Professional Documents

Culture Documents

Elan-Tron MC4260 W4260 Ing

Uploaded by

Zdzisław LatoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elan-Tron MC4260 W4260 Ing

Uploaded by

Zdzisław LatoCopyright:

Available Formats

EN

Product Information

Elan-tron MC 4260/W 4260

100:10

(Epoxylite EIP 4260 RESIN/Epoxylite EIP 4260 HARDENER)

2-component epoxy potting compound

ELANTAS Beck GmbH

Grossmannstr. 105 20539 Hamburg Germany Tel +49 40 78946 0 Fax +49 40 78946 276 info.elantas.beck@altana.com www.elantas.com

ELANTAS Camattini S.p.A.

Strada Antolini n1 loc. Lemignano 43044 Collecchio (PR) Italy Tel +39 0521 304711 Fax +39 0521 804410 info.elantas.camattini@altana.com www.elantas.com

ELANTAS Deatech S.r.l.

Via San Martino 6 15028 Quattordio (AL) Italy Tel +39 0131 773870 Fax +39 0131 773875 info.elantas.deatech@altana.com www.elantas.com

ELANTAS UK Ltd

Keate House 1 Scholar Green Road Cobra Court Manchester M32 0TR United Kingdom Tel +44 (0)161 864 1689 Fax +44 (0)161 864 6090 info.elantas.uk@altana.com www.elantas.com

A member of

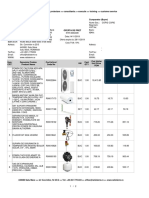

TECHNICAL DATA SHEET

pag.1/3

Resin

Hardener

Mixing ratio by weight

MC 4260

Application:

W 4260

100:10

Encapsulation of conventional electrical motors, linear motors and transformers. Excellent thermal cycling characteristics ensure service performance in applications requiring large bulk castings. Manual and/or automatic casting. Under vacuum casting with automatic mixing/dispensing devices. Room temperature or moderate temperature curing. The long pot life of the system allows the pre-heating of the parts to be casted to facilitate the impregnation of complex components. Two component epoxy system filled with abrasive fillers, self-extinguishing, thermal class H (180 C). Low viscosity. High impregnation properties. Low exothermic peak. Good electrical and mechanical properties. Good heat dissipation. The system is UL 94 HB and listed (File E143115 and E116643). The system is RoHS conform (European directive 2002/95/EC). SYSTEM SPECIFICATIONS

Processing:

Description:

Resin Density at: Viscosity at: Hardener FTIR spectrum (correlation factor) Gelation time

IO-10-75

25C 50C

IO-10-51 (ASTM D 1475) IO-10-50 (EN13702-2)

g/ml mPas

1,80 2.500

1,85 5.500

0,990 min 15

1,000 25

80C

IO-10-52b (UNI 8701)

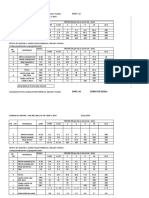

TYPICAL SYSTEM CHARACTERISTICS Processing Data Mixing ratio by weight Mixing ratio by volume Resin Colour Hardener Colour Viscosity at: 25C Resin Viscosity at: 25C Hardener Density at: 25C Hardener Pot life (doubled initial viscosity) 50C 80C

for 100 g resin for 100 ml resin

g ml

IO-10-50 (EN13702-2) IO-10-50 (EN13702-2)

mPas mPas g/ml min min mPas mPas h min

100:10 100:18 Black Neutral 15.000 25.000 5 15 0,94 15 10 3.000 400 5 50 0,98 25 15 4.000 700 6 60

IO-10-51 (ASTM D 1475)

IO-10-50 (EN13702-2) (*)

Initial mixture viscosity at: Gelation time Gelation time Suggested curing cycles

25C 50C 25C (15ml;6mm) 60C 100ml

IO-10-50 (EN13702-2)

IO-10-73 (*) IO-10-52b (UNI 8701)

(**)

48 hours at 25C or 6 hours at 80C

TECHNICAL DATA SHEET

pag.2/3

MC 4260/W 4260

TYPICAL CURED SYSTEM PROPERTIES Properties determined on specimens cured: 24 h TA + 15 h 60C Surface Density 25C Hardness 25C Glass transition (Tg) Linear thermal expansion (Tg -10C) Linear thermal expansion (Tg +10C) Flammability Thermal conductivity Dielectric constant at: Loss factor at: Volume resistivity at: Dielectric strength Tracking index Flexural strength Strain at break Flexural elastic modulus Tensile strength Elongation at break 25C 25C 25C 25C g/ml Shore D/15 C 10^-6/C 10^-6/C mm W/(mK) x 10^-3 Ohm x cm kV/mm CTI MN/m % MN/m MN/m % 0,60 3,5 10 8 x 10^14 19 Bright 1,73 1,77 85 55 60 135 6 0,70 4,5 30 3 x 10^15 21 90 65 70 155

IO-10-54 (ASTM D 792) IO-10-58 (ASTM D 2240) IO-10-69 (ASTM D 3418)

