Professional Documents

Culture Documents

CFD

Uploaded by

Shantanu KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CFD

Uploaded by

Shantanu KumarCopyright:

Available Formats

Heat Transfer Simulation of a Hybrid Vehicle Battery Pack

Sponsored By:

Introduction The battery pack is the heart of every hybrid-electric vehicle on the road today. It supplies the power to turn the wheels and stores the recovered energy to help these vehicles obtain as many miles out of a single tank of fuel as possible. From this constant cycle of charging and discharging, an immense amount of heat is generated by the battery pack which must be mitigated, not only for the longevity of the pack but also for the safety of the passengers. The design of such a cooling system requires powerful software throughout the design phase, which CFdesign upfront CFD was able to provide.

Problem Statement The Penn State Advanced Vehicle Technology (AVT) Team has received a custom 330 Volt Lithium-ion (Li-ion) battery pack. The pack is designed to power a Saturn Vue over 25 miles before requiring the combustion engine to run a generator and begin to recharge the cells. This extreme power demand means that the battery pack will be generating over 1.7 kW of heat during operation which must be transferred safely out of the battery container and radiated to the outside air. Due to the battery pack being a custom design, no cooling system currently exists that has been optimized for the teams application.

To tackle this heat transfer problem, the Penn State AVT Team has teamed up with Blue Ridge Numerics, Inc. and utilized their CFdesign upfront CFD software to design and simulate an effective cooling network for the Li-ion battery pack. By using this software, the Penn State AVT Team hopes to simulate the heat generation cycles of the battery pack and design an efficient cooling network. This will ensure peak battery performance throughout the life of the vehicle.

Solution Once the initial design of the battery pack container and coolant network had been completed, CFdesign was loaded from the solid modeling program. This helped make certain the design would stay as it was originally developed, eliminating any sources of error associated with converting part files to another format.

After a couple simple simulations were completed to become acquainted with upfront CFD, Penn State was then able to begin the cooling system analysis. Preliminary research had defined that an air to water system was the most capable system that could effectively transfer the heat and be manufactured in house using available aftermarket components. This research then lead to the development of a coiled copper tubing design run within the battery container and plumbed to an outside radiator. The initial procedure for analyzing the design included defining points where heat generation sources were located (battery module locations), defining the material compositions of the various components and fluids, and highlighting the important factors of the design. With regards to important factors, the team identified the temperature of the fluid running through the coils as the most important factor to consider within the design. After identifying the critical factors the program was then run through the cooling system analysis. The analysis ran quickly considering the amount of information being processed and was attributed to CFdesigns advanced simulation ability.

Original Coil Design Run through CFdesign

Two heat generation cycles were used in the analysis of the battery pack. These heat generation cycles were based off of the power needed to run the vehicle during steady state and extended peak power output cases. The use of the two cycles would ensure a robust design and the ability to handle worst case scenarios in terms of required cooling. The output of the first iteration showed that the initial design was inadequate when attempting to transfer the generated heat produced by the peak power cycle. As a result, the Penn State AVT team began to progressively change the model to better account for the coolant system requirements.

The team started with minor changes to the materials and eventually progressed to dimensionally changing the components of the coolant system. Through this process, design changes in coolant, tubing diameter, coil radius, and tubing length were all made until a design was reached which was capable of transferring heat effectively through both heat generation cycles.

Temperature Distribution Gradient of Coolant throughout the Coil

Reasons for Choosing CFdesign Upfront CFD The Penn State AVT Team sought out the CFdesign upfront CFD software from Blue Ridge Numerics, Inc. because of the softwares ability to provide an in-depth heat transfer analysis, which was crucial in designing the teams custom cooling system. Penn State currently uses two different modeling programs in the design of its hybrid vehicle, so the ability to have one analysis program that is compatible with both modeling packages was a huge advantage. Using the same program minimizes the learning curve of using the software and allowed the team to complete simultaneous analyses, even when the designs were at different development stages. Many CFD analysis programs require user input to completely define all objects such as boundary conditions and meshes, but CFdesign is able to automatically perform these laborious functions with minimal input required from the user. As changes were made to the model throughout the design process, CFdesign would automatically adjust for the changes and output new results. CFdesign also includes an extensive library of standard fluids, which made defining a coolant for the cooling system much easier. Penn States team member Shawn Getty gave the Help Tutorial PDF high marks, stating that, It was easy to search for topics and the information provided was meaningful to the solution of the problem. It was due to these advantages that the Penn State AVT Team was glad to have CFdesign available throughout the battery pack design and looks forward to using the technology as the design process for the rest of the vehicle continues.

Final Design From the output results of CFdesign, the final coolant system design will utilize a copper tubing coil using a water and ethylene glycol mix coolant. An aluminum support plate will also assist in removing heat from the battery pack.

