Professional Documents

Culture Documents

Armstrong Kit Sello Mecanico

Uploaded by

Giorgio FerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Armstrong Kit Sello Mecanico

Uploaded by

Giorgio FerCopyright:

Available Formats

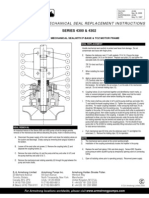

S e rie s 4 03 0, 4 2 8 0, 4 3 6 0 D, 4 3 8 0, 4 3 8 2 & 4 3 92 MECHANICAL SEAL KITS

service work instructions

File No: 40.90 Date: jan. 06, 2011 Supersedes: 40.90 Date: mar. 28, 2011

versionfranaise / versin enespaol / - armstrongintegr ated.com

Refer to appropriate service work instructions (swi) le for breakdown instructions for the pump being serviced. Mechanical seal replacement instructions are included in the pump swi. The following instructions are included for convenience.

in with bare ngers; use a clean cloth or the cardboard disc typically supplied with the seal. Contamination of the polished and lapped seat face could cause immediate leakage. 7. Replace the adapter, taking care that the seal seat is carefully guided over the shaft.

caution

Always disconnect power supply from motor before beginning service work.

seal kit installation instructions

1. Remove impeller and mechanical seal from pump or motor shaft. The mechanical seal spring and spring holder usually comes free with the impeller. The mechanical seal rotating element must be pried loose with pry bars or screwdrivers. Once loosened, the seal may be pulled free of the shaft. When removing the impeller and seal from a motor shaft, take care to retrieve the spacer from between the impeller and shaft sleeve. Store for later use. The o-ring or l-cup mounted mechanical seal seat must be pried loose from the recess in the adapter. To do this: Separate the adapter from the bearing housing or motor. A screwdriver may then be used to push the seal seat out of the adapter from the rear. Clean the shaft sleeve surface, ensuring the entire former seal elastomeric residue has been removed. Inspect for damage and replace if necessary. (See separate instructions, File No. 6042.25, for removal of the motor shaft sleeve). Inspect the water slinger and replace if damaged. Silicon carbide is a suitable replacement for ceramic, ni-resist, or tungsten carbide and is the seal seat of choice. Ceramic and silicon carbide are more brittle than ni-resist or tungsten carbide and should be handled accordingly. Install a new seal seat in the adapter cavity, being sure the lapped (polished) surface of the insert is facing up. Ensure that the cavity has been thoroughly cleaned. Lubricate the outside of the seat elastomer o-ring or l-cup with a small amount of temporary rubber lubricant emulsion and press down, straight and even, into the cavity. Do not press the seat

seal head assembly

rotating washer, bellows, retainer and drive band assembly seat old generation tangential discharge 4030, 4280, 4380 d&e and l-cup 4360d w/bracket 426990, 426991

2.

{

both seat designs used 2011 & later

spring holder

spring

seal hardware tab (typ)

seat o-ring new generation centerline discharge 4030/4280 numerical series 4380, 4360d w/bracket 426988, 426989

3.

shaft key shaft spacer*(used on old and new generation 4280 and 4380, 4360d w/jm motor frame) seat seal cavity

4.

5.

*important: Spacer may come off when old seal kit is removed. be sure it is on when installing new seal kit.

6.

caution

Do not use oil, Vaseline or other petroleum or silicon based products for seal elastomer lubrication. Otherwise elastomer swelling may occur, causing seal failure. Recommended: International Products Corp p-80 Rubber Lubricant Emulsion in usa & uk www.ipcol.com

servi ce wo r k i nstru cti o ns

Series 4030, 4280, 4360d, 4380, 4382 & 4392 Mechanical Seal Kits

8.

Lubricate the inside of the seal rotating assembly (The rubber bellows) with a small amount of temporary rubber lubricant emulsion and slide onto the shaft sleeve with a twisting motion, carbon face rst, until pressed to the carbon face. Ensure the seal is securely in place by pushing rmly with 2 screw drivers simultaneously on opposite tabs of the seal hardware.

9.

