Professional Documents

Culture Documents

L&T ECCD Inspection & Test Plan for Structural Works

Uploaded by

manu_giteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L&T ECCD Inspection & Test Plan for Structural Works

Uploaded by

manu_giteCopyright:

Available Formats

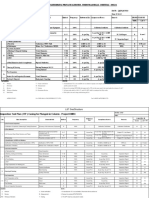

LARSEN & TOUBRO LIMITED

ECC DIVISION

ECCD

DOC No. : LTCD/ITP/STR Approved By : NATURE OF CHECK/INSPECTION Rev : 0 DATE : Method of Check Freequency of Check Dept : QA / QC

CLIENT : IOCL

PAGE :

1 OF 4

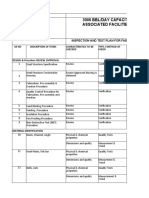

10.02 INSPECTION & TEST PLAN - STRUCTURAL WORKS

Sr. No. ACTIVITY Reference Procedure / Document Format for Record Inspection Authority L&T-ECCD CLIENT REMARKS

1 Material Inspection Rolled section and plates for a. Mechanical framing columns, beams, bracing, members, stiffeners etc. b. Chemical c. Dimensional & external defects d. Raw material identification and correlation of TC's Review MTC Heat No./ Batch No. -doMeasurement & Visual Visual & Review Each Lot IS 2062 LTCD/QAQC/STR/02 CP RP

-do100% 100%

-doDrgs, BOQ & P.O requirements -do-

CP CP CP

RP RP RP

( Mtc Should have MR No. & Receipt Date Stamp.

Steel for gratings, chequered a. Mechanical Review MTC plate, hand rail etc. b.Dimensional & external defects Measurement steel Plates & visual c) UT test for lamination check - As applicableInspection Welding Electrodes Make, identification & certification mark Visual

Each Lot 100% Random Each lot

IS 2062 or equivalent Drgs, BOM & P.O requirements IS 3644 IS 815,816 ASME SEC -II part-C IS 3757 IS 6623 IS 1367 -doDrgs, BOM & P.O requirements Client spec. / Mfg. literture / IS codes or equivalent IS - 2074

LTCD/QAQC/STR/02

CP CP

RP RP

Register

CP

RP

Register to Contain Receipt & Issue Information

Fasteners -Mild steel & High strength friction grip bolts/ Foundation Bolts

a. Mechanical b. Chemical c. Dimensional & external defects Make, identification & certification mark

Review of Manu. Each manu. Certificates and heat batch -doMeasurement & Visual Visual -do100% Each lot

LTCD/QAQC/STR/02

CP CP CP

RP RP RP RP

PAINTS

LTCD/QAQC/STR/02

CP

LEGEND :

MTC : MATERIAL TEST CERTIFICATE LTR :LAB TEST REPORT SIR : MATERIAL INSPECTION RECORD

MIR : MATERIAL INSPECTION REPORT

CP : CHECK POINT WP :WITNESS POINT RP : REVIEW POINT

HP : HOLD POINT

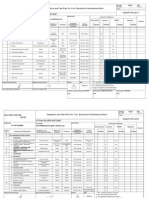

LARSEN & TOUBRO LIMITED

ECC DIVISION

ECCD

DOC No. : LTCD/ITP/STR Approved By : NATURE OF CHECK/INSPECTION Rev : 0 DATE : Method of Check Freequency of Check Dept : QA / QC

CLIENT : IOCL

PAGE :

2 OF 4

10.02 INSPECTION & TEST PLAN - STRUCTURAL WORKS

Sr. No. ACTIVITY Reference Procedure / Document Format for Record LTCD/QAQC/WPS LTCD/QAQC/PQR LTCD/QAQC/STR/WEL/01 LTCD/QAQC/STR/03 Inspection Authority L&T-ECCD CLIENT REMARKS

