Professional Documents

Culture Documents

SEO Design Examples

Uploaded by

Anonymous YDwBCtsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEO Design Examples

Uploaded by

Anonymous YDwBCtsCopyright:

Available Formats

Design examples

6 / 2010

48

'HVLJQH[DPSOHV

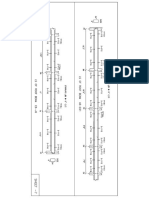

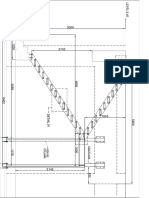

ExampIe 1: mechanicaI anchor in non-cracked concrete

Anchoring conditions

concrete

number of anchors

h 250 mm

s 300 mm

c 120 mm

E 90

N

Sd

55,0 kN

V

Sd

20,0 kN

N

Sd

(1)

27,5 kN

V

Sd

(1)

10,0 kN

SHEAR design action (fixing point)

base material thickness

anchor spacing

edge distance

shear load direction perpendicular to free edge

Non-cracked concrete C40/50

Group of two anchors close to the edge

TENSON design action per anchor

SHEAR design action per anchor

TENSON design action (fixing point)

h

ef

100 mm

s

cr,sp

380 mm

s

cr,N

300 mm

c

cr,sp

190 mm

c

cr,N

150 mm

s

min

100 mm

c < 240 mm

c

min

100 mm

s < 240 mm

HSL-3-G M16 anchor

minimum edge distance

for

minimum spacing

for

effective anchorage depth

critical spacing for splitting failure

critical spacing for concrete cone failure

critical edge distance for splitting failure

critical edge distance for concrete cone failure

The parameters are given in the

anchor-section in the tables setting

details and setting parameters

(for HSL-3-G M16)

GeneraI remarks

According ETAG 001, Annex C, concrete cone, splitting, pryout and concrete edge design

resistance must be verified for the anchor group. Steel and pull-out design resistance must be

verified for the most unfavourable anchor of the anchor group.

According to the simplified design method given in this Fastening Technology Manual all

anchors of a group are loaded equally, the design resistance values given in the tables are valid

for one anchor.

Design examples

6 / 2010

49

Tension Ioading

Design steeI resistance

83,7 kN N

Rd,s

=

See basic design tensile

resistance

(for HSL-3-G M16)

Design concrete puII-out resistance

N

0

Rd,p

-

concrete f

B

-

N

Rd,p

= N

0

Rd,p

f

B

= -

basic resistance

non-cracked concrete C40/50

See basic design tensile

resistance

(for HSL-3-G M16 pull-out failure is

not decisive in non-cracked

concrete)

Design concrete cone resistance

N

0

Rd,c

33,6 kN

concrete f

B

1,41

f

1,N

0,94

f

2,N

0,90

s = 300 mm s

cr,N

= 300 mm s/s

cr,N

= 1,00

f

3,N

1,00

f

re,N

1,00

40,1 kN

non-cracked concrete C40/50

HSL-3-G M16

N

Rd,c

= N

0

Rd,c

f

B

f

1,N

f

2,N

f

3,N

f

re,N

=

anchor

basic resistance

0,80 c = 120 mm c

cr,N

= 150 mm c/c

cr,N

=

See basic design tensile

resistance

(for HSL-3-G M16)

and influencing factors

(for HSL-3-G M16)

nfluencing factors may be

interpolated.

Design spIitting resistance

N

0

Rd,c

33,6 kN

concrete f

B

1,41

f

1,sp

0,89

f

2,sp

0,82

s = 300 mm s

cr,sp

= 380 mm s/s

cr,sp

= 0,79

f

3,sp

0,89

h = 250 mm h

ef

= 100 mm [h/(2h

ef

)]

2/3

= 2,5

f

h,sp

1,16

f

re,N

1,00

35,7 kN

c = 120 mm c

cr,sp

= 190 mm c/c

cr,sp

=

0,63

anchor HSL-3-G M16

N

Rd,sp

= N

0

Rd,c

f

B

f

1,sp

f

2,sp

f

3,sp

f

h,sp

f

re,N

=

basic resistance

non-cracked concrete C40/50

See basic design tensile

resistance

(for HSL-3-G M16)

and influencing factors

(for HSL-3-G M16)

nfluencing factors may be

interpolated.

N

Rd

= 35,7 kN Tension design resistance: Iowest vaIue

Design examples

6 / 2010

50

Shear Ioading

Design steeI resistance

68,6 kN V

Rd,s

=

See basic design shear resistance

(for HSL-3-G M16)

Concrete pryout design resistance

V

0

Rd,cp

67,2 kN

concrete f

B

1,41

f

1,N

0,94

f

2,N

0,90

s = 300 mm s

cr,N

= 300 mm s/s

cr,N

= 1,00

f

3,N

1,00

f

re,N

1,00

80,2 kN

0,80

basic resistance

c = 120 mm c

cr,N

= 150 mm

non-cracked concrete C40/50

anchor HSL-3-G M16

V

Rd,cp

= V

0

Rd,cp

f

B

f

1,N

f

2,N

f

3,N

f

re,N

=

c/c

cr,N

=

See basic design shear resistance

(for HSL-3-G M16)

and influencing factors

(for HSL-3-G M16)

nfluencing factors may be

interpolated.

