Professional Documents

Culture Documents

27

Uploaded by

zacriasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

27

Uploaded by

zacriasCopyright:

Available Formats

SINTER PLANT # 1(MECH)

FALIURE ANALYSIS OF EXCITER GEARBOX AT SINTER PLANT # 1

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

EQUIPMENT NO COMPONENT WHICH FAILED FAILURE DATE TIME TOTAL DOWN PERIOD

: : : : :

2080 (HOT FEEDER) EXCITER GEARBOX 10/11/2005 6:00 PM TO 11:35 PM 5.5 HOURS 70000 X 5.5 = 385000 = 3.85 Lac.

LOSS DUE TO DOWN TIME IN RS :

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

GENERAL INTRODUCTION ABOUT EQUIPMENT

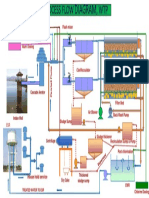

Sinter Plant # 1 has two machine. Hot feeder(2080) is in the line of machine no two. It is installed after hot screen which receives +5 mm hot sinter. After this feeder hot sinter is feed to sinter cooler for cooling. The feeder is in the critical part of the machine. The production stops completely if any equipment of the circuit fails. General Arrangement of the equipment is as follows.

Exciter Units

Motor Drive shaft Intermediate shaft

Screen Panel EXCITER G/B FAILURE ANALYSIS A.K.JHA

SINTER PLANT # 1(MECH) Phenomenon Observation

When What Where Who Why How

10th Nov 2005 in B Shift at 0600 PM Hot Feeder (2080) Tripped. Sinter Plant # 1 2080 offside exciter gearbox. Mr.P.R.Jhanghel , Sr.Technician (Mechanical) has checked. Exciter gearbox got jam due to bearing failure. The motor was tripped on high current.

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

HISTORY

There are two Hot Feeder in Sinter Plant # 1 and each of them have two exciter gearboxes. On 8/11/2005 hot feeder (2080) tripped at 12:05 am. Offside exciter gearbox of hot feeder finally failed on 10/11/2005 at 6:00 pm. The gearbox was replaced with new one and failed gearbox was taken to mechanical repair shed for failure analysis.

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

OBSERVATION NO : 1

Damaged bearing shows sign of oil starvation.

DRY GEARBOX

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

OBSERVATION NO : 2

It has double row spherical roller bearing .The cage had got OIL DRAIN BLOCKED completely damaged and the rollers had got disoriented.

BEARING DISORIENTED

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

OBSERVATION NO : 3

The drain oil port on the damaged bearing side was choked

OIL DRAIN BLOCKED

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

OBSERVATION NO : 4

The labyrinth ring was also badly damaged . Labyrinth ring seized on end cover.

DAMAGED LABYRINTH RING

EXCITER G/B FAILURE ANALYSIS

LABYRINTH SEIZED ON END COVER

A.K.JHA

SINTER PLANT # 1(MECH)

OBSERVATION NO : 5

The inner race of the damaged bearing showed signs of excess heat on the roller tracks INNER RACE BURNT

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

Excess oil from the end cover goes back into the gearbox through the drain port which lubricates bearing. Felt used for sealing worn out due to excess heat and its ageing. Damaged felt chocked the oil drain port. Due to blockage of drain port oil does not go back to gearbox and oil level starts reducing. This leads to oil starvation of bearing and bearing fails.

ANALYSIS (REASONS FOR INCIDENCE)

OIL DRAIN BLOCKED

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

RECOMENDATIONS

For sealing purpose felts should be replaced by rolled yarn

consisting of PTFE which can absorb maximum temperature. Correct oil level of the gearbox to be maintained. A Time based maintenance schedule to be prepared for exciter gearbox changing to overcome ageing effect.

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

Mr.T.Watanabes Comments

1. The trend of current variation in the motor must be noted 2. Continuous current monitoring device with alarm may be used 3. If the gear box is in use for quite a long time, all the last failures in the gear box must be analyzed 4. Considering the application of Gear box, it should not fail so frequently

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

SINTER PLANT # 1(MECH)

EXCITER G/B FAILURE ANALYSIS

A.K.JHA

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Oracle Rman Tutorial - 161CSC57014229Document13 pagesOracle Rman Tutorial - 161CSC57014229zacriasNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Lab 7 Worksheet: 1. Item 1: Screenshot of Your Single Core: 1 Thread / 1 Million Iterations Run ResultsDocument4 pagesLab 7 Worksheet: 1. Item 1: Screenshot of Your Single Core: 1 Thread / 1 Million Iterations Run ResultszacriasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hibernate Interview Questions and AnswersDocument39 pagesHibernate Interview Questions and AnswerszacriasNo ratings yet