2 In Process Inspection

2.1 Welding qualification test 2.1.1 WPS/PQR 2.1.2 WELDER Qualification test 2.2 Structural fabrication 2.2.1 Fitup 2.2.2 Edge Preparation 2.3 Welded Joints Structural works Doc. Review Testing Measurement & Visual Measurement & Visual Visual 100% -do100% 100% IS 7307,ASME IX / Equivalent IS 817 / IS 7370 Drawings / Technical spec. AWS D1.1 / Technical Spec. AWS D 1.1 / IS 9595 -doCP CP CP CP RP WP RP RP

2.3.1 Butt welds to major structural components like beams,columns bracings, base plates etc. 2.3.2 Fillet welds to major structural components like reinforcements to flange / web of rolled Sections , End plates, 'base plates,Splices & Gusset plates, etc.

100%

LTCD/QAQC/STR/04

WP

RP

Visual

100%

WP

RP

2.4 NDT on completed weld joints Surface & Internal Weld defects a) UT test - As applicable b. DPT - as applicable 2.5 Painting

Testing

1 test per 50 T

ASME Sec.V / Tech spec. As Per Tech. Spec. IS - 2074 Mfg.recomm/ IS 5 IS 1477

LTCD/QAQC/STR/05 LTCD/QAQC/STR/06 LTCD/QAQC/STR/08

CP

WP

2.5.1 Cleaning with wire Brushes & sand papering Surface Finish

As Per Tech. Spec. 100% Random

CP

RP

2.5.2 Surface Coating 2.5.3 Application LEGEND : MTC : MATERIAL TEST CERTIFICATE LTR :LAB TEST REPORT SIR : MATERIAL INSPECTION RECORD

Visual &DFT Visual

LTCD/QAQC/STR/08 LTCD/QAQC/STR/08 CP : CHECK POINT WP :WITNESS POINT RP : REVIEW POINT

CP CP

RP RP

MIR : MATERIAL INSPECTION REPORT

HP : HOLD POINT

LARSEN & TOUBRO LIMITED

ECC DIVISION

ECCD

DOC No. : LTCD/ITP/STR Approved By : NATURE OF CHECK/INSPECTION Rev : 0 DATE : Method of Check Visual Freequency of Check Complete Dept : QA / QC

CLIENT : IOCL

PAGE :

3 OF 4

10.02 INSPECTION & TEST PLAN - STRUCTURAL WORKS

Sr. No. ACTIVITY Reference Procedure / Document Drgs/Tech. Specs Format for Record LTCD/QAQC/STR/04 Inspection Authority L&T-ECCD CLIENT CP RP REMARKS

3 Final Inspection Assembly

Dimensions,match marking, Painting & Completeness Visual & Alignment

4 Erection Check foundation for proper location & orientation as per level / elevation. Check Foundation Bolts/ Size/Location/Alignment Check erected columns / beams etc. before grouting 5 Grouting 5.1 Grouting with Non-Shrink Grout

Visual & Alignment -do-

Visual,Water level, spirit level, plump pob, Theodolite Visual & Measurement -do-

100%

Drgs

LTCD/QAQC/STR/07

CP

RP

100% 100%

Drgs./Tech.Specs Drgs LTCD/QAQC/STR/07

CP CP

RP WP

Material Fluidity and expansion of Grout Material - Surface preparation - Supports and grout tightness of form work -Check for mixing & W/C Ratio -Verify estimated and consumed Qty -Curing -Final Inspection

Review of Tc Inspection Inspection Inspection Inspection Inspection Visual

Every Batch 100% 1 1 1 1 1

Method Statement -do-do-do-do-doLTCD/QAQC/STR/01 CP : CHECK POINT WP :WITNESS POINT RP : REVIEW POINT

CP CP CP CP CP CP CP

RP RP RP RP RP RP RP

LEGEND :