Concrete edge design resistance

V

0

Rd,c

13,7 kN

concrete f

B

1,41

90 f

E

2

h = 250 mm c = 120 mm h/c = 2,08

f

h 1

c = 120 mm h

ef

= 100 mm c/h

ef

= 1,20

s = 300 mm h

ef

= 100 mm s/h

ef

= 3,00

46,4 kN

non-cracked concrete C40/50

V

Rd,c

= V

0

Rd,c

f

B

f

E

f

h

f

4

=

1,20 f

4

shear load direction

perpendicular to free edge

basic resistance

See basic design shear resistance

(for HSL-3-G M16)

and influencing factors

(for HSL-3-G M16)

nfluencing factors may be

interpolated.

Shear design resistance: Iowest vaIue V

Rd

= 46,4 kN

Combined tension and shear Ioading

The following equation must be satisfied for combined tension and shear

loads:

(Eq. 1) (E

N

)

1,5

+ (E

V

)

1,5

> 1

E

N

(E

V

) ratio between design action and design

resistance for tension (shear) loading

According to ETAG 001, Annex C, the following simplified equation may

be applied:

(Eq. 2) E

N

+ E

V

> 1,2 and E

N

> 1, E

V

> 1

ExampIe (Ioad vaIues are vaIid for one anchor)

N

Sd

(1)

= 27,5 kN

V

Sd

(1)

= 10,0 kN

N

Rd

= 35,7 kN

V

Rd

= 46,4 kN

E

N

= N

Sd

(1)

/N

Rd

= 0,770 > 1 3 33 3

E

V

= V

Sd

(1)

/V

Rd

= 0,216 > 1 3 33 3

E

N

+ E

V

= 0,986 > 1,2 3 33 3

(E

N

)

1,5

+ (E

V

)

1,5

= 0,776 > 1 3 33 3

0

0,2

0,4

0,6

0,8

1

1,2

0 0,2 0,4 0,6 0,8 1 1,2

E EE EV

E E E E

N

(Eq. 1)

(Eq. 2)

Design examples

6 / 2010

51

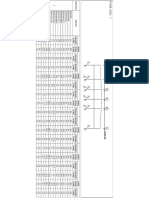

ExampIe 2: mechanicaI anchor in cracked concrete with dense reinforcement

Anchoring conditions

concrete

number of anchors

h 150 mm

s 70 mm

c 120 mm

E 90

N

Sd

10,0 kN

V

Sd

10,0 kN

N

Sd

(1)

5,0 kN

V

Sd

(1)

5,0 kN

Group of two anchors close to the edge

TENSON design action per anchor

SHEAR design action per anchor

TENSON design action (fixing point)

Cracked concrete C30/37

base material thickness

anchor spacing

edge distance

shear load direction perpendicular to free edge

SHEAR design action (fixing point)

h

ef

70 mm

s

cr,sp

270 mm

s

cr,N

210 mm

c

cr,sp

135 mm

c

cr,N

105 mm

s

min

70 mm

c < 100 mm

c

min

70 mm

s < 160 mm

HSL-3-SK M10 anchor

minimum edge distance

for

minimum spacing

for

effective anchorage depth

critical spacing for splitting failure

critical spacing for concrete cone failure

critical edge distance for splitting failure

critical edge distance for concrete cone failure

The parameters are given in the

anchor-section in the tables setting

details and setting parameters

(for HSL-3-SK M10)

GeneraI remarks

According ETAG 001, Annex C, concrete cone, splitting, pryout and concrete edge design

resistance must be verified for the anchor group. Steel and pull-out design resistance must be

verified for the most unfavourable anchor of the anchor group.

According to the simplified design method given in this Fastening Technology Manual all

anchors of a group are loaded equally, the design resistance values given in the tables are valid

for one anchor.

Design examples

6 / 2010

52

Tension Ioading

Design steeI resistance

30,9 kN N

Rd,s

=

See basic design tensile

resistance

for HSL-3- SK M10

Design concrete puII-out resistance

N

0

Rd,p

10,7

concrete f

B

1,22

N

Rd,p

= N

0

Rd,p

f

B

= 13,1 kN

Cracked concrete C30/37

basic resistance

See basic design tensile

resistance

(for HSL-3- SK M10 pull-out failure

is not decisive in non-cracked

concrete)

Design concrete cone resistance

N

0

Rd,c

14,1 kN

concrete f

B

1,22

f

1,N

1,00

f

2,N

1,00

s = 70 mm s

cr,N

= 210 mm s/s

cr,N

= 0,33

f

3,N

0,67

f

re,N

0,85

9,8 kN

Cracked concrete C30/37

HSL-3-SK M10

N

Rd,c

= N

0

Rd,c

f

B

f

1,N

f

2,N

f

3,N

f

re,N

=

anchor

basic resistance

c = 120 mm c

cr,N

= 105 mm 1,14 c/c

cr,N

=

See basic design tensile

resistance

(for HSL-3- SK M10)

and influencing factors

(for HSL-3- SK M10)

nfluencing factors may be

interpolated.

