Professional Documents

Culture Documents

Ultrasonic Listener - Microcontroller Based Frequency Shifter

Uploaded by

Caddish DiyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Listener - Microcontroller Based Frequency Shifter

Uploaded by

Caddish DiyCopyright:

Available Formats

i

Ultrasonic Listener

Microcontroller Based Frequency Shifter

A Senior Project

presented to

the Faculty of the Electrical Engineering

California Polytechnic State University, San Luis Obispo

In Partial Fulfillment

of the Requirements for the Degree

Bachelor of Science

by

Troy Fredriks

7 June 2010

2010 Troy Fredriks

ii

Contents

INTRODUCTION .............................................................................................................................. 1

BACKGROUND ............................................................................................................................... 2

THEORY......................................................................................................................................... 2

UNDERSTANDING THE ANALOG CIRCUIT APPROACH .......................................................................... 3

WHY CHOOSE A MICROCONTROLLER? ............................................................................................. 4

REQUIREMENTS ............................................................................................................................ 8

EQUIPMENT .................................................................................................................................... 9

DESIGN TOOLS .............................................................................................................................. 9

MPLAB IDE V8.36 ................................................................................................................... 9

MPLAB ICD 3 Debugger ......................................................................................................... 9

Microchip Explorer 16 Development Board ........................................................................... 10

LAB EQUIPMENT ........................................................................................................................... 10

HARDWARE .................................................................................................................................. 11

BLOCK DIAGRAM .......................................................................................................................... 11

ULTRASONIC TRANSDUCER .......................................................................................................... 11

A/D CONVERTER .......................................................................................................................... 13

MCU MICROCHIP DSPICFJ256GP710A ................................................................................... 14

LCD DISPLAY AND BUTTONS ......................................................................................................... 14

DIGITAL TO ANALOG CONVERTER................................................................................................... 15

OUTPUT CIRCUITRY ...................................................................................................................... 16

PROGRAM CODE ......................................................................................................................... 18

MAIN LOOP .................................................................................................................................. 18

INTERRUPT SERVICE ROUTINE ...................................................................................................... 21

ANALYSIS ..................................................................................................................................... 24

DATA ........................................................................................................................................... 24

COST CONSIDERATIONS............................................................................................................ 33

SUSTAINABILITY/SOCIETAL IMPACTS ..................................................................................... 34

BIBLIOGRAPHY ............................................................................................................................ 35

APPENDIX ..................................................................................................................................... 36

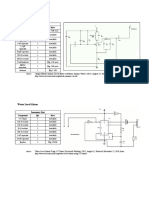

SCHEMATIC ................................................................................................................................. 36

iii

Tables and Figures

FIGURE 1: THEORETICAL OUTPUT OF MULTIPLIED WAVES WITH ZERO OFFSET ......................................... 6

FIGURE 2: THEORETICAL OUTPUT OF MULTIPLIED WAVES WITH POSITIVE OFFSET ................................... 7

FIGURE 3: HIGH LEVEL HARDWARE BLOCK DIAGRAM ......................................................................... 11

FIGURE 4: ULTRASONIC TRANSDUCER CIRCUITRY .............................................................................. 12

FIGURE 5: A/D CONVERTER CIRCUITRY .............................................................................................. 13

FIGURE 6: DAC-312 WIRING SCHEMATIC (SET UP FOR 2'S COMPLIMENT OUTPUT) ............................... 15

FIGURE 7: FINAL OUTPUT CIRCUITRY CONSISTS OF COUPLING CAPACITOR AND VOLTAGE DIVIDER ......... 17

TABLE 1: MAIN LOOP STATE DATA ...................................................................................................... 19

FIGURE 8: PROGRAM FLOW OF MAIN LOOP ......................................................................................... 20

FIGURE 9: PROGRAM FLOW OF ISR ................................................................................................... 22

FIGURE 10: LCD INITIALIZE TEST ....................................................................................................... 25

FIGURE 11: LCD DISPLAY WITH STATE 0 LOADED ............................................................................... 26

FIGURE 12: MCU GENERATED SINUSOID @ 10 KHZ ........................................................................... 27

FIGURE 13: MCU GENERATED SINUSOID @ 14.93 KHZ ...................................................................... 28

FIGURE 14: MCU GENERATED SINUSOID @ 20 KHZ ........................................................................... 28

FIGURE 15: MCU FAILS TO PROPERLY PRODUCE 25 KHZ.................................................................... 29

FIGURE 16: 10 KHZ GENERATED BY MCU MIXED WITH 14 KHZ PROVIDED BY FUNCTION GENERATOR .... 30

FIGURE 17: 20 KHZ GENERATED BY MCU MIXED WITH 25 KHZ PROVIDED BY FUNCTION GENERATOR .... 31

FIGURE 18: DOG WHISTLE MIXED WITH 10 KHZ RESULTS IN 1.2 KHZ PLUS 22 KHZ ............................... 32

1

Introduction

Ever wonder what kind of sounds are going on outside of the human audible

range? Perhaps the warning signs of a leaky high pressure pipe or some

interesting nature sounds are just outside what the human ear is tuned to pick

up. This project addresses this very issue. By shifting higher frequency sounds

down to the range where human ears can hear, the user is able to get an idea of

what kind of sounds are being made that humans cannot detect.

