Professional Documents

Culture Documents

Cca

Uploaded by

ghaffaryanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cca

Uploaded by

ghaffaryanCopyright:

Available Formats

Bulletin No.

CCA/94

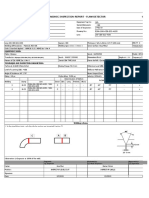

CCA Series Circular Arch Isolators

A New Concept in Shock & Vibration Control

The CCA Series Circular Arch Isolators...

Developed from a unique family of Shock and Vibration Control Isolators

Wire rope isolators have protected sensitive equipment in severe environments for over twenty years. Now, Korfund Dynamics has developed a revolutionary new type of wire rope cable isolator - The CCA Circular Arch Series. The CCA Series isolators incorporate captive, exible, stainless steel wire rope elements with steel attachment housings for easy installation and long life. The fully compliant wire rope elements provide a high degree of damping with predictable shock and vibration isolation performance characteristics over an unusually wide temperature range.

CCA-4

CCA-2

Circular Arch Isolator - Features/Benets

Rugged, metal construction Low frequency, highly damped vibration isolation Excellent shock attenuation Wide temperature range, -200F to +650F Fail-safe construction Maintenance-free

Typical Applications

Airborne avionics and equipment Shipboard/Marine equipment and electronics Mobile equipment and electronics Computer equipment and disc drives Blowers and Fans Motors and Pumps Medical Equipment Motor Generators and Compressors HVAC Equipment

CCA-8

The Series CCA Circular Arch provides all shock and vibration protection and can be loaded in Compression, 45 Compression/Roll, or Shear through its stainless steel cables.

Installation / Designation

COMPRESSION

Thru Hole Dia. Top Disc Bottom Disc

.213 .281 .406 .160 .218 .281

Series

CCA2 CCA4 CCA8

45

Materials & Finishes

COMPRESSION/ROLL

MATERIAL Cable: Stainless Steel per MIL-W-83420 Discs: Low Carbon Steel per ASTM A-366 FINISH Cable: Per MIL-W-83420 Discs: Zinc Plate QUALITY ASSURANCE SPECIFICATIONS MIL-I-45208

SHEAR

Spacer Washer

Recommended Spacer Sizes Series

CCA2 CCA4 CCA8

"HEART SHAPING" Heart-Shaping refers to the Isolator coil moving upward, under load, above the plane of the top mounting disc, as shown below. The spacer will negate

Part No.

148099-14 148099-15 148099-16

'A'

.25 .30 .45

'B'

1.00 2.38 1.38

'T'

.13 .25 .31

'A' Dia.

'B' Dia.

'T' thickness

CCA2 Series Circular Arch Isolator

1/16" Wire Rope Technical Data/ Load Deection Curves

50 CCA2 - 18 W/SPACER CCA2 - 18 W/O SPACER CCA2 - 28 W/SPACER CCA2 - 28 W/O SPACER CCA2 - 38 W/SPACER CCA2 - 38 W/O SPACER

40

Isolator

Height (in.) COMP.

Static KAVG (lb/in.) Stiffness 90 120 60 77 30 45 48 12 36

Max Dynamic Travel (in.) 0.32 0.12 0.42 0.48 0.22 0.86 0.65 0.45 1.20

LOAD - LBS.

30

CCA2 - 1 ( * )

0.86

SHEAR 45 C/R

20

COMP. CCA2 - 2 ( * 0 1.03 SHEAR 45 C/R

10

COMP. CCA2 - 3 ( * )

0 0 0.04 0.08 0.12 0.16 0.20 0.24 0.28 0.32 0.36 0.40 0.44 0.48 0.52 0.56 0.60 0.64 DEFLECTION - INCHES

1.30

SHEAR 45 C/R

( * ) Reects the number of Coils. The KAVG curves listed are based on an 8 coil conguration. To nd the correct KVAG and loading, multiply by ( * )/8

20 CCA2 - 18 CCA2 - 28 CCA2 - 38 15 CCA2 - 18 CCA2 - 28 CCA2 - 38

40 35 30 25 LOAD - LBS. 20 15 10 5 0 0 0.04 0.08 0.12 0.16 0.20 0.24 0.28 0.32 0.36 0.40 DEFLECTION - INCHES LOAD - LBS.