Design spIitting resistance

N

0

Rd,c

14,1 kN

concrete f

B

1,22

f

1,sp

0,97

f

2,sp

0,94

s = 70 mm s

cr,sp

= 270 mm s/s

cr,sp

= 0,26

f

3,sp

0,63

h = 150 mm h

ef

= 70 mm [h/(2h

ef

)]

2/3

= 2,14

f

h,sp

1,05

f

re,N

0,85

8,8 kN

Cracked concrete C30/37

N

Rd,sp

= N

0

Rd,c

f

B

f

1,sp

f

2,sp

f

3,sp

f

h,sp

f

re,N

=

basic resistance

anchor HSL-3-SK M10

0,89 135 mm c/c

cr,sp

=

c = 120 mm c

cr,sp

=

See basic design tensile

resistance

(for HSL-3- SK M10)

and influencing factors

(for HSL-3- SK M10)

nfluencing factors may be

interpolated.

N

Rd

= 8,8 kN Tension design resistance: Iowest vaIue

Design examples

6 / 2010

53

Shear Ioading

Design steeI resistance

39,4 kN V

Rd,s

=

See basic design shear resistance

(for HSL-3- SK M10)

Concrete pryout design resistance

V

0

Rd,cp

28,1 kN

concrete f

B

1,22

f

1,N

1,00

f

2,N

1,00

s = 70 mm s

cr,N

= 210 mm s/s

cr,N

= 0,33

f

3,N

0,67

f

re,N

0,85

19,5 kN

1,14

Cracked concrete C30/37

basic resistance

c = 120 mm c

cr,N

= 105 mm

anchor HSL-3-SK M10

V

Rd,cp

= V

0

Rd,cp

f

B

f

1,N

f

2,N

f

3,N

f

re,N

=

c/c

cr,N

=

See basic design shear resistance

(for HSL-3- SK M10)

and influencing factors

(for HSL-3- SK M10)

nfluencing factors may be

interpolated.

Concrete edge design resistance

V

0

Rd,c

4,6 kN

concrete f

B

1,22

90 f

E

2

h = 150 mm c = 120 mm h/c = 1,25

f

h 0,88

c = 120 mm h

ef

= 70 mm c/h

ef

= 1,71

s = 70 mm h

ef

= 70 mm s/h

ef

= 1,00

13,2 kN

Cracked concrete C30/37

V

Rd,c

= V

0

Rd,c

f

B

f

E

f

h

f

4

=

1,34 f

4

shear load direction

perpendicular to free edge

basic resistance

See basic design shear resistance

(for HSL-3- SK M10)

and influencing factors

(for HSL-3- SK M10)

nfluencing factors may be

interpolated.

Shear design resistance: Iowest vaIue V

Rd

= 13,2 kN

Combined tension and shear Ioading

The following equation must be satisfied for combined tension and shear

loads:

(Eq. 1) (E

N

)

1,5

+ (E

V

)

1,5

> 1

E

N

(E

V

) ratio between design action and design

resistance for tension (shear) loading

According to ETAG 001, Annex C, the following simplified equation may

be applied:

(Eq. 2) E

N

+ E

V

> 1,2 and E

N

> 1, E

V

> 1

ExampIe (Ioad vaIues are vaIid for one anchor)

N

Sd

(1)

= 5,0 kN

V

Sd

(1)

= 5,0 kN

N

Rd

= 8,8 kN

V

Rd

= 13,2 kN

E

N

= N

Sd

(1)

/N

Rd

= 0,567 > 1 3 33 3

E

V

= V

Sd

(1)

/V

Rd

= 0,378 > 1 3 33 3

E

N

+ E

V

= 0,945 > 1,2 3 33 3

(E

N

)

1,5

+ (E

V

)

1,5

= 0,659 > 1 3 33 3

0

0,2

0,4

0,6

0,8

1

1,2

0 0,2 0,4 0,6 0,8 1 1,2

E EE EV

E E E E

N

(Eq. 1)

(Eq. 2)

Design examples

6 / 2010

54

ExampIe 3: adhesive anchoring system with variabIe embedment depth in

non-cracked concrete

Anchoring conditions

number of anchors

h 100 mm

s 150 mm

c 100 mm

E 0

N

Sd

15,0 kN

V

Sd

15,0 kN

N

Sd

(1)

7,5 kN

V

Sd

(1)

7,5 kN

h

ef

70 mm

Non-cracked concrete C50/60

Group of two anchors close to the edge

TENSON design action per anchor

SHEAR design action per anchor

base material thickness

anchor spacing

edge distance

shear load direction perpendicular to free edge

TENSON design action (fixing point)

temperature range

concrete

service temperature

range of base material

SHEAR design action (fixing point)

effective anchorage depth

d 12 mm

h

ef,typ

110 mm

s

min

60 mm

c

min

60 mm

Hilti HT-RE 500-SD with HT-V 5.8, size M12 anchor

typical anchorage depth

minimum edge distance

minimum spacing

external diameter

The parameters are given in the

anchor-section in the tables setting

details and setting parameters

(for HT-RE 500-SD with HT-V 5.8,

size M12)

