Professional Documents

Culture Documents

Production Operations Management MB0044

Uploaded by

Nitin SanilOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production Operations Management MB0044

Uploaded by

Nitin SanilCopyright:

Available Formats

NAME: ROLL NUMBER: COURSE: SEMESTER: SUBJECT:

KOTIAN SUBHA RAMESH 511016602 MASTER OF BUSINESS ADMINISTRATION Second production and operations management

SUBJECT CODE: MB0044 Centre code: 02542 I

ASSIGNMENT SET:

1. What are the components of systems productivity? Explain how CAD and CIM help in improving productivity.

Page 1 of 23

Production and operations management

Productivity is a measure of output from a production process, per unit of input. It is expressed as: Productivity can calculated for a: be Productivity=Outpu t Inpu t

o Functional Unit o Department or division o Plan

o Single Operation

It is a measure of the efficiency of the system and looks at the economies achieved during the processes. Every process will have number of contributors-people machines, facilitating goods, ancillary equipments, technology, etc. Each element attempting to enhance the contribution of other elements. Opportunities exist at all stages of the workflow. The entire system of introduce measures for increasing productivity. However in actual manufacturing situations, the inefficiencies will have cascading effect in hampering productivity. Communication, effective review processes and innovative methods will ensure optimization of resources. Quality circles are efficient in incorporating low cost and non-intrusive methods of improving productivity and quality throughout the organization. Capital deployed in plant, machinery, buildings and the distribution system as well as working capital are components of the oust of manufacture and need to be productive. Demand fluctuations, uncertainties of production owing to breakdowns and inventories being created drag the productivity down. Computer Aided Design (CAD) is an electronic system for designing new parts or products or altering existing ones, replacing drafting traditionally done by hand. The designs are made using powerful desktop computers and graphics software. Designer can create drawings and view them from any angle on a display monitor. Views can be made from different angles and positions so that the visualization process of the designed component helps the designer to suggest alternative to the customer and production department. The software can generate the volume, weights of components as also other engineering loads, and various other engineering parameters like centre of gravity, deflections under estimated loads, and various other design parameters on complicate forms, either for single components or assemblies. CAD helps to increase the efficiency of a designers work. This aids in reducing the time required for making a design or modifying a product and thus concept market period gets drastically cut. This implementation also cuts the cost of product development and sharply reduces the time to market new products. It saves time by Page 2 of 23

Production and operations management

enabling designers to access and modify old designs quickly, rather than start from scratch. Computer Integrated manufacturing (CIM) Integration occurs when a broad range of manufacturing and supporting activities are linked. It is the complete automation of a manufacturing plant, with all process functioning under computer control and digital information tying them together. Activities include engineering design, production planning, shop control, order processing, material control, distribution etc. Information flow across all functions takes place with the help of computers. Transmission, processing, distribution and feedback happen almost in real time so that intended activities are conducted rapidly. This process helps in rapid production and also reduces indirect costs. As response times decrease, customer satisfaction increases resulting in better business. CIM helps in avoiding accumulation of materials resulting in better throughput and better utilization of space. Bar coded labels that accompany materials contain instructions for processing them which are read by sensing devices and display the status on monitors. This information is available to all concerned personnel responsible in planning. Identifying shortages, ensuring faster deliveries becomes easy with CIM. It is an important aspect of technology in manufacturing. 2. What do you understand by industry best practice? Briefly explain different types of Benchmarking. For setting up or development of an industry it takes decades and during this decade many changes related to production has taken place. As time goes product and services keep on changing as per customer requirement. The companies that were at the front innovate to stay in business as new entrants would be adopting the latest techniques that the pioneers had taken decades to establish. In this case he various firms in any industry would end up adopting almost similar methods of getting an output required. The changing practices which give better output will give rise to Industry Best Practices. These tend to get stabilized or changed owing to the development of new equipments which are designed. A manufacture will keep track on demands for higher quality and reduced prices and those who can use all these advantage will benefit. Industry best practices open up the field for benchmarking by companies which need to improve their performance. Benchmarking involves management identifying the best firms in their industry, or any other industry where similar processes exist, and comparing the results. Benchmarking is an essential ingredient in Page 3 of 23