10

0 0 0.08 0.16 0.24 0.32 0.40 0.48 0.56 0.64 0.72 0.80 0.88 0.96 1.04 1.12 1.20 DEFLECTION - INCHES

CCA4 Series Circular Arch Isolator

1/8" Wire Rope Technical Data/ Load Deection Curves

150 CCA4 - 18 W/SPACER CCA4 - 18 W/O SPACER CCA4 - 28 W/SPACER CCA4 - 28 W/O SPACER CCA4 - 38 W/SPACER CCA4 - 38 W/O SPACER

125

Isolator

Height (in.) COMP.

Static KAVG (lb/in.) Stiffness 540 165 380 225 105 180 135 23 75

Max Dynamic Travel (in.) 0.60 0.45 0.85 0.80 0.55 1.55 1.20 0.80 2.15

100 LOAD - LBS.

CCA4 - 1 ( * )

75

1.60

SHEAR 45 C/R COMP.

50

CCA4 - 2 ( * 0

2.00

SHEAR 45 C/R

25

COMP. CCA4 - 3 ( * ) 2.55 SHEAR 45 C/R

0 0 0 .10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.10 1.20 DEFLECTION - INCHES

( * ) Reects the number of Coils. The KAVG curves listed are based on an 8 coil conguration. To nd the correct KVAG and loading, multiply by ( * )/8

90 CCA4 - 18 CCA4 - 28 CCA4 - 38 80 70 60 CCA4 - 18 CCA4 - 28 CCA4 - 38

200 175 150 125 LOAD - LBS. LOAD - LBS.

50 40 30

100 75 50 25 0 0 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 DEFLECTION - INCHES

20 10 0 0 0.08 0.40 0.60 0.80 1.00 1.20 1.40 1.60 1.80 2.00 2.20 DEFLECTION - INCHES

CCA8 Series Circular Arch Isolator

1/4" Wire Rope Technical Data/ Load Deection Curves

500 CCA8 - 18 W/SPACER CCA8 - 18 W/O SPACER CCA8 - 28 W/SPACER CCA8 - 28 W/O SPACER CCA8 - 38 W/SPACER CCA8 - 38 W/O SPACER

400

Isolator

Height (in.) COMP. w/spacer COMP. w/o spacer SHEAR 45 C/R COMP. w/spacer COMP. w/o spacer SHEAR 45 C/R COMP. w/spacer COMP. w/o spacer SHEAR 45 C/R

Static Max KAVG (lb/in.) Dynamic Stiffness Travel (in.) 1300 1300 820 1000 930 930 420 600 600 600 240 420 0.90 0.60 0.70 1.30 1.20 0.80 0.90 2.00 1.60 1.30 1.20 2.60

LOAD - LBS.

300

CCA8 - 1 ( * )

2.10

200

CCA8 - 2 ( * 0

100

2.60

CCA8 - 3 ( * )

0 0 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.10 1.20 1.30 1.40 1.50 1.60 DEFLECTION - INCHES

3.10

( * ) Reects the number of Coils. The KAVG curves listed are based on an 8 coil conguration. To nd the correct KVAG and loading, multiply by ( * )/8

500 CCA8 - 18 CCA8 - 28 CCA8 - 38 CCA8 - 18 CCA8 - 28 CCA8 - 38

600

500

400

400 LOAD - LBS. LOAD - LBS. 0 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.10 1.20 300

300

200

200 100

100

0 DEFLECTION - INCHES

0 0 0.20 0.40 0.60 0.80 1.00 1.20 1.40 1.60 1.80 2.00 2.20 2.40 2.60 DEFLECTION - INCHES

CIRCULAR ARCH SELECTION GUIDE

Static Load Applied: A = Compression B = Shear C = 45 Compression/Roll VEHICULAR / Rough Terrain (Off-Highway) / 20Hz Vertical