CriticaI spacings and edge distances

210 mm

105 mm

2,26 h

ef

4,6 h

ef

- 1,8 h

1,0 h

ef

h = 100 mm h

ef

= 70 mm h/h

ef

= 1,43

c

cr,sp

= 142 mm

284 mm

h

ef

=

critical spacing for concrete cone failure s

cr,N

and critical spacing for combined

pull-out and concrete cone failure s

cr,Np

s

cr,N

= s

cr,Np

= 3 h

ef

= h

ef

= 70 mm

c

cr,N

= c

cr,Np

= 1,5 h

ef

=

critical spacing for splitting failure

c

cr,sp

=

c

cr,sp

=

for 1,3 h

ef

< h < 2 h

ef

for h > 1,3 h

ef

critical edge distance for splitting failure

c

cr,sp

=

critical edge distance for concrete cone failure c

cr,N

and critical edge distance for

combined pull-out and concrete cone failure c

cr,Np

70 mm

c

cr,sp

= 142 mm

for h < 2 h

ef

s

cr,sp

= 2 c

cr,sp

=

GeneraI remarks

According EOTA Technical Report TR 029, concrete cone, combined concrete cone and pull-

out, splitting, pryout and concrete edge design resistance must be verified for the anchor group.

Steel design resistance must be verified for the most unfavourable anchor of the anchor group.

According to the simplified design method given in this Fastening Technology Manual all

anchors of a group are loaded equally, the design resistance values given in the tables are valid

for one anchor.

Design examples

6 / 2010

55

Tension Ioading

Design steeI resistance

28,0 kN N

Rd,s

=

See basic design tensile

resistance

(for HT-RE 500-SD with HT-V

5.8, size M12)

Design combined puII-out and concrete cone resistance

N

0

Rd,p

29,9 kN

concrete f

B,p

1,09

h

ef

= 70 mm h

ef,typ

= 110 mm 0,64

f

1,N

0,99

f

2,N

0,97

s = 150 mm s

cr,N

= 210 mm s/s

cr,N

= 0,71

f

3,N

0,86

h

ef

= 70 mm

f

re,N

1,00

N

Rd,p

= N

0

Rd,p

f

B,p

f

1,N

f

2,N

f

3,N

f

h,p

f

re,N

= 17,1 kN

basic resistance

Non-cracked concrete C50/60

c/c

cr,N

= 0,95

f

h,p

= h

ef

/h

ef,typ

=

c = 100 mm c

cr,N

= 105 mm

See basic design tensile

resistance

(for HT-RE 500-SD with HT-V

5.8, size M12)

Design concrete cone resistance

N

0

Rd,c

32,4 kN

concrete f

B

1,55

h

ef

= 70 mm h

ef,typ

= 110 mm 0,51

f

1,N

0,99

f

2,N

0,97

s = 150 mm s

cr,N

= 210 mm s/s

cr,N

= 0,71

f

3,N

0,86

h

ef

= 70 mm

f

re,N

1,00

21,1 kN

basic resistance

Non-cracked concrete C50/60

N

Rd,c

= N

0

Rd,c

f

B

f

h,N

f

1,N

f

2,N

f

3,N

f

re,N

=

c/c

cr,N

=

c

cr,N

= 105 mm 0,95 c = 100 mm

f

h,N

= (h

ef

/h

ef,typ

)

1,5

=

See basic design tensile

resistance

(for HT-RE 500-SD with HT-V

5.8, size M12)

and influencing factors

(for HT-RE 500-SD with HT-V

5.8, size M12)

nfluencing factors may be

interpolated.

Design spIitting resistance

N

0

Rd,c

32,4 kN

concrete f

B

1,55

h

ef

= 70 mm h

ef,typ

= 110 mm 0,51

f

1,sp

0,91

f

2,sp

0,85

s = 150 mm s

cr,sp

= 284 mm s/s

cr,sp

= 0,53

f

3,sp

0,76

h

ef

= 70 mm

f

re,N

1,00

15,0 kN N

Rd,sp

= N

0

Rd,c

f

B

f

h,N

f

1,sp

f

2,sp

f

3,sp

f

re,N

=

basic resistance

c/c

cr,sp

=

f

h,N

= (h

ef

/h

ef,typ

)

1,5

=

c

cr,sp

=

Non-cracked concrete C50/60

142 mm 0,70 c = 100 mm

See basic design tensile

resistance

(for HT-RE 500-SD with HT-V

5.8, size M12)

and influencing factors

(for HT-RE 500-SD with HT-V

5.8, size M12)

nfluencing factors may be

interpolated.

