Professional Documents

Culture Documents

Factsheet RAPID

Uploaded by

primavera1969Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Factsheet RAPID

Uploaded by

primavera1969Copyright:

Available Formats

Glass handling

Cell testing

Cell soldering

Interconnection

Lamination

Edge trimming

J-Box

Framing

Testing

RAPID ONE 600 cells/h

RAPID TWO 1200 cells/h

SOMONT RAPID Stringer

RAPID connects your cells

Outstanding worldwide reputation for reliable cell connection

High outputs from 600 2400 cells/h Low breakage rates < 0,2%* Capacities

2400 Cells / hour 1800 1200 600 0

Technical specifications RAPID

RAPID FOUR: 2 x (10720 x 1700 x 2250 mm) Weight RAPID FOUR: 2 x 5550 kg Max. string length: 2000 mm Min. / Max. cell gap: 1.5 mm / 40 mm, freely programmable

Stringer availability of > 95% High productivity and reliability due to industry proven components Fast reaction time due to remote access Very modular and flexible concept Easy and fast integration into new and existing module lines Flexible for 5, 6, 8 cells 2 and 3BB, lead or lead-free ** 10720

RAPID

Highest quality due to innovative key features

Reliable high quality soldering results Excellent peeling forces and reproducible high-quality soldering results due to optimal temperature management and Somont s Soft Touch Soldering Constant process stability and quality control Early and fast detection of cell defects and precise alignment with optical vision Avoids production downtime and leads to increased productivity Increase in uptime and flexibility Fast product change due to smart machine concept High flexibility in relation to different cell and ribbon types 1700 12408 6300

We reserve the right to make changes reflecting technical progress (12/2011)

Factory environment

Floor load: 1000 kg/m Min. floor thickness: 200 mm Factory temperature: Min. 5 C / Max. 45 C Factory humidity: < 80% Required connections electricity, compressed air, exhaust and an Internet connection

Cell details

Cells Si Mono- or polycrystalline, square or semi square Cell dimensions: from 5, 6 and 8, 2 and 3BB Min. cell thickness: 160

User and maintenance friendly

Fast installation and ramp-up times due to sophisticated machine design Short set-up times: from 2 and 3BB < 45 min Perfect accessibility to all stations

* with 180 6 cells, pre-sorted, based on 10 cells/string ** material testing is necessary in advance

Somont GmbH, info@somont.com, www.somont.com

A member of Meyer Burger Group

Glass handling

Cell testing

Cell soldering

Interconnection

Lamination

Edge trimming

J-Box

Framing

Testing

Glass handling

Cell testing

Cell soldering

Interconnection

Lamination

Edge trimming

J-Box

Framing

Testing

Steps to produce a String

RAPID FOUR 2400 cells/h

10 |

Steps to produce strings

01 | Cell loading station

The cells are carefully taken out of the magazine and are placed on a conveyor belt.

Options

06 | Lay-up

After the turning units of both stringers have turned the strings sunny side down the lay-up arm pick up the strings and transport them gently to the glass plate.

02 | Cell alignment

07 | Glass plate feeding

Glass plates are loaded on the belt and are forwarded to the lay-up station.

05 | 04 | 02 |

06 | 09 | 08 | 09 | 06 |

The first vision system checks the cells for cracks and breakage. Then the data is used to align the cells on the soldering belt via cell-transfer system.

05 | 03 | 01 | 02 | 07 | 04 |

03 | Ribbon handling

The ribbon is uncoiled and conveyed to the flux station. After fluxing, the ribbon is dried and prepared to the required length.

08 | String placement station (part of the lay-up)

Once the glass plate is automatically aligned, the strings are placed precisely on the EVA glass plate sandwich.

03 | 01 |

Drawing incl. all options.

04 | Soldering Station

Ribbons and cells meet on the soldering belt where a combination of accurate temperature management and Somonts Soft Touch Soldering Process produces a perfect and repeatable soldered joint.

09 | Ribbon cutting and bending

In order to prepare the strings for an automatic interconnection.

RAPID Optional Equipment

Lay-up systems (for string placement on glass plate or into boxes) String Flasher String Tester Glass plate feeding conveyor Ribbon cutting and bending unit (for automated interconnection) Manual working stations for further processing of the module Accessories: Special tool set and string transport boxes

05 | String check

After soldering the strings run through a second vision system in order to inspect the alignment of the cells with the ribbon as well as a breakage check.

