Professional Documents

Culture Documents

Interface Management Philosophy

Uploaded by

ironi2002Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Interface Management Philosophy

Uploaded by

ironi2002Copyright:

Available Formats

KCP-ARP-PMG-DPR-0002 Rev.

: 03 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Interface Management Philosophy Page 1 of 10

Interface Management Philosophy

Table of Contents

1. 2. 3. Scope and Functional Requirements .................................................................. 2 Contributors ......................................................................................................... 2 FEED 1A Deliverables Interface Management.................................................... 3 3.1. Working Groups ............................................................................................ 3 3.1.1. Transport & Storage Working Group (TSWG) ....................................... 3 3.1.2. Operating Philosophy for Abated Plant (OPAPP) Working Group ........ 4 3.1.3. Operational Safety Working Group (OSWG) ......................................... 4 3.1.4. Working Group Composition ................................................................. 4 3.1.5. Remit of individual Working Groups: ..................................................... 5 3.2. Roles and Responsibilities............................................................................ 5 3.2.1. Participant Team ................................................................................... 5 3.2.2. E.ON Single Point of Contact (SPOC)................................................... 6 3.2.3. E.ON Technical Project Manager .......................................................... 6 3.2.4. E.ON Commercial Project Manager / Bid Lead ..................................... 6 3.2.5. Project Lead .......................................................................................... 6 3.3. Delivery Principles ........................................................................................ 6 4. FEED 1A Technical Interface Management ........................................................ 6 4.1. Project Design Philosophies ......................................................................... 7 4.2. Holds Register .............................................................................................. 8 4.3. Integrated Master Schedule (IMS) ................................................................ 8 4.4. Request for Information Process (RFIs) ....................................................... 9 5. FEED 2 Technical Interface Management .......................................................... 9 5.1. Division of Responsibility (DoR) Matrix......................................................... 9 5.2. Interface Schedule ........................................................................................ 9 5.3. Technical Interface Management Flow Chart ............................................. 10

Sch 7 ref.: 6.07 Signature: Date:

Approved for Knowledge Transfer

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-ARP-PMG-DPR-0002 Rev.: 03 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Interface Management Philosophy Page 2 of 10

1. Scope and Functional Requirements

The objective of this document is to develop a simple philosophy with clear information that enables all parties to understand their roles and responsibilities in managing design interfaces, in the form of documentation review through various Working Groups, and technical interfaces, in the form of physical details at the interface points between different components of the CCS chain, and the concepts surrounding the information interchange that take place during the project life. This Philosophy describes the approach used to ensure that effective communication occurs between different design contributors and that design conflicts at interfaces are identified and resolved. This Philosophy will be applied throughout the conceptual design phase (FEED 1) and FEED 2. This philosophy is not applicable to the detailed design phase and must be reviewed and updated for the detailed design phase.

2. Contributors

While all significant contributors to the project are paid directly by E.ON-UK the responsibility for production of design deliverables is split generally as follows: E.ON-UK: Integrated Power Station Performance Specification (Technical & Commercial) Overall Project Management, Monitoring & Control with support from Arup Commercial and Legal Coordination with support from Norton Rose Overall Planning and Consents Co-ordination with support from ENT (E.ON New Build & Technology), Genesis, Baker RDS, RSK, Atmos and Fisher German Overall Design Co-ordination with support from Arup & ENT

Note: Selected ENT and Arup staff are working directly for E.ON-UK and discharging duties on behalf of E.ON-UK. ENT: Power Station Design & CCS Integration Pipeline Equipment Specification (Valves, Meters etc.) & Supplier Review Pipeline and Power Station Integrated SCADA Design Capture Design supported by FW/MHI Compression & Conditioning Design supported by FW

Genesis: Pipeline Design

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-ARP-PMG-DPR-0002 Rev.: 03 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Interface Management Philosophy Page 3 of 10

Offshore Facilities and Topsides Design

Baker RDS: Wells and Storage Systems Design ENT is responsible for the performance of FW and MHI under the FW/MHI and the FW contracts. ENT is therefore responsible for managing information flows across the internal ENT interfaces with FW & MHI. E.ON-UK, with support from the participants as identified above, is responsible for managing its all other interfaces between Planning/Consenting, Technical Coordination, Commercial & Legal Co-ordination, General Project Management, Monitoring and Control. E.ON-UK will also coordinate with E.ON Gas Storage who will provide transport and storage system operability review input in the role of nominated asset manager for transport and storage. E.ON-UK is also responsible for managing external interfaces between ENT, Genesis, and Baker RDS.