N

Rd

= 15,0 kN Tension design resistance: Iowest vaIue

Design examples

6 / 2010

56

Shear Ioading

Design steeI resistance

16,8 kN V

Rd,s

=

See basic design shear

resistance

(for HT-RE 500-SD with HT-V

5.8, size M12)

Concrete pryout design resistance

V

0

=

17,1 kN

h

ef

= 70 mm k 2

34,3 kN V

Rd,cp

= k V

0

=

lower value of N

Rd,p

and N

Rd,c

See basic design shear

resistance

(for HT-RE 500-SD with HT-V

5.8, size M12)

and influencing factors

(for HT-RE 500-SD with HT-V

5.8, size M12)

Concrete edge design resistance

V

0

Rd,c

11,6 kN

concrete f

B

1,55

0 f

E

1,00

h = 100 mm c = 100 mm h/c = 1,00

f

h

0,82

c = 100 mm h

ef

= 70 mm c/h

ef

= 1,43

s = 150 mm h

ef

= 70 mm s/h

ef

= 2,14

h

ef

= 70 mm d = 12 mm h

ef

/d = 5,83

f

hef

0,97

c = 100 mm d = 12 mm c/d = 8,33

f

c

0,67

12,3 kN

1,28

V

Rd,c

= V

0

Rd,c

f

B

f

f

h

f

4

f

hef

f

c

=

basic resistance

Non-cracked concrete C50/60

f

4

shear load direction

perpendicular to free edge

See basic design shear

resistance

(for HT-RE 500-SD with HT-V

5.8, size M12)

and influencing factors

(for HT-RE 500-SD with HT-V

5.8, size M12)

nfluencing factors may be

interpolated.

Shear design resistance: Iowest vaIue V

Rd

= 12,3 kN

Combined tension and shear Ioading

The following equation must be satisfied for combined tension and shear

loads:

(Eq. 1) (E

N

)

1,5

+ (E

V

)

1,5

> 1

E

N

(E

V

) ratio between design action and design

resistance for tension (shear) loading

According to ETAG 001, Annex C, the following simplified equation may

be applied:

(Eq. 2) E

N

+ E

V

> 1,2 and E

N

> 1, E

V

> 1

ExampIe (Ioad vaIues are vaIid for one anchor)

N

Sd

(1)

= 7,5 kN

V

Sd

(1)

= 7,5 kN

N

Rd

= 15,0 kN

V

Rd

= 12,3 kN

E

N

= N

Sd

(1)

/N

Rd

= 0,500 > 1 3 33 3

E

V

= V

Sd

(1)

/V

Rd

= 0,612 > 1 3 33 3

E

N

+ E

V

= 1,112 > 1,2 3 33 3

(E

N

)

1,5

+ (E

V

)

1,5

= 0,832 > 1 3 33 3

0

0,2

0,4

0,6

0,8

1

1,2

0 0,2 0,4 0,6 0,8 1 1,2

E EE EV

E E E E

N

(Eq. 1)

(Eq. 2)

Design examples

6 / 2010

57

You might also like

- 500 Selected ProblemsDocument425 pages500 Selected ProblemsRahul50% (2)

- Design of Below-the-Hook Lifting Devices: ASME BTH-1-2008Document3 pagesDesign of Below-the-Hook Lifting Devices: ASME BTH-1-2008arash0000No ratings yet

- IS 6623.2004 High Strength Structural Nuts PDFDocument11 pagesIS 6623.2004 High Strength Structural Nuts PDFD Vijay Kumar RaoNo ratings yet

- High-Rise Structural Embedded Design Based On 2019 CBC/2018 IBC Design CriteriaDocument1 pageHigh-Rise Structural Embedded Design Based On 2019 CBC/2018 IBC Design CriteriaPhạm Quốc ViệtNo ratings yet

- Exact Anchor Bolt Placement Critical for Metal Building ConstructionDocument6 pagesExact Anchor Bolt Placement Critical for Metal Building ConstructionRam BabuNo ratings yet

- Fundamentals of Structural DynamicsDocument217 pagesFundamentals of Structural DynamicsAndy Garcia100% (8)

- Unit 3 (DESIGN THEORY: LIMIT STATES AND BENDING)Document23 pagesUnit 3 (DESIGN THEORY: LIMIT STATES AND BENDING)Zara Nabilah100% (7)

- Embed Design - Core WallDocument39 pagesEmbed Design - Core Wallkalpanaadhi100% (1)

- AD 331 - Open Top Box Girders For BridgesDocument2 pagesAD 331 - Open Top Box Girders For Bridgessymon ellimacNo ratings yet

- Machine FoundationsDocument249 pagesMachine Foundationsnizamaniza100% (32)

- Design of Headed Concrete AnchorDocument121 pagesDesign of Headed Concrete AnchorkalpanaadhiNo ratings yet

- Hilti Calculation ExamplesDocument10 pagesHilti Calculation ExamplesNgoc TruongNo ratings yet

- Edexcel As Physics Unit 2 Revision PowerpointDocument92 pagesEdexcel As Physics Unit 2 Revision PowerpointAnonymous tlSLEPRRe92% (12)