Remove the spring retainer from the seal spring and place the seal spring over the seal rotating assembly. Re-install the shaft sleeve spacer, if appropriate, and impeller key on the shaft and place the seal spring retainer onto the impeller hub register. Slide the impeller into place on the shaft, taking care and ensuring the seal spring is kept in place on the seal rotating assembly and ts well into the retainer on the impeller hub. Secure impeller and nish reassembling pump.

s - 1 . 25" seal kit part number Fluid Type Temperature Rotating Face Seat Elastomer Material Code m - 1 .625" l - 2 .125"

9 9750 01 - 817 9 9750 01 - 837 9 9750 01 - 87 7

9 9750 01 - 818 9 9750 01 - 83 8 9 9750 01 - 878

9750 0 0 - 9 82 9750 0 0 - 9 84 9750 0 0 - 9 85

9 9750 01 - 813 9 9750 01 - 833 9 9750 01 - 87 3

9750 0 0 - 9 82 9750 0 0 - 9 84 9750 0 0 - 9 85

9 9750 01 - 613 9 9750 01 - 633 9 9750 01 - 67 3

All Glycols > 30% wt conc to 200f/93c over 200f/93c

All Other Non-Potable Fluids to 200f/93c Resin bonded carbon epdm (l-cup) C-sc l epss over 200f/93c Antimony loaded carbon epdm (o-ring) ACsc o epss

Potable (Drinking) Water to 200f/93c over 200f/93c

Silicone carbide epdm (l-cup) SCsc l epss epdm (o-ring) SCsc o epss

Resin bonded carbon epdm (l-cup) C-sc l epss epdm (o-ring) C-sc o epss

Used on: 4030/4280 Centerline discharge es, 4380/4382/4392 vil & 4360d w/bracket 426988 or 426989 Seal Type: 2a Pump Construction: bf/ab/ai Stationary Seat: Silicone carbide Secondary Seal: epdm Spring: Stainless steel Rotating Hardware: Stainless steel

toronto

416 755 2291

notes: 1. Seal kit consists of rotating seal head, spring holder, stationary seal seat and o-ring or l-cup. Pump casing gasket and other minor hardware components possibly required to reassemble the pump are not included. Consult service parts bulletins for more detail. 2. o-ring and l-cup style seats are interchangeable between centerline discharge pumps. Both styles are used as standard for inside seals after October 2011. 3. o-ring and l-cup style seats are not interchangeable between centerline and legacy tangential discharge pumps.

buffalo

716 693 8813

birmingham

+44 (0) 8444 145 145

manchester

+44 (0) 8444 145 145

bangalore

+91 (0) 80 4906 3555

shanghai

86 21 3756 6696

a r m s t r o n g i n t e g r at e d . c o m

You might also like

- Cummins Isx QSX Disassembly and Assembly Abby PDFDocument514 pagesCummins Isx QSX Disassembly and Assembly Abby PDFLyn Evans100% (4)

- Common Rail Next Generation Engines EDC 7 Electronic Engine Control UnitDocument41 pagesCommon Rail Next Generation Engines EDC 7 Electronic Engine Control UnitLuis Antonio Vega Parangueo100% (3)

- 416E, 422E, and 428E Backhoe Loader Hydraulic System (Interactive) 225-6836-04 05102011 PDFDocument13 pages416E, 422E, and 428E Backhoe Loader Hydraulic System (Interactive) 225-6836-04 05102011 PDFChagas Oliveira50% (2)

- Cummins Ism, QSMDocument11 pagesCummins Ism, QSMibnu67% (6)

- Grua GROVE Hydraulic SchematicDocument6 pagesGrua GROVE Hydraulic SchematicGiorgio Fer100% (3)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Service Manual: (From Serial Number 100 To 1186)Document275 pagesService Manual: (From Serial Number 100 To 1186)Giorgio FerNo ratings yet

- Organic Chemistry by Perkin and KippingDocument373 pagesOrganic Chemistry by Perkin and KippingSanjayShirodkarNo ratings yet

- CP150 SMDocument50 pagesCP150 SMjacklyn ade putra100% (1)

- Rod Install PDFDocument8 pagesRod Install PDFVeterano del Camino100% (1)

- 99924-2094-01 FS600V FS541V FS481V English-EbookDocument167 pages99924-2094-01 FS600V FS541V FS481V English-EbookJeff Comfort100% (1)

- 3.06 10K EK Quad BOP PDFDocument25 pages3.06 10K EK Quad BOP PDFJose Leonardo Materano Perozo100% (1)

- Cummin KTA50-G3 Main Bearing Installation ManualDocument15 pagesCummin KTA50-G3 Main Bearing Installation ManualRey Anthony Pole100% (2)

- 199R7948 5rev5 PDFDocument16 pages199R7948 5rev5 PDFbatman2054No ratings yet

- K38 Rocker HousingDocument13 pagesK38 Rocker HousinghindraNo ratings yet

- Cat Ground Engaging ToolsDocument484 pagesCat Ground Engaging ToolsDennis Farquhar100% (2)

