Professional Documents

Culture Documents

Gujarat Technological University: Instructions

Uploaded by

Bhavesh PipaliyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gujarat Technological University: Instructions

Uploaded by

Bhavesh PipaliyaCopyright:

Available Formats

Seat No.

: _____

Enrolment No.______

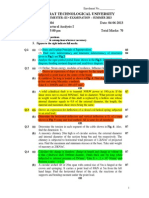

GUJARAT TECHNOLOGICAL UNIVERSITY

B.E. Sem-II [All Branch] examination June 2009

Subject code: 110010 Subject ame : Mechanics of Solids

Date: 18/06/2009 Total Marks: 70 Time: 10:30am-1:00pm

Instructions:

1. Attempt all questions. 2. Make suitable assumptions wherever necessary. 3. Figures to the right indicate full marks. (a) Answer the following: (Write complete statements) i) Splitting of force in given directions is known as __________ of force. (resolution, composition, division) ii) Poissons ratio is ratio of ___________ (longitudinal to lateral strain, lateral to longitudinal strain, shear stress to shear strain) iii) For self locking machines, the efficiency of machine should be ________ ( 50%, more than 50%, less than 50%) iv) Bending moment is ________ at a hinged support. (always maximum, always zero) (b) Find stress and deformation in each part of rod ABCD shown in fig.1. (c) Find magnitude and direction of resultant of force system shown in fig. 2. (a) Find magnitude, direction and location of resultant of force system with respect to point O shown in fig. 3. (b) Calculate location of centroid of a triangular lamina using first principle. OR (b) Derive expression for maximum shear stress in a rectangular cross section using first principle. Determine ratio of maximum shear stress to average shear stress. (a) Explain following terms : i) Mechanical advantage ii) Velocity ratio iii) Ideal load iv) Efficiency (b) Determine forces in members of truss shown in fig 4. (c) A block weighing 250N rest against wall as shown in fig 5. A wedge is placed under it. Find out minimum force P required to lift the block. The coefficient of friction at all contacting surfaces is 0.25. Neglect self weight of wedge. OR (a) Draw characteristic stress-strain curve for mild steel under tension and show salient points on it. (b) Calculate reactions at support due to applied load on the beam as shown in fig. 6. (c) Draw shear force and bending moment diagram for beam shown in fig 7. (a) What do you understand by pure bending? Write various assumptions made in theory of pure bending.

Q.1

04

05 05 07 07

Q.2

07

Q.3

04

05 05

Q.3

04 05 05

Q.4

04

Q. 4

(b) Find out maximum bending stresses at top and bottom of beam as shown in fig.8. (c) Find out moment of resistance of beam made by attaching 10mmx300mm steel plate on one side of timber section 200 mm x 300 mm. Allowable stress in timber and steel is 7MPa and 150MPa and their modular ratio is 10. OR (a) Draw variation of shear stress across the cross section of i) Hollow rectangle ii) Hollow circle iii) Hollow triangle iv) H section (b) Draw shear stress distribution diagram across the cross section of a T beam, having flange 200x20mm and web 10x300mm and carrying shear force 100kN. (c) Find out uniformly distributed load which can be safely applied to a cantilever beam having span 2m. The beam has rectangular cross section 200x300mm. The allowable bending stress and allowable shear stress in beam material is 15MPa and 10MPa respectively. (a) What do you understand by principal planes? Write expression to determine magnitude of principal stress and maximum shear stress and, location of planes carrying them for a generalized stress condition. (b) Derive expression to determine stress on an inclined plane when an element carries tensile stress and compressive stress in perpendicular directions. (c) An element is loaded by tensile stress 5MPa and compressive stress 4MPa in perpendicular directions alongwith shear stress 3MPa as shown in fig 9. Calculate normal, tangential and resultant stress on a plane making 300 angle in anticlockwise direction with the plane carrying tensile stress. OR (a) Derive relationship between modulus of elasticity, modulus of rigidity and Poissons ratio. (b) Give statement of i) Varignons theorem ii) Parallel and Perpendicular axis theorem iii) Pappus Guldinus Theorem (c) A composite bar madeup of steel and copper rods, connected in series. The ends of composite bars are fixed. Find the stress developed in steel and copper due to increase in temperature by 500C. Other relevant data are given below Copper Steel 1.2 m 1.0 m Length 30 mm 30 mm Diameter -6 0 12x10-6/0C 17x10 / C Coefficient of thermal expansion 0.8x105 MPa 2.0x105 MPa Modulus of elasticity