LBS./MOUNT CCA2 SERIES CCA2-34 A CCA2-24 B CCA2-34 C CCA2-38 A CCA2-28 B CCA2-38 C CCA2-28 A CCA2-14 B CCA4 SERIES CCA4-38 B CCA4-34 C CCA8 SERIES LBS./MOUNT CCA2 SERIES CCA4 SERIES CCA4-14 A CCA4-18 C CCA8 SERIES CCA8-36 A CCA8-26 B CCA8-38 C CCA8-24 A CCA8-14 B CCA8-26 C CCA8-38 A CCA8-28 B CCA8-14 C CCA8-14 A CCA8-16 B CCA8-28 C CCA8-26 A CCA8-16 B CCA8-18 C CCA8-28 A CCA8-18 C

0.5

N/A

8 10

N/A

CCA4-24 B CCA4-34 C N/A CCA4-36 A CCA4-14 B CCA4-24 C CCA4-28 A CCA4-16 B CCA4-26 C CCA4-38 A CCA4-18 B CCA4-28 C

CCA4-16 A 10 12 N/A

CCA4-18 A N/A 12 15 N/A

CCA2-18 A CCA2-16 B

CCA8-34 B 15 17 N/A

CCA2-18 B 4

CCA8-36 B 17 20 N/A N/A

N/A

CCA4-26 A CCA4-14 C

CCA8-24 B CCA8-34 C

20 25

N/A

N/A

25 30 68 N/A CCA4-24 A CCA4-16 C CCA8-34 A CCA8-38 B CCA8-36 C

N/A

N/A

CCA8-16 A

30 35

N/A B = Shear

N/A

CCA8-18 A

A = Compression

C = 45 Compression/Roll

COMPUTER EQUIPMENT / JET AIRCRAFT /10Hz Vertical

LBS./MOUNT CCA2 SERIES 0.5 CCA2-36 B CCA4 SERIES N/A CCA8 SERIES N/A LBS./MOUNT CCA2 SERIES 6 CCA4 SERIES CCA4-14 B CCA4-24 C CCA8 SERIES

N/A

N/A

CCA2-38 B CCA2-34 C

CCA4-34 B N/A 78 N/A CCA4-34 A CCA4-28 B CCA4-38 C CCA4-24 A CCA4-16 B CCA4-14 C CCA4-26 A CCA4-18 B CCA4-28 C CCA4-38 A CCA4-16 C N/A

CCA2-34 A CCA2-28 B CCA2-36 C CCA2-36 A CCA2-28 C CCA2-26 A CCA2-16 C

CCA4-36 B N/A 8 10 CCA4-38 B N/A CCA4-24 B CCA4-34 C 10 12 N/A 12 15 N/A N/A N/A N/A N/A

N/A

CCA8-34 B

CCA2-28 A CCA2-18 C

CCA4-26 B CCA4-36 C

Computers/Jet Aircraft - Continued

LBS./MOUNT CCA2 SERIES 15 20 N/A CCA4 SERIES CCA4-28 A CCA4-18 C CCA4-14 A CCA8 SERIES CCA8-36 B LBS./MOUNT CCA2 SERIES CCA4 SERIES CCA8 SERIES CCA8-24 A CCA8-28 B CCA8-26 C CCA8-38 A CCA8-16 B CCA8-14 C CCA8-14 A CCA8-18 B CCA8-28 C CCA8-26 A CCA8-16 B CCA8-28 A CCA8-18 C