10 | Manual working stations

For manual interconnection and preparation of the modules before lamination.

You might also like

- AML Bonder FlyerDocument2 pagesAML Bonder FlyerghobaNo ratings yet

- Russian GFRP Rebars Bend Mesh Machines and Technology 1667726954Document20 pagesRussian GFRP Rebars Bend Mesh Machines and Technology 1667726954Rdvn YgtNo ratings yet

- TF 85 SeriesDocument3 pagesTF 85 SeriesLakshmi NairNo ratings yet

- Plating TechnologyDocument4 pagesPlating TechnologyHenry ZhengNo ratings yet

- 4 - PRO - Alpha 355 - ENDocument6 pages4 - PRO - Alpha 355 - ENGuillermo Betancourt100% (1)

- Fused Deposition Modelling SystemsDocument14 pagesFused Deposition Modelling SystemsParth ModiNo ratings yet

- Enfinity 240Wp MonoDocument2 pagesEnfinity 240Wp MonoNoel Gregorio SantosNo ratings yet

- Final Automated Welding PresentationDocument26 pagesFinal Automated Welding PresentationAbie RexoMenNo ratings yet

- Busbar Trunking SystemDocument21 pagesBusbar Trunking SystemJordan Ansh50% (2)

- Summer Tranning-Evaluation: Indian Telephone Industry Santosh PatelDocument28 pagesSummer Tranning-Evaluation: Indian Telephone Industry Santosh PatelVishal Singh MallNo ratings yet

- Comp Repair Sol HeatonDocument116 pagesComp Repair Sol HeatonDevesh KumarNo ratings yet

- Oxford, England 1Hr From LondonDocument12 pagesOxford, England 1Hr From Londonapi-3709410No ratings yet

- Oxford, England 1Hr From LondonDocument12 pagesOxford, England 1Hr From Londonapi-3709410No ratings yet

- Wedge Bonding CatalogDocument35 pagesWedge Bonding CatalogRonnie MagsinoNo ratings yet

- Komax Zeta 630Document12 pagesKomax Zeta 630OussamaNo ratings yet

- Acw 0219Document2 pagesAcw 0219anna_malai078351No ratings yet

- Komax Alpha 550 1 30 T Fully Automatic Wire Processing MachineDocument12 pagesKomax Alpha 550 1 30 T Fully Automatic Wire Processing MachineZayene KhmaisNo ratings yet

- Robofil x40 CC UsDocument28 pagesRobofil x40 CC UsMahdi ElgolliNo ratings yet

- Histopathology InstrumentsDocument6 pagesHistopathology InstrumentsLawrence LeeNo ratings yet

- TECHNICAL PAPERS Microrolling Process For The Wire Industry 2016 PDFDocument2 pagesTECHNICAL PAPERS Microrolling Process For The Wire Industry 2016 PDFmazaherramazaniNo ratings yet

- Catalog - Sikora High - Voltage - Cable - Production PDFDocument24 pagesCatalog - Sikora High - Voltage - Cable - Production PDFjigmaster0% (1)

- 0201Document80 pages0201Ashenafi Gebremeskel MezgeboNo ratings yet

- SRI SensorDocument7 pagesSRI SensorArun GuptaNo ratings yet

- Technology, Process Layout, Machineries & EquipmentDocument14 pagesTechnology, Process Layout, Machineries & EquipmentIcy MakerNo ratings yet

- Fiberforge RELAY Station BrochureDocument4 pagesFiberforge RELAY Station BrochureSunilBhandariNo ratings yet

- LC-2012 C1 NT Punch-Laser Machine: Punching Technology Laser TechnologyDocument8 pagesLC-2012 C1 NT Punch-Laser Machine: Punching Technology Laser TechnologyVenkatesh BantwalNo ratings yet

- Cilindros e Servo CilindrosDocument16 pagesCilindros e Servo CilindrosluisbottonNo ratings yet

- AS 4051.024 Wire Terminal WT Fully Automated Wire Processing MachineDocument4 pagesAS 4051.024 Wire Terminal WT Fully Automated Wire Processing MachineLOI HONo ratings yet

- Enfinity Datasheet 50M6 PV250006Document2 pagesEnfinity Datasheet 50M6 PV250006Noel Gregorio SantosNo ratings yet