- Reeving Information v2Document19 pagesReeving Information v2Giorgio Fer100% (2)

- Cummins Ism QSM PDFDocument11 pagesCummins Ism QSM PDFEng-AhmedRashadNo ratings yet

- Maxiforce 2013 CatalogDocument314 pagesMaxiforce 2013 CatalogAdolfo MoscosoNo ratings yet

- Medidas Cigüeñal KTA 38Document20 pagesMedidas Cigüeñal KTA 38Chardy Jarith Piragua AlvaradoNo ratings yet

- Lab Report - SugarDocument7 pagesLab Report - SugarPeter AndrewNo ratings yet

- Englisch Allgemein Hetronic InfoDocument32 pagesEnglisch Allgemein Hetronic InfoGiorgio Fer75% (4)

- Fluke 77 Series III Service ManualDocument59 pagesFluke 77 Series III Service ManualGiorgio FerNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Alternative FuelDocument358 pagesAlternative FuelEduardo Vasconcelos100% (1)

- Marine Loading ArmsDocument23 pagesMarine Loading ArmskendiBos100% (1)

- qs3/pubsys2/xml/en/manual/4022256/4022256-Titlepage HTMLDocument7 pagesqs3/pubsys2/xml/en/manual/4022256/4022256-Titlepage HTMLIan Woods100% (2)

- Regasification HamworthyDocument19 pagesRegasification HamworthyMoustapha Seye100% (1)

- Module 4a - Line Sizing CalculationDocument9 pagesModule 4a - Line Sizing CalculationEkundayo JohnNo ratings yet

- Plant Startup Shutdown Sequence Description ForRelease PDFDocument65 pagesPlant Startup Shutdown Sequence Description ForRelease PDFRahil TasawarNo ratings yet

- Ice Qube ManualDocument16 pagesIce Qube ManualGiorgio FerNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-50-00Document40 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-50-00anony8103No ratings yet

- Technical Manual Rotary ValveDocument8 pagesTechnical Manual Rotary ValvexichengrenNo ratings yet

- Presentation2 Power Point/ Improve Cooking StoveDocument67 pagesPresentation2 Power Point/ Improve Cooking StoveRamon Chua Jr.No ratings yet

- 002-004 Tapa de Cilindro-3Document34 pages002-004 Tapa de Cilindro-3Jose Leandro Del ZarNo ratings yet

- DHDSDocument36 pagesDHDSravichandraNo ratings yet

- Single Buoy MooringDocument5 pagesSingle Buoy MooringRachmat Hidayat SapwariNo ratings yet

- 40 90 Mechanical Seal Kits SWIDocument2 pages40 90 Mechanical Seal Kits SWIWong DaNo ratings yet

- Elite - Instruction ManualDocument4 pagesElite - Instruction Manualforevertay2000No ratings yet

- 2761 252 00Document8 pages2761 252 00joravicaNo ratings yet

- QuickServe Online - (4021531) QSB4.5 and QSB6.7 Operation and Maintenance ManualDocument7 pagesQuickServe Online - (4021531) QSB4.5 and QSB6.7 Operation and Maintenance Manualibrahim salemNo ratings yet

- Akrapovic Racing & Evolution Exhaust System: Installation InstructionsDocument17 pagesAkrapovic Racing & Evolution Exhaust System: Installation InstructionscarlosNo ratings yet

- Dv300 STD MMDocument40 pagesDv300 STD MMjacklyn ade putraNo ratings yet

- TCI 220500 TRANS-SCAT: Installation Instructions For A500 (42RH/42RE) - 1989 and Up A518 (46RH/47RH) - 1989 and UpDocument8 pagesTCI 220500 TRANS-SCAT: Installation Instructions For A500 (42RH/42RE) - 1989 and Up A518 (46RH/47RH) - 1989 and UphidraulicNo ratings yet

- Service Manual Troubleshooting Flow Chart GuideDocument5 pagesService Manual Troubleshooting Flow Chart GuideJose GuzmanNo ratings yet

- HH125 Smanual Completed - Master Updated 30-3-06Document41 pagesHH125 Smanual Completed - Master Updated 30-3-06jacklyn ade putra0% (1)

- DV100 SMDocument51 pagesDV100 SMjacklyn ade putraNo ratings yet

- QuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service ManualDocument10 pagesQuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service Manualcarlosar1477No ratings yet