05 05

04

05

05

Q.5

04

05

05

Q.5

04 05

05

You might also like

- Gujarat Technological University: InstructionsDocument3 pagesGujarat Technological University: InstructionsBhavesh PipaliyaNo ratings yet

- Gujarat Technological University: InstructionsDocument4 pagesGujarat Technological University: InstructionsBhavesh PipaliyaNo ratings yet

- Mos 07062012Document2 pagesMos 07062012Bhavesh PipaliyaNo ratings yet

- Gujarat Technological University: InstructionsDocument3 pagesGujarat Technological University: InstructionsBhavesh PipaliyaNo ratings yet

- Gujarat Technological University: InstructionsDocument3 pagesGujarat Technological University: InstructionsBhavesh PipaliyaNo ratings yet

- Mechanical Eng Ses Main 2016 First PDFDocument8 pagesMechanical Eng Ses Main 2016 First PDFSumeet TiwariNo ratings yet

- WWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)Document3 pagesWWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)mahendra babu mekalaNo ratings yet

- Som Questions PaperDocument4 pagesSom Questions PaperL RevathiNo ratings yet

- Mechanicsofsolids Dec 2010Document10 pagesMechanicsofsolids Dec 2010simalaraviNo ratings yet

- GTU Mos 1Document2 pagesGTU Mos 1ashikshahNo ratings yet

- MDID Machine Design GTU PaperDocument3 pagesMDID Machine Design GTU PaperjaydeepNo ratings yet

- Reg No.: - NameDocument3 pagesReg No.: - NameSijuKalladaNo ratings yet

- Mechanics of SolidsDocument8 pagesMechanics of SolidsKhaista RahmanNo ratings yet

- Strength of Materials: at Least TWO Questions From Each PartDocument2 pagesStrength of Materials: at Least TWO Questions From Each PartnvnrevNo ratings yet

- 1111-110010-Mech - of SolidsDocument4 pages1111-110010-Mech - of SolidsjaydeepNo ratings yet

- Mace 60035Document7 pagesMace 60035eng_ayman_H_MNo ratings yet

- Mechanics of SolidsDocument9 pagesMechanics of SolidsSrikanth GogineniNo ratings yet

- (Join AICTE Telegram Group) 22303 (MOS) Mechanics of StructuralDocument4 pages(Join AICTE Telegram Group) 22303 (MOS) Mechanics of StructuralVivek Sharma0% (1)

- Mechanics of Solids Question PapersDocument10 pagesMechanics of Solids Question PapersNandu Sreekumar SNo ratings yet

- Engineering Mechanics 3rd Sem GTU IMPDocument9 pagesEngineering Mechanics 3rd Sem GTU IMPSwastik PanchalNo ratings yet

- At Least TWO Questions From Each Part.: (06 Marks)Document2 pagesAt Least TWO Questions From Each Part.: (06 Marks)nvnrevNo ratings yet

- AMMDocument3 pagesAMMRajesh Kumar PNo ratings yet

- Strength of Materials: at Least TWO Questions From Each PartDocument2 pagesStrength of Materials: at Least TWO Questions From Each PartnvnrevNo ratings yet

- Used Papers SEP 2021: (Civil Engineering)Document3 pagesUsed Papers SEP 2021: (Civil Engineering)AYRUSNo ratings yet

- Tutorial Questions 4523Document29 pagesTutorial Questions 4523Toby Joseph ThomasNo ratings yet