- HDB Sor Jul2023Document239 pagesHDB Sor Jul2023dineshkumar1009No ratings yet

- ESKOM Medupi Power Station Crawl Beam Calculation SheetDocument22 pagesESKOM Medupi Power Station Crawl Beam Calculation SheetMbalekelwa MpembeNo ratings yet

- Pages From Hilti BE 500Document1 pagePages From Hilti BE 500Anonymous S7Cq7ZDgPNo ratings yet

- HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, MixerDocument11 pagesHIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixerlael00No ratings yet

- Friction Buffer Stop Design PDFDocument4 pagesFriction Buffer Stop Design PDFJ.GuerhardNo ratings yet

- UPDATED MARKET RATESDocument21 pagesUPDATED MARKET RATESMD Maruf HussainNo ratings yet

- 2 Piles Pilecap DesignDocument4 pages2 Piles Pilecap Designwun chwenNo ratings yet

- Drain DWGDocument1 pageDrain DWGSharun ShajiNo ratings yet

- Coefficient of Dynamic AugmentDocument1 pageCoefficient of Dynamic Augmentnikhilarora1988No ratings yet

- Bảng Kiểm Toán Khe Cà LồDocument12 pagesBảng Kiểm Toán Khe Cà LồhuychungngNo ratings yet

- Fatigue Design FaDocument6 pagesFatigue Design FaSani Adipura WinataNo ratings yet

- Metal Beam Crash Barriers: Highway SafetyDocument6 pagesMetal Beam Crash Barriers: Highway SafetyAbrar Ahmad100% (1)

- Girder Stressing CalculationsDocument11 pagesGirder Stressing CalculationsSarmad WaqasNo ratings yet

- Final 175T Crane Spec DT 11.1.16 PDFDocument57 pagesFinal 175T Crane Spec DT 11.1.16 PDFRohan KulkarniNo ratings yet

- Bridge Solution BrochureDocument41 pagesBridge Solution BrochurearunjacobnNo ratings yet

- Stopping Sight DistanceDocument20 pagesStopping Sight DistanceDushan SenarathneNo ratings yet

- Differences between Indian and Chinese structural codesDocument4 pagesDifferences between Indian and Chinese structural codesMuralidhar SivarajuNo ratings yet

- Indian Highway Feb 2013Document104 pagesIndian Highway Feb 2013mnsahoo2003No ratings yet

- Scienceclinic Smartprep GR11 Dbe Eng 1 PDFDocument44 pagesScienceclinic Smartprep GR11 Dbe Eng 1 PDFCayden Davids100% (2)

- 03 Section 2 Example Bridge (E)Document11 pages03 Section 2 Example Bridge (E)Diego Benavides KNo ratings yet

- Steel Girder Comparison and Sensitivity AnalysisDocument6 pagesSteel Girder Comparison and Sensitivity AnalysisvinoraamNo ratings yet

- Example 1: Single-Anchor Fastening Close To Two Edges of A ColumnDocument8 pagesExample 1: Single-Anchor Fastening Close To Two Edges of A Columnproteor_srlNo ratings yet

- Wheel Calculation IDEA Analyzes Wheel Material OptionsDocument35 pagesWheel Calculation IDEA Analyzes Wheel Material Optionsbambang satryojatiNo ratings yet

- Appendix G PDFDocument1 pageAppendix G PDFarif_rubinNo ratings yet

- Zipline Reference 3Document11 pagesZipline Reference 3Jomo-Rhys GilmanNo ratings yet

- 1374561914836-Guidelines For Use of HSFG Bolts On Bridges RevisedDocument25 pages1374561914836-Guidelines For Use of HSFG Bolts On Bridges RevisedDurgesh GovilNo ratings yet

- L3 PQRforQualificationDocument1 pageL3 PQRforQualificationBernardo LeorNo ratings yet

- 1307078105903-TSC - 81-RBOrders FinalDocument100 pages1307078105903-TSC - 81-RBOrders FinalSatish DmNo ratings yet

- Eurocode 4: Design of Composite Steel and Concrete StructuresDocument19 pagesEurocode 4: Design of Composite Steel and Concrete StructuresGautam BudhNo ratings yet

- Monitoring Fouling BallastDocument58 pagesMonitoring Fouling BallastSuciu Florin100% (1)

- NA To SS EN 1991-2-2012 - Amd 1Document6 pagesNA To SS EN 1991-2-2012 - Amd 1Olivia OeyNo ratings yet

- (Te, Teq & Ta) - 00-14.05.2019Document4 pages(Te, Teq & Ta) - 00-14.05.2019VB665No ratings yet

- Network Management System: Submitted by Guru Vashist 0830531011 E.C. Vii SemDocument46 pagesNetwork Management System: Submitted by Guru Vashist 0830531011 E.C. Vii SemGuru VashistNo ratings yet

- Chapter05 - Plane Frame and Grid EqDocument63 pagesChapter05 - Plane Frame and Grid EqAgus BaeNo ratings yet

- Indian Raiilway - BS-105 With A&c 2Document17 pagesIndian Raiilway - BS-105 With A&c 2paimpillyNo ratings yet