The human ear is designed to pick up sounds in frequencies ranging from 20 Hz

to 20 kHz. However, many interesting sounds are being

frequencies that are much higher; bats, dolphins, and orcas typically

communicate in the 20 kHz

higher frequency sounds, and thus, needs to be shifted down to the human

audible range.

Theory

The basic idea of how to

frequency. Consider the basic trigonometric identity [1]:

Therefore, down shifting an ultrasonic frequency of 25 kHz t

would require multiplying the 25 kHz signal with a 20 kHz signal

25 kHz 20 kHz = 5 kHz

In addition to the downshifted signal of 5 kHz, the multiply will also generate an

up shifted signal at:

Background

The human ear is designed to pick up sounds in frequencies ranging from 20 Hz

to 20 kHz. However, many interesting sounds are being made all the time with

frequencies that are much higher; bats, dolphins, and orcas typically

communicate in the 20 kHz 100 kHz range. It is desirable to listen in on these

higher frequency sounds, and thus, needs to be shifted down to the human

The basic idea of how to down shift a frequency is to multiply it with another

frequency. Consider the basic trigonometric identity [1]:

Therefore, down shifting an ultrasonic frequency of 25 kHz to an audible 5 kHz

would require multiplying the 25 kHz signal with a 20 kHz signal:

20 kHz = 5 kHz

In addition to the downshifted signal of 5 kHz, the multiply will also generate an

2

The human ear is designed to pick up sounds in frequencies ranging from 20 Hz

made all the time with

frequencies that are much higher; bats, dolphins, and orcas typically

100 kHz range. It is desirable to listen in on these

higher frequency sounds, and thus, needs to be shifted down to the human

a frequency is to multiply it with another

1.1

o an audible 5 kHz

In addition to the downshifted signal of 5 kHz, the multiply will also generate an

3

25 kHz + 20 kHz = 45 kHz

This signal is undesired and should be filtered out for high fidelity applications or

simply ignored in low fidelity applications (most consumer audio electronics

would not be able to actually physically produce this frequency anyhow).

Understanding the analog circuit approach

The basic approach for shifting the frequencies into the audible region involves

the use of a double balanced mixer. Recall that the basic function of the double

balanced mixer is to output a sum and difference of the two input frequencies (via

multiplication):

O

= (

1

+

2

) + (

1

-

2

) 1.2

We can use this property to our advantage by focusing on the difference portion

of the mixer (the sum portion can simply be filtered out). For example, to shift the

frequencies over the range of 20 kHz to 40 kHz down to the audible range, a

subtraction of 20 kHz is needed. Substituting

1

, in equation 1.2 above, with the

range of 20 kHz to 40 kHz and

2

with 20 kHz, the following output is observed:

O

= (40-60 kHz) + (0 -20 kHz)

4

Note that now we have a range from 0 20 kHz (desired) and another range

from 40 kHz 60 kHz (undesired). To eliminate the unwanted range from 40

kHz 60 kHz, a lowpass filter with a 3 dB roll off at 20 kHz is added after the

output stage. Finally we arrive at a solution that will shift frequencies from 20-40

kHz range down to the audible range. One major limitation with this approach is

that in order to change the range, the 20 kHz oscillator will need to be changed

accordingly (40 kHz to shift the range 40 kHz -60 kHz , etc.). This limitation can

be easily overcome, along with other added benefits, by implementing a digital

design using a microcontroller.

Why choose a Microcontroller?

The microcontroller approach resembles the basic analog approach very closely.

In the microcontroller design, the double balanced mixer will be implemented in

the digital realm by the processor as a simple multiply. In addition, the oscillator

frequency can be generated by the processor, and thus, can easily be changed

for quick range changes.

Moving from the analog realm (where the signal is generated) to the digital realm

(where the signal processing takes place) requires the use of an analog to digital

converter (ADC). Once the signal has been processed, the signal passes through

a digital to analog converter (DAC) to be amplified through a speaker.

5

Additional benefits of using a microcontroller include: use of an LCD display to

monitor ranges and create an easier user interface and limits use of outboard

hardware because many filters can be implemented in the digital world.

Because the microcontroller operates at a voltage range of 0 to +3.3 volts, an

additional consideration needs to be made to ensure accuracy of the multiply: will

offsetting the signals by a positive DC bias negatively affect multiply?

To help visualize this dilemma, plots have been created demonstrating both

cases.