- MCC Enclosure CatalogueDocument12 pagesMCC Enclosure CatalogueBch Electric ltd100% (1)

- Loaia Star Linger MachineryDocument30 pagesLoaia Star Linger MachinerySaif MastoiNo ratings yet

- Relaknit TechnologyDocument2 pagesRelaknit Technologysabbirtex88100% (2)

- Web Tension Load CellDocument4 pagesWeb Tension Load CellDhaneshwar PatilNo ratings yet

- Fiber Optic EquipmentsDocument6 pagesFiber Optic Equipmentssaurabh_acmasNo ratings yet

- Power Transformers: Your Partner in Energy SolutionsDocument24 pagesPower Transformers: Your Partner in Energy SolutionsHamayoun MurtazaNo ratings yet

- Alfanar Low Voltage Solutions Catalog PDFDocument28 pagesAlfanar Low Voltage Solutions Catalog PDFAbdul LateefNo ratings yet

- 9 PRO Alpha550 ENDocument12 pages9 PRO Alpha550 ENZayene KhmaisNo ratings yet

- Philips 3C85 Ferrite MaterialDocument9 pagesPhilips 3C85 Ferrite Materialcatalin0827No ratings yet

- Type of Drawout PDFDocument58 pagesType of Drawout PDFrantaroNo ratings yet

- Castflex EngDocument12 pagesCastflex EngJuanNo ratings yet

- Mayer Cie MBF 3.2 Knit MachineDocument4 pagesMayer Cie MBF 3.2 Knit Machineadali2020No ratings yet

- CH 16Document59 pagesCH 16mustafam1No ratings yet

- Sat Belt FeederDocument17 pagesSat Belt Feederapi-345282939No ratings yet

- Acws 230DDocument8 pagesAcws 230Dlucy leeNo ratings yet

- ABB Cast Resin Dry Type Transformer CATDocument16 pagesABB Cast Resin Dry Type Transformer CATTruong Minh Rang50% (2)

- Pointek: Instruction Manual April 2005Document33 pagesPointek: Instruction Manual April 2005Freddy JironNo ratings yet

- Hanil Catalogue (2012)Document100 pagesHanil Catalogue (2012)Soma GhoshNo ratings yet

- 1 MW Quotation Documnets For Solar Panel Proudction Line 2014Document16 pages1 MW Quotation Documnets For Solar Panel Proudction Line 2014Madhu Babu JattiNo ratings yet

- Terminales y EmpalmesDocument167 pagesTerminales y EmpalmesJose Luis Limongi VeltriNo ratings yet

- Barmag Eafk Brochure enDocument28 pagesBarmag Eafk Brochure enBritney YoungNo ratings yet

- Datasheet Solar PanelsDocument2 pagesDatasheet Solar PanelsNeoNo ratings yet

- DMLM - X Line - Bro - 8 - US - EN - v1Document4 pagesDMLM - X Line - Bro - 8 - US - EN - v1devalpscNo ratings yet

- IC AssemblyDocument18 pagesIC AssemblyRio PerezNo ratings yet

- Gamma 333Document3 pagesGamma 333हिमांशु बिष्टNo ratings yet

- Micadur Compact Industry Insulation System For RotatingDocument8 pagesMicadur Compact Industry Insulation System For Rotatingreygrant3900100% (2)

- Dieless Wire DrawingDocument16 pagesDieless Wire DrawingRohit GothwalNo ratings yet

- Group D: Filament Winding Process For CompositesDocument33 pagesGroup D: Filament Winding Process For CompositesTerminal VelocityNo ratings yet

- PANalytical CNA CementDocument4 pagesPANalytical CNA CementDhandapani Manoharan100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- Tower Crane CONCISE - MANUAL - STT200Document81 pagesTower Crane CONCISE - MANUAL - STT200chandrasekaran_11100% (4)

- Et Talon NageDocument14 pagesEt Talon Nageprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- PN W BrochureDocument2 pagesPN W Brochureprimavera1969No ratings yet

- Et Talon NageDocument14 pagesEt Talon Nageprimavera1969No ratings yet

- Land Reclamation in SingaporeDocument27 pagesLand Reclamation in SingaporeAbdul JabbarNo ratings yet