40 50

N/A

N/A

20 25

N/A

CCA8-24 B CCA8-34 C CCA8-38 B CCA8-24 C CCA8-34 A CCA8-26 B CCA8-36 C CCA8-36 A CCA8-14 B CCA8-38 C

50 60

N/A

N/A

25 30

N/A

CCA4-16 A

60 -70

N/A

N/A

CCA4-18 A 30 35 N/A

70 -80

N/A

N/A

80 100

N/A

N/A

35 40

N/A

N/A

100 120

N/A

N/A

CCA8-18 A

A = Compression

B = Shear

C = 45 Compression/Roll

VEHICULAR / Smooth Highway. AIRCRAFT - propellor / 8-9Hz Vertical

LBS./MOUNT CCA2 SERIES 0.5 CCA2-34 B CCA4 SERIES N/A CCA8 SERIES N/A 10 12 1 CCA2-38 B N/A N/A 12 15 N/A CCA4-36 B 15 20 N/A CCA4-38 A CCA4-16 C CCA4-28 A CCA4-18 C CCA-14 A N/A CCA8-34 B CCA4-36 A CCA4-28 C N/A LBS./MOUNT CCA2 SERIES CCA4 SERIES CCA4-24 A CCA4-28 B CCA4-26 C CCA8 SERIES

N/A

CCA2-38 A CCA2-24 C CCA2-24 A CCA2-14 C CCA2-38 A CCA2-28 C

CCA4-34 B

N/A

N/A

N/A

CCA4-38 B

N/A

20 25

CCA8-36 B

N/A

CCA2-26 A CCA2-16 C

CCA4-38 B CCA4-34 C

25 30 N/A 30 35

CCA8-24 B CCA8-34 C

N/A

CCA4-16 A

CCA8-38 B CCA8-24 C

CCA2-28 C CCA2-18 C

CCA4-24 B CCA4-24 C

N/A CCA4-18 A 35 40 N/A CCA8-34 A CCA8-26 B CCA8-36 C

78

N/A

CCA4-26 B CCA4-36 C

N/A

8 10

N/A

CCA4-34 A CCA4-26 B CCA4-38 C

N/A

40 45

N/A

N/A

CCA8-36 A CCA8-14 B CCA8-26 C

Vehicular - smooth highway/Aircraft - propellor - Continued

LBS./MOUNT CCA2 SERIES CCA4 SERIES CCA8 SERIES CCA8-24 A CCA8-28 B CCA8-14 C CCA8-38 A CCA8-16 B CCA8-28 C CCA8-26 A CCA8-18 B CCA8-16 C LBS./MOUNT CCA2 SERIES CCA4 SERIES CCA8 SERIES CCA8-28 A CCA8-18 C

50 60

N/A

N/A

80 100

N/A

N/A

60 70

N/A

N/A

100 120

N/A

N/A

CCA8-16 A

70 80

N/A

N/A

120 140

N/A

N/A

CCA8-18 A

A = Compression

B = Shear

C = 45 Compression/Roll

ENGINES / Gen Sets, Marine , Compressors / 7.5 Hz Vertical

LBS./MOUNT CCA2 SERIES 1 2 CCA2-34 B CCA2-38 B CCA2-24 C CCA2-24 A CCA2-26 C CCA2-36 A CCA2-28 C CCA2-38 A CCA2-16 C CCA4 SERIES N/A CCA8 SERIES N/A LBS./MOUNT CCA2 SERIES 25 30 CCA4 SERIES CCA4-28 A CCA4-18 C CCA8 SERIES CCA8-24 B

N/A

N/A CCA4-34 B

N/A 30 35 N/A CCA4-14 A N/A CCA4-16 A N/A CCA4-18 A N/A 40 50 N/A CCA8-38 B CCA8-34 C CCA8-38 B CCA8-36 C CCA8-34 A CCA8-26 B CCA8-24 C CCA8-36 A CCA8-26 B CCA8-38 C CCA8-24 A CCA8-28 B CCA8-26 C CCA8-38 A CCA8-14 B CCA8-14 C CCA8-14 A CCA8-16 B CCA8-28 C CCA8-26 A CCA8-18 B CCA8-16 C CCA8-16 A CCA8-18 C CCA8-28 A CCA8-18 A