MTC : MATERIAL TEST CERTIFICATE LTR :LAB TEST REPORT SIR : MATERIAL INSPECTION RECORD

MIR : MATERIAL INSPECTION REPORT

HP : HOLD POINT

LARSEN & TOUBRO LIMITED

ECC DIVISION

ECCD

DOC No. : LTCD/ITP/STR Approved By : NATURE OF CHECK/INSPECTION Materials -Cement -Sand Grading -Surface preparation -Mix preparation -Form work grout tightness, Supports Mixing -Placing and compaction -Curing -Final Inspection -Check for Material -Check for sequence of Sheeting -Check for metering / Overlap -Slopes. Lines. Levels of Sheets -Barge Boards, Ridges & Gutters -Checks for slopes of rain Gutters,Downtake Pipes & Supports of Gutters -Check for Overhang of Sheets -Check for Proper size of bolts, Washers & Leak in any final inspection Rev : 0 DATE : Method of Check Review of Tc Lab Test Inspection Inspection Inspection Inspection Inspection Inspection Inspection Inspection Inspection Inspection Inspection Inspection Inspection Inspection Freequency of Check Every Batch 1 1 100% 1 1 100% 1 1 per source 1 100% 100% 100% 1 1 1 Dept : QA / QC

CLIENT : IOCL

PAGE :

4 OF 4

10.02 INSPECTION & TEST PLAN - STRUCTURAL WORKS

Sr. No. ACTIVITY Reference Procedure / Document Tech Specs Tech Specs Tech Specs Tech Specs Tech Specs Tech Specs Tech Specs Drawings Drawings Drawings Drawings Drawings Drawings WP/FIN/09 LTCD/QAQC/FIN/09 Format for Record Inspection Authority L&T-ECCD CLIENT CP CP CP CP CP CP CP CP CP CP CP CP CP CP CP CP RP RP RP RP RP REMARKS 5.2 Grouting with Cement Grout

LTR

LTCD/QAQC/STR/01

RP WP WP RP RP RP RP RP RP RP RP

6 GI Sheeting

LEGEND :

MTC : MATERIAL TEST CERTIFICATE LTR :LAB TEST REPORT SIR : MATERIAL INSPECTION RECORD

MIR : MATERIAL INSPECTION REPORT

CP : CHECK POINT WP :WITNESS POINT RP : REVIEW POINT

HP : HOLD POINT

You might also like

- Inspection Test Plan For Fabrication & Erection 2016Document14 pagesInspection Test Plan For Fabrication & Erection 2016Boj Mingi0% (1)

- INSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFDocument7 pagesINSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFgst ajah100% (4)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- QA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)Document10 pagesQA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)miaicarba100% (2)

- Inspection & Test Plan for SEPCOIII Electric Power Construction CorporationDocument3 pagesInspection & Test Plan for SEPCOIII Electric Power Construction Corporationtrey100% (4)

- Inspection and Test Plan For Steel StrucDocument6 pagesInspection and Test Plan For Steel Strucwawan gunawan100% (1)

- Inspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Document8 pagesInspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Santosh Kumar Bogela100% (12)

- ITP For Steel Structure1Document3 pagesITP For Steel Structure1吴兴泊No ratings yet

- ITP - Fabrication of Structural SteelDocument2 pagesITP - Fabrication of Structural Steelsahad100% (6)

- ITP AllDocument1 pageITP AllMuhammadIqbalMughalNo ratings yet

- Inspection Test Plan For FabricationDocument4 pagesInspection Test Plan For FabricationAshwani Dogra100% (9)

- Itp For Steel Structure Erection (Content) Rev.1Document3 pagesItp For Steel Structure Erection (Content) Rev.1Anonymous nLMJGu100% (5)

- X6 Structural Steel Erection Inspection Test PlanDocument11 pagesX6 Structural Steel Erection Inspection Test PlanNoor A Qasim100% (1)

- ITP Structural SteelDocument14 pagesITP Structural SteelNavneet SinghNo ratings yet

- FM-D-01 Steel Structure ErectionDocument1 pageFM-D-01 Steel Structure ErectionG Vamsi ChandNo ratings yet

- ITP ErectionDocument3 pagesITP Erectionjanpaul2481No ratings yet

- Fabrication Procedure Steel Structure TSEDocument21 pagesFabrication Procedure Steel Structure TSEspazzbgt67% (6)