- Tutorial 5 FinalDocument2 pagesTutorial 5 FinalAtul SharmaNo ratings yet

- PMO Department - Engineering Test:: Name: Nationality: Visa Status: Current Salary/package: Family Status: Notice PeriodDocument8 pagesPMO Department - Engineering Test:: Name: Nationality: Visa Status: Current Salary/package: Family Status: Notice PeriodMohamed Gamal100% (1)

- Be Winter 2019Document2 pagesBe Winter 2019Swastik PanchalNo ratings yet

- TED (15) 4053 QPDocument3 pagesTED (15) 4053 QPiqbalNo ratings yet

- Mechanics of MaterialsDocument0 pagesMechanics of Materialssatishkumarkolluru9809No ratings yet

- StressDocument5 pagesStressmessel2013No ratings yet

- Ahmedabad Center-9Document3 pagesAhmedabad Center-9RenieNo ratings yet

- Mechanic Sof Solids (CIE 1051)Document4 pagesMechanic Sof Solids (CIE 1051)Alok KumarNo ratings yet

- Gujarat Technological University: InstructionsDocument3 pagesGujarat Technological University: Instructionsharnishtanna21285No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Sheet - 2Document3 pagesSheet - 2Abdel Hamied EbrahemNo ratings yet

- Seat No.: - Enrolment No.Document3 pagesSeat No.: - Enrolment No.Bhavesh PipaliyaNo ratings yet

- 3 Hours / 70 Marks: Seat NoDocument5 pages3 Hours / 70 Marks: Seat NoMadao111No ratings yet

- Mechanics of Solids (CIE 1051)Document4 pagesMechanics of Solids (CIE 1051)aryansorout1612No ratings yet

- 2018 April CE201-D - Ktu QbankDocument2 pages2018 April CE201-D - Ktu Qbanklakshmi dileepNo ratings yet

- Assignment Pure Bending PDFDocument3 pagesAssignment Pure Bending PDFFazir AzlanNo ratings yet

- TCW1101200904 Engineering Mechanics I StaticsDocument6 pagesTCW1101200904 Engineering Mechanics I StaticsTanaka MurekachiroNo ratings yet

- Engineering MechanicsDocument1 pageEngineering MechanicsmafiapumbaNo ratings yet

- Me2254 - Strength of Materials 2008 PDFDocument4 pagesMe2254 - Strength of Materials 2008 PDFAndrew CrawfordNo ratings yet

- 10CV/EV33: Strength of MaterialsDocument2 pages10CV/EV33: Strength of MaterialsnvnrevNo ratings yet

- Mech4005y 5 2010 2Document4 pagesMech4005y 5 2010 2Balgo BalgobinNo ratings yet

- 3 Hours / 70 Marks: Seat NoDocument5 pages3 Hours / 70 Marks: Seat Noopwigs444No ratings yet

- Tutorial 3 - LoadStressAnalysisDocument2 pagesTutorial 3 - LoadStressAnalysisSanthosh AmaraNo ratings yet

- 10CV33 Dec2012Document2 pages10CV33 Dec2012nvnrevNo ratings yet

- Tutorial On SFD and BMDDocument2 pagesTutorial On SFD and BMDAlvin TamaNo ratings yet

- Sheet No.2 (Simple Stress)Document3 pagesSheet No.2 (Simple Stress)elhalawanyh46No ratings yet

- QP293A2 20MET201 Mechanics of SolidsDocument4 pagesQP293A2 20MET201 Mechanics of SolidsJASON CHERIAN MENo ratings yet

- Tutorial Sheet 3Document3 pagesTutorial Sheet 3Ayush KumarNo ratings yet

- Question Paper Code:: Reg. No.Document4 pagesQuestion Paper Code:: Reg. No.Keesanth Geetha ChandrasekaranNo ratings yet

- Structural Analysis-I-Summer-13Document2 pagesStructural Analysis-I-Summer-13harnishtanna21285No ratings yet

- Q4Document15 pagesQ4dramiltNo ratings yet

- Thermal EngineeringDocument1 pageThermal EngineeringBhavesh Pipaliya75% (4)

- Industrial Safety & Maintenance EngineeringDocument1 pageIndustrial Safety & Maintenance EngineeringBhavesh Pipaliya100% (2)