Figure 1, below, shows a plot with zero DC bias; series 1 is multiplied by series 2

and the output is series 3. This is idealized case and contains no parasitic leak

thru of the original signals.

6

Figure 1: Theoretical output of multiplied waves with zero offset

Figure 2 shows the case with a positive DC bias; it concludes a non-ideal case

where extreme peaking occurs in certain locations as well as leak-thru of the

original signals.

-8

-6

-4

-2

0

2

4

6

8

1 5 9 13 17 21 25 29 33 37 41 45 49 53 57 61 65 69 73 77 81

Series1

Series2

Series3

7

This non-ideality can be compensated by using signed numbers in the program.

In this way we can treat the midpoint of the microcontrollers operating voltage

(1.65V) as a 0 to make the multiply function correctly.

Figure 2: Theoretical output of multiplied waves with positive offset

0

5

10

15

20

25

30

35

1 5 9 13 17 21 25 29 33 37 41 45 49 53 57 61 65 69 73 77 81

Series1

Series2

Series3

8

Requirements

Functionalities:

Shift frequencies from 20 kHz 60 kHz down to 200 10200 kHz

Filter unwanted frequencies

Establish appropriate line levels

Data Requirements:

Microcontroller based signal processing

High-speed A/D and D/A conversion

User Interface:

LCD display

Input for frequency selection

1/4 output jack

System Requirements:

Ultrasonic Transducer (at least 20 kHz 60 kHz bandwidth)

Microcontroller with A/D and D/A conversion

Audio Amplifier

Other Requirements:

Ultrasonic frequency generator (for testing)

9

Equipment

This section details the necessary equipment needed to design and test the

project. Microchips MPLAB IDE V8.36, MPLAB ICD 3 Debugger, and the

Explorer 16 development board all integrate to allow full functionality of the MCU.

Design Tools

MPLAB IDE V8.36

MPLAB IDE V8.36 is Microchips development environment for any of its many

different MCUs. MPLAB IDE allows the user to create programs in C, assembly

language, or other with the appropriate compiling software. MPLAB IDE

integrates with, and controls the MPLAB ICD 3 to allow for programming and

debugging of programs. MPLAB IDE also has an emulator that enables the user

to test their programs on a simulated version of any MCU Microchip offers.

MPLAB ICD 3 Debugger

MPLAB ICD 3 is Microchips newest edition of the ICD series for programming

and debugging. With this tool, I was able to easily debug the errors in my

program code. This tool allows insertion of break points in the code; these break

points halt the program where the break point is inserted, allowing inspection of

10

all registers for verification of correct values. The debugging tool also allows for

instructions to be processed step by step, further allowing me to investigate

errors in the code.

Microchip Explorer 16 Development Board

The Explorer 16 is a demo board designed to provide easily integrated

peripherals to many of Microchips 16 bit and 32 bit processors, and allows for

quick exchange of MCUs with the intelligent Plug-in Module (PIM) design. The

LCD display, buttons, LEDs and power connections are of particular interest to

the design process of this project. Using the Explorer 16 demo board reduced

development time considerably and allowed me to focus on the program and

other peripherals.

Lab Equipment

In addition to the software development tools, two pieces of lab equipment are

necessary in the development process:

Oscilloscope

Function Generator

11

Hardware

Block Diagram

The block diagram helps to get the overall big picture of what is going on at the

hardware level. Figure 6 below shows the main blocks of the project, with arrows

indicating the direction of signal flow.

Figure 3: High Level Hardware Block Diagram

Ultrasonic Transducer

The first piece of hardware in the overall chain is the ultrasonic transducer. The

chosen device is Knowles Acoustics SPM0404UD5 : Mini SiSonic Ultrasonic

Acoustic Sensor. This device was chosen for its wide and relatively flat pass

band response over 10 kHz to 65 kHz.

12

Figure 4: Ultrasonic Transducer Circuitry

Figure 7 shows a detailed schematic of the ultrasonic transducer and the

appropriate gain stage that follows. The .1uF capacitor couples the transducer

output to the gain input; acting as a DC blocker isolating the transducer output

from the gain stage so only an unbiased AC signal feeds thru.

Gain is accomplished via simple inverting operational amplifier configuration with

a variable feedback resistor (potentiometer) for appropriate gain selection.

Maximum gain is calculated (ignoring phase inversion):

A =

2Sk

7S

= SSS.S

I

I

In dB:

A = 2u log SSS.S = Su.4S JB

Ultrasonic Transducer

25k

+9V

LM348

1

3

2

4

1

1

OUT

+

-

V

+

V

-

75

.1uF Output to ADC Circuitry

-9V

3.3 Vdc

13

Thus, the gain can vary from -dB to +50dB, providing sufficient flexibility for the

input to the AD converter for maximum resolution.