- Owner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionDocument5 pagesOwner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionLuqman OsmanNo ratings yet

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- ITP For Pipeline (Sampel)Document5 pagesITP For Pipeline (Sampel)Reza RkndNo ratings yet

- Fabrication Division QMDDocument11 pagesFabrication Division QMDRakesh RanjanNo ratings yet

- QCF108 Grouting Inspection ReportDocument1 pageQCF108 Grouting Inspection Reportminhnn100% (3)

- Inspection Plan TemplateDocument1 pageInspection Plan Templatedennis386100% (1)

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionDocument2 pagesInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- Inspection Test PlanDocument6 pagesInspection Test PlanMOST PASON100% (1)

- ITP Fencing Rev - 00 PDFDocument3 pagesITP Fencing Rev - 00 PDFanon_987276020No ratings yet

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Structural Steel Checklist 17Document2 pagesStructural Steel Checklist 17mgb2010hotmailcomNo ratings yet

- QAPDocument46 pagesQAPAkash Singh TomarNo ratings yet

- Structural Steel Work Check ListDocument1 pageStructural Steel Work Check ListAhmad BilalNo ratings yet

- QUALITY ASSURANCE PROTOCOLDocument2 pagesQUALITY ASSURANCE PROTOCOLShah Newaz KabirNo ratings yet

- Welder Test Param19!03!201211Document151 pagesWelder Test Param19!03!201211VapaVapaNo ratings yet

- ItpDocument7 pagesItpJose Sherin100% (1)

- ITP - Steel ErectionDocument10 pagesITP - Steel ErectionGhayas RanjhaNo ratings yet

- Check List of Steel Structure ErectionDocument1 pageCheck List of Steel Structure ErectionUtku Can Kılıç50% (2)

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanNESTOR YUMULNo ratings yet

- INSPECTION AND TEST PLAN - Driven of Pre Cast Concrete Piles PDFDocument3 pagesINSPECTION AND TEST PLAN - Driven of Pre Cast Concrete Piles PDFmustafaNo ratings yet

- 026-Itp For Structural Steel PDFDocument18 pages026-Itp For Structural Steel PDFKöksal Patan100% (11)

- QC FORMDocument3 pagesQC FORMRicardo LourençoNo ratings yet

- Steel Structure Fabrication Inspection ReportDocument1 pageSteel Structure Fabrication Inspection ReportFerhan Dikilitaş86% (14)

- L&T GeoStructure casing inspection planDocument2 pagesL&T GeoStructure casing inspection plansanil50% (2)

- ITP For Pipeline Construction Table 1Document3 pagesITP For Pipeline Construction Table 1wahyu100% (2)

- QC Inspection and Test PlanDocument9 pagesQC Inspection and Test PlanGK VISWANATH100% (3)

- Itp For Storage TanksDocument7 pagesItp For Storage TanksHamid MansouriNo ratings yet

- Fabrication and Inspection ChecklistsDocument12 pagesFabrication and Inspection ChecklistsSuresh ShuklaNo ratings yet

- Field ITP Civil Rev-8after Lump-Sump.Document17 pagesField ITP Civil Rev-8after Lump-Sump.Echik Kici100% (3)

- Structural Steel Installation ChecklistDocument1 pageStructural Steel Installation Checklistboz vanduyn100% (1)

- Inspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksDocument9 pagesInspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksDelta akathehuskyNo ratings yet

- Method Statement - Structural Steel Erection Methodology For Dome & Connecting Bridge - VR MallDocument19 pagesMethod Statement - Structural Steel Erection Methodology For Dome & Connecting Bridge - VR MallAkash YadavNo ratings yet

- Itp For Structural Steel WorkDocument12 pagesItp For Structural Steel Worknguyen thangNo ratings yet

- Inspection and Testing PlanDocument7 pagesInspection and Testing PlanStephen David Gozun50% (2)