3. FEED 1A Deliverables Interface Management

Every contract with any significant contributor to the overall project will be managed by a SPOC (Single Point of Contact) acting on behalf of E.ON UK. All significant communication is channelled through this SPOC. The SPOC for each contract is effectively also the contract manager. Design interface management is handled by the use of Working Groups that meet regularly to review, comment on and recommend additions to the first and subsequent drafts of all deliverables.

3.1. Working Groups The following Working Groups have been established. 3.1.1. Transport & Storage Working Group (TSWG)

Chairman - Deliverable Coordinator, Arup for E.ON-UK Wells and Storage SPOC, ENT for E.ON-UK Flow Assurance Lead for Genesis Compression SPOC for ENT Pipeline / Platform SPOC, ENT for E.ON-UK Wells Lead for Baker RDS Pipeline and Offshore Structure Lead (Genesis Project Manager) Development/Consents Manager for E.ON-UK (Optional Observer)

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-ARP-PMG-DPR-0002 Rev.: 03 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Interface Management Philosophy Page 4 of 10

NB: All design philosophies and key deliverables related to Transport and Storage will be reviewed by E.ON Gas Storage in parallel with the TSWG to confirm commonality of approach with other E.ON CCS projects.

3.1.2. Operating Philosophy for Abated Plant (OPAPP) Working Group

Chairman - Deliverable Coordinator, Arup for E.ON-UK E.ON UK Operations representative Carbon Capture SPOC for ENT Compression SPOC for ENT Development/Consents Manager for E.ON-UK ENT Process Engineer ENT Pipelines Engineer (As Required) Technical Project Manager (E.ON-UK Optional Observer) Chairman - Deliverable Coordinator, Arup for E.ON-UK ENT COMAH and Hazardous Substances Expert E.ON-UK Project Safety Manager & CDMC External Safety and Health Consultant ENT Dispersion Modelling E.ON-UK Operations Representative E.ON-UK Asset Risk Management and HAZOP Expert Genesis Safety Manager Part Time (As Required) (Pipelines and Offshore) Development/Consents Manager for E.ON-UK Technical Project Manager (E.ON-UK Optional Observer)

3.1.3. Operational Safety Working Group (OSWG)

3.1.4. Working Group Composition

Each Working Group comprises members of the overall design team who represent interests from both sides of any internal or external interface along the CCS process chain, from power generation through to storage. Other personnel invited to participate in the Working Groups generally have a role with either a project overview or a significant specific design responsibility. It is the job of the Working Groups to assess deliverables from initial review and comment through to recommendation for approval of the deliverables for a defined purpose. The sign off process is defined in the Document Life Cycle Process. Chairmen of the Working Groups meet together with both TPMs regularly. The frequency of these meetings will be arranged as necessary (but at least once per month) to discuss progress, bottlenecks and deliverables over which

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-ARP-PMG-DPR-0002 Rev.: 03 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Interface Management Philosophy Page 5 of 10

there is may be some debate. Disputed decisions can be resolved by joint agreement between both TPMs. The Transport and Storage TPM will be responsible for co-ordinating official responses to comments by EGS after these comments have been considered by the Working Groups. In accordance with the requirements of the Document Life Cycle Process, Technical Approval is given by sign off by one TPM (T&S) or TPM (Power Station) or both, as appropriate. Final sign off is given by PEG (Project Executive Group).

3.1.5. Remit of individual Working Groups:

TSWG To review and recommend for approval (with comment where necessary) all deliverables that are related to transport and storage design and operation or have an impact across the interface between transport and storage and the power station. OPAPP To review and recommend for approval (with comment where necessary) all deliverables that are related to the abated power station design and operation. OSWG To review and comment on all deliverables that are related to design for safety and/or to safety management across the whole CCS chain.