A/D converter

The 10-bit analog to digital converter is built on-board the microcontroller making

integration much easier. A DC bias network is created from two 100k ohm

resistors in series from +3.3V to ground. This voltage divider ensures the zero

point into the A/D is right in the middle of its maximum voltage swing. Two

voltage protection diodes are added, one each, in parallel with the biasing

resistors to protect the A/D from over, or under, voltage inputs. A coupling

capacitor links the output of the ultrasonic transducer stage to the DC bias

network to block DC and only allow AC to pass. Figure 8 shows the schematic.

Figure 5: A/D converter circuitry

A/D

100k

D1N4007

D1N4007

+3.3V

From output of Ultrasonic

Transducer stage

.1uF

100k

Digital Data

14

MCU Microchip dsPICFJ256GP710A

The processor chosen for this project was Microchips dsPIC33FJ256GP710A.

This is one of Microchips fastest and feature rich processors and includes many

special features with digital signal processing in mind. Special considerations

pertaining to this project include:

Up to 40 Million Instructions per second (MIPS)

On board A/D with sampling rates as high as 1.1 MHz

DSP Engine provides single cycle multiply and barrel shifts

Detailed information on the programming of this block will be discussed in the

Program Code section of this document.

LCD display and buttons

The LCD display and the buttons are integrated on the Explorer 16 development

board for easy integration into the project. The LCD is a two line 16 character

display which guides the user thru the program flow. The buttons allow the user

to navigate thru the different program states. Further information on the use of

the LCD and the buttons will be discussed in the Program Code section of this

document.

15

Digital to analog converter

The 12-bit digital to analog converter is external to the processor and converts

the processed signal back to an analog form that can be amplified and played

through a speaker. The DAC chosen is Analog Devices DAC312 for its parallel

input, to save clock cycles, and for its extremely low settling time (250ns). The

DAC is a 20 pin DIP package and has been configured to operate on 2s

compliment logic due to the nature of the signed logic that was implemented.

Figure 6: DAC-312 wiring Schematic (set up for 2's Compliment output)

Figure 9 shows the complete schematic with the required op amp current to

voltage converter (recommended setup connections and values from datasheet).

The DAC reads a 12 bit 2s compliment number and outputs a voltage from -9v to

+9v. This signal is then passed to the final circuit for preparation as output at

standard consumer audio levels.

10k

DAC-312

10k

Vref(-)

Vref(+)

Digital Data In

LM348

1

3

2

4

1

1

OUT

+

-

V

+

V

-

Io

_

Io

-9V

5k

+9V

5k

Data from MCU

(12 bits)

5k

+9V

Analog out (-9v to +9v)

16

Output circuitry

Once the signal has been produced in the analog realm via the DAC, the signal

finally needs to be processed to properly integrate with consumer electronic

amplifiers.

First the signal needs to pass thru a coupling capacitor to remove any possible

DC offset errors produced by the DAC.

Consumer electronics are designed for an input of -10 dBV or .316V

RMS

.

Considering the maximum peak voltage from the DAC is 9v the max RMS

voltage would be:

9I

2

= 6.S6 IRHS

Dividing the 6.36 V

RMS

by the target .316 V

RMS

results in the resistor ratio of the

voltage divider:

6.S6

. S16

= 2u.12 (unitlcss)

Thus, the appropriate resistor values for the voltage divider network are

approximately 20:1. The chosen resistors of 47k and 2k were chosen based on

availability and have a ratio of 23.5:1.

17

Lastly the output has been terminated with a 1/4 output jack for easy interfacing

with many consumer grade electronic amplifiers.

Figure 7: Final output circuitry consists of coupling capacitor and voltage divider

Signal from DAC

.1uF

Fully processed output to 1/4" jack

47k

2k

18

Program Code

The program code is broken up into two main parts: the main infinite loop and the

interrupt service routine (ISR). Coding is done in C programming language and

has been optimized for fewest clock cycles.

Main Loop

The main loop can be characterized by having two functions: 1) setting up and

modifying the all the variables that control which frequency band is to be shifted

and 2) to act as a system idle service when no other instructions are being

executed.

The main loop can change between ten different states, where each state

handles the information necessary for updating the LCD display with the correct

frequency band and for setting up the frequency of the self generated sine wave

(this is done by setting up the timer that controls the ISR). The table below shows

each state and the corresponding LCD display and generated sine frequency

data.

19

State Number LCD Display Sine Frequency

0 10 kHz 20 kHz 10 kHz

1 15 kHz 25 kHz 15 kHz

2 20 kHz 30 kHz 20 kHz

3 25 kHz 35 kHz 25 kHz

4 30 kHz 40 kHz 30 kHz

5 35 kHz 45 kHz 35 kHz

6 40 kHz 50 kHz 40 kHz

7 45 kHz 55 kHz 45 kHz

8 50 kHz 60 kHz 50 kHz

9 55 kHz 65 kHz 55 kHz

Table 1: Main loop state data

With the use of the buttons, one and two, the program can change states and

update the correct information. Button one lowers the frequency band with each

press unless it is already at the minimum, in which case, it does nothing more.