- Delhi Metrorail Tender Documents Volume-1Document187 pagesDelhi Metrorail Tender Documents Volume-1Donato GaloisNo ratings yet

- Martin LiDocument20 pagesMartin Lia74engNo ratings yet

- Design of Coastal Revetments, Seawalls, and BulkheadsDocument110 pagesDesign of Coastal Revetments, Seawalls, and BulkheadsSøren MørchNo ratings yet

- Cracking in Steel Bridges PDFDocument336 pagesCracking in Steel Bridges PDFjoaobarbosa22No ratings yet

- Descriptio Station Length Elev GRADE M-Value: Length of Vert. Curve ADDocument4 pagesDescriptio Station Length Elev GRADE M-Value: Length of Vert. Curve ADRain GarvidaNo ratings yet

- Combined SheetDocument45 pagesCombined SheetVenkat PalliNo ratings yet

- Microstran EquarkeloadDocument6 pagesMicrostran Equarkeloadshantanu chowdhuryNo ratings yet

- Is 1367 1 2002 PDFDocument9 pagesIs 1367 1 2002 PDFBsc Aditya Singh DinkarNo ratings yet

- Hot Finished Square Hollow Sections in Accordance With EN 10210Document5 pagesHot Finished Square Hollow Sections in Accordance With EN 10210bggariyoNo ratings yet

- 141667-FAF-SPE-EOH-000007 OEE Galvanised Structural Steel Specifications PDFDocument12 pages141667-FAF-SPE-EOH-000007 OEE Galvanised Structural Steel Specifications PDFmarigusatuNo ratings yet

- Davit Trolley - Validation of Davit & Support BracketDocument17 pagesDavit Trolley - Validation of Davit & Support BracketRanjit S KashyapNo ratings yet

- CE2155 Structural Mechanics and Materials IntroductionDocument44 pagesCE2155 Structural Mechanics and Materials IntroductionJuliaNo ratings yet

- Krishi Secunderabad 06-07-2019Document58 pagesKrishi Secunderabad 06-07-2019Basava SowmyaNo ratings yet

- Hilti Hit RE 500 - Hilti Aust Pty LTDDocument5 pagesHilti Hit RE 500 - Hilti Aust Pty LTDBiju_PottayilNo ratings yet

- Taglineuse PEERREVIEWDOCDocument56 pagesTaglineuse PEERREVIEWDOCMohamed Said0% (1)

- Welding Inspection: BS 499 Part 2 Course Reference WIS 5Document11 pagesWelding Inspection: BS 499 Part 2 Course Reference WIS 5ibson045001256No ratings yet

- LTS 6 TableOfContents PDFDocument29 pagesLTS 6 TableOfContents PDFTAHANo ratings yet

- Railway Concrete SleeperDocument12 pagesRailway Concrete SleeperDEBOPRASAD BISWAS100% (1)

- Case StudyDocument11 pagesCase StudyGuransh SinghNo ratings yet

- Anchor Fastening Technology ManualDocument152 pagesAnchor Fastening Technology ManualfdsafsadfNo ratings yet

- BucklingDocument1 pageBucklingAnonymous YDwBCtsNo ratings yet

- Column Location ModelDocument1 pageColumn Location ModelAnonymous YDwBCtsNo ratings yet

- WPFOutputDocument6 pagesWPFOutputAnonymous YDwBCtsNo ratings yet

- Design of StaircaseDocument1 pageDesign of StaircaseAnonymous YDwBCtsNo ratings yet

- Ug TankDocument1 pageUg TankAnonymous YDwBCtsNo ratings yet

- Typical ConnectionsDocument1 pageTypical ConnectionsAnonymous YDwBCtsNo ratings yet

- Crash BarDocument1 pageCrash BarAnonymous YDwBCtsNo ratings yet

- L.S of BeamDocument1 pageL.S of BeamAnonymous YDwBCtsNo ratings yet

- Structural DrawingqwDocument1 pageStructural DrawingqwAnonymous YDwBCtsNo ratings yet

- First Floor PlanDocument1 pageFirst Floor PlanAnonymous YDwBCtsNo ratings yet

- Design of Connection Detail 2 GDocument2 pagesDesign of Connection Detail 2 GAnonymous YDwBCtsNo ratings yet

- Section x1x1Document1 pageSection x1x1Anonymous YDwBCtsNo ratings yet

- Stair New Block-ModelDocument1 pageStair New Block-ModelAnonymous YDwBCtsNo ratings yet

- Load CalcultionDocument1 pageLoad CalcultionAnonymous YDwBCtsNo ratings yet

- Structural Drawing123Document1 pageStructural Drawing123Anonymous YDwBCtsNo ratings yet

- Beam To Column Flange Connection-ASDDocument7 pagesBeam To Column Flange Connection-ASDAnonymous YDwBCtsNo ratings yet

- SectionsDocument1 pageSectionsAnonymous YDwBCtsNo ratings yet

- Cooling Water Pool Layout1Document1 pageCooling Water Pool Layout1Anonymous YDwBCtsNo ratings yet