Where there is overlap, one Working Group will be nominated as the main reviewer and the chairman of the Working Group nominated will refer the result of comments to the other nominated Working Group(s).

3.2. Roles and Responsibilities

The roles and responsibility of all parties needs to be clearly defined, in particular with respect to who is doing what and when. This section provides the definition of the key roles and each roles individual responsibility in managing the interface process. Each responsible individual must have a clear understanding of: Role: What their responsibility is in the process Accountability: Who they are responsible to

The roles and their reporting lines are defined in the Project Organisation Chart detailed in the Project Handbook Section 2 (Organisation). Specific individuals with key roles during the FEED 1A activities are:

3.2.1. Participant Team

The Participant SPOC is responsible for working closely with the E.ON SPOC to provide accurate and timely interface information to ensure the successful delivery of the deliverables. This is through the provision of documentation, drawings and schedules, adherence to the agreed project schedule key milestones and active participation in interface co-ordination workshops and meetings as required.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-ARP-PMG-DPR-0002 Rev.: 03 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Interface Management Philosophy Page 6 of 10

The participant team will be governed by the Participant Companies Quality management procedures which will define the requirements for sign off by the document Originator, Checker and Approver. 3.2.2. E.ON Single Point of Contact (SPOC) Responsible The person who owns the task of overall management of the delivery of the documentation through the technical review and sign off process. Accountable To the Technical Project Manager.

3.2.3. E.ON Technical Project Manager

Responsible The person ultimately responsible for ensuring that the documents are technically acceptable and are successfully managed and signed off in a timely and cost efficient manner. Ultimate decision maker on all technical interface issues. Accountable To the General Project Manager.

3.2.4. E.ON Commercial Project Manager / Bid Lead

Responsible The person responsible for ensuring that the documents are commercially and contractually acceptable to E.ON-UK and are acceptable to be issued to DECC under the terms of the contract. They are responsible for ensuring that the requirements for Knowledge Transfer (including Blacklist provisions) and Gateway Review Requirements are met. Ultimate decision maker on all commercial and contractual interface issues. Accountable To the Project Lead.

3.2.5. Project Lead

Responsible The person responsible for the final sign off of all deliverables prior to release to DECC and for use within the project.

3.3. Delivery Principles

The key principles being adopted are: Deliverables being shared, reviewed and updated with the participants regularly as part of the SPOCs role. Regular interface meetings being scheduled throughout the project life.

4. FEED 1A Technical Interface Management

In any complex project environment, particularly where there are multiple participants involved, a critical factor for success is a timely exchange of interface data between all involved parties to ensure scopes of work correctly match up at the point where the two scopes of work meet. The resulting consequences of a failure to identify and match up interface points correctly are primarily: Delays to the programme

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-ARP-PMG-DPR-0002 Rev.: 03 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Interface Management Philosophy Page 7 of 10

Claims or compensation events Increased project management effort Ultimate overall project cost increases.

It is therefore vital that a robust interface management philosophy is in place which provides each participant a clear definition on what the limits of supply are for their respective work packages, including who is doing what and when. An interface is defined as the point, area, or surface along which two substances or other qualitatively different things meet; it is also used metaphorically for the juncture between items. In a complex engineering project environment, interfaces or junctions exist in many forms across the various contract lots, but in most cases can be classified into three distinct categories: Physical: e.g. machine to foundation, pipe to pipe, cable to switchboard etc. Process e.g. fuel feed, quantity/hr at a certain calorific value, steam flow at temperature & pressure; delivery of materials between lots and expediting. Data e.g. Fan / Motor unit loading data for a foundation design

There is a risk that a failure to identify and properly manage interfaces on a project can lead to adverse effects on time, quality and cost. Therefore, in order to manage any risk from the onset of the project, a distinct and clear philosophy of interface management is required. The philosophy underpinning the management of technical interfaces between participants encompasses: Interfaces being identified upfront and actively managed within the Project Team. The roles and responsibilities of all parties being clearly defined. Each participant having clearly defined limits of supply. Each identified interface providing sufficient details including type, content and extent of information appropriate to this stage of the project, for example technical parameter (e.g. dimensioned locations, weights, etc.), delivery dates, who is providing, how will it be provided (drawing, emails, reports), what checking / verification will be performed and by whom.