Button two does the opposite, increasing the state number one by one until it

reaches the maximum. The program is initialized in state 0.

20

Figure 8: Program flow of main loop

Figure 11, above, shows the program flow of the main loop. If no buttons are

pressed, the program simply loops around until either: 1) a button gets pressed

or 2) an interrupt is generated. The code for the main loop is shown below, each

line with a descriptive comment following the C code. The variable CtrFreq acts

as the state number.

21

Interrupt Service Routine

The interrupt service routine is a simple routine that performs the multiply and

outputs the data to the port pins of the MCU. When the ISR first gets called, it

fetches a data point from a table of values that correspond to the sine function.

For the sine wave generation, a table consists of 20 points, equally spaced,

throughout one full period of the wave. The ISR timer is configured in the main

loop (with state changes) to generate an interrupt corresponding to the desired

frequency of the sine wave. To generate the 10 kHz sine wave, the ISR timer

needs to be configured to generate an interrupt, then, at 20 times (because there

are 20 sample points per period) 10 kHz or 200 kHz. During each ISR the data

is also read from the ADC, thus, the sampling rate for the ADC is also 200 kHz at

the lowest 10 kHz 20 kHz state and increases as the state increases.

22

Once the ISR has loaded the data from the sine table and the ADC, it then

follows by performing the multiply and outputting the data to the correct ports.

Figure 12 below shows the program flow of the ISR.

Figure 9: Program flow of ISR

23

The code for the ISR is slightly more complicated mainly due to the fact that it

must compensate for moving the data to fit into the correct data output port

registers. The code for the ISR is shown below, each line with a descriptive

comment following the C code.

24

Analysis

This section uses analysis tools such as the oscilloscope and function generator

to confirm and demonstrate correct operation. Most of the work involved in

confirming operation is done with the aid of the ICD 3 debugging unit which

allows the programmer to perform step by step instructions while simultaneously

confirming the correct values for all registers of interest.

Data

The first thing that can be evaluated is that the LCD and the buttons are

functioning correctly. Upon start up, during the initialization stage, the LCD

correctly displays my name, Troy Fredriks, along with Cal Poly as seen below in

figure 13 below.

25

Figure 10: LCD initialize test

The LCD also displays the frequency range of interest accordingly in the display.

The buttons allow proper state changes from the lowest state to the highest state

and back again.

26

Figure 11: LCD display with state 0 loaded

With the LCD and buttons working properly, testing of the self generated sine

waves can now be performed. In state 0, the generated sine should be

approximately 10 kHz. By tying the ADC to a fixed extreme value, the sine will be

multiplied by a constant and will show up at the output as a sine wave of 10 kHz.

27

Figures 15, 16 and 17 show properly constructed sine waves at 10 kHz, 15 kHz,

and 20 kHz, respectively. These plots correspond to increasing state values of 0,

1, and 2.

Figure 12: MCU generated sinusoid @ 10 kHz

28

Figure 13: MCU generated sinusoid @ 14.93 kHz

Figure 14: MCU generated sinusoid @ 20 kHz

29

Figure 18 below shows how the MCU fails to properly produce the next state

frequency of 25 kHz. This is due to the fact that the processor has run out of

clock cycles to perform all of the program code fast enough.

Figure 15: MCU fails to properly produce 25 kHz

With confirmation of the DAC and sine wave generation from the previous testing

step, analysis of the multiply function is now ready to be performed. Testing is

first performed by bypassing the ultrasonic transducer and inputting a pure sine

wave from the function generator. Figure 19 below shows the output results of

mixing a 14 kHz test signal with the MCUs self generated 10 kHz signal. The

output shows a downshifted signal of 4 kHz and an upshifted signal of 24 kHz.

The multiply has succeeded.

30

Figure 16: 10 kHz generated by MCU mixed with 14 kHz provided by function generator

Next we mix a 25 kHz signal from the function generator with the 20 kHz signal

generated by the MCU. The results can be seen in figure 20 below; 5 kHz signal

and 45 kHz signals are produced.

31

Figure 17: 20 kHz generated by MCU mixed with 25 kHz provided by function generator

The final test is to hook up the transducer and use a real acoustic source as

input. A dog whistle was chosen as an adequate test source due to its high

frequency acoustic properties. Figure 21 below shows the results, indicating the

dog whistles fundamental frequency is on the order of approximately 11.2 kHz.

32

Figure 18: Dog whistle mixed with 10 kHz results in 1.2 kHz plus 22 kHz

33

Cost Considerations

Cost is a very important consideration when creating a new design. Costs need

to be minimized to maximize profits in a business environment. Very rarely is

cost of little concern. What follows is a cost analysis of the entire design process.

