Professional Documents

Culture Documents

Mobile Calibration Carts

Uploaded by

The Tool House, Inc.Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mobile Calibration Carts

Uploaded by

The Tool House, Inc.Copyright:

Available Formats

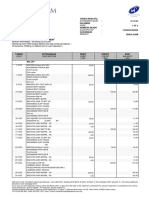

tJRS Opta 500Nm threaded Joint Rate Simulator

500Nm tJRS Opta Detailed Description Introduction

The tJRS Opta offers the latest technology in tool testing in accordance with VDI/VDE 2647 Transducers for nutrunner systems Guidelines for dynamic checking of tools according to ISO 5393 The system uses a nut and a threaded bolt, which automatically unwind. This method gives a true representation of a fastener rather than a friction brake. The joint rate for nut and bolt tightening is varied automatically by a patented process. The threads and clamp surfaces of the bolt and nut are auto-greased to ensure trouble free operation. Maximum Torque: 500Nm 3 sets of beams: 500Nm beam 100Nm beam 10Nm beam 100 - 500Nm 10 - 100Nm 1 - 10Nm M24 bolt M16 bolt M8 bolt Minimum Torque: 1Nm

Each beam set works independently of other beam sets.

Only one beam set can be operated at a time. The bolts and nuts are replaceable parts.

Operation

Through the controlling software the operator can automatically set the joint rate of the simulator before carrying out testing. Cycle Time: Typically a 30 sample study can be carried out in less than 3 minutes. Release Mechanism: The joint is automatically reset between each run-down. The following measurement types can be performed on the beams: Peak (torque only and torque with angle) Impulse Click The following tool types can be evaluated: DC electric (nutrunners and screwdrivers) Clutch (nutrunners and screwdrivers) Impulse Torque wrenches Battery tools

Torque Measurement

The tJRS Opta uses established Crane data collecting techniques and displays the results on the OMS software. 3 CheckStar rotary transducers 10Nm, 100Nm and 500Nm, are mounted under the top surface with only the female socket protruding.

Controller

Supplied with a touch panel PC with solid state hard drive.

Software: Single licence of Opta Management Software (OMS) for standalone use on the tJRS Opta. Threaded JRS Controller and SQL database. OMS modules (tools, applications, certifications, administration, report generation) and SQL database. OMS Automation service for updating calendar events.

Electrical/Environmental

Powered by two 12V sealed lead acid batteries that typically give 8 hours of use. The internal battery charger fully re-charges the batteries in less than 10 hours. Installed software provides sophisticated and reliable battery management. The tJRS Opta operates between +5C and +40C.

Construction

Weight: Dimensions: 425Kg (approx) Length = 1100mm (1195mm with handle) Width = 600mm Height = 940mm (floor to work surface). Extruded aluminium frame Aluminium laminate panel work Anti-slip surface

Material:

There are reaction posts enabling safe testing of tools. The tJRS Opta is mobile.

Maintenance

The tJRS Opta is easy to maintain and service. Crane Electronics Ltd can carry this out under a service contract, or the customers maintenance department can undertake it.

Delivery

Leadtime is 12-16 weeks from acceptance of Purchase Order.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- MisDocument5 pagesMisjohnNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Recovering Windows XPDocument43 pagesRecovering Windows XPdavid_kuberaNo ratings yet

- SAP SEM BPS Interview Questions Strategic Enterprise Management and Business Planning With SAP SEMDocument153 pagesSAP SEM BPS Interview Questions Strategic Enterprise Management and Business Planning With SAP SEMLuis Enrique StobschinskiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Components DetailsDocument14 pagesComponents DetailssukanyagggNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- E Kasneb FAQDocument1 pageE Kasneb FAQChris OgolaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Wor ShopDocument4 pagesWor ShopDavid Santiago Ayala RodriguezNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- LIT - RFA Series Dryers - SAPRFADRY - enDocument4 pagesLIT - RFA Series Dryers - SAPRFADRY - encarlos chavezNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Exadata X10M Platform Overview Part 2Document3 pagesExadata X10M Platform Overview Part 2jonseverloveNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- StingrayStudio 12.1 ReleaseNotesDocument9 pagesStingrayStudio 12.1 ReleaseNoteshokkuyopNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- LFOTool 15 ManualDocument25 pagesLFOTool 15 ManualMarius AndreiNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Q1) What Are The Primary Functions of Cyberark?Document8 pagesQ1) What Are The Primary Functions of Cyberark?santoshs2002848No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Aatru Medical Announces FDA Clearance and Commercial Launch of The NPSIMS™ - Negative Pressure Surgical Incision Management SystemDocument4 pagesAatru Medical Announces FDA Clearance and Commercial Launch of The NPSIMS™ - Negative Pressure Surgical Incision Management SystemPR.comNo ratings yet

- Reflex IML BrochureDocument8 pagesReflex IML BrochurereflextechNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Cs 315 Lecture 4Document48 pagesCs 315 Lecture 4jumarichkingaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 3.5 - MBR 15k Spare Part List 1-2-5 YearsDocument8 pages3.5 - MBR 15k Spare Part List 1-2-5 YearsWayneNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Telkomsel Lte FDD Interworking Strategy For l1800 Amp U900 U2100Document10 pagesTelkomsel Lte FDD Interworking Strategy For l1800 Amp U900 U2100achmad amrullohNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Acue 3000 V1Document36 pagesAcue 3000 V1MARCO SILVA CABREJONo ratings yet

- Chapter 13 The Future of InformationDocument19 pagesChapter 13 The Future of InformationKhairul bariahNo ratings yet

- AEROMAG LAKOTA Dealer Brochure Wind TurbinesDocument4 pagesAEROMAG LAKOTA Dealer Brochure Wind TurbinesAldana OrleneNo ratings yet

- TDS 00201 C PDFDocument4 pagesTDS 00201 C PDFJohan VillarrealNo ratings yet

- Gardner Denver Rotary Screw Compressors: History, Stability, & DependabilityDocument4 pagesGardner Denver Rotary Screw Compressors: History, Stability, & DependabilitySpark ElectricNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Certified Information Systems Auditor (CISA) 2019 Information System Auditing TranscriptDocument15 pagesCertified Information Systems Auditor (CISA) 2019 Information System Auditing TranscriptMahmoudAbdElGhaniNo ratings yet

- Project MajorDocument2 pagesProject MajorHarshNo ratings yet

- A.H PMS ReportDocument58 pagesA.H PMS ReportHitesh MichaelNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Estatement-202310 20240118082918Document3 pagesEstatement-202310 20240118082918jooamir70No ratings yet

- R2 SignallingDocument55 pagesR2 SignallingSuman GhimireNo ratings yet

- IOI City Mall PPXDocument34 pagesIOI City Mall PPXnima mobarakiNo ratings yet

- Men 4210 QigDocument13 pagesMen 4210 QigVivek Kumar RaiNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Ugc Net Updated Syllabus For Library and Information ScienceDocument4 pagesUgc Net Updated Syllabus For Library and Information SciencePrince JNo ratings yet

- Lec 1Document45 pagesLec 1JannoNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)