Key aspects of the management of the technical interfaces include:-

4.1. Project Design Philosophies

In order to define the requirements of the project, Design Philosophy documents (together with key layouts, PFDs and P&IDs etc.) will need to be written which set out the outline of the design concepts to be adopted across the whole CCS chain and within all the main engineering disciplines. Design can only proceed once the design input documentation has been both written and agreed internally with and by the client (E.ON UK).

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-ARP-PMG-DPR-0002 Rev.: 03 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Interface Management Philosophy Page 8 of 10

Preparation and approval of the necessary design input documentation will ensure that the significant number of design contractors (around 6 to 8 firms including ENT) are fully informed on the agreed philosophy, assumptions and known parameters and design guidelines that are currently available to inform the necessary design work. The Design Philosophies (and other input documents) need to be consistent with each other and provide sufficient information for all design disciplines to make an effective start to actual design work. The aim of the documentation is to allowing different designers to work simultaneously and efficiently in separate design locations toward a common overall objective. Design of a large complex project where design activity is being carried out at multiple locations cannot be managed without the disciplined organisation of input documentation described above. The process of preparing the documentation also disciplines the client to properly inform the engineering functions on exactly what it is that the client wants to receive/achieve from the project. Definition of the project requirements using the Design Philosophy approach will ensure that the information is properly documented, cross referenced between chain elements and changes can be properly managed and controlled. The Design Philosophy Process document further describes the production, use and revision of Design Philosophies.

4.2. Holds Register

In the case where a requirement or item of design data has not yet been confirmed, a HOLD X.X.X.X-YYY-ZZZ shall be put in brackets immediately after the information at question. This is to highlight to users of the Design Philosophy (or any FEED1A deliverable) that the data or requirements is preliminary and that work is to be completed during the future phases of work. The HOLD will start with the WBS number (X.X.X.X) of the chain element, it will then reference the unique schedule 2 deliverable number (YYY) and then have a consecutive number (ZZ) added to it starting with 01 for the first HOLD in that deliverable. The HOLDs will then be populated onto a HOLD List. It is the Design Philosophy Owners responsibility to inform the Deliverable Co-ordinator who will maintain this HOLD list and report back to the Project Team to determine the impact and resolution of HOLDs.

4.3. Integrated Master Schedule (IMS)

An overall Integrated Master Schedule (IMS) (Primavera P6 programme) will be used as a master controlling tool for managing the Phase 1A deliverables and interfaces between them. Key deliverable delivery dates will be integrated into the IMS and dependencies logic linked between participants. Full details are included in the Programme Management Procedure.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-ARP-PMG-DPR-0002 Rev.: 03 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Interface Management Philosophy Page 9 of 10

4.4. Request for Information Process (RFIs)

The RFI process is initiated from one organisation to another formally requesting clarification or information regarding a specific technical or design query. This is done via the extranet document control tool, which produces live updates and register of all requests. Full details are included in the Request for Information Procedure.

5. FEED 2 Technical Interface Management

During FEED 2 a more detailed interface management approach will be required for managing the flow of information and data across both the physical and technical interface boundaries. A documented Interface Management System shall be implemented by all contractors and parties that are involved with interface issues (throughout the FEED2, design, procurement, construction and commissioning phases of the project) in accordance with an Interface Management Plan. Contractors will also be required to define the interface control process for their subcontractors and suppliers within their interface management system. An Interface Management System Procedure will be issued and training carried out to all Company nominated Interface Parties. The primary features of the Interface Management System for FEED 2 will be: Project interface boundaries and the strategy for managing interfaces will be clearly defined. Roles and responsibilities of focal points from all interface parties will be identified. Interface parties shall be trained in the use of the system. Retention of quality records to verify the flow of information across the interface.

Key aspects of the Interface Management System Procedure will include

5.1. Division of Responsibility (DoR) Matrix

This tabulated document identifies the key steps through either a physical area or structure or a mechanical / electrical system including who is involved, who is leading and any other supporting roles.