Production and operations management

strategic planning and operational improvement. Benchmarking makes it possible to gain competitive superiority rather than competitive parity. The term benchmark refers to the reference point by which performance is measured against. It is the indicator of what can and is being achieved. The term benchmarking refers to the actual activity of establishing benchmarks and 'best' practices. Following are the types of Benchmarking: o o o o o Process Benchmarking-Business Process Financial Benchmarking Performance Benchmarking Product Benchmarking Strategic Benchmarking

o Functional Benchmarking Process Benchmarking-Business Process: Process Benchmarking focuses on improving specific critical processes and operations. Benchmarking partners are sought from best practice organizations that perform similar work or deliver similar services. Process benchmarking invariably involves producing process maps to facilitate comparison and analysis. This type of benchmarking often results in short term benefits. Financial benchmarking: Financial benchmarking helps in analyzing and comparing the results in an effort to assess overall competitiveness and productivity.

Performance Benchmarking: Performance benchmarking allows the initiator firm to assess their competitive position by comparing products and services with those of target firms. Product Benchmarking: Product Benchmarking helps in designing new products or upgrades to current ones.

o Strategic Benchmarking: Strategic Benchmarking helps in observing how others compete.

o

Functional Benchmarking: Functional Benchmarking helps in benchmarking on a single function to improve the operation of that particular function. This can lead to innovation and dramatic improvements. Page 4 of 23

Production and operations management

Benchmarking goes beyond comparisons with competitors to understanding the practices that lie behind the performance gaps. It is not a method for 'copying' the practices of competitors, but a way of seeking superior process performance by looking outside the industry. Benchmarking makes it possible to gain competitive superiority rather than competitive parity. Benchmark refers to the reference point by which performance is measured against. It is the indicator of what can and is being achieved. The term benchmarking refers to the actual activity of establishing benchmarks and executing best practices. 3. List out the various automated systems for transfer of materials in the production plant. What do you understand by Line Balancing? Explain with an example. The various automated systems for transfer of materials in the production plant are: o Fixed, o Programmable o Flexible o Fixed: fixed automation is rigid .They are designed for high volume production and their rigidity ensures less variability. They are not amenable to change in product or process. They need minimal human intervention. E.g.: Pharmaceutical Machines and textile machines. o Programmable: Programming devices enable machines to operate automatically. The machines have sensing and control devices that enable the simplest of them called machine attachments replace human effort. They guide, locate, move, and achieve relative positions by means of cams, optical sensing, and load sensing mechanisms and activate the controls to remove human intervention. Numerically controlled machines read instructions and convert them to machine operations. Computers are used for controlling one machine or a number of them and they have programmes written into them for operations. They are Computer Numerically Controlled or for short CNC machines.

Page 5 of 23

Production and operations management

o Flexible: Robots are higher in the order of automation as they perform a variety of tasks. They are designed to move materials by holding them in their arms and making precise movements according to programmes written into the computers that reside in them. They simulate human actions. They can grip and hold tools with the help of sensors. These sensors are sensitive to touch and force to know that the material is to be held with the requisite pressure for the conduct of operations. Vision sensors are used for inspection, identification and guidance. They use optics based instruments to gather data and feed them to the computers for activating the other parts of the robot. Identification and movement of materials are helped by bar codes which are read and fed into the system for monitoring quantity, location, and movement. They help the automated systems to sort information and provide information for effecting any changes necessary. Computers and information systems are used for placing orders for materials, giving commands and adjusting inventory records which show the location and quantity of materials available.

