Professional Documents

Culture Documents

Fast Clad Urethane Spec Sheet

Uploaded by

Scott Van PeltCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fast Clad Urethane Spec Sheet

Uploaded by

Scott Van PeltCopyright:

Available Formats

Protective & Marine Coatings

Revised 2/11

FAST CLAD URETHANE

PART A PART A PART B B65-950 SERIES B65-960 SERIES B65V950 SEMI-GLOSS GLOSS HARDENER

5.26

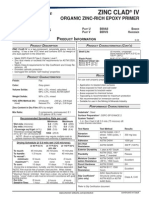

PRODUCT DESCRIPTION

FAST CLAD URETHANE is a fast dry, single coat, polyaspartic urethane specically formulated for accelerated maintenance painting. Fast drying minimizes dust and grit "pick-up" Allows entire maintenance coating systems to be completed in one shift Single coat application High lm build in one coat No gassing Outstanding application properties

RECOMMENDED USES

Ideal for use as a nish coat for projects requiring rapid return to service, such as bridge maintenance painting. Use directly over organic zinc rich primers Can be used in various coatings applications where fast cure-to-service is desired, such as: Bridges Hand rails Structural steel High visibility areas Wind Towers - onshore and offshore Acceptable for use in high performance architectural applications. Suitable for use in USDA inspected facilities

PRODUCT CHARACTERISTICS

Finish: Color: Volume Solids: Weight Solids: VOC (EPA Method 24): Mix Ratio: Semi-gloss or gloss Wide range of colors possible 64% 2%, calculated and mixed May vary by color 80% 2%, mixed, may vary by color <300 g/L; 2.5 lb/gal, unreduced 4:1 by volume (Pre-measured units)

PERFORMANCE CHARACTERISTICS

Substrate*: Steel Surface Preparation*: SSPC-SP6/NACE 3 System Tested*:

1 ct. Corothane I Galvapac @ 3.0-4.0 mils (75-100 microns) dft 1 ct. Fast Clad Urethane (semi-gloss) @ 6.0-9.0 mils (150-225 microns) dft

*unless otherwise noted below

Test Name Maximum 15.0 (375) 9.0 (225) 174 (4.3) Abrasion Resistance Adhesion Corrosion Weathering

Recommended Spreading Rate per coat:

Wet mils (microns) Dry mils (microns) ~Coverage sq ft/gal (m2/L) Minimum 10.0 (250) 6.0 (150) 116 (2.8)

Test Method ASTM D4060, CS17 wheel, 1000 cycles, 1 kg load ASTM D4541 ASTM D5894, 15 cycles ASTM D522, 180 bend, > 3/4" mandrel 30 cycles ASTM B117, 5000 hours

Results 90 mg loss 825 psi Rating 10 per ASTM D714 for blistering; Rating 10 per ASTM D610 for rusting Passes No loss of Patti Adhesion Rating 10 per ASTM D714 for blistering; Rating 10 per ASTM D610 for rusting

Theoretical coverage sq ft/gal 1024 (25.0) (m2/L) @ 1 mil / 25 microns dft NOTE: Brush or roll application may require multiple coats to achieve maximum lm thickness and uniformity of appearance.

Drying Schedule @ 10.0 mils wet (250 microns):

@ 35F/1.6C @ 77F/25C 50% RH @ 120F/49C

Flexibility Freeze/Thaw Stability Salt Fog Resistance

To touch: To handle: To recoat: minimum: maximum: To cure: Pot Life: Sweat-in-Time:

1.5 hours 3 hours 3 hours 36 hours 4 days 3 hours

30 minutes 45 minutes 45 minutes 24 hours 2 days 2 hours None

15 minutes 30 minutes 30 minutes 24 hours 24 hours 30 minutes

Pot life is temperature and humidity dependent. If maximum recoat time is exceeded, abrade surface before recoating. Drying time is temperature, humidity, and lm thickness dependent.

Tested in accordance with NTPEP (National Transportation Product Evaluation Program) requirements as outlined by AASHTO Designation R31-02.