5.2. Interface Schedule

This is a database listing all interfaces within each system and includes technical data relevant to the design of the interface. Data will include process information, physical location, details of the actual connection including who provides what and who does what at the interface. The Interface Schedule is intended to be used as the tool to manage the coordination of technical information rather than the technical data source.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-ARP-PMG-DPR-0002 Rev.: 03 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Interface Management Philosophy Page 10 of 10

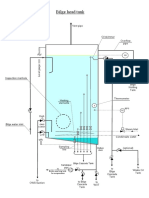

5.3. Technical Interface Management Flow Chart

The following flow chart shows the proposed route for recording technical interfaces on the Interface Schedule:

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

You might also like

- FormulasDocument9 pagesFormulasShankar JhaNo ratings yet

- Progress Measurement System (PMS)Document7 pagesProgress Measurement System (PMS)F88% (8)

- Project Execution ModelDocument99 pagesProject Execution ModelEdha Ali100% (3)

- Project Risk Management ProcedureDocument28 pagesProject Risk Management Procedureatifali492100% (12)

- 4.7 Construction PhilosophyDocument13 pages4.7 Construction PhilosophyPaidar Engineering and Energy Development Co.No ratings yet

- 1.6 Project Control PlanDocument11 pages1.6 Project Control Planaswar100% (1)

- Interface Management PlanDocument12 pagesInterface Management PlanAdeoye Ogunlami100% (7)

- ProjectExecutionPlan PDFDocument69 pagesProjectExecutionPlan PDFrmagan100% (5)

- 1.9 Engineering PlanDocument9 pages1.9 Engineering PlanaswarNo ratings yet

- Interface Management Plan CombinedDocument30 pagesInterface Management Plan CombinedTayo TinuoyeNo ratings yet

- Project - Execution - Plan - SHELL Sample PDFDocument96 pagesProject - Execution - Plan - SHELL Sample PDFChijioke Obi86% (7)

- Project Execution PlanDocument7 pagesProject Execution PlanJOHNK100% (12)

- Project Execution PlanDocument69 pagesProject Execution PlanGraco Calle100% (6)

- General Requirements For A FEED Study and PTE PreparationDocument3 pagesGeneral Requirements For A FEED Study and PTE PreparationklmNo ratings yet

- Project Execution PlanDocument25 pagesProject Execution Planvnarveka90% (21)

- 6 1 Engineering Quality PlanDocument35 pages6 1 Engineering Quality PlanRangga Adi PutraNo ratings yet

- Progress Reporting Procedure DraftDocument9 pagesProgress Reporting Procedure DraftOhomina Josh100% (2)

- 5A-QA-PL-02Rev00 - Project Execution and Quality PlanDocument34 pages5A-QA-PL-02Rev00 - Project Execution and Quality Planirzaldy100% (8)

- Interface RegisterDocument9 pagesInterface RegisterSheik Ali (QA/QC Manager Coastal)100% (1)

- Interface Management Procedure TemplateDocument20 pagesInterface Management Procedure TemplateYan FerizalNo ratings yet

- Progress Measurement ProcedureDocument15 pagesProgress Measurement ProcedureSendhil_Kumar_2023100% (2)

- Developing Standard Logic For A Detailed Engineering Project Schedule in The Process IndustryDocument40 pagesDeveloping Standard Logic For A Detailed Engineering Project Schedule in The Process Industrysubir2160% (1)

- Method Statement of Lowerin inDocument9 pagesMethod Statement of Lowerin inahmed08839494No ratings yet

- Ssg-Ng01012401-Gen-Aa-5760-00001 - R04 - Project Execution PlanDocument114 pagesSsg-Ng01012401-Gen-Aa-5760-00001 - R04 - Project Execution PlanStroom Limited100% (7)

- Planning Cement Terminal OperationsDocument10 pagesPlanning Cement Terminal Operationsasad55001No ratings yet

- 4.6 Full System Leak Detection PhilosophyDocument6 pages4.6 Full System Leak Detection PhilosophyPaidar Engineering and Energy Development Co.No ratings yet

- Project Execution PlanDocument49 pagesProject Execution PlanSunday Paul100% (1)