The total hours spent developing the project, from start to finish, is on the order

of approximately 120 hours. Considering an estimated typical salary of $50,000

per year, labor costs are approximately $3,125.00 assuming a 40 hour work

week.

The design tools are the next largest contributor. The ICD3 debugger, Explorer

16 development board, and the dsPIC33 MCU are sold bundled together for

$300.00

The last consideration is the other hardware components including: the ultrasonic

transducer ($17) the DAC ($9) and various resistors and capacitors ($4).

This results in a total design cost of approximately $3500.

34

Sustainability/Societal Impacts

The importance of considering sustainability and societal impacts has never been

greater in our society. Sustainability considerations are ones that promote

endurance of our species, habitat and interactions of our surroundings. Using

microcontrollers to program specific functions as opposed to implementing the

same task in analog hardware components provides significant benefits to

sustainability. Not only is it possible to upgrade the device with a simple software

change, as opposed to swapping out physical hardware; if the device becomes

obsolete, it can be totally reprogrammed with an entirely different function in

mind. This greatly serves to limit the undesirable impacts concerning

sustainability.

35

Bibliography

[1]

http://en.wikipedia.org/wiki/Frequency_mixer

[2]

http://www.microchip.com/stellent/idcplg?IdcService=SS_GET_PAGE&nodeId=1

406&dDocName=en019469&part=SW007002

[3]

http://www.microchip.com/stellent/idcplg?IdcService=SS_GET_PAGE&nodeId=1

406&dDocName=en537580

[4]

http://www.microchip.com/stellent/idcplg?IdcService=SS_GET_PAGE&nodeId=2

519¶m=en025319&page=wwwdevdsPICBoardKits

3

6

A

p

p

e

n

d

i

x

S

c

h

e

m

a

t

i

c

You might also like

- Ultrasonic Listener Microcontroller Based Frequency Shifter PDF FreeDocument39 pagesUltrasonic Listener Microcontroller Based Frequency Shifter PDF FreeMohamed NourNo ratings yet

- An Introduction To FluorescenceDocument36 pagesAn Introduction To FluorescenceFrank LaporteNo ratings yet

- Distance Measurement Using Ultrasonic SensorDocument68 pagesDistance Measurement Using Ultrasonic Sensorsaran52_ece0% (1)

- Ultrasound Review 1Document12 pagesUltrasound Review 1aliosarusNo ratings yet

- Sonar 2008Document60 pagesSonar 2008sreesree123100% (1)

- Echo Sounders: Asst. Prof. Dr. Ender AsyalıDocument33 pagesEcho Sounders: Asst. Prof. Dr. Ender AsyalıGf MilesNo ratings yet

- FURUNO Transducer Handbook HR09 WebDocument20 pagesFURUNO Transducer Handbook HR09 WebJan JbaNo ratings yet

- Underwater Acoustics: A Brief IntroductionDocument15 pagesUnderwater Acoustics: A Brief IntroductionDr. Ir. R. Didin Kusdian, MT.No ratings yet

- MOSQUITO REPELLENT CIRCUITDocument7 pagesMOSQUITO REPELLENT CIRCUITKatamba Rogers67% (3)

- Upgraded Ultrasonic Animal Deterrent DeviceDocument6 pagesUpgraded Ultrasonic Animal Deterrent DevicePatrick LambotteNo ratings yet

- Underwater Wireless 07012013125531 Underwater WirelessDocument15 pagesUnderwater Wireless 07012013125531 Underwater Wirelessmahendrarm2112No ratings yet

- GBPPR 'Zine - Issue #63Document78 pagesGBPPR 'Zine - Issue #63GBPPRNo ratings yet

- High frequency fiber optic hydrophoneDocument4 pagesHigh frequency fiber optic hydrophoneMale RamìrezNo ratings yet

- Multiple-Feedback Band Pass FilterDocument13 pagesMultiple-Feedback Band Pass FilterJunaid tariq100% (2)

- Wave QuestionsDocument37 pagesWave QuestionsFatema KhatunNo ratings yet

- C02 Wireless Transmission 1Document30 pagesC02 Wireless Transmission 1Akil KumarNo ratings yet

- Statistical Characterization of Multipath Rayleigh Faded ChannelsDocument29 pagesStatistical Characterization of Multipath Rayleigh Faded ChannelsAliAlissNo ratings yet

- HD370 Echosounder ManualDocument45 pagesHD370 Echosounder ManualAledj MartinezNo ratings yet

- Ultrasonic Transducer FundamentalsDocument12 pagesUltrasonic Transducer FundamentalsClaudia Ioana100% (2)

- Ultrasonic Distance Measurement With The MSP430Document18 pagesUltrasonic Distance Measurement With The MSP430lgrome73No ratings yet

- Oscilador Cristal PDFDocument9 pagesOscilador Cristal PDFMiguel Angel Lazarte ChavezNo ratings yet