Shelf Life:

Flash Point: Reducer/Clean Up: Below 80F (27C): Above 80F (27C): Brush / Roll:

Part A - 24 months, unopened Part B - 24 months, unopened Store indoors at 40F (4.5C) to 100F (38C). 55F (13C), PMCC, mixed MEK, R6K10 Reducer R7K216 Reducer R7K216

Meets the requirements of SSPC Paint 39, Level III (QUV). Complies with ISO 12944-5 C5I and C5M requirements.

www.sherwin-williams.com/protective

continued on back

Protective & Marine Coatings

RECOMMENDED SYSTEMS

FAST CLAD URETHANE

PART A PART A PART B B65-950 SERIES B65-960 SERIES B65V950 SEMI-GLOSS GLOSS HARDENER

5.26

PRODUCT INFORMATION

SURFACE PREPARATION

Dry Film Thickness / ct. Mils (Microns) Steel: 1 ct. Corothane I GalvaPac Zinc Primer 1 ct. Fast Clad Urethane Steel: 1 ct. Macropoxy 646 1 ct. Fast Clad Urethane Concrete, masonry: 1 ct. Kem Cati-Coat HS Epoxy Filler/Sealer 1 ct. Fast Clad Urethane Aluminum/Galvanizing: 1 ct. DTM Wash Primer 1 ct. Fast Clad Urethane ISO 12944 C5M System: 1 ct. Zinc Clad III HS 1 ct. Fast Clad Urethane or 1 ct. Corothane I GalvaPac Zinc Primer 1 ct. Fast Clad Urethane *Other acceptable primers: Fast Clad Zinc HS Steel Spec Epoxy Primer Zinc Clad III HS Zinc Clad IV 3.0-4.0* 6.0-9.0 (75-100) (150-225)

5.0-10.0 6.0-9.0

(125-250) (150-225)

10.0-20.0 (250-500) 6.0-9.0 (150-225)

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, loose rust, and other foreign material to ensure adequate adhesion. Refer to product Application Bulletin for detailed surface preparation information. Minimum recommended surface preparation: **Iron & Steel: SSPC-SP6, 2 mil (50 micron) prole **Concrete/Masonry: SSPC-SP13/NACE 6, or ICRI No. 310.2, CSP1-3 **Aluminum/Galvanizing: SSPC-SP1 Spot Prime / Touch-up: SSPC-SP3 **Primer required

Surface Preparation Standards

Condition of Surface White Metal Near White Metal Commercial Blast Brush-Off Blast Hand Tool Cleaning Rusted Rusted Pitted & Power Tool Cleaning Rusted Rusted Pitted & ISO 8501-1 BS7079:A1 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 Swedish Std. SIS055900 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 SSPC SP 5 SP 10 SP 6 SP 7 SP 2 SP 2 SP 3 SP 3 NACE 1 2 3 4 -

0.7-1.3 6.0-9.0

(18-32) (150-225)

TINTING

3.0-5.0 6.0-9.0 3.0-4.0 6.0-9.0 (75-125) (150-225) (75-100) (150-225) Tint with Maxitoner colorants only into Part A at 100% tint strength. Five minutes minimum of mixing on a mechanical shaker is required for complete mixing of color.

APPLICATION CONDITIONS

Temperature: 20F (-7C) minimum, 120F (49C) maximum (air, surface, and material) At least 5F (2.8C) above dew point Relative humidity: 85% maximum Refer to product Application Bulletin for detailed application information.

ORDERING INFORMATION

Components are pre-measured for either 1 gallon (3.78L) mixes or 5 gallon (18.9L) mixes. Packaging : Part A: 1 gallon (3.78L) - short lled 4 gallon (15.1L) - short lled 5 gallon (18.9L) pail Part B: 1 quart (0.94L) - short lled 1 gallon (3.78L) Weight: 12.0 0.2 lb/gal ; 1.44 Kg/L, mixed (may vary with color)

SAFETY PRECAUTIONS

The systems listed above are representative of the product's use, other systems may be appropriate.

Refer to the MSDS sheet before use. Published technical data and instructions are subject to change without notice. Contact your Sherwin-Williams representative for additional technical data and instructions.

DISCLAIMER

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommendations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your SherwinWilliams representative to obtain the most recent Product Data Information and Application Bulletin.

WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control procedures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

www.sherwin-williams.com/protective

Protective & Marine Coatings

Revised 2/11

FAST CLAD URETHANE

PART A PART A PART B B65-950 SERIES B65-960 SERIES B65V950 SEMI-GLOSS GLOSS HARDENER

5.26

APPLICATION BULLETIN

SURFACE PREPARATIONS APPLICATION CONDITIONS

Temperature:

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, loose rust, and other foreign material to ensure adequate adhesion. Iron & Steel (primer required) Remove all oil and grease from surface by Solvent Cleaning per SSPC-SP1. Minimum surface preparation is Commercial Blast Cleaning per SSPC-SP6/NACE 3. For better performance, use Near White Metal Blast Cleaning per SSPC-SP10/NACE 2. Blast clean all surfaces using a sharp, angular abrasive for optimum surface prole (2 mils / 50 microns). Prime any bare steel the same day as it is cleaned or before ash rusting occurs. Aluminum Remove all oil, grease, dirt, oxide and other foreign material by Solvent Cleaning per SSPC-SP1. Primer required. Galvanized Steel Allow to weather a minimum of six months prior to coating. Solvent Clean per SSPC-SP1. When weathering is not possible, or the surface has been treated with chromates or silicates, rst Solvent Clean per SSPC-SP1 and apply a test patch. Allow paint to dry at least one week before testing adhesion. If adhesion is poor, brush blasting per SSPC-SP7 is necessary to remove these treatments. Rusty galvanizing requires a minimum of Hand Tool Cleaning per SSPC-SP2, prime the area the same day as cleaned or before ash rusting occurs. Primer required. Concrete and Masonry For surface preparation, refer to SSPC-SP13/NACE 6, or ICRI No. 310.2, CSP 1-3. Surfaces should be thoroughly clean and dry. Concrete and mortar must be cured at least 28 days @ 75F (24C). Remove all loose mortar and foreign material. Surface must be free of laitance, concrete dust, dirt, form release agents, moisture curing membranes, loose cement and hardeners. Fill bug holes, air pockets and other voids with Steel-Seam FT910. Primer required. Follow the standard methods listed below when applicable: ASTM D4258 Standard Practice for Cleaning Concrete. ASTM D4259 Standard Practice for Abrading Concrete. ASTM D4260 Standard Practice for Etching Concrete. ASTM F1869 Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete. SSPC-SP 13/Nace 6 Surface Preparation of Concrete. ICRI No. 310.2 Concrete Surface Preparation.

20F (-7C) minimum, 120F (49C) maximum (air, surface, and material) At least 5F (2.8C) above dew point 85% maximum

Relative humidity:

APPLICATION EQUIPMENT

The following is a guide. Changes in pressures and tip sizes may be needed for proper spray characteristics. Always purge spray equipment before use with listed reducer. Any reduction must be compliant with existing VOC regulations and compatible with the existing environmental and application conditions. Reducer/Clean Up Below 80F ....................R6K10 (MEK) Above 80F ....................R7K216 Brush and roll .................R7K216 Airless Spray Pump..............................30:1 Pressure.........................2800 - 3000 psi Hose...............................3/8" ID Tip ...................................017" - .021" Filter ...............................60 mesh Reduction .......................As needed up to 5% by volume Conventional Spray Gun ................................Binks Cap ................................63P Fluid Tip .........................69PB Atomization Pressure .....50-70 psi Fluid Pressure ................20-25 psi Reduction .......................As needed up to 5% by volume Brush (small areas only) Brush..............................Natural Bristle Reduction .......................R7K216, up to 5% by volume Roller (small areas only) Cover .............................1/4" woven with solvent resistant core Reduction .......................R7K216, up to 5% by volume

Surface Preparation Standards

ISO 8501-1 BS7079:A1 White Metal Sa 3 Near White Metal Sa 2.5 Commercial Blast Sa 2 Brush-Off Blast Sa 1 Rusted Hand Tool Cleaning Pitted & Rusted C St 2 D St 2 Power Tool Cleaning Rusted Rusted C St 3 Pitted & D St 3 Condition of Surface Swedish Std. SIS055900 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 SSPC SP 5 SP 10 SP 6 SP 7 SP 2 SP 2 SP 3 SP 3 NACE 1 2 3 4 -

If specic application equipment is not listed above, equivalent equipment may be substituted.

www.sherwin-williams.com/protective

continued on back

Protective & Marine Coatings

APPLICATION PROCEDURES

Surface preparation must be completed as indicated.

FAST CLAD URETHANE

PART A PART A PART B B65-950 SERIES B65-960 SERIES B65V950 SEMI-GLOSS GLOSS HARDENER

5.26

APPLICATION BULLETIN

PERFORMANCE TIPS

Stripe coat all crevices, welds, and sharp angles to prevent early failure in these areas. When using spray application, use a 50% overlap with each pass of the gun to avoid holidays, bare areas, and pinholes. If necessary, cross spray at a right angle. Spreading rates are calculated on volume solids and do not include an application loss factor due to surface prole, roughness or porosity of the surface, skill and technique of the applicator, method of application, various surface irregularities, material lost during mixing, spillage, overthinning, climatic conditions, and excessive lm build.