CCA4-36 B

N/A

35 40

CCA4-38 B

CCA2-28 A CCA2-18 C

CCA4-24 B CCA4-34 C

N/A

50 60

N/A

N/A

7 8

N/A

CCA4-24 B CCA4-24 C

N/A

60 70

N/A

N/A

8 10

N/A

CCA4-26 B CCA4-36 C

N/A

70 80

N/A

N/A

10 12

N/A

CCA4-34 A CCA4-26 B CCA4-38 C

N/A 80 100 N/A N/A

12 15

N/A

CCA4-36 A CCA4-28 B CCA4-26 C

N/A

100 120

N/A

N/A

15 20

N/A

CCA4-38 A CCA4-28 C

CCA8-34 B

120 140 140 160

N/A N/A N/A B = Shear

N/A N/A N/A

20 25

N/A

CCA4-26 A CCA4-16 C

CCA8-36 B

160 180

A = Compression

C = 45 Compression/Roll

INSTRUMENTS/ Delicate Instruments, Laboratory Equipment, etc. / 5Hz Vertical

LBS./MOUNT CCA2 SERIES 2 3 CCA2-34 C CCA2-36 C CCA2-34 A CCA2-38 C CCA4 SERIES N/A N/A N/A N/A 50-60 N/A N/A CCA8-24 B CCA8-36 C CCA8-34 A CCA8-26 B CCA8-24 C CCA8-36 A CCA8-28 B CCA8-38 C CCA8-24 A CCA8-14 C CCA8-38 A CCA8-28 C CCA8 SERIES N/A N/A LBS./MOUNT CCA2 SERIES 35-40 40-50 N/A CCA4 SERIES N/A CCA8 SERIES CCA8-38 B CCA8-38 B CCA8-34 C

N/A

N/A

CCA2-36 A CCA2-28 C

CCA4-34 B N/A 60-70 N/A N/A

6-8

CCA2-38 A

CCA4-36 B CCA4-34 C

N/A 70-80 N/A N/A

8-10

N/A

CCA4-38 B CCA4-24 C

N/A 80-100 N/A N/A

10-12

N/A

CCA4-36 C

N/A

12-15

N/A

CCA4-34 A CCA4-26 C

100-120 N/A

N/A

N/A

15-17

N/A

CCA4-32 A CCA4-38 C

N/A

120-140

N/A

N/A

CCA8-14 A CCA8-28 C CCA8-26 A CCA8-16 C CCA8-16 A CCA8-18 C

17-20

N/A

CCA4-36 A CCA4-14 C

N/A

140-160

N/A

N/A

20-25

N/A

CCA4-38 A CCA4-28 C

CCA8-34 B

160-180

N/A

N/A

25-30

N/A

CCA4-26 A CCA4-16 C

CCA8-36 B

180-200

N/A

N/A

CCA8-28 A

30-35

N/A

CCA4-28 A CCA4-18 C

CCA8-36 B

200-240

N/A

N/A

CCA8-18 A

A = Compression

B = Shear

C = 45 Compression/Roll

10

Circular Arch Isolators/Typical Applications

Base Mounted Computers & Peripherals

Base Mounted Compressors & Equipment

Tray Mounted Electronics Base Mounted Printers & Equipment

45 Compression/Roll Gen-Set Mounting 11

Bulkhead Mounted (Shear Loaded) Equipment

Korfund Dynamics / Capabilities

Korfund Dynamics (an ARX subsidiary company) is a manufacturer of shock, vibration and structureborne noise isolation products for stationary, mobile and marine equipment. Engineering, sales and production facilities are located in Farmingdale, N.Y., and Caguas, Puerto Rico, with a total workforce of 200 and approximately 120,000 square feet of manufacturing space. Korfund Dynamics product line includes spring, elastomer, cable and pad type isolators. Inventories of standard products are maintained for off-shelf delivery. Production tooling exists for all standard series and large quantities can be supplied in 2 - 4 weeks from order placement Engineering development and test facilities are based in Plainview, N.Y., and include computerized testing for static and dynamic shock and vibration evaluation. If one of Korfund Dynamics standard products is not suitable for a particular application, our engineering division will work closely with the customer to develop a modied standard or special design to provide the optimum isolation system. Special engineered designs can usually be developed with prototype tooling in 4 - 6 weeks. Within the past three years, Korfund Dynamics has developed new products primarily to serve the industrial OEM markets. These new products include a range of elastomer designs offering light weight, rugged, low prole installations. Typical applications include motor generator sets, gas and diesel engines, radiators and charge air coolers, cabs and all types of industrial equipment.