- dr605 SMDocument54 pagesdr605 SMJaco Le RouxNo ratings yet

- Experiment No.1 Attenuation in Transmission Line Objectives: EquipmentsDocument3 pagesExperiment No.1 Attenuation in Transmission Line Objectives: Equipmentsمروان الحاسيNo ratings yet

- Unit - II: Acoustics and UltrasonicDocument5 pagesUnit - II: Acoustics and Ultrasonicrafey314No ratings yet

- Microwave Systems Part1Document100 pagesMicrowave Systems Part1John Brix BalisterosNo ratings yet

- Hydroacoustics and Underwater Acoustics: SessionsDocument53 pagesHydroacoustics and Underwater Acoustics: Sessionsle_luan_166No ratings yet

- Ultrasonic Transducers Technical NotesDocument11 pagesUltrasonic Transducers Technical NotesBelaliaNo ratings yet

- Speed, Wavelength Calculations of Sound & EM WavesDocument19 pagesSpeed, Wavelength Calculations of Sound & EM WavesAbtahee Haque0% (1)

- Sound From UltrasoundDocument9 pagesSound From UltrasoundNakul NemaNo ratings yet

- Icom IC-V68 Service ManualDocument37 pagesIcom IC-V68 Service ManualRossi Paulo89% (9)

- Understanding AM ModulationDocument7 pagesUnderstanding AM ModulationERICK ADONIS ANAYA FLORESNo ratings yet

- Wideband PLL System As A Clock - 2009Document118 pagesWideband PLL System As A Clock - 2009Purushothamachary PolojuNo ratings yet

- Microwave Devices Final Lectures BDocument55 pagesMicrowave Devices Final Lectures BPolAxeNo ratings yet

- Ultra SonicDocument15 pagesUltra SonicSridhar KumarNo ratings yet

- Training Report On Radio BroadcastingDocument44 pagesTraining Report On Radio BroadcastingDhawal Kirti VasudevNo ratings yet

- Chapter19pp171 180 PDFDocument10 pagesChapter19pp171 180 PDFInderMahesh0% (1)

- 9 2013-2ultrasonicpestrepellerDocument15 pages9 2013-2ultrasonicpestrepellercjah gandekanNo ratings yet

- R. LA HONG PHUC LT truyền sóng 18Document18 pagesR. LA HONG PHUC LT truyền sóng 18Hai AuNo ratings yet

- Experiment No.1 Attenuation in Transmission Line ObjectivesDocument3 pagesExperiment No.1 Attenuation in Transmission Line Objectivesمروان الحاسي0% (1)

- Ramsey DAP25 - Amplified Broadband Discone AntennaDocument20 pagesRamsey DAP25 - Amplified Broadband Discone Antennay8314263No ratings yet

- Microphone HandbookDocument20 pagesMicrophone HandbookDiego Urbina100% (1)

- Phase-Locked Loop Tutorial, PLLDocument12 pagesPhase-Locked Loop Tutorial, PLLKarthik MurthyNo ratings yet

- RadiosDocument48 pagesRadiosKarloz Reyez MarianoNo ratings yet

- Microwave Tubes ExplainedDocument135 pagesMicrowave Tubes ExplainedAditya MewaraNo ratings yet

- Sub-Bottom Profiler ORE Model 1036Document65 pagesSub-Bottom Profiler ORE Model 1036gabelendaNo ratings yet

- Jan 02Document12 pagesJan 02Romel BhaiNo ratings yet

- Sample MainpageDocument7 pagesSample Mainpagevipin171986No ratings yet

- TX4500S ImDocument57 pagesTX4500S Imphilnick59No ratings yet

- Thesis 02Document28 pagesThesis 02woodksdNo ratings yet

- The Loudspeaker StudyDocument20 pagesThe Loudspeaker Studycnottoli18No ratings yet

- Naval Postgraduate School Monterey, California: ThesisDocument53 pagesNaval Postgraduate School Monterey, California: ThesisjowihuNo ratings yet

- Ultrasonic-Assisted Wet Processing Processing Dyeing Amp Finishing FeaturesDocument9 pagesUltrasonic-Assisted Wet Processing Processing Dyeing Amp Finishing FeaturesPranav PrajapatiNo ratings yet

- TX3350 ImDocument43 pagesTX3350 Imscrib_999No ratings yet

- Sound Engineering PDFDocument16 pagesSound Engineering PDFkskumargieNo ratings yet

- Build Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterFrom EverandBuild Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterRating: 5 out of 5 stars5/5 (4)

- Spectrum Requirement Planning in Wireless Communications: Model and Methodology for IMT - AdvancedFrom EverandSpectrum Requirement Planning in Wireless Communications: Model and Methodology for IMT - AdvancedHideaki TakagiNo ratings yet