Mix contents of each component thoroughly with low speed power agitation. Make certain no pigment remains on the bottom of the can. Then combine 4 parts by volume of Part A with 1 part by volume of Part B. Thoroughly agitate the mixture with power agitation. If reducer solvent is used, add only after both components have been thoroughly mixed.

Apply paint at the recommended lm thickness and spreading Excessive reduction of material can affect lm build, appearance, and rate as indicated below: adhesion.

Recommended Spreading Rate per coat:

Wet mils (microns) Dry mils (microns) ~Coverage sq ft/gal (m2/L) Minimum 10.0 (250) 6.0 (150) 116 (2.8) Maximum 15.0 (375) 9.0 (225) 174 (4.3)

Do not apply the material beyond recommended pot life. Do not mix previously catalyzed material with new. In order to avoid blockage of spray equipment, clean equipment before use or before periods of extended downtime with Reducer R6K10 (MEK). When used as part of a rapid recoat system for bridge maintenance painting over Corothane I Galvapac Primer, use 4 oz. per gallon of the KA Accelerator, B65V11, in the Galvapac Primer. This will allow topcoating within 1-2 hours. Mixed coating is sensitive to water. Use water traps in all air lines. Moisture contact can reduce pot life and affect gloss and color. Pot life will be shorter with high humidity and large volume of material Recoat time may be shorter with high humidity during curing / drying stages Floating a small amount of MEK R6K10 over the top of mixed material may help extend pot life.

Theoretical coverage sq ft/gal 1024 (25.0) (m2/L) @ 1 mil / 25 microns dft NOTE: Brush or roll application may require multiple coats to achieve maximum lm thickness and uniformity of appearance.

Drying Schedule @ 10.0 mils wet (250 microns):

@ 35F/1.6C @ 77F/25C 50% RH @ 120F/49C

To touch: To handle: To recoat: minimum: maximum: To cure: Pot Life: Sweat-in-Time:

1.5 hours 3 hours 3 hours 36 hours 4 days 3 hours

30 minutes 45 minutes 45 minutes 24 hours 2 days 2 hours None

15 minutes 30 minutes 30 minutes 24 hours 24 hours 30 minutes

Pot life is temperature and humidity dependent. If maximum recoat time is exceeded, abrade surface before recoating. Drying time is temperature, humidity, and lm thickness dependent.

Application of coating above maximum or below minimum recommended spreading rate may adversely affect coating performance.

Refer to Product Information sheet for additional performance characteristics and properties.

SAFETY PRECAUTIONS

Refer to the MSDS sheet before use. Published technical data and instructions are subject to change without notice. Contact your Sherwin-Williams representative for additional technical data and instructions.

CLEAN UP INSTRUCTIONS

Clean spills and spatters immediately with Reducer R6K10 (MEK). Clean tools immediately after use with Reducer R6K10 (MEK). Follow manufacturer's safety recommendations when using any solvent.

WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control procedures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

DISCLAIMER

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommendations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your SherwinWilliams representative to obtain the most recent Product Data Information and Application Bulletin.

www.sherwin-williams.com/protective

You might also like

- Zinc Clad IIIDocument4 pagesZinc Clad IIIScott Van PeltNo ratings yet

- Acrolon 218 HSDocument4 pagesAcrolon 218 HSAndres MoralesNo ratings yet

- Zinc Clad IVDocument4 pagesZinc Clad IVvitrolaNo ratings yet

- Coal Tar PDFDocument4 pagesCoal Tar PDFMohammadreza AsheghNo ratings yet

- 7) PPG Amercoat 385 - Pds - AiDocument4 pages7) PPG Amercoat 385 - Pds - AididbeauNo ratings yet

- DP B58W00610Document4 pagesDP B58W00610tangouzeNo ratings yet

- ZRC GALVILITE Galvanizing Repair CompoundDocument2 pagesZRC GALVILITE Galvanizing Repair CompoundRaymond LalumiereNo ratings yet

- ZRC Zero VocDocument2 pagesZRC Zero Vochksn77No ratings yet

- ZRC 3 07Document2 pagesZRC 3 07groelzjNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetDocument7 pagesAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasingheNo ratings yet

- Carbo Guard 893 SGDocument2 pagesCarbo Guard 893 SGsuzilamatsallehNo ratings yet