A Unit of VMC, an Aeroex, Inc., Company

113 Main Street, Box 270, Bloomingdale, New Jersey 07403 Tel: 973/838-1780 TOLL FREE: 1-800-LOW-VIBE Fax: 973/492-8430

http://www.vmc-kdc.com

Vibration Mountings & Controls, Inc. 2.5M 10/01

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- As 1926.1 - 2012 Swimming Pool SafetyDocument49 pagesAs 1926.1 - 2012 Swimming Pool SafetyrteteNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- BS StandardsDocument41 pagesBS Standardstakias67% (3)

- Case Study (DM)Document28 pagesCase Study (DM)Jai - Ho100% (1)

- 11qvul PDFDocument14 pages11qvul PDFghaffaryanNo ratings yet

- Airbus Reference Language AbbreviationsDocument66 pagesAirbus Reference Language Abbreviations862405No ratings yet

- Singular and Plural NounsDocument3 pagesSingular and Plural NounsJosé BulquesNo ratings yet

- Abinitio Interview QuesDocument30 pagesAbinitio Interview QuesVasu ManchikalapudiNo ratings yet

- 1555 3 2008Document27 pages1555 3 2008ghaffaryanNo ratings yet

- U B W, I .: Nited Rass Orks NCDocument1 pageU B W, I .: Nited Rass Orks NCghaffaryanNo ratings yet

- Note PDFDocument1 pageNote PDFghaffaryanNo ratings yet

- Vision (SH)Document9 pagesVision (SH)ghaffaryanNo ratings yet

- Learn PascalDocument33 pagesLearn Pascalapi-3778380No ratings yet

- PhotoShop CSDocument2 pagesPhotoShop CSghaffaryanNo ratings yet

- Internet Applications: A New Frontier: by Kevin Lynch Updated October 2003Document19 pagesInternet Applications: A New Frontier: by Kevin Lynch Updated October 2003ghaffaryanNo ratings yet

- Organizational Culture DecryptDocument86 pagesOrganizational Culture DecryptghaffaryanNo ratings yet

- Adjustable-Arc or Full-Circle Gear-Driven Sprinkler for Large AreasDocument1 pageAdjustable-Arc or Full-Circle Gear-Driven Sprinkler for Large AreasghaffaryanNo ratings yet

- Poseshgaree (SH)Document12 pagesPoseshgaree (SH)ghaffaryanNo ratings yet

- City ZaribDocument4 pagesCity ZaribghaffaryanNo ratings yet

- TankDocument2 pagesTankghaffaryanNo ratings yet

- How To Use The ProgramDocument14 pagesHow To Use The ProgramghaffaryanNo ratings yet

- 21 12 00 Fire-Suppression StandpipesDocument3 pages21 12 00 Fire-Suppression StandpipesghaffaryanNo ratings yet

- Cabinet Selection InformationDocument6 pagesCabinet Selection InformationghaffaryanNo ratings yet

- AppleDocument2 pagesAppleghaffaryanNo ratings yet

- Apple Bluetooth ManualDocument4 pagesApple Bluetooth ManualghaffaryanNo ratings yet

- AppleDocument1 pageAppleghaffaryanNo ratings yet

- Tecra A8-S8514Document9 pagesTecra A8-S8514ghaffaryan100% (1)

- Satellite P850 BT2G22Document4 pagesSatellite P850 BT2G22ghaffaryanNo ratings yet

- Heat Controller ductless mini-split warrantyDocument2 pagesHeat Controller ductless mini-split warrantyghaffaryanNo ratings yet