- Front ElevaDocument1 pageFront ElevaAnonymous YDwBCtsNo ratings yet

- Load Calcultion PDFDocument1 pageLoad Calcultion PDFAnonymous YDwBCtsNo ratings yet

- TNEA 2017 How To Apply NewDocument44 pagesTNEA 2017 How To Apply NewAnonymous YDwBCtsNo ratings yet

- Product Packing Storage (S-065-S-071) - Rev-02 ModelDocument1 pageProduct Packing Storage (S-065-S-071) - Rev-02 ModelAnonymous YDwBCtsNo ratings yet

- Steel Building Roof Str.Document1 pageSteel Building Roof Str.Anonymous YDwBCtsNo ratings yet

- UB305X305X137+UB533X210X82 ModelDocument1 pageUB305X305X137+UB533X210X82 ModelAnonymous YDwBCtsNo ratings yet

- Sri Namagiri Thaayar Strothram PDFDocument1 pageSri Namagiri Thaayar Strothram PDFAnonymous YDwBCtsNo ratings yet

- Design of RCC Rectangular Columns: 230 X 300 Column With Reinf Safe Summary of DesignDocument1 pageDesign of RCC Rectangular Columns: 230 X 300 Column With Reinf Safe Summary of DesignAnonymous YDwBCtsNo ratings yet

- Mass PhotoDocument1 pageMass PhotoAnonymous YDwBCtsNo ratings yet

- Aluminum - 2 Slides Per PageDocument35 pagesAluminum - 2 Slides Per PageSurendra PatilNo ratings yet

- RCDC 7.0 Release NotesDocument5 pagesRCDC 7.0 Release NotesJayChristian QuimsonNo ratings yet

- 04 Work Energy and PowerDocument6 pages04 Work Energy and PowerJerico LlovidoNo ratings yet

- Big Bang WebquestDocument4 pagesBig Bang WebquestblackwellbertNo ratings yet

- Key Antenna Parameters Explained in DetailDocument28 pagesKey Antenna Parameters Explained in Detailsree2728100% (1)

- CHM031L - ThermodynamicsDocument88 pagesCHM031L - ThermodynamicsKath CarmonaNo ratings yet

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFbosschellenNo ratings yet

- Clarification of Ejection and Sweep in Rectangular Channel Turbulent FlowDocument21 pagesClarification of Ejection and Sweep in Rectangular Channel Turbulent FlowmedianuklirNo ratings yet

- BITS Pilani AssignmentDocument9 pagesBITS Pilani AssignmentNaresh SehdevNo ratings yet

- Elastic Foundations - Beams - Materials - Engineering Reference With Worked ExamplesDocument3 pagesElastic Foundations - Beams - Materials - Engineering Reference With Worked Examplessebastian9033No ratings yet

- Hake ViscoTester VT550Document6 pagesHake ViscoTester VT550Jiral PatelNo ratings yet

- Turbulent Models and ApplicationsDocument64 pagesTurbulent Models and Applicationsuday gouthamaNo ratings yet

- A. Virosztek and K. Maki - Phason Dynamics in Charge and Spin Density WavesDocument6 pagesA. Virosztek and K. Maki - Phason Dynamics in Charge and Spin Density WavesTellusz4532No ratings yet

- CET I 4. Second Law 2021Document63 pagesCET I 4. Second Law 2021Dhruv AgarwalNo ratings yet

- Adobe Scan Feb 10, 2021Document4 pagesAdobe Scan Feb 10, 2021Filip SalekNo ratings yet

- Physics Lesson (Lesson 1)Document4 pagesPhysics Lesson (Lesson 1)Douglas Kufre-Abasi GilbertNo ratings yet

- SAP2000 Frame Partial Fixity TestDocument4 pagesSAP2000 Frame Partial Fixity TestJuan Pablo González CarballoNo ratings yet

- Prediction of Static Liquefaction by Nor Sand Constitutive ModelDocument9 pagesPrediction of Static Liquefaction by Nor Sand Constitutive ModelJorge PalominoNo ratings yet

- Heat exchanger specification sheetDocument2 pagesHeat exchanger specification sheetDycka Anugerah PuryantoroNo ratings yet

- MCQs On Electrical LawsDocument6 pagesMCQs On Electrical LawsnasimNo ratings yet

- Dedan Kimathi University of Technology exam paper electromagnetic wavesDocument3 pagesDedan Kimathi University of Technology exam paper electromagnetic wavesHenry Kabasa100% (1)

- Steam Turbine: Life Time Calculations and Life Limitings FactorsDocument38 pagesSteam Turbine: Life Time Calculations and Life Limitings FactorsPPG CoverNo ratings yet

- Class XI (Mome+Height) Jee Mains Rakhi Ass PDFDocument56 pagesClass XI (Mome+Height) Jee Mains Rakhi Ass PDFprateek amrawanshiNo ratings yet

- Wave-Particle Duality FundamentalsDocument7 pagesWave-Particle Duality FundamentalsRahmatullahNo ratings yet

- openFoamUserManual PFMDocument383 pagesopenFoamUserManual PFMHans JensenNo ratings yet