- 6.38 10M EH Single Shear Seal BOPDocument19 pages6.38 10M EH Single Shear Seal BOPpramodptvpm_65797156No ratings yet

- Akrapovic ManualDocument20 pagesAkrapovic ManualTrần Nhật AnhNo ratings yet

- Universal Bosch Common Rail CP1 High Pressure Fuel Repair Kit Overhaul Seals Orings Fix Instructions Guide InstallDocument10 pagesUniversal Bosch Common Rail CP1 High Pressure Fuel Repair Kit Overhaul Seals Orings Fix Instructions Guide InstallPlamen LyutskanovNo ratings yet

- Camshaft / Lifters / Lube Kit CATALOG # 3702 General InstructionsDocument4 pagesCamshaft / Lifters / Lube Kit CATALOG # 3702 General InstructionsFREDDYJIMENEZNo ratings yet

- 8011 289-302 FORD "ACTION PLUS" Intake Manifold Installation InstructionsDocument2 pages8011 289-302 FORD "ACTION PLUS" Intake Manifold Installation InstructionsFabio Luis ArgentaNo ratings yet

- Bomba de Alta Precion de CombustibleDocument10 pagesBomba de Alta Precion de Combustiblehamilton mirandaNo ratings yet

- MSA Cylinder ValveDocument13 pagesMSA Cylinder ValveTammanurRaviNo ratings yet

- 002-004 Tapa de Cilindro-2Document34 pages002-004 Tapa de Cilindro-2Jose Leandro Del ZarNo ratings yet

- Disamble Cylinder HeadDocument17 pagesDisamble Cylinder HeadFredy Mauricio Diaz VargasNo ratings yet

- Installation - Service Instructions: Front Brake KitsDocument2 pagesInstallation - Service Instructions: Front Brake KitsCokhiducminh VinhphucNo ratings yet

- Workshop Manual 500R Reversing Drum Mixers Issue 10 2016Document176 pagesWorkshop Manual 500R Reversing Drum Mixers Issue 10 2016ZimChild GAMINGNo ratings yet

- Maintenance: Inspection and Maintenance ScheduleDocument5 pagesMaintenance: Inspection and Maintenance ScheduleMohammed BasionyNo ratings yet

- Air CylinderDocument4 pagesAir Cylindersimbua720% (1)

- Piston GrptsDocument46 pagesPiston GrptsPramono AdiNo ratings yet

- Accelerator Control, Fuel & Exhaust Systems: GI MADocument12 pagesAccelerator Control, Fuel & Exhaust Systems: GI MAaymendabNo ratings yet

- 199 R10013 RevDocument8 pages199 R10013 RevJanko ArtukovićNo ratings yet

- Repair Instructions - Off Vehicle PDFDocument37 pagesRepair Instructions - Off Vehicle PDFFernando OrtizNo ratings yet

- 2012 Dorado Pro Service ManualDocument29 pages2012 Dorado Pro Service ManualSea RidersNo ratings yet

- Sjannualservicev1.1 190Document39 pagesSjannualservicev1.1 190antoineNo ratings yet

- Pole Position 14 VKMC 01250 1 EN Highres PDFDocument6 pagesPole Position 14 VKMC 01250 1 EN Highres PDFRita PcomputerNo ratings yet

- 500sm Sani Bomba MoynoDocument4 pages500sm Sani Bomba MoynoRonaldo JanglinNo ratings yet

- Manual SSW10Document31 pagesManual SSW10Victor RodriguezNo ratings yet

- Cat 330 BLDocument9 pagesCat 330 BLluisf.rodriguez.salazarNo ratings yet

- MR Valve Guide, SealDocument15 pagesMR Valve Guide, SealbejoythomasNo ratings yet

- Ford C-4 Trans-Brake Installation Instructions Reversed Pattern Manual (PRN123) #72021Document2 pagesFord C-4 Trans-Brake Installation Instructions Reversed Pattern Manual (PRN123) #72021G Ramon SPNo ratings yet

- 5529790Document11 pages5529790Hewa PCNo ratings yet

- Moocoowooodoo 987Document32 pagesMoocoowooodoo 987scribbedd55No ratings yet

- SOP - Bob CatDocument37 pagesSOP - Bob CatvozefjadavNo ratings yet

- Informacion de Equipo CaterpillarDocument6 pagesInformacion de Equipo CaterpillarfelixNo ratings yet

- Injector CumminsDocument5 pagesInjector CumminsPLANTKAI TABANGNo ratings yet

- Brakes, Hydraulic and MechanicalDocument62 pagesBrakes, Hydraulic and MechanicalSlobodanNo ratings yet