Line Balancing:

When several automated machines are linked by a transfer system which moves the parts by using handling machines which are also automated, we have an automated flow line. After completing an operation on a machine, the semi-finished parts are moved to the next machine in the sequence determined by the process requirements and a flow line is established. The parts at various stages from raw material to ready for fitment or assembly are processed continuously to attain the required shapes or acquire special properties to enable them to perform desired functions. The materials need to be moved, held, rotated, lifted, and positioned for completing different operations. Sometimes, a few of the operations can be done on a single machine with a number of attachments. They are moved further to other machines for performing further operations. Human intervention may be needed to verify that the operations are taking place according to standards. When these can be achieved with the help of automation and the processes

Page 6 of 23

Production and operations management

The main consideration is to balance times that different machines take to complete the operations assigned to them. It is necessary to design the machines in such a way that, the operation times are the same throughout the sequence in the flow of the martial. In fixed automation or hard automation, where one component is manufactured using several operations and machines, it is possible to achieve this condition. We assume that product life cycles are sufficiently stable to invest heavily on the automated flow lines to achieve reduced cost per unit. Automated flow lines are considered only when the product is required to be made in high volumes over a relatively long period. Designers now incorporate flexibility in the machines which will take care of small changes in dimensions by making adjustments or minor changes in the existing machine or layout. The change in movements needed can be achieved by programming the machines. Provisions for extra pallets or tool holders or conveyors are made in the original design to accommodate anticipated changes. The logic to be followed is to find out whether the reduction in cost per piece justifies the costs of designing, manufacturing, and setting up automated flow lines. Group Technology and Cellular Manufacturing along with conventional Product and Process Layouts are still resorted to, as they allow flexibility for the production system.

Page 7 of 23

Production and operations management

4. Explain the different types of Quality Control Tools with examples? How do Crosbys absolutes of quality differ from Demings principles? There are seven basic control tools considered for achieving quality. They are as follows: 1. 2. 3. 4. 5. 6. 7. Flow Chart Check Sheet Histogram Pareto Analysis Scatter Diagram Control Chart Causes and Effect diagram

1 Flow Chart: Flow chart is a visual representation of process showing the various steps. Like other types of diagram, they help visualize what is going on and thereby help the viewer to understand a process, and perhaps also find flaws and other less-obvious features within it. There are many different types of flowcharts, and each type has its own list of boxes and notational conventions. The two most common types of boxes in a flowchart are:

A processing step which is as called activity and denoted as a rectangular box A decision usually denoted as a diamond.

Page 8 of 23

Production and operations management

Each decision point generates alternatives. Criteria and consequences that go with decisions are amenable to evaluation for purposes of assessing quality which shows the responsibility of each organizational for different parts of a single process.

Start

Insp ect

Open

Inspe ct

Close

Reject Sample of Flow Chart 1. Check Sheet:

Reject

The check sheet is a simple document that is used for collecting data in real-time like number of defects, types of defects, and at the location and time where the data is generated. Check Sheet contain classification, location, frequency, measurement scale and check list. Sample check sheet No. of Defects 1 In Shirt Day 1 2 3 4 5 6 II I II II III II

2 III IIIIIIII IIIIII IIII IIIIII III

3 IIII IIIIIII IIII IIII II II

4 IIIIII IIII II II I IIII

5 II III II II III II

The table shows that the number of defects in shirt 1 and 5 are not many as compared to defect no 2 which increased over the days and appears to be stabilizing at the higher side and therefore needs to be attended immediately. Page 9 of 23

Production and operations management

2. Histogram: A histogram is a graphical representation, showing a visual impression of the distribution of data. It is an estimate of the probability distribution of a continuous variable. It is used when there is large amount of data about process. They reveal whether the pattern of distribution has a single peak, or many peaks and also the extent of variation around the peak value. This helps in identifying whether the problem is serious. When used in conjunction with comparable parameters, the visual patterns help us to identify the problem which should be attended to. Below sample of Histogram of wages of workers A B C D in Rs. Sample Histogram Chart

3. Pareto Analysis: Pareto analysis is a tool for classifying problem areas according to the degree of importance and attending to the most important. Pareto principle, also called 80-20 rule, states that 80 percent of the problems Page 10 of 23

Production and operations management

that we encounter arise out of 20 percent of items. If we find that, in a day, we have 164 assemblies having problems and there are 11 possible causes, it is observed that 80 percent of them, that is, 147 of them have been caused by just 2 or 3 of them. It will be easy to focus on these 2 or 3 and reduce the number of defects to a great extent. When the cause of these defects has been attended, we will observe that some other defect becomes predominantly observed and if the process is continued, we are marching toward zero defects. Sample of Pareto Analysis

Pareto Analysis when used correctly is powerful and effective tool in continuous improvement and problem solving to break up few from other causes in terms of cost and frequency.

4. Scatter Diagram: Scatter diagram is used when we have two variables and want to know the degree of relationship between them. This diagram simply plots pairs of corresponding data from two variables, which are usually two variables in a process being studied. The scatter diagram does not determine the exact relationship between the two variables, but it does indicate whether they are correlated or not and also does not predict cause and effect relationships between these variables. It is used to provide a graphical representation of the strength of the relationship between two variables and serve as a follow-up step to a cause-effect analysis to establish whether a change in an identified cause can indeed produce a change in its identified effect. Sample of Scatter Diagram

Page 11 of 23

Production and operations management

A scatter Diagram is also very useful when we want to see how two comparable data sets agree with each other. 5. Control Chart: Control charts are used to verify whether a process is under control. Variables, when they remain within a range, will render the product and maintain the specifications. This is called the quality of conformance. If the chart indicates that the process being monitored is not in control, analysis of the chart can help determine the sources of variation, which can then be eliminated to bring the process back into control. The control chart can be seen as part of an objective and disciplined approach that enables correct decisions regarding control of the process, including whether or not to change process control parameters. Samples are taken and the mean and range of the variable of each sample (subgroup) is recorded.

6.

Causes and Effect diagram:

A Cause-and-Effect Diagram is a tool that is useful for identifying and organizing the known or potential causes of quality. These are arranged in such a way that different branches representing causes connect the stem in the direction of the discovery of the problem. Cause and Effect Diagrams help you to think through causes of a Page 12 of 23

Production and operations management

problem thoroughly. Their major benefit is that it pushes to consider all possible causes of the problem rather than just the ones that are most clear.

Machine

Product Process Major Defects

Inspection Training

Product

Sample Cause and Effect Diagram Crosbys absolutes of quality differ from Demings principles: Crosby also lays emphasis on top management commitment and responsibility for designing the system so that defects are not inevitable. He urged that there be no restriction on spending for achieving quality. In the long run, maintaining quality is more economical than compromising on its achievement. Crosby adopted his basic theories about quality in four Absolutes of Quality Management as follows: 1. Quality means conformance to requirements, not goodness. 2. The system for causing quality is prevention, not appraisal. 3. The performance standard must be zero defects, not "that's close enough." 4. The measurement of quality is the price of nonconformance, not indexes. Crosby also has given 14 points similar to those of Deming. His approach emphasizes on measurement of quality, increasing awareness, corrective action, error cause removal and continuously reinforcing the system, so that advantages derived are not lost over time. He opined that the quality management regimen should improve Page 13 of 23

Production and operations management

the overall health of the organization and prescribed a vaccine. The ingredients are: 1) Integrity: Honesty and commitment help in producing everything right first time, every time. 2) Communication: Flow of information between departments, suppliers, customers helps in identifying opportunities. 3) Systems and operations: These should bring in a quality environment so that nobody is comfortable with anything less than the best

5. Define project cycle, project management, and scope of project. List the various project management knowledge areas? What are the reasons for failure of a project? Project Cycle A project cycle consists of the various activities of operations, resources, and the limitations imposed on them. Project Management: A Project is a temporary endeavor with a finite completion date undertaken to create a unique product or service. Projects bring form or function to ideas or needs. A project is undertaken to achieve a purpose. Whereas Management is the technique of understanding the problems, needs, and controlling the use of resources such as cost, time, manpower and materials. Thus Project management is a methodical approach to planning and guiding project processes from start to finish. Scope of project: Scope of the project refers to the various parameters that affect the project in its planning, formulation, and executions. Scope of project is to clearly describe and gain agreement on the logical boundaries of the project. Various project management knowledge areas:

Page 14 of 23

Production and operations management

The knowledge areas of project management are the following: o Project integration management, cost management, communications management o Project scope management, quality management, risk management o Project time management, human management, procurement management Project Management Knowledge Areas

o Project Integration Management: It Deals with processes that integrate different aspects of project management. This knowledge area deals with developing Project Charter, Preliminary Project Scope, and Project Management Plan. It also deals with monitoring and controlling project work, integrated change control, and closing a project.

o Project Cost Management: It deals with processes concerning the cost constrains of the project. Some of the processes that are part of this knowledge area are Cost Estimating, Budgeting, and Control. Page 15 of 23

Production and operations management

o Project Communication Management: It deals with the processes concerning communication mechanisms of a project, namely, Communication Planning, Performance Reporting, and Information Distribution.

o Project Scope Management: It deals with the processes that are responsible for controlling project scope. It consists of Scope Planning, Definition, Verification, and Control.

o Project Quality Management: It deals with the processes that assure that the project meets its quality obligations. It consists of Quality Planning, Quality Assurance, and Quality Control. o Project Risk Management: It deals with the processes concerned with project-related risk management. It consists of Risk Identification, Quantitative and Qualitative Risk Analysis, Risk Response Planning, and Risk Monitoring.

o Project Time Management: It deals with the processes concerning the time constraints of the project. It deals with Activity definition, sequencing, resource estimating, and duration estimating. It also deals with schedule development and control.

o Project Human Resources Management: It deals with the processes that deal with obtaining and managing the project team. Some of the processes of this knowledge area are Human Resource Planning, Acquire Project Team, Develop Project Team, and Manage Project Team.

o Project Procurement Management: It deals with the processes that deal with obtaining products and services needed

Page 16 of 23

Production and operations management

to complete a project. It consists of Plan Contracting, Select Seller Responses, Select Seller, and Contract Closer.

For successful project it is necessary to understand its relationship with other management disciplines. Other management supporting disciplines are business legal issues, strategic planning, logistics, human resource management, and domain knowledge. Reasons for Failure of a project: The measure of project success or failure has a great deal to do with how projects are defined. A project is a temporary endeavor undertaken to create a unique product or service .Organizations that successfully use project management disciplines know exactly how rigorously they mean to apply the disciplines and how to measure success. A project may fail because of the following reasons: o Incidence of project failure o Factors contributing to project success not emphasized o Overview of Information and Communication Technologies (ICT) projects o Common problems encountered during projects

Incidence of project failure: o o o o o o Projects being initiated at random at all levels Project objective not in line with business objective Project management not observed No prior experience of Project manager in the related project Non-dedicated team Lack of complete support from clients

Factors contributing to project success not emphasized: Project objective in alignment with business objective Page 17 of 23

Production and operations management

Working within methodology the framework of project management Effective scoping, planning, estimation, execution, controls and reviews, closure intertwined with quality Proactive approach towards project bottlenecks Communication and managing expectations effectively with clients, team members, and stake holders Prior experience of project manager in a similar project

Overview of Information and Communication Technologies (ICT) projects: Involve information and communications technologies such as the World Wide Web, e-mail, fiber-optics, and satellites Enable societies to produce, access, adapt and apply information in greater amounts, more rapidly and at reduced costs Offer enormous opportunities for enhancing business and economic viability

Common problems encountered during projects: No prioritization of project activity from an organizational position One or more of the stages in the project mishandled Less qualified or non-dedicated manpower Absence of smooth flow of communication between the involved parties

6. Explain the various phases in project management life cycle. Explain the necessity and objectives of SCM. Project management is an important phase of any project. The Project manager must first understand the change processes in a project to bring about any changes. Project management life cycle has six phases:

Page 18 of 23

Production and operations management

1. 2. 3. 4. 5. 6. Analysis and evaluation phase Marketing phase Design phase Execution phase Control inspecting, testing, and delivery phase Closure and post completion analysis phase

1. Analysis and evaluation phase: Analysis and evaluation phase is the initial phase of any project. information is collected from the customer pertaining to the project and the requirements of the project are analyzed. According to the customer requirement, the entire project is planned in a strategic manner. The project manager conducts the analysis of the problem and submits a detailed report to the top management.

Project Manager Analysis Report consists of the following: o o o o Details of the project justification Details on what the problem is Methods of solving the problem List of the objectives to be achieved Page 19 of 23

Production and operations management

o o o o Estimation of project budget Success rate of completing the project Information on the project feasibility Information of the risks involved in the project

The important task of the project manager during the phase of analysis and evaluation are: o Specification Requirements Analysis to determine the vital requirements of a project in order to achieve the desired target. o Feasibility Study to analyze whether the project is technically, economically, and practically feasible to be undertaken. o Trade-off Analysis to understand and examine the various alternatives which could be considered for solving the problem. o Estimation to conduct on the project cost, effort required for the project, and the functionality of various processes in the project. o System design to choose to fulfill the requirements. o Project Evaluation to evaluate in terms of expected profit, cost, and risks involved. 2. Marketing phase A project proposal is prepared by a group of people including the project manager. This proposal has to contain the strategies adopted to market the product to the customers. As customer is one to accept it and led to long lasting. 3. Design phase Design phase involve inputs and outputs of the various project stages. Page 20 of 23

Production and operations management

Inputs and Outputs in Design Phase o Inputs received consist of project feasibility study, preliminary project evaluation details, project proposal, and customer interviews. o Outputs produced consist of system design specifications, functional specifications of the project, design specifications of the project, and project plan. 4. Execution phase In this phase the plan is executed by Project Manager and his executives and at every stage reports are prepared 5. Control inspecting, testing and delivery phase The project team works under the guidance of the project manager. It has to be ensured by project manager that the team working under him is implementing the project designs accurately. The project has to Page 21 of 23

Production and operations management

be tracked or monitored through its cost, manpower, and schedule. The project manager has to ensure ways of managing the customer and marketing the future work as well as ways to perform quality control work. 6. Closure and post completion analysis phase Closure and post completion analysis phase upon satisfactory completion and delivery of the intended product or service the staff performance has to be evaluated. Document the lessons from the project. Prepare the reports on project feedback analysis followed by the project execution report. The phases which involve in the above are: o The preparation stage involves the preparation and approval of project outline, project plan and project budget. o Assigning task to the team members o The feasibility or research stage establishes whether the project is feasible or not and establishes the risk factors o A detailed definition and plan for the project and its execution is prepared by the team and coordinated by the project manager. o The implementation stage involves the execution of the project as per the plan. o The final stage involves satisfactory product/service to the customers. Necessity and Objectives of SCM SCM is required by an enterprise as a tool to improve management effectiveness with the following objectives: o Reduction of inventory. o Enhancement of participation level and empowerment level. Page 22 of 23 delivery of the

Production and operations management

o Increase in functional effectiveness of existing systems like Enterprise Resource Planning (ERP), Accounting Software, and Documentation such as financial reports/ Statements/ISO 9000 Documents. o Effective integration of multiple systems like ERP, communication systems, documentation system and security. o Design / Research & Development (R&D) systems. o Better operation of resources like men, material, equipment, and money. o Optimization of money flow cycle within the organization as well as from external agencies. o Enhancement of value of products, operations, and services. These enhancements will consequently enhance the profitability of organization. o Enhancement of satisfaction level of customers and clients, supporting institutions, statutory control agencies, suppliers and vendors, employees and executives. o Enhancement of flexibility in the organization to help in easy implementation of schemes involving modernization, expansion and diversification even divestments, mergers and acquisitions. o Enhancement of coverage information systems. and accuracy of management

Page 23 of 23

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Configuracion 854k 428Document9 pagesConfiguracion 854k 428dj danielilloNo ratings yet

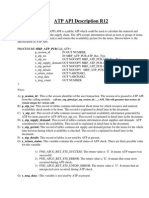

- Atp Api R12Document16 pagesAtp Api R12prasad_jampanaNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNo ratings yet

- Ece SyllabusDocument39 pagesEce SyllabusbaruaeeeNo ratings yet

- Kawasaki Bajaj CT 125 Operating ManualDocument48 pagesKawasaki Bajaj CT 125 Operating ManualRoger MifaNo ratings yet

- ICR 225 Factsheet Steve 6RDocument2 pagesICR 225 Factsheet Steve 6RRizwan MNo ratings yet

- Cisco Configure Cisco Meeting Server and CUCMDocument11 pagesCisco Configure Cisco Meeting Server and CUCMandreicainNo ratings yet

- Multiple-Choice QuestionsDocument8 pagesMultiple-Choice Questionsvijayganesh pinisettiNo ratings yet

- Data Sheet mbr320 PDFDocument2 pagesData Sheet mbr320 PDFthanggimme.phanNo ratings yet

- Proteza Oticon More Minirite R Instructions For UseDocument49 pagesProteza Oticon More Minirite R Instructions For UseOvidiu PascuNo ratings yet

- Electromechanical Test MachinesDocument2 pagesElectromechanical Test Machinesapi-254876696No ratings yet

- Valuation: Philippine Residential Broadband MarketDocument5 pagesValuation: Philippine Residential Broadband MarketNico Angeles MenesesNo ratings yet

- Get Current Location Address For Android App - Stack Overflow PDFDocument5 pagesGet Current Location Address For Android App - Stack Overflow PDFShoaib QuraishiNo ratings yet

- Datasheet External Antenna 2000 - Alpha-Con-V7Document4 pagesDatasheet External Antenna 2000 - Alpha-Con-V7Bravemon23No ratings yet

- 1.1 Notes - Functional Elements of An InstrumentDocument4 pages1.1 Notes - Functional Elements of An InstrumentB. MeenakshiNo ratings yet

- Starting and Stopping Procdure of GeneratorDocument3 pagesStarting and Stopping Procdure of GeneratorSumit SinhaNo ratings yet

- JBT Exp-310 Brochure 0313cDocument2 pagesJBT Exp-310 Brochure 0313cCiprian OprescuNo ratings yet

- 5 Day Course Outline of Process Safety Related TopicsDocument3 pages5 Day Course Outline of Process Safety Related Topicskanakarao1No ratings yet

- gddr6 Sgram 8gb BriefDocument22 pagesgddr6 Sgram 8gb BriefВладимир ИльиновNo ratings yet

- House Guide TemplateDocument8 pagesHouse Guide TemplatewandolyNo ratings yet

- Medium Access Control Sublayer (Chapter 4) - CSHub PDFDocument15 pagesMedium Access Control Sublayer (Chapter 4) - CSHub PDFSpeed PianoNo ratings yet

- FTTX Technology ReportDocument48 pagesFTTX Technology ReportanadiguptaNo ratings yet

- A5 EXPERIMENT LVDT and RVDTDocument14 pagesA5 EXPERIMENT LVDT and RVDTDuminduJayakodyNo ratings yet

- 6cinox SumotoDocument8 pages6cinox Sumotoboubakeur atouiNo ratings yet

- Apachehvac: Training Notes - Part 1Document31 pagesApachehvac: Training Notes - Part 1joe1256100% (1)

- Security Specialization Sample Exam - ENDocument8 pagesSecurity Specialization Sample Exam - ENbloodscreamNo ratings yet

- Alternator Data Sheet: General CharacteristicsDocument2 pagesAlternator Data Sheet: General CharacteristicsJuly E. Maldonado M.No ratings yet

- Paragon Hard Disk Manager Pro 2009 Portable Rar PDFDocument4 pagesParagon Hard Disk Manager Pro 2009 Portable Rar PDFDanNo ratings yet

- Building A Computer: Electronic Numerical Integrator and Computer (ENIAC)Document31 pagesBuilding A Computer: Electronic Numerical Integrator and Computer (ENIAC)Anonymous HsoXPyNo ratings yet

- PRODUCTS Final 1Document133 pagesPRODUCTS Final 1Soigne ConsultantsNo ratings yet