- Interface PlanDocument4 pagesInterface Planchanchalpc100% (1)

- Construction Execution PlanDocument40 pagesConstruction Execution PlanDaniel Dambo100% (26)

- S-000-5131-301 - 0 Project Excution PlanDocument35 pagesS-000-5131-301 - 0 Project Excution PlanMahadevan Mahalingam100% (2)

- 7 Interface Management PlanDocument18 pages7 Interface Management PlanFerry Triwahyudi100% (2)

- Interface Management PlanDocument17 pagesInterface Management Planislam leopard100% (1)

- 6.40 Offshore Platform Hazid Envid ReportDocument26 pages6.40 Offshore Platform Hazid Envid ReportGaluh Pramudipto100% (1)

- Interface Management PresentationDocument25 pagesInterface Management Presentationlabunas100% (3)

- Execution PlanDocument50 pagesExecution Planmuhamedz100% (5)

- Project Execution Plan - KLEDocument63 pagesProject Execution Plan - KLEDebashish Das80% (5)

- Power T&D Reliance PDFDocument63 pagesPower T&D Reliance PDFRonak JajooNo ratings yet

- Project Execution PlanDocument4 pagesProject Execution PlanAzzeddine GundNo ratings yet

- 6.8 Pipeline Testing and Drying Philosophy PDFDocument9 pages6.8 Pipeline Testing and Drying Philosophy PDFDonald.KNo ratings yet

- Turbine RollingDocument3 pagesTurbine RollingAnudeep Chittluri100% (1)

- 131 - 100-Yer-Pm-Ppm-0031 - Interface Management Coordination ProcedureDocument14 pages131 - 100-Yer-Pm-Ppm-0031 - Interface Management Coordination ProcedureIonut LefterNo ratings yet

- KE01!00!000 AK A PR 0001 000 AGIP Document NumberingDocument30 pagesKE01!00!000 AK A PR 0001 000 AGIP Document NumberingmasahinNo ratings yet

- Select Instrum TransfmerDocument75 pagesSelect Instrum TransfmerJheny B. Bayon100% (1)

- Project Execution PlanDocument26 pagesProject Execution PlanMarzuqi Aqila100% (8)

- Uzu With CPF Upgrade - Interface Management PlanDocument20 pagesUzu With CPF Upgrade - Interface Management PlanOkeymanNo ratings yet

- Interface Management PresentationDocument36 pagesInterface Management PresentationAhmed Imtiaz RaoNo ratings yet

- Project Execution Plan For Pipe Lines - Piping ConstructionDocument10 pagesProject Execution Plan For Pipe Lines - Piping Constructionsudeesh kumar33% (3)

- Interface Management PhilosophyDocument10 pagesInterface Management Philosophykarthikugan66No ratings yet

- White Paper 2009 System Neutral Resistance Grounding LBDocument7 pagesWhite Paper 2009 System Neutral Resistance Grounding LBLong LeoNo ratings yet

- Interface Management ProcedureDocument4 pagesInterface Management Procedureubabu100% (6)

- 6.28 Offshore and Pipeline Control and Instrument System Design ReportDocument8 pages6.28 Offshore and Pipeline Control and Instrument System Design ReportSaoloan NaiborhuNo ratings yet

- Ssg-Ng01012401-Gen-Aa-5800-00008 - C01 - Project Interface Managment PlanDocument16 pagesSsg-Ng01012401-Gen-Aa-5800-00008 - C01 - Project Interface Managment PlanStroom LimitedNo ratings yet

- Construction Execution Plan - ShellDocument41 pagesConstruction Execution Plan - Shellrohit12389100% (3)

- Interface EngineerDocument3 pagesInterface EngineernjennsNo ratings yet

- Coreworx Improving Project Outcomes With Interface ManagementDocument18 pagesCoreworx Improving Project Outcomes With Interface ManagementtriNo ratings yet

- 10.15 Economic and Commercial Definitions PhilosophyDocument4 pages10.15 Economic and Commercial Definitions PhilosophyharryNo ratings yet

- 02 - Schedule Management PlanDocument6 pages02 - Schedule Management PlantonbaldinNo ratings yet