- Thermal EngineeringDocument1 pageThermal EngineeringBhavesh Pipaliya75% (4)

- Refrigeration and AirconditioningDocument2 pagesRefrigeration and AirconditioningBhavesh Pipaliya100% (1)

- Machine Design - IIDocument1 pageMachine Design - IIBhavesh PipaliyaNo ratings yet

- Gas DynamicsDocument1 pageGas DynamicsBhavesh PipaliyaNo ratings yet

- Production TechnologyDocument1 pageProduction TechnologyBhavesh PipaliyaNo ratings yet

- Machine Tool DesignDocument2 pagesMachine Tool DesignBhavesh Pipaliya50% (2)

- Software Engineering GTU SyllabusDocument3 pagesSoftware Engineering GTU SyllabusKeyur ThakkarNo ratings yet

- 19 Teaching SchemeDocument1 page19 Teaching SchememalohiaNo ratings yet

- Automobile Body EngineeringDocument1 pageAutomobile Body EngineeringBhavesh PipaliyaNo ratings yet

- 8Th Sem Teaching SchemeDocument15 pages8Th Sem Teaching SchemeDevang_GhiyaNo ratings yet

- Project - IDocument1 pageProject - InikunjkavadiaNo ratings yet

- Quality and Reliability Engineering - Department Elective - IDocument2 pagesQuality and Reliability Engineering - Department Elective - IARaval88No ratings yet

- Energy Conservation and Management - Department Elective - IDocument2 pagesEnergy Conservation and Management - Department Elective - IBhavesh PipaliyaNo ratings yet

- Computer Integrated ManufacturingDocument2 pagesComputer Integrated ManufacturingDhiren Patel100% (1)

- Mechanical Engg. Sem-VII With Project Teaching SchemeDocument1 pageMechanical Engg. Sem-VII With Project Teaching SchemeBhavesh PipaliyaNo ratings yet

- Product Design and Value EngineeringDocument2 pagesProduct Design and Value EngineeringBhavesh Pipaliya50% (2)

- Operation ResearchDocument3 pagesOperation ResearchBhavesh Pipaliya50% (2)

- Industrial Tribology - Department Elective - IDocument2 pagesIndustrial Tribology - Department Elective - IBhavesh PipaliyaNo ratings yet

- Internal Combustion EnginesDocument3 pagesInternal Combustion EnginesBhavesh PipaliyaNo ratings yet

- BE SEM-VII Exam Scheme & Subject CodeDocument8 pagesBE SEM-VII Exam Scheme & Subject Codeirfanmomin55No ratings yet

- Automobile EngineeringDocument4 pagesAutomobile EngineeringRita KalaniNo ratings yet

- Industrial EngineeringDocument3 pagesIndustrial Engineeringriddhi_25100% (1)

- Control EngineeringDocument2 pagesControl EngineeringPradip PatelNo ratings yet

- Mechanical Engg. Sem - VI Teaching SchemeDocument1 pageMechanical Engg. Sem - VI Teaching SchemeShivam PurohitNo ratings yet

- Dynamics of MachineryDocument2 pagesDynamics of MachineryBhavesh PipaliyaNo ratings yet

- Heat & Mass TransferDocument2 pagesHeat & Mass TransferChintan PatelNo ratings yet

- Computer Aided DesignDocument2 pagesComputer Aided DesignKeyur TNo ratings yet

- BE SEM-VI Exam Scheme & Subject CodeDocument8 pagesBE SEM-VI Exam Scheme & Subject Codesuchit_thakkarNo ratings yet

- 075 DPDocument9 pages075 DPsharvan10No ratings yet

- Sheet Metal FormingDocument7 pagesSheet Metal FormingHussien EbrhimNo ratings yet

- Structural Design Calculation For WPC PergolaDocument81 pagesStructural Design Calculation For WPC Pergolamaamoun100% (2)

- Oedometer Test: Soil Mechanics 2 CE PC 504Document26 pagesOedometer Test: Soil Mechanics 2 CE PC 504SumanHaldarNo ratings yet