- Exercise: Getting Started With Bootstrap: Index - HTMLDocument3 pagesExercise: Getting Started With Bootstrap: Index - HTMLzacriasNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- LAB 10 Worksheet AssignmentDocument1 pageLAB 10 Worksheet AssignmentzacriasNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- LAB 14 - ApplicationPerfDocument8 pagesLAB 14 - ApplicationPerfzacriasNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- GRE Word ListDocument29 pagesGRE Word ListzacriasNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Aditya Hrudayam in TeluguDocument4 pagesAditya Hrudayam in Telugujana8kNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 20HIMx6 Series A 1 006 07 en UpdateDocument8 pages20HIMx6 Series A 1 006 07 en UpdatezacriasNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Micro830® Programmable Logic Controller: Bulletin 2080 Product ProfileDocument2 pagesMicro830® Programmable Logic Controller: Bulletin 2080 Product ProfilezacriasNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Ten Top IELTS Writing Tips-DC IELTSDocument15 pagesTen Top IELTS Writing Tips-DC IELTSzacrias100% (4)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- POINT I/O 4 Channel High Density Current Input Module: Installation InstructionsDocument24 pagesPOINT I/O 4 Channel High Density Current Input Module: Installation InstructionszacriasNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- PLC To Deltav Systems MigrationDocument14 pagesPLC To Deltav Systems MigrationzacriasNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Commercial Terms and Conditions 163121Document1 pageCommercial Terms and Conditions 163121zacriasNo ratings yet

- POINT I/O 2 Port Ethernet Adapter: Installation InstructionsDocument28 pagesPOINT I/O 2 Port Ethernet Adapter: Installation InstructionszacriasNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Universal Isolated Interface Converter: Eurotherm OntrolsDocument4 pagesUniversal Isolated Interface Converter: Eurotherm OntrolszacriasNo ratings yet

- Nava Graha Stotram TeluguDocument2 pagesNava Graha Stotram TeluguBhamidipati PremNo ratings yet

- Physics Cun It PacketsDocument226 pagesPhysics Cun It PacketsRana MukherjeeNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Astm C12Document7 pagesAstm C12omarguillermogarzon100% (1)

- Industrial Attachment ReportDocument20 pagesIndustrial Attachment ReportAlbert OjiamboNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Moog ServoMotors MDSeries Catalog enDocument63 pagesMoog ServoMotors MDSeries Catalog enArsonval FleuryNo ratings yet

- Outdoor Unit Indoor Unit: Excellent Ecodan's Heating Performance, Even at Low Outdoor Temperature!Document19 pagesOutdoor Unit Indoor Unit: Excellent Ecodan's Heating Performance, Even at Low Outdoor Temperature!Ивайло СтояновNo ratings yet

- Depth of Water: A. Soil and Water Conservation EngineeringDocument36 pagesDepth of Water: A. Soil and Water Conservation EngineeringJayvee Laureta100% (1)

- List of Transferred ASME StandardsDocument3 pagesList of Transferred ASME StandardsShakeel AhmedNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Steering Gear TestingDocument9 pagesSteering Gear TestingArun GK100% (1)

- Assignment-1 (2020011108)Document28 pagesAssignment-1 (2020011108)Atul KumarNo ratings yet

- Statically Indeterminate BeamsDocument7 pagesStatically Indeterminate BeamsMary Jane PelaezNo ratings yet

- Cooling Tower SolutionDocument38 pagesCooling Tower SolutionThabangNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Mobiscreen Ms 702 - Ms 703 - Ms 952 - Ms 953 Evo: Feed HopperDocument2 pagesMobiscreen Ms 702 - Ms 703 - Ms 952 - Ms 953 Evo: Feed HopperTEKLEWEYNI TsegayNo ratings yet

- Control EngineeringDocument14 pagesControl EngineeringCheong JkNo ratings yet

- 10 Technologies/Methods For Controlling Nox & Sox Emissions From ShipsDocument2 pages10 Technologies/Methods For Controlling Nox & Sox Emissions From ShipsRaji MNNo ratings yet

- MIDAS ChecklistDocument27 pagesMIDAS ChecklistBhagirath JoshiNo ratings yet

- WTP Process DiagramDocument1 pageWTP Process DiagramKumar AbhishekNo ratings yet

- Compressed Air MonitoringDocument4 pagesCompressed Air MonitoringRonak JoshiNo ratings yet

- Maxon DC MotorDocument16 pagesMaxon DC MotorteguhNo ratings yet

- L3548 4 07Document2 pagesL3548 4 07Héctor Hugo Sánchez GómezNo ratings yet

- D4B8046FF18-Suspension Wheels SteeringDocument469 pagesD4B8046FF18-Suspension Wheels SteeringDaniel CharlesNo ratings yet

- AXI90104 Manual enDocument40 pagesAXI90104 Manual enChristian EscandonNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Riwayat Pemeliharaan Alat Wirtgen 2Document2 pagesRiwayat Pemeliharaan Alat Wirtgen 2Aulia Rizeky JanuaryNo ratings yet

- Carrier VRF Installation Manual For 20 - 22 - 26 KWDocument16 pagesCarrier VRF Installation Manual For 20 - 22 - 26 KWMohamedNo ratings yet

- Timken Tapered Roller Bearings CatalogDocument1 pageTimken Tapered Roller Bearings CatalogFakhar FirdausNo ratings yet

- w73621 Int Gcse Physics 4ph1 4sd0 Exam AidDocument4 pagesw73621 Int Gcse Physics 4ph1 4sd0 Exam AidjenifaNo ratings yet

- Power Plant QuestionsDocument20 pagesPower Plant QuestionsSubhransu Mohapatra50% (2)

- Eccentric ConnecctionsDocument41 pagesEccentric ConnecctionsShyam Suryawanshi100% (1)

- Multi ElementDocument1 pageMulti Elementapi-3703371No ratings yet

- Helicoil GB 0180Document40 pagesHelicoil GB 0180MamdouhAlhanafyNo ratings yet

- Quiz 2 2013 ThermodynamicDocument2 pagesQuiz 2 2013 ThermodynamicPaartiban PaneerselvamNo ratings yet