37Document8 pages88 m37Mohammed Essam ShatnawiNo ratings yet

- 3 Oxidation and ReductionDocument25 pages3 Oxidation and ReductiondonutNo ratings yet

- Energy Conservation in Sugar IndustriesDocument7 pagesEnergy Conservation in Sugar IndustriesKetty Puspa JayantiNo ratings yet

- Water-Treatment-For-Closed-Heating-And-Cooling-Systems (Sample) PDFDocument8 pagesWater-Treatment-For-Closed-Heating-And-Cooling-Systems (Sample) PDFstarykNo ratings yet

- Sporlan Adlse-2Document12 pagesSporlan Adlse-2Serrefriair Garcia RefriNo ratings yet

- MPSP Mill - Simhadri1Document18 pagesMPSP Mill - Simhadri1santoshkumar777No ratings yet

- Pip Ctse1000-2018Document82 pagesPip Ctse1000-2018John BuntalesNo ratings yet

- Sheet Metal Forming PDFDocument8 pagesSheet Metal Forming PDFAlpha WolfNo ratings yet

- Sedar Perkasa SDN BHD - Company Profile 2023Document48 pagesSedar Perkasa SDN BHD - Company Profile 2023choong chloeNo ratings yet

- CSA C22 No.131Document1 pageCSA C22 No.131metin yurtseverNo ratings yet

- Checklist To Design AssembliesDocument1 pageChecklist To Design AssembliesRobert GalarzaNo ratings yet

- Jurnal SanitasiDocument12 pagesJurnal SanitasiAnnisa FadlilahNo ratings yet

- 01 Samss 048 PDFDocument21 pages01 Samss 048 PDFMohamed SolimanNo ratings yet

- Procedure For Flooring WorksDocument4 pagesProcedure For Flooring WorksAkhilesh Kumar0% (1)

- UNF Vs BSFDocument18 pagesUNF Vs BSFJonathan GentNo ratings yet

- Nonferrous Nuts For General UseDocument10 pagesNonferrous Nuts For General Usejuniuni18100% (2)

- Entrepreneurship Module 6Document8 pagesEntrepreneurship Module 6Cync KlayNo ratings yet

- All DocumentsDocument12 pagesAll Documentsangusbeef1012No ratings yet

- Engine: Aftermarket Parts ForDocument353 pagesEngine: Aftermarket Parts ForJohn Maisonnett100% (2)

- Multipower Cha K 726-P÷36012-P CLB 41.7Document40 pagesMultipower Cha K 726-P÷36012-P CLB 41.7Xavi Tendre100% (1)

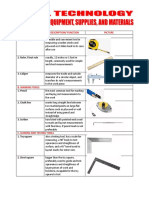

- Tool/ Equipment Description/ Function Picture A. Measuring ToolsDocument13 pagesTool/ Equipment Description/ Function Picture A. Measuring ToolsNicolas AntiguaNo ratings yet

- Spot Weld Growth On 304L Austenitic Stainless Steel For Equal and Unequal ThicknessesDocument9 pagesSpot Weld Growth On 304L Austenitic Stainless Steel For Equal and Unequal ThicknessesAmin MojiriNo ratings yet

- Weldspec ASME WPS ASME IXDocument2 pagesWeldspec ASME WPS ASME IXPadmanabhan VenkateshNo ratings yet