IO-10-71 (ASTM E 831) IO-10-71 (ASTM E 831) IO-10-68 (UL 94 HB)

IO-10-87 (ASTM C518) IO-10-59 (ASTM D 150) IO-10-59 (ASTM D 150) IO-10-60 (ASTM D 257) IO-10-61 (ASTM D 149) IEC 60112

> 600 75 1,5 4.500 40 1,5 85 2,5 5.500 50 3,0

IO-10-66 (ASTM D 790)

IO-10-66 (ASTM D 790) IO-10-66 (ASTM D 790) IO-10-63 (ASTM D 638) IO-10-63 (ASTM D 638)

IO-00-00 = Elantas Camattini's test method. The correspondent international method is indicated whenever possible. nd = not determined na = not applicable RT = TA = laboratory room temperature (232C) Conversion units: 1 mPas = 1 cPs 1MN/m2 = 10 kg/cm2 = 1 MPa (*) for larger quantities pot life is shorter and exothermic peak increases (**) the brackets mean optionality (***) the maximum recommended operating temperature is given on the basis of available laboratory information. Users should make their own assessments to verify the real component thermal class which is the result of the applied construction technology and used protective materials.

A member of

TECHNICAL DATA SHEET

pag.3/3

MC 4260/W 4260

Instructions: It is advisable to pre-heat the resin at 50C to make easier the application of the product. In prefilled products it is good practice to check and carefully rehomogenize the material if some settling is present. Add the appropriate quantity of hardener to the resin, mix carefully. Avoid air trapping. For a room temperature curing system post-curing allows fast stabilization of the material and obtainment of the best electrical and mechanical properties. During the curing process it is advisable to avoid thermal variations higher than 10C/hour. Epoxy resins and their hardeners can be stored for one year in the original sealed containers stored in a cool, dry place. After that period or if the material has been stored in anomalous conditions, pre-filled resins can be settled down and their use is possible, only if they are accurately re-homogenized with the help, if necessary, of a mechanical mixer. The hardeners are moisture sensitive therefore it is good practice to close the vessel immediately after each use. Refer to the safety data sheet and comply with regulations relating to industrial health and waste disposal.

Curing Post-curing:

Storage:

Handling precautions:

emission date: revision n 00

September

2008

The information given in this publication is based on the present state of our technical knowledge but buyers and users should make their own assessments of our products under their own application conditions.

Issued by: Elantas Camattini S.p.A.

A member of

You might also like

- RCDD Flash Cards - Chapter 1 Principle of TransmissionDocument286 pagesRCDD Flash Cards - Chapter 1 Principle of TransmissionTony Leonard80% (5)

- ABB Motors for Hazardous AreasDocument65 pagesABB Motors for Hazardous Areaslaem269No ratings yet

- Camera Tehnica Cu Pompa Caldura 16KW - Boiler - Puffer - Grupuri Pompare - Pachet Complet PDFDocument2 pagesCamera Tehnica Cu Pompa Caldura 16KW - Boiler - Puffer - Grupuri Pompare - Pachet Complet PDFCsaba VitusNo ratings yet

- Bread baking machine manualDocument66 pagesBread baking machine manualpiopio1234No ratings yet

- Convertizor de Frecventa Delta ManualDocument25 pagesConvertizor de Frecventa Delta ManualdanimihalcaNo ratings yet

- Dimensions and cross-sections of round copper conductorsDocument1 pageDimensions and cross-sections of round copper conductorsCipri RengleNo ratings yet

- QKNA For Mining GeologistDocument10 pagesQKNA For Mining GeologistAchanNo ratings yet

- Prop Chimice :oteluri Aliate PT Piese TratateDocument2 pagesProp Chimice :oteluri Aliate PT Piese TratateCiprian NitaNo ratings yet

- C - EWM - 90 - SAP Certified Application Associate - Extended Warehouse Management 9Document4 pagesC - EWM - 90 - SAP Certified Application Associate - Extended Warehouse Management 9Padma Raju0% (1)

- WWW - Chorus.ro: 3.1.1 Cabluri de Energie Din CupruDocument38 pagesWWW - Chorus.ro: 3.1.1 Cabluri de Energie Din CupruAlisa MariaNo ratings yet

- 005 PDFDocument8 pages005 PDFGrootNo ratings yet

- Relee MediasDocument50 pagesRelee MediasnorakutyNo ratings yet

- Dilatometry Measuring length-changes of your sample thermal expansion, magnetostrictionDocument41 pagesDilatometry Measuring length-changes of your sample thermal expansion, magnetostrictionUpendra93No ratings yet

- E SCH MX 122 - V0.7Document21 pagesE SCH MX 122 - V0.7Đỗ Hữu Khương100% (1)

- Geological Storage Site Screening and ApprovalDocument56 pagesGeological Storage Site Screening and ApprovalIbukun OpeyemiNo ratings yet

- Service Manual: Logamax Plus GB062Document57 pagesService Manual: Logamax Plus GB062marton elekesNo ratings yet