- Pirate Radio and Video: Experimental Transmitter ProjectsFrom EverandPirate Radio and Video: Experimental Transmitter ProjectsRating: 5 out of 5 stars5/5 (1)

- The Physics and Technology of Diagnostic Ultrasound: Study Guide (Second Edition)From EverandThe Physics and Technology of Diagnostic Ultrasound: Study Guide (Second Edition)No ratings yet

- Microwave and Wireless Communications TechnologyFrom EverandMicrowave and Wireless Communications TechnologyRating: 5 out of 5 stars5/5 (1)

- Serie GMD06Document2 pagesSerie GMD06Popescu IonicaNo ratings yet

- BTS 3900A Product DescriptionDocument22 pagesBTS 3900A Product DescriptionMuhammad AqeelNo ratings yet

- Littelfuse Thyristor MAC228A D Datasheet PDFDocument5 pagesLittelfuse Thyristor MAC228A D Datasheet PDFHamid AbdNo ratings yet

- Positive Voltage Regulators Up to 1.5A OutputDocument25 pagesPositive Voltage Regulators Up to 1.5A OutputJulioSanchesNo ratings yet

- E.E Labe-IVDocument97 pagesE.E Labe-IVTadese AtomssaNo ratings yet

- Irf5305 Mosfet Canal PDocument2 pagesIrf5305 Mosfet Canal PYEISON ANDRES VEGA MUÑOZNo ratings yet

- Advanced Photoelectric Smoke Detectors: FeaturesDocument8 pagesAdvanced Photoelectric Smoke Detectors: FeaturesoscarninanNo ratings yet

- Philips Lighting 1987 Lamp Specification GuideDocument102 pagesPhilips Lighting 1987 Lamp Specification GuideAlan Masters100% (1)

- 2 Kontrolleri ATS 021 enDocument36 pages2 Kontrolleri ATS 021 enFranky Roi SiahaanNo ratings yet

- Work Instructions: Air Filter Replacement Capstone Model C200 Microturbine /C1000 Series Purpose and ScopeDocument11 pagesWork Instructions: Air Filter Replacement Capstone Model C200 Microturbine /C1000 Series Purpose and ScopeJefferson MosqueraNo ratings yet

- PV Cell ModelingDocument12 pagesPV Cell Modelingtran duyNo ratings yet

- APD55A6Document4 pagesAPD55A6Juan Antonio PantaleonNo ratings yet

- AC2100 AC2500 Installation GuideDocument16 pagesAC2100 AC2500 Installation GuideEduardo MartínezNo ratings yet

- 2019handout1 Automatic Control SystemsDocument91 pages2019handout1 Automatic Control SystemsMU Len GANo ratings yet

- STCC2540: USB Charging Controller With Integrated Power SwitchDocument32 pagesSTCC2540: USB Charging Controller With Integrated Power SwitchAndré Andersen PicerniNo ratings yet

- Heating Cable Selection GuideDocument4 pagesHeating Cable Selection Guidehassan3012No ratings yet

- Info CC CandDocument16 pagesInfo CC CandAndres Felipe Urazan MartinezNo ratings yet

- Mobile Jammer Circuit: Inventory ListDocument2 pagesMobile Jammer Circuit: Inventory ListCarlo Piere DayaoNo ratings yet

- WWW Coilws ComDocument2 pagesWWW Coilws ComClerk LoloNo ratings yet

- Amv (E) 55,56Document4 pagesAmv (E) 55,56AleksandarSashaStankovichNo ratings yet

- A Simple Low Cost Lock-In Amplifier For MeasurementDocument10 pagesA Simple Low Cost Lock-In Amplifier For MeasurementKarthikeyan SubbuNo ratings yet

- Tractor D7R Schematic Sstem HydraulicDocument11 pagesTractor D7R Schematic Sstem HydraulicGerald Gutierrez100% (1)

- WEG w22 Three Phase Motor Technical Nema Market 50029265 Brochure EnglishDocument44 pagesWEG w22 Three Phase Motor Technical Nema Market 50029265 Brochure EnglishDerwaish JeeNo ratings yet

- Vanteddu Sai Kiran Reddy: Mtech Microelectronics at Iiit-AllahabadDocument1 pageVanteddu Sai Kiran Reddy: Mtech Microelectronics at Iiit-AllahabadSai Kiran Reddy VantedduNo ratings yet

- RRL 2Document2 pagesRRL 2Jessie BasasNo ratings yet

- Instruction Manual: Dedicated Communication Unit RS-232C Output TypeDocument4 pagesInstruction Manual: Dedicated Communication Unit RS-232C Output TypeM Farhan Al FananiNo ratings yet

- BGC-L Data Sheet 4921240306 UKDocument5 pagesBGC-L Data Sheet 4921240306 UKRafael Charry Andrade100% (1)

- Electric Power Systems Course OverviewDocument25 pagesElectric Power Systems Course OverviewRizkyHaryogiNo ratings yet