- Check List For Connection BoltsDocument1 pageCheck List For Connection BoltstreyNo ratings yet

- Pt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and ErectionDocument5 pagesPt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and Erectioneldobie3100% (1)

- Daily Welding Progress ReportDocument1 pageDaily Welding Progress ReportManoj KumarNo ratings yet

- ITP Format For New PVDocument8 pagesITP Format For New PVDavid LambertNo ratings yet

- Docslide - Us - Itp Structural WorkDocument4 pagesDocslide - Us - Itp Structural Workomda4wadyNo ratings yet

- Itp For Main SteelaaaaaaDocument4 pagesItp For Main SteelaaaaaaaymanmalahNo ratings yet

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- Piping Scope: Construction Area Sum of Total Inch Dia Sum of Total Inch MeterDocument1 pagePiping Scope: Construction Area Sum of Total Inch Dia Sum of Total Inch Metermanu_giteNo ratings yet

- Details of Hanger Clamps Table For Mut Project: BCPA-W-4-C1Document2 pagesDetails of Hanger Clamps Table For Mut Project: BCPA-W-4-C1manu_giteNo ratings yet

- Ibr FormsDocument152 pagesIbr Formsmanu_giteNo ratings yet

- Carbon FootprintDocument4 pagesCarbon Footprintmanu_giteNo ratings yet

- BOQ FittingsDocument8 pagesBOQ Fittingsmanu_giteNo ratings yet

- Proforma of Declaration of Black Listing/Holiday ListingDocument3 pagesProforma of Declaration of Black Listing/Holiday Listingmanu_giteNo ratings yet

- Check Valve A2 800 MSD 793Document1 pageCheck Valve A2 800 MSD 793manu_giteNo ratings yet

- New TBR Mat ReqDocument6 pagesNew TBR Mat Reqmanu_giteNo ratings yet

- Ball Valve A2 800 MSD 792Document1 pageBall Valve A2 800 MSD 792manu_giteNo ratings yet

- Texas Flange: Dimensions of Ring-Joint FacingsDocument6 pagesTexas Flange: Dimensions of Ring-Joint Facingsmanu_giteNo ratings yet

- Carbon Footprint Strategy 40 CharactersDocument3 pagesCarbon Footprint Strategy 40 Charactersmanu_giteNo ratings yet

- Oisd 118Document34 pagesOisd 118manu_gite100% (1)

- MTC (JSL & MSL)Document2 pagesMTC (JSL & MSL)manu_giteNo ratings yet

- Texas Flange: Dimensions of Ring-Joint FacingsDocument6 pagesTexas Flange: Dimensions of Ring-Joint Facingsmanu_giteNo ratings yet

- SUMMARY OF SCHEDULED SIZES (All Dimensions in MM)Document2 pagesSUMMARY OF SCHEDULED SIZES (All Dimensions in MM)manu_giteNo ratings yet

- Density of MetalsDocument3 pagesDensity of Metalsmanu_giteNo ratings yet

- Lafarge Quality Control PlanDocument64 pagesLafarge Quality Control Planmanu_giteNo ratings yet

- S BeamDocument1 pageS Beammanu_giteNo ratings yet

- Weights of ISMB, ISA, ISMCDocument7 pagesWeights of ISMB, ISA, ISMCnavikumar_nr87% (97)

- APM Terminals Safety Policy SummaryDocument1 pageAPM Terminals Safety Policy SummaryVaviNo ratings yet

- Group 4-Hospital Information System - His - QuizDocument2 pagesGroup 4-Hospital Information System - His - QuizGeeyan Marlchest B NavarroNo ratings yet

- 3) Stages of Group Development - To StudsDocument15 pages3) Stages of Group Development - To StudsDhannesh SweetAngelNo ratings yet

- 9IMJan 4477 1Document9 pages9IMJan 4477 1Upasana PadhiNo ratings yet

- Individual Differences: Mental Ability, Personality and DemographicsDocument22 pagesIndividual Differences: Mental Ability, Personality and DemographicsAlera Kim100% (2)