- SigmaCover 280Document5 pagesSigmaCover 280ajuhaseenNo ratings yet

- 385 PDS AiDocument4 pages385 PDS Ai전상문No ratings yet

- Plasite 9133 Product Data SheetDocument3 pagesPlasite 9133 Product Data SheetChris StroudNo ratings yet

- 5200 DTM AcrylicDocument4 pages5200 DTM AcrylicMarshall BravestarNo ratings yet

- Carbomastic 15 PDS 2013Document2 pagesCarbomastic 15 PDS 20134508366279No ratings yet

- Data Sheet FBEDocument4 pagesData Sheet FBEAnonymous Xaf2033No ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- 3M2216Document8 pages3M2216pat_kunal1601No ratings yet

- Roadsaver Silicone SLDocument2 pagesRoadsaver Silicone SLTeddy TPNo ratings yet

- Amercoat 370Document3 pagesAmercoat 370Victor Hugo Bustos Beltran100% (1)

- 97 145Document2 pages97 145anon_251242493No ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- 7430 - Sigmacover 630Document0 pages7430 - Sigmacover 630eraswastaNo ratings yet

- Rex ThaneDocument4 pagesRex Thanesas999333No ratings yet

- Duraplate Uhs EnglishDocument4 pagesDuraplate Uhs EnglishLuis JaraNo ratings yet

- Molub Alloy 860Document3 pagesMolub Alloy 860akshatmalhotraNo ratings yet

- Carboguard 888 PDSDocument3 pagesCarboguard 888 PDSsalamrefighNo ratings yet

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Document3 pagesMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsNo ratings yet

- Alpha SP Range: DescriptionDocument3 pagesAlpha SP Range: Descriptionvicky kNo ratings yet

- Devran 224HS PdsDocument2 pagesDevran 224HS Pdsjopedro96No ratings yet

- Carbomastic 15 PDSDocument2 pagesCarbomastic 15 PDSAnonymous 4fVUDODNo ratings yet

- PDS - 7863 - Sigmacap Zinc Silicate IIDocument5 pagesPDS - 7863 - Sigmacap Zinc Silicate IIIbrahim MahranNo ratings yet

- Vacuoline 1400 SeriesDocument2 pagesVacuoline 1400 SeriesRagos SegundoNo ratings yet

- Pressure Vessel Manufacturing and Inspection RequirementsDocument30 pagesPressure Vessel Manufacturing and Inspection Requirementsr.devendran25% (4)

- Pds Psx700 Jan 2008Document3 pagesPds Psx700 Jan 2008mjayhawk28No ratings yet

- Bitumastic 300MDocument2 pagesBitumastic 300Mtharman749781No ratings yet

- Azko Coating Hjf14r r4 Es eDocument4 pagesAzko Coating Hjf14r r4 Es eKrishna KumarNo ratings yet

- Aliphatic Acrylic Polyurethane Finish CoatDocument4 pagesAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueNo ratings yet

- Amer Coat 385Document4 pagesAmer Coat 385Mehman NasibovNo ratings yet

- International Coatings System ISO 12944Document7 pagesInternational Coatings System ISO 12944jr_satishNo ratings yet

- Amerlock 400Document4 pagesAmerlock 400eternalkhutNo ratings yet

- HT Mobilgear 600 Series EngDocument2 pagesHT Mobilgear 600 Series Engmgamal1080No ratings yet

- Quality Plan 1325-27 Rev 02 - Blasting PaintingDocument10 pagesQuality Plan 1325-27 Rev 02 - Blasting Paintingsuriya100% (1)

- 323 Data Sheet and Application GuideDocument4 pages323 Data Sheet and Application Guidejast111No ratings yet

- 5 Star GroutDocument2 pages5 Star Groutchong pak limNo ratings yet

- 3M InfnDocument32 pages3M InfnAkash AkuNo ratings yet

- Description Packaging Product Data SheetDocument2 pagesDescription Packaging Product Data SheetRonald Fernandez ManubuluNo ratings yet

- 206N Fluid Bed GradeDocument4 pages206N Fluid Bed Gradepilot76No ratings yet

- Solder Paste SC Blf03: Lead-FreeDocument2 pagesSolder Paste SC Blf03: Lead-FreeluismcmcNo ratings yet

- 1040 Stangard (ST) Epoxy MasticDocument5 pages1040 Stangard (ST) Epoxy MasticMayank Gupta50% (2)

- Dacromet Coating: World Class Corrosion ProtectionDocument6 pagesDacromet Coating: World Class Corrosion Protectionmarcelogf74No ratings yet