- Basic Hydraulics PaperDocument42 pagesBasic Hydraulics PaperAzhar PashaNo ratings yet

- Single Package (New 50Hz, Above 5ton) : LK5C 2004-B1Document32 pagesSingle Package (New 50Hz, Above 5ton) : LK5C 2004-B1ghaffaryanNo ratings yet

- 1555 5 2008Document14 pages1555 5 2008ghaffaryanNo ratings yet

- King 2012Document45 pagesKing 2012ekhazeniNo ratings yet

- Pakage PAU (Fruits)Document70 pagesPakage PAU (Fruits)Gary Bhullar57% (7)

- Kamera Basler Aca2500-20gmDocument20 pagesKamera Basler Aca2500-20gmJan KubalaNo ratings yet

- Raj Priya Civil Court Clerk FinalDocument1 pageRaj Priya Civil Court Clerk FinalRaj KamalNo ratings yet

- Introduction To Machine Learning Top-Down Approach - Towards Data ScienceDocument6 pagesIntroduction To Machine Learning Top-Down Approach - Towards Data ScienceKashaf BakaliNo ratings yet

- Barker-Choucalas, Vida PDFDocument176 pagesBarker-Choucalas, Vida PDFAnn GarbinNo ratings yet

- GTA Max Profit Bunker Locations Update v1.4Document1 pageGTA Max Profit Bunker Locations Update v1.4Sam FarrelNo ratings yet

- Tips For Effective Presentation Design and DeliveryDocument2 pagesTips For Effective Presentation Design and DeliveryJames Manrique100% (1)

- 935 Ubi PBK Statement PDFDocument20 pages935 Ubi PBK Statement PDFTECHNO ACCOUNTNo ratings yet

- 1 FrameworkDocument26 pages1 FrameworkIrenataNo ratings yet

- Chapter 27 Protists I. Evolution of EukaryotesDocument7 pagesChapter 27 Protists I. Evolution of EukaryotesNadeem IqbalNo ratings yet

- Vortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimDocument7 pagesVortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimhiraNo ratings yet

- User Manual - Rev3Document31 pagesUser Manual - Rev3SyahdiNo ratings yet

- Pneapple Waste To Bioethanol Casabar - Et - Al-2019-Biomass - Conversion - and - BiorefineryDocument6 pagesPneapple Waste To Bioethanol Casabar - Et - Al-2019-Biomass - Conversion - and - Biorefineryflorian willfortNo ratings yet

- Investigation Report on Engine Room Fire on Ferry BerlinDocument63 pagesInvestigation Report on Engine Room Fire on Ferry Berlin卓文翔No ratings yet

- Assignment - Stocks and CBDocument2 pagesAssignment - Stocks and CBGhulam HassanNo ratings yet

- C++ Practical FileDocument15 pagesC++ Practical FilePreetish ChandraNo ratings yet

- Procedure For NC and CapaDocument2 pagesProcedure For NC and CapaSAKTHIVEL ANo ratings yet

- Sonochemical Synthesis of NanomaterialsDocument13 pagesSonochemical Synthesis of NanomaterialsMarcos LoredoNo ratings yet

- Effects of Zero Moment of Truth On Consumer Behavior For FMCGDocument14 pagesEffects of Zero Moment of Truth On Consumer Behavior For FMCGBoogii EnkhboldNo ratings yet

- Big Data, Consumer Analytics, and The Transformation of MarketingDocument17 pagesBig Data, Consumer Analytics, and The Transformation of MarketingPeyush NeneNo ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- Admission Notice 2023-24Document2 pagesAdmission Notice 2023-24Galav PareekNo ratings yet

- Guidelines To MAS Notice 626 April 2015Document62 pagesGuidelines To MAS Notice 626 April 2015Wr OngNo ratings yet

- M and S Code of ConductDocument43 pagesM and S Code of ConductpeachdramaNo ratings yet

- Product 243: Technical Data SheetDocument3 pagesProduct 243: Technical Data SheetRuiNo ratings yet