Final Heat Transfer Plate and Coil Design Following CFdesign Upfront CFD Analysis

Design Conclusions Hybrid-electric vehicles rely on the ability of a battery pack to undergo an extensive series of discharge and recharge power cycles throughout a driving sequence. These intense power cycles cause the battery pack to generate a great deal of waste heat which must be effectively transferred out of the battery pack container to preserve both vehicle performance and passenger safety. Thanks to the aid of CFdesign, the team was able to analyze and improve the design of the battery pack cooling system. Throughout each coolant system simulation, the team was able to see where design improvements were required and what options were available to increase the performance in both transient and steady state analyses. Overall, the custom cooling network was designed quickly and efficiently, and the Penn State AVT Team is confident that the final design that will integrate smoothly into the vehicle chassis and provide consistent cooling performance.

By: Mark Hull, Penn State AVT Team

Mark Hull is a senior in Mechanical Engineering at The Pennsylvania State University and is a member of the Penn State AVT Teams Auxiliary Power Unit Group. He has experience with both solid modeling and computational fluid dynamics software.

Publication Opportunities CFdesign promotional material or website as a product testimonial Penn State AVT Team website Mechanical engineering periodicals such as Machine Design Automotive engineering periodicals such as Automotive DesignLine and Automotive Engineering International

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

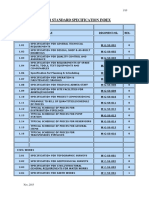

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- WM2077CW Service ManualDocument44 pagesWM2077CW Service ManualMichael David SharkeyNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- P6112 Alstom PG9171E PowerPlant SpecificationsDocument1 pageP6112 Alstom PG9171E PowerPlant SpecificationsSunario YapNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- New Holland Cargador w170 B Tier III Na RepuestosDocument555 pagesNew Holland Cargador w170 B Tier III Na Repuestosarmando vara chavez100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Bomba Electrica 1500gpm 300HP (Medidas)Document1 pageBomba Electrica 1500gpm 300HP (Medidas)Fire ChileNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 42SL80 TrainingDocument93 pages42SL80 Trainingvmalvica67% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Design, Development and Future of Electric Vehicle: Prof. Eric ChengDocument18 pagesThe Design, Development and Future of Electric Vehicle: Prof. Eric ChengDeepak ChaurasiaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Line Sizing GuidelinesDocument31 pagesLine Sizing Guidelinesc_nghia100% (3)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Photovoltaic Silicon Wafer - SUMCO CORPORATIONDocument21 pagesPhotovoltaic Silicon Wafer - SUMCO CORPORATIONlawrence_yuen_3No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Annual Syllabus 9 & 10Document6 pagesAnnual Syllabus 9 & 10Kumar SiddhantNo ratings yet

- Units: Muhammad AhsanDocument2 pagesUnits: Muhammad AhsanAreeb WaseemNo ratings yet

- Deepwater Training Seminar Presented ToDocument36 pagesDeepwater Training Seminar Presented ToSergio Jesus MarquezNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 568100Document2 pages568100Talha TariqNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- MPU 2201 Online HGNotes - 1 ACADEMIC ESSAYDocument19 pagesMPU 2201 Online HGNotes - 1 ACADEMIC ESSAYtharaaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Easy Genset Control: OperationDocument51 pagesEasy Genset Control: OperationdonothearNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Transfer Switching Equipment 100, 200, 260, 400A: Instr Uction ManualDocument32 pagesTransfer Switching Equipment 100, 200, 260, 400A: Instr Uction ManualMesseňger HệŢhốngNo ratings yet

- 2ND YEAR PHYSICS Full Book Topical MCQS With ANSWERSDocument47 pages2ND YEAR PHYSICS Full Book Topical MCQS With ANSWERSArhamNo ratings yet

- Numatics Series 342Document6 pagesNumatics Series 342Jebran FarazNo ratings yet

- Ul 854 - 2014 PDFDocument64 pagesUl 854 - 2014 PDFDouglasNo ratings yet

- SIA Guidance Note 47Document11 pagesSIA Guidance Note 47Ali BiomyNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pressure MeasurementDocument19 pagesPressure MeasurementShadmanSakiefHridoyNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- How Electric Cars Work: A Guide to EV TechnologyDocument4 pagesHow Electric Cars Work: A Guide to EV TechnologyCarla LoiaconoNo ratings yet

- Current Transformer - Electrical Notes & ArticlesDocument47 pagesCurrent Transformer - Electrical Notes & Articlesnomy158100% (1)

- SGP Chapter-1Document81 pagesSGP Chapter-1Shashank ReddyNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- GH G ConversionDocument146 pagesGH G ConversionjorgeNo ratings yet

- GX30R 100RDocument53 pagesGX30R 100RSergio Garcia100% (1)

- Fire Pump Installation GuideDocument3 pagesFire Pump Installation GuideJeff D. AgustinNo ratings yet

- Exhaust ManifoldDocument5 pagesExhaust ManifoldDeepak Chachra100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Final Directory Handbook For ADIPEC 2023Document54 pagesFinal Directory Handbook For ADIPEC 2023Zharif ZainiNo ratings yet

- Solar Refrigerator SpecsDocument4 pagesSolar Refrigerator SpecsFaisal Bin FaheemNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)