- Project Report On Calcined Petroleum CokeDocument11 pagesProject Report On Calcined Petroleum CokeSachin Sharma0% (2)

- Tepng Onshore Const Itt Project Quality PlanDocument42 pagesTepng Onshore Const Itt Project Quality PlanTrustEmma50% (2)

- Interface REsponsibility MatrixDocument2 pagesInterface REsponsibility Matrixthmaraishri0% (1)

- CBIP Guidelines On Protection: Auto-ReclosingDocument7 pagesCBIP Guidelines On Protection: Auto-Reclosingss_chinniNo ratings yet

- 4.8 Inspection and Maintenance PhilosophyDocument10 pages4.8 Inspection and Maintenance PhilosophyMohamed KenawyNo ratings yet

- Mega Project Interface ManagementDocument3 pagesMega Project Interface ManagementLTE002100% (2)

- Bombardier Transportation CountryBrochure India enDocument7 pagesBombardier Transportation CountryBrochure India enVignesh MohanrajNo ratings yet

- Carbon AuditDocument30 pagesCarbon Auditvijayanandadb100% (1)

- Ess Interface Management PlanDocument11 pagesEss Interface Management PlanTAHER AMMAR100% (1)

- Project Finance Project Evaluation at Indian Oil Project ReportDocument92 pagesProject Finance Project Evaluation at Indian Oil Project Reportyasirrk100% (2)

- 6.7 Pipeline Material Selection Corrosion Protection and Monitoring Philosophy PDFDocument13 pages6.7 Pipeline Material Selection Corrosion Protection and Monitoring Philosophy PDFDonald.KNo ratings yet

- 6.7 Pipeline Material Selection Corrosion Protection and Monitoring PhilosophyDocument13 pages6.7 Pipeline Material Selection Corrosion Protection and Monitoring Philosophyadenlan100% (3)

- Interface Management PDFDocument2 pagesInterface Management PDFEdwin HarrisNo ratings yet

- Manual Partes 1B40V-1B50V PDFDocument38 pagesManual Partes 1B40V-1B50V PDFromaldoagurtoNo ratings yet

- B2C Lighting - Product Explorer 2018-Vol IDocument40 pagesB2C Lighting - Product Explorer 2018-Vol IAshish Tamang0% (1)

- Bleed ValveDocument8 pagesBleed Valvejanju81No ratings yet

- DME CapcostDocument16 pagesDME Capcostjano2906No ratings yet

- Construction TodayDocument164 pagesConstruction Todaypmd100% (1)

- Schulz Bare Pump CatalogDocument6 pagesSchulz Bare Pump CatalogjerrNo ratings yet

- Head TankDocument1 pageHead TankAndrzej KozłowskiNo ratings yet

- UCTE 2008 Final ReportDocument55 pagesUCTE 2008 Final ReportelcracNo ratings yet

- Annual ReportDocument146 pagesAnnual Reportabhimanyu singhNo ratings yet

- 20MBA0117 (BHEL) Capstone ReportDocument79 pages20MBA0117 (BHEL) Capstone ReportHaustin SolomonNo ratings yet

- 360 DrillingDocument14 pages360 Drillingfahad noumanNo ratings yet

- IRF IGBT Product Selection GuideDocument6 pagesIRF IGBT Product Selection GuidePhuc LeNo ratings yet

- Sample Letters To Request SupportDocument4 pagesSample Letters To Request SupportVineet DuhanNo ratings yet

- Aquarian Cladding Brochure 2013Document16 pagesAquarian Cladding Brochure 2013Jamie WilliamsNo ratings yet

- Petronas Group of Companies 2021Document7 pagesPetronas Group of Companies 2021Loges WarryNo ratings yet

- Sample Greenaura IGBC AP NOTESDocument2 pagesSample Greenaura IGBC AP NOTESMayank SharmaNo ratings yet

- Label Odner BantexDocument4 pagesLabel Odner Bantexdana setiawanNo ratings yet

- Power TradingDocument5 pagesPower TradingCpgeorge JohnNo ratings yet

- CRS Bushing CatalogueDocument12 pagesCRS Bushing Cataloguedwas1314No ratings yet