- Tutorial 5 HExDocument16 pagesTutorial 5 HExishita.brahmbhattNo ratings yet

- 7th Kannada Science 01Document160 pages7th Kannada Science 01Edit O Pics StatusNo ratings yet

- 13-07-01 Declaration in Support of Skyhook Motion To CompelDocument217 pages13-07-01 Declaration in Support of Skyhook Motion To CompelFlorian MuellerNo ratings yet

- Shoib CV Scaffold EngineerDocument3 pagesShoib CV Scaffold EngineerMohd Shoib100% (1)

- ITS America's 2009 Annual Meeting & Exposition: Preliminary ProgramDocument36 pagesITS America's 2009 Annual Meeting & Exposition: Preliminary ProgramITS AmericaNo ratings yet

- PNB - Recruitment For The Post of Chief Security OfficerDocument3 pagesPNB - Recruitment For The Post of Chief Security OfficerCareerNotifications.comNo ratings yet

- Royal Enfield Market PositioningDocument7 pagesRoyal Enfield Market PositioningApoorv Agrawal67% (3)

- PTAS-11 Stump - All About Learning CurvesDocument43 pagesPTAS-11 Stump - All About Learning CurvesinSowaeNo ratings yet

- Q&A Session on Obligations and ContractsDocument15 pagesQ&A Session on Obligations and ContractsAnselmo Rodiel IVNo ratings yet

- Chapter 7 - Cash BudgetDocument23 pagesChapter 7 - Cash BudgetMostafa KaghaNo ratings yet

- 2022 Product Catalog WebDocument100 pages2022 Product Catalog WebEdinson Reyes ValderramaNo ratings yet

- POS CAL SF No4 B2 BCF H300x300 7mmweld R0 PDFDocument23 pagesPOS CAL SF No4 B2 BCF H300x300 7mmweld R0 PDFNguyễn Duy QuangNo ratings yet

- Weibull Statistic and Growth Analysis in Failure PredictionsDocument9 pagesWeibull Statistic and Growth Analysis in Failure PredictionsgmitsutaNo ratings yet

- C 7000Document109 pagesC 7000Alex Argel Roqueme75% (4)

- Milton Hershey's Sweet StoryDocument10 pagesMilton Hershey's Sweet Storysharlene sandovalNo ratings yet

- Mini Ice Plant Design GuideDocument4 pagesMini Ice Plant Design GuideDidy RobotIncorporatedNo ratings yet

- Defect Prevention On SRS Through ChecklistDocument2 pagesDefect Prevention On SRS Through Checklistnew account new accountNo ratings yet

- Expert Business Analyst Darryl Cropper Seeks New OpportunityDocument8 pagesExpert Business Analyst Darryl Cropper Seeks New OpportunityRajan GuptaNo ratings yet

- DrugDocument2 pagesDrugSaleha YounusNo ratings yet

- Proposed Delivery For PAU/AHU Method Statement SEC/MS/3-25Document4 pagesProposed Delivery For PAU/AHU Method Statement SEC/MS/3-25Zin Ko NaingNo ratings yet

- Palmetto Bay's Ordinance On Bird RefugeDocument4 pagesPalmetto Bay's Ordinance On Bird RefugeAndreaTorresNo ratings yet

- SAP PS Step by Step OverviewDocument11 pagesSAP PS Step by Step Overviewanand.kumarNo ratings yet

- Abb Drives: User'S Manual Flashdrop Mfdt-01Document62 pagesAbb Drives: User'S Manual Flashdrop Mfdt-01Сергей СалтыковNo ratings yet

- Computers As Components 2nd Edi - Wayne WolfDocument815 pagesComputers As Components 2nd Edi - Wayne WolfShubham RajNo ratings yet

- 3.4 Spending, Saving and Borrowing: Igcse /O Level EconomicsDocument9 pages3.4 Spending, Saving and Borrowing: Igcse /O Level EconomicsRingle JobNo ratings yet