- Plasite 7159 PDS 1-07 PDFDocument2 pagesPlasite 7159 PDS 1-07 PDFFabricio Jiménez TNo ratings yet

- Polyclad 975 H PDSDocument2 pagesPolyclad 975 H PDSLinnie McleodNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- 75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014From Everand75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014S. K. SundaramNo ratings yet

- IOM 3000 Dolphin Watercare 6-30-08Document56 pagesIOM 3000 Dolphin Watercare 6-30-08serge.danis7746100% (1)

- Hardscape Specification SummaryDocument20 pagesHardscape Specification SummarychialunNo ratings yet

- 14 Hand Pump Spares List From BIS PDFDocument125 pages14 Hand Pump Spares List From BIS PDFNaresh Babu MuddamsettiNo ratings yet

- Metal WorksDocument4 pagesMetal WorksKhristine Lerie PascualNo ratings yet

- New BS EN CodesDocument2 pagesNew BS EN Codessivaraju1No ratings yet

- Cable Tray: BA BADocument12 pagesCable Tray: BA BAsubramanyaNo ratings yet

- Design and Behavior of Steel StructuresDocument87 pagesDesign and Behavior of Steel StructuresMaqMaikNo ratings yet

- Astm A 767 - A 767MDocument4 pagesAstm A 767 - A 767Meddyew100% (1)

- Step7 Corrosion GuideDocument18 pagesStep7 Corrosion GuideShariff Zaffar100% (1)

- Saic M 1032Document3 pagesSaic M 1032Hussain Nasser Al- NowiesserNo ratings yet

- Unified SOR Inte RevisedDocument70 pagesUnified SOR Inte RevisedAncil AlexNo ratings yet

- How Not To Slackline - Bolting BibleDocument134 pagesHow Not To Slackline - Bolting BiblePoccort00No ratings yet

- How To Use The Sinclair Clamp Selection Guide: Rev 9.0 January 3, 2012Document32 pagesHow To Use The Sinclair Clamp Selection Guide: Rev 9.0 January 3, 2012Touati HoudjedjNo ratings yet

- Painting Procedure OptimizationDocument6 pagesPainting Procedure Optimizationmahan moradiNo ratings yet

- Recubrimiento ProtectorDocument62 pagesRecubrimiento ProtectorWitchfinder GeneralNo ratings yet

- Kundalia RB Project - Cage Ladder QAPDocument2 pagesKundalia RB Project - Cage Ladder QAPHarshit AdwaniNo ratings yet

- Union Wire Rope - Galfan CoatingDocument1 pageUnion Wire Rope - Galfan CoatingBosNo ratings yet

- Procedure for Fireproofing InstallationDocument13 pagesProcedure for Fireproofing InstallationRodelio RemoNo ratings yet

- Riser & Lateral System: Unique Modular Pe System For Multi Occupancy DwellingsDocument7 pagesRiser & Lateral System: Unique Modular Pe System For Multi Occupancy DwellingsRafael GranadoNo ratings yet

- Section 130 Jet Blast ScreenDocument10 pagesSection 130 Jet Blast ScreenKwan Chun SingNo ratings yet

- Parts Illustration - IT4 - C135063Document27 pagesParts Illustration - IT4 - C135063Franklin Gustavo Zagaceta Bautista0% (1)

- MDX - Specifications Doc - Bridgerail BR45Document5 pagesMDX - Specifications Doc - Bridgerail BR45200365530No ratings yet

- STRAUB TM 072019 en LQ CPDocument128 pagesSTRAUB TM 072019 en LQ CPJoaoNo ratings yet

- Meadow Burke PrecastDocument197 pagesMeadow Burke PrecastmrnaeemNo ratings yet

- JournalDocument70 pagesJournalAnonymous RxKiSLmuoNo ratings yet

- HIT-RE 500 V3 injection mortar technical datasheetDocument42 pagesHIT-RE 500 V3 injection mortar technical datasheetVance KangNo ratings yet

- Indian Schedule Rates-03Document100 pagesIndian Schedule Rates-03abbasNo ratings yet

- Practical Guidelines Inspect Repair HDG Coatings 2008Document24 pagesPractical Guidelines Inspect Repair HDG Coatings 2008forbeskaNo ratings yet

- Rexsteel English72Document10 pagesRexsteel English72Bogie Prastowo MahardhikaNo ratings yet

- Volume - IIIDocument81 pagesVolume - IIIGani Osal TyNo ratings yet