- Phase Transformations in Metals and Alloys PDFDocument37 pagesPhase Transformations in Metals and Alloys PDFWillmans Nolberto Ticlla MostaceroNo ratings yet

- Training D112 - V3 - 02E PDFDocument77 pagesTraining D112 - V3 - 02E PDFkratmelNo ratings yet

- NATURAL SELECTION (Battle of The Beaks)Document5 pagesNATURAL SELECTION (Battle of The Beaks)Julius CortezoNo ratings yet

- List of HEIsDocument2 pagesList of HEIsNadine MercadoNo ratings yet

- MIS (Management Information Systems) : Margaret RouseDocument3 pagesMIS (Management Information Systems) : Margaret RouseSANDUN KAVINDANo ratings yet

- Formalization of UML Use Case Diagram-A Z Notation Based ApproachDocument6 pagesFormalization of UML Use Case Diagram-A Z Notation Based ApproachAnonymous PQ4M0ZzG7yNo ratings yet

- Star Burst EffectDocument22 pagesStar Burst EffectDexter AlcantaraNo ratings yet

- Condition Surveys and Asset Data Capture - Sample PDFDocument5 pagesCondition Surveys and Asset Data Capture - Sample PDFfghabboonNo ratings yet

- Nij 0115.00Document46 pagesNij 0115.00officerfrankNo ratings yet

- SAP SD ConsultantDocument5 pagesSAP SD Consultantneverever143No ratings yet

- History 541gDocument21 pagesHistory 541gkarl1802No ratings yet

- Learning StoryDocument13 pagesLearning Storyapi-582461316No ratings yet

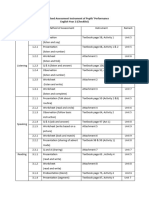

- Concept Screening-PostedDocument16 pagesConcept Screening-PostedCintia NurliyanaNo ratings yet

- Pass Microsoft 74-343 Exam: Number: 74-343 Passing Score: 800 Time Limit: 120 Min File Version: 40.2Document26 pagesPass Microsoft 74-343 Exam: Number: 74-343 Passing Score: 800 Time Limit: 120 Min File Version: 40.2tapera_mangeziNo ratings yet

- Introduction To Forensic Science Questioned DocumentsDocument50 pagesIntroduction To Forensic Science Questioned DocumentsLyka C. De Guzman100% (2)

- Acupuncture Desk ReferenceDocument418 pagesAcupuncture Desk Referencegigicarvajal96% (27)

- Communication Studies Unit 1 Data Collection MethodsDocument9 pagesCommunication Studies Unit 1 Data Collection MethodsPaulCampbell50% (2)

- WilkersonDocument4 pagesWilkersonmayurmachoNo ratings yet

- P 1075 Basic E 03 - 08Document2 pagesP 1075 Basic E 03 - 08Marco Andres Saldias SagredoNo ratings yet

- 6 1Document19 pages6 1Zubair AhmedNo ratings yet

- Statistics in Experimental Research: Mark Anthony F. Casimiro Marikina Science High School-JHSDocument32 pagesStatistics in Experimental Research: Mark Anthony F. Casimiro Marikina Science High School-JHSJeanne Emerose TalabuconNo ratings yet

- SpeedwayReaderQuickStartGuide 50484060407Document2 pagesSpeedwayReaderQuickStartGuide 50484060407LuisNo ratings yet

- Load Testing Best Practices Using Web LoadDocument39 pagesLoad Testing Best Practices Using Web Loadaustinfru7No ratings yet

- UNIT-3 Biodiversity and Biotic Resources:: 1 Genetic DiversityDocument4 pagesUNIT-3 Biodiversity and Biotic Resources:: 1 Genetic DiversityMansour Controversial KhanNo ratings yet

- Microsoft Word - Performance AppraisalDocument7 pagesMicrosoft Word - Performance Appraisalapi-3809437100% (1)

- TG Comply With WP Hygiene Proc 270812 PDFDocument224 pagesTG Comply With WP Hygiene Proc 270812 PDFEmelita MendezNo ratings yet

- Edible Cell WorksheetDocument3 pagesEdible Cell Worksheetm_frajman100% (4)

- TCS Verbal Placement QuestionsDocument5 pagesTCS Verbal Placement QuestionsNivashini100% (1)

- Penyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Document2 pagesPenyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Hui YingNo ratings yet