- R134a Refrigerant Property DataDocument1 pageR134a Refrigerant Property DatanotasdelingenieroNo ratings yet

- PeDocument55 pagesPeمنير أحمدNo ratings yet

- Catalog CabTecDocument78 pagesCatalog CabTecnemarc08No ratings yet

- Genetic Algorithms Optimize Synchronous Reluctance Motor DesignDocument6 pagesGenetic Algorithms Optimize Synchronous Reluctance Motor DesignedumacerenNo ratings yet

- Installation and maintenance instructions for MAX OPTIMUS C17 SPV 31 MEF wall hung gas boilerDocument27 pagesInstallation and maintenance instructions for MAX OPTIMUS C17 SPV 31 MEF wall hung gas boilerCristu CristianNo ratings yet

- Solved HT ProblemsDocument34 pagesSolved HT ProblemsRavichandran GNo ratings yet

- Instructiuni Instalare, Utilizare Si Service, Cazane Otel 2 Drumuri 'Unical - Ellprex' (En)Document32 pagesInstructiuni Instalare, Utilizare Si Service, Cazane Otel 2 Drumuri 'Unical - Ellprex' (En)bsambNo ratings yet

- Böhler Welding Produktkatalog EN 2019 1Document671 pagesBöhler Welding Produktkatalog EN 2019 1Bouzaida Maher100% (1)

- A620s80 81 Int69kf2 PDFDocument1 pageA620s80 81 Int69kf2 PDFMIGUEL ÁNGEL TOMÉNo ratings yet

- Arc140 S350 (16) CL System SpecDocument20 pagesArc140 S350 (16) CL System SpecKandregula Mohan BabuNo ratings yet

- Toc Doconcd Sinumerik v4.7sp2Document15 pagesToc Doconcd Sinumerik v4.7sp2davidcristian2009No ratings yet

- Catalog Contacor SiemensDocument49 pagesCatalog Contacor Siemenstayantrungquoc100% (2)

- Catalog Recuperator de Caldura Teknogen TevhrDocument3 pagesCatalog Recuperator de Caldura Teknogen TevhrRichard BradyNo ratings yet

- Diameter Nominal DN Nominal Pipe Size NPS: (MM) (Inches)Document3 pagesDiameter Nominal DN Nominal Pipe Size NPS: (MM) (Inches)Tecu CristiNo ratings yet

- Vana Fluture BiplanaDocument51 pagesVana Fluture BiplanaMaryus GeambyNo ratings yet

- The Flame Ionization Detector Maintenance and Troubleshooting GuideDocument35 pagesThe Flame Ionization Detector Maintenance and Troubleshooting GuideAbhishek SinghNo ratings yet

- METRIC INTERNAL CIRCLIPSDocument5 pagesMETRIC INTERNAL CIRCLIPSJhonny BNo ratings yet

- Chillere Cu Adsorbtie: Recuperare de Caldura Racire SolaraDocument18 pagesChillere Cu Adsorbtie: Recuperare de Caldura Racire Solaraxenia_1970No ratings yet

- KV XLDocument832 pagesKV XLTuấn NguyễnNo ratings yet

- Grundfosliterature 1847 PDFDocument88 pagesGrundfosliterature 1847 PDFismail 811No ratings yet

- STAKO CatalogueDocument23 pagesSTAKO CatalogueLeni SanchezNo ratings yet

- SG 557 Racorduri ErmetoDocument27 pagesSG 557 Racorduri ErmetoLeo CrisuNo ratings yet

- Chery Fengyun 2 Service Manual (Power Assembly)Document29 pagesChery Fengyun 2 Service Manual (Power Assembly)CarlosLauferNo ratings yet

- SecuriFire 500 1000 2000 3000 PC2018 F001en DDocument118 pagesSecuriFire 500 1000 2000 3000 PC2018 F001en DLorand BartaNo ratings yet

- Mounting, Operating, Usage of CF 55Document2 pagesMounting, Operating, Usage of CF 55Dan Provide100% (1)

- Corectie Dozaj Bapc 16 - 05,05,2020Document30 pagesCorectie Dozaj Bapc 16 - 05,05,2020Carmen MantaNo ratings yet

- Rezervor Apa Calda ElbiDocument4 pagesRezervor Apa Calda ElbiIonut Bucur100% (1)

- Grundfosliterature UPA Homebooster PDFDocument28 pagesGrundfosliterature UPA Homebooster PDFStefan DumitruNo ratings yet

- ROB0206EN - A - IRB 460 Data SheetDocument2 pagesROB0206EN - A - IRB 460 Data SheetDraghescu DanielNo ratings yet

- Grundfos UPA 120 HOME BOOSTER PDFDocument17 pagesGrundfos UPA 120 HOME BOOSTER PDFJuan Carlos Pulido100% (1)

- Ascon ManualDocument76 pagesAscon ManualZulfiqar AhmedNo ratings yet

- Cutit Roat modul m=2 mm plansaDocument1 pageCutