Professional Documents

Culture Documents

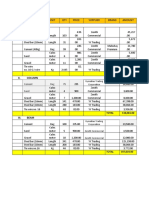

PRV

Uploaded by

bill_lee_242Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PRV

Uploaded by

bill_lee_242Copyright:

Available Formats

high pressure: - for firefighting - to overcome loss of pressure as the elevation increases for high rise building - to maintain

water supply in water towers and supply tanks - at the lower stories supplies from the upper/ roof water tank - can exceed 200 psi - could rupture pipes, damage fixtures, leakage, noisy and injure the people - waste water increases directly proporsional to pressure prv: - prv required at pressure of > 60 - 80 psi or > 30.5 psi (depends) - preferably pressure < 30.5 psi - prv can reduces the bills of water, sewerage & water heater energy for about 30% - desired pressure achieved by adjust/ turning the screw - even if the supply water pressure fluctuates, the pressure reducing valve ensures a constant flow of water at a functional pressure, as long as the supply pressure does not drop below the valve's pre-set pressure designing prv: - properly sized valve prevents noisy operation or premature valve failure - over sizing water pressure reducing valves can lead to problems such as wire draw under low flow conditions - in general, the minimum flow through a water pressure reducing valve should be 10% to 15% of the maximum flow rate desired in the system - water prv should be selected based on the flow and pressure ranges listed in the literature, and not by the diameter of pipeline - select a regulator whose operating pressures fall within the middle of its rated range - 2 stage reduction is recommended when initial pressures are 200psi or greater, or when the desired pressure reduction ratio is greater than 4:1, e.g., from 200psi to 50psi, or where the inflow pressure fluctuates greatly - the parallel installation makes use of two or more smaller size water pressure reducing valves serving a large size supply pipe main; this approach should be used wherever there is a wide variation of reduced pressure requirements such as an apartment building where demand could be 0.5 gpm at 1am and 100 gpm at 6am and where you must maintain a continuous water supply; in addition, the parallel configuration improves valve performance for wide variable demands and permits servicing of an individual valve without shutting down water flow to the building completely, thus avoiding costly shutdowns;

- please refer to the valve model for specific availability of end connection options; - performance curves on WPRV specification sheets for each type and size of valve giving the capacities of each with reduced pressure fall-offs up to 25psi; by the use of these charts, the most suitable and economical valve can be selected to satisfy the job requirements addition : - it is recommended to install by-pass isolation valve for maintenance purpose without shutting down the systems - it is advisable to install a strainer before the control valve to prevent any solid particle from entering the valve body - to monitor valve inlet and outlet pressure, intall pressure gauge - install inlet and outlet isolation valves - avoid installing valves size 150mm and larger vertically - if installation subject to very low or potentially static condition, a prv (1/2'' minimum) to be intalled downstream for additional system protection - if pressure drop fall inside cavitations zone (refer to Cavitation Chart) 2 prvs need to to be installed in series may required to reduce the pressure to two stages reduction - if flow requirements fall outside the capacity of the single prv 2 prvs need to be installed parallel may be required.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pre Concreting ChecklistDocument1 pagePre Concreting Checklistbill_lee_24271% (7)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Repair Grouting ChecklistDocument1 pageRepair Grouting Checklistbill_lee_242100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Astm A-615Document8 pagesAstm A-615bill_lee_24267% (6)

- Pre Piling ChecklistDocument1 pagePre Piling Checklistbill_lee_242No ratings yet

- WIDAC Abbreviated Foundation Coffman GolderDocument60 pagesWIDAC Abbreviated Foundation Coffman GolderIng Ricardo HernándezNo ratings yet

- Pile Testing For Driven or Jack-In Pile PDFDocument25 pagesPile Testing For Driven or Jack-In Pile PDFBMZNo ratings yet

- Aashto t119 - Slump TestDocument4 pagesAashto t119 - Slump Testbill_lee_242No ratings yet

- HM-27 - AASHTO Material BooksDocument31 pagesHM-27 - AASHTO Material Booksbill_lee_242No ratings yet

- Guideline On Use of Ready Mix ConcreteDocument2 pagesGuideline On Use of Ready Mix Concretebill_lee_242No ratings yet

- Effect of Chemical Elements in Steel PDFDocument2 pagesEffect of Chemical Elements in Steel PDFbill_lee_242No ratings yet

- (Steady Non Uniform Flow - Gradually Varied Flow) : Graphical Integration Method - Back Flow CalculationDocument4 pages(Steady Non Uniform Flow - Gradually Varied Flow) : Graphical Integration Method - Back Flow Calculationbill_lee_242No ratings yet

- Daily ReportDocument2 pagesDaily Reportbill_lee_242No ratings yet

- Water Balance and Water BudgetDocument17 pagesWater Balance and Water BudgetCt Kamariah Md SaatNo ratings yet

- Is 5620Document31 pagesIs 5620Lokesh Krishnappa0% (1)

- Tempered Glass: MACARAMPAT, Johainah S. Bsa 4Document17 pagesTempered Glass: MACARAMPAT, Johainah S. Bsa 4Kristine JadeNo ratings yet

- Design of Steel Buildings For Earthquake and StabilityDocument6 pagesDesign of Steel Buildings For Earthquake and StabilityFredy Alonzo Moreno SanchezNo ratings yet

- Everyday DetailsDocument7 pagesEveryday DetailsJake WilliamsNo ratings yet

- Groundwater Recharge EstimationDocument207 pagesGroundwater Recharge EstimationValen RamiirezNo ratings yet

- Prod Choke BasicsDocument39 pagesProd Choke BasicsJuan Francisco SantiagoNo ratings yet

- Composite Materials: Asst - Prof. Dr. Ayşe KALEMTAŞDocument32 pagesComposite Materials: Asst - Prof. Dr. Ayşe KALEMTAŞŞebnem Gül İlarslanNo ratings yet

- ECCECCS PublicationsDocument2 pagesECCECCS PublicationsDaniel JamesNo ratings yet

- ITEMDocument7 pagesITEMGintokiNo ratings yet

- HMA Mixture Design: SuperpaveDocument30 pagesHMA Mixture Design: Superpavevinay rodeNo ratings yet

- Bend SIF CalculationDocument3 pagesBend SIF CalculationMallela Sampath KumarNo ratings yet

- Mix Design For Concrete Grade M 25Document7 pagesMix Design For Concrete Grade M 25fevahe756No ratings yet

- Aqc Steel Structure Paint Area ASAD WORKINGDocument3 pagesAqc Steel Structure Paint Area ASAD WORKINGMUHAMMAD WARIS SQNo ratings yet

- MS0401C0291-V00.C - (Bearing-Plate-&-Steel-Plate-for-Moving-Walk-&-Escalator) PDFDocument18 pagesMS0401C0291-V00.C - (Bearing-Plate-&-Steel-Plate-for-Moving-Walk-&-Escalator) PDFnoufalNo ratings yet

- Characterization of Mechanical Properties and Fracture Mode of PLADocument12 pagesCharacterization of Mechanical Properties and Fracture Mode of PLAatef.selmi01No ratings yet

- Individual Research ProjectDocument77 pagesIndividual Research Projectakila perera100% (2)

- M1A120014 - Pria Abdillah Hendra - Uts BingDocument9 pagesM1A120014 - Pria Abdillah Hendra - Uts BingPriaNo ratings yet

- 02 Vol II - PART 1 Technical Specs Road WorksDocument185 pages02 Vol II - PART 1 Technical Specs Road WorksMAULIK RAVALNo ratings yet

- Test 0 Paper1Document6 pagesTest 0 Paper1ICE Group of Education BhopalNo ratings yet

- Types of DrawingsDocument25 pagesTypes of DrawingsRajesh Prabtani100% (1)

- ACI CCS-1 (1994) Slabs On Grade-Second EditionDocument128 pagesACI CCS-1 (1994) Slabs On Grade-Second Editionmd shahid ahmadNo ratings yet

- Heat Load Calculation (Rev-A)Document86 pagesHeat Load Calculation (Rev-A)Project enghvacNo ratings yet

- 5-Retention PondsDocument7 pages5-Retention PondsBondoc, Miles Jerome Z.No ratings yet

- Study of Strength of RC Shear Wall at Different Location On Multi-Storied Residential BuildingDocument8 pagesStudy of Strength of RC Shear Wall at Different Location On Multi-Storied Residential BuildingSyed Ehtesham aliNo ratings yet

- Rev A Ecz Boq 7Document10 pagesRev A Ecz Boq 7Defrim KabashiNo ratings yet

- Flow Measurement Design Criteria - Oct 2015Document18 pagesFlow Measurement Design Criteria - Oct 2015rolwinNo ratings yet

- Beton Katkı NanoCast 630 ENG v1Document3 pagesBeton Katkı NanoCast 630 ENG v1Berk BaştürkmenNo ratings yet

- Vernacular DesignDocument7 pagesVernacular DesignMahima AgarwalNo ratings yet