- Avid Technical Manual: (English)Document27 pagesAvid Technical Manual: (English)mcallaNo ratings yet

- rt600 Tier3amptier4i Parts Manual For Reference Only April2013 PDFDocument370 pagesrt600 Tier3amptier4i Parts Manual For Reference Only April2013 PDFGiorgio Fer100% (1)

- Armstrong Kit Sello MecanicoDocument2 pagesArmstrong Kit Sello MecanicoGiorgio FerNo ratings yet

- Bandas CartekDocument26 pagesBandas CartekGiorgio FerNo ratings yet

- Genie Aerial Equip. Floor Load SpecsDocument15 pagesGenie Aerial Equip. Floor Load Specssethhoffman85No ratings yet

- TS 50S Manual HF RADIODocument61 pagesTS 50S Manual HF RADIOGiorgio FerNo ratings yet

- Serial Number Range: To SN 780Document110 pagesSerial Number Range: To SN 780Giorgio FerNo ratings yet

- Spare Part List: Diamond Coring Tool DD 80 115V USDocument6 pagesSpare Part List: Diamond Coring Tool DD 80 115V USGiorgio FerNo ratings yet

- Mechanical Seal Replacement InstructionsDocument1 pageMechanical Seal Replacement InstructionsGiorgio FerNo ratings yet

- Control Valves WECC1000Document32 pagesControl Valves WECC1000Giorgio FerNo ratings yet

- Powerwizard1 2Document1 pagePowerwizard1 2Giorgio FerNo ratings yet

- Mechanical Seal Replacement InstructionsDocument1 pageMechanical Seal Replacement InstructionsGiorgio FerNo ratings yet

- KMK6190Document12 pagesKMK6190Giorgio FerNo ratings yet

- 21ih-In-Valv Solenoide InoxDocument1 page21ih-In-Valv Solenoide InoxMonica CarrenoNo ratings yet

- TelusDocument3 pagesTelusGembonz Crew Gon'z SpeedNo ratings yet

- 9.8 Endothermic and ExothermicDocument24 pages9.8 Endothermic and ExothermicHema LataNo ratings yet

- Marine Engineering Practice MEP Questions and Answers-Part 5Document4 pagesMarine Engineering Practice MEP Questions and Answers-Part 5Basuraj Am-bigerNo ratings yet

- Piston RingDocument8 pagesPiston RingashokkumarNo ratings yet

- Меган 2 Схема ВпрыскаDocument4 pagesМеган 2 Схема ВпрыскаВолодимир КолесникNo ratings yet

- Spe 192465 MSDocument13 pagesSpe 192465 MSPatricio EspinosaNo ratings yet

- Class 10 Foundation NTSEDocument290 pagesClass 10 Foundation NTSEMihikaNo ratings yet

- (181536741) Panel 1-1 Briefing On ASEAN Power GridDocument46 pages(181536741) Panel 1-1 Briefing On ASEAN Power GridlisaaliyoNo ratings yet

- Function 1 MAREDocument100 pagesFunction 1 MARERj DeciertoNo ratings yet

- GMA Garnet PremiumBlast 2013Document2 pagesGMA Garnet PremiumBlast 2013Carlos Santiago Gomez ToledoNo ratings yet

- Metric and Inch (Sae) Fasteners: All ModelsDocument22 pagesMetric and Inch (Sae) Fasteners: All ModelsMONTACARGAS AVSNo ratings yet

- 2812 1Jan08T28423Document12 pages2812 1Jan08T28423Philip_830No ratings yet

- PERKINS 250-330 kVA: Technical SpecificationsDocument2 pagesPERKINS 250-330 kVA: Technical Specificationsentreprise.tgctp2015No ratings yet

- 9702 s12 QP 11 PDFDocument24 pages9702 s12 QP 11 PDFLawrence Lim Ah KowNo ratings yet

- Welding Products (Pg164-180)Document17 pagesWelding Products (Pg164-180)EswaranNo ratings yet

- RoadMaster Titanium 2019-01-14Document1 pageRoadMaster Titanium 2019-01-14Cao Đức TrungNo ratings yet

- GPL Golf 6Document22 pagesGPL Golf 6Iordan Adrian100% (1)

- Maharashtra Jeevan Pradhikaran DSR 1213Document298 pagesMaharashtra Jeevan Pradhikaran DSR 1213rajeshtripathi75588100% (1)