- Reinforced Earth Retaining Wall - 01Document12 pagesReinforced Earth Retaining Wall - 01nithuNo ratings yet

- Food Rheology: (Based On The Rheological Properties of Food)Document15 pagesFood Rheology: (Based On The Rheological Properties of Food)Goutham RevuruNo ratings yet

- Chapter 2 Tutorial PDFDocument35 pagesChapter 2 Tutorial PDFChong Qi Wen92% (12)

- Role of Comp in The Fatigue Resistance of Asphalt PavementsDocument8 pagesRole of Comp in The Fatigue Resistance of Asphalt PavementsGiora RozmarinNo ratings yet

- Week 09 MG Answer-FormatDocument7 pagesWeek 09 MG Answer-FormatJohn Carlo BaralNo ratings yet

- Erathquake and Motions of The EarthDocument8 pagesErathquake and Motions of The EarthLeah Ruales100% (1)

- I Dewa Ayu Marokta Utami Dewi, I Made Dwie Pradnya SusilaDocument7 pagesI Dewa Ayu Marokta Utami Dewi, I Made Dwie Pradnya Susilaagung widiantaraNo ratings yet

- Analysis & Design By: Er. Bishnu Pandey Civil Engineer NEC Regd. No. 8547 "A"Document5 pagesAnalysis & Design By: Er. Bishnu Pandey Civil Engineer NEC Regd. No. 8547 "A"Khim KhadkaNo ratings yet

- B. Design of SubstructureDocument14 pagesB. Design of SubstructureDeepak Kr Gupta100% (4)

- TEK 12-6 Reinforcement & Connectors (2007)Document6 pagesTEK 12-6 Reinforcement & Connectors (2007)B0B_PNo ratings yet

- Bearing Capacity of Foundations: Lesson 3Document20 pagesBearing Capacity of Foundations: Lesson 3Julz PDNo ratings yet

- Structural Wall - AnalysisDocument16 pagesStructural Wall - AnalysiscdestudosNo ratings yet

- Artigo 5Document8 pagesArtigo 5Edmilson LimaNo ratings yet

- Geotech PDFDocument286 pagesGeotech PDFYulia Diongi100% (2)

- Rock Mechanics Course QuestionsDocument6 pagesRock Mechanics Course QuestionsAbdulrahman G. ElgamalNo ratings yet

- Bored Pile FDN - BearingCapacity-450mmDocument16 pagesBored Pile FDN - BearingCapacity-450mm폴로 쥰 차No ratings yet

- Chapter 4 Stress, Strain and Stress Distribution in SoilDocument13 pagesChapter 4 Stress, Strain and Stress Distribution in SoilBiruk AkliluNo ratings yet

- WWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)Document3 pagesWWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)mahendra babu mekalaNo ratings yet

- Tensile Properties and Viscoelastic Model of A Polyimide FilmDocument10 pagesTensile Properties and Viscoelastic Model of A Polyimide FilmShengde ZhangNo ratings yet

- STR'L Calc. For Cuplock Scaffolding SystemDocument61 pagesSTR'L Calc. For Cuplock Scaffolding SystemZeeZ HNo ratings yet

- Tsu m19 Practice Problems Smat2Document1 pageTsu m19 Practice Problems Smat2Mark Lester ValdozNo ratings yet

- ME605 Assignment1Document2 pagesME605 Assignment1Nishant Patil100% (1)

- Lat Pile PYDocument38 pagesLat Pile PYpperic13No ratings yet

- Column DesignDocument6 pagesColumn Design123444123No ratings yet

- Steel Truss CalculationDocument15 pagesSteel Truss Calculationphong00x3No ratings yet

- Rilem TC 162-TDF PDFDocument17 pagesRilem TC 162-TDF PDFAref AbadelNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- A Welder’s Handbook to Robotic ProgrammingFrom EverandA Welder’s Handbook to Robotic ProgrammingRating: 5 out of 5 stars5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesFrom EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo ratings yet

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEFrom EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATERating: 4 out of 5 stars4/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyFrom EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyRating: 4 out of 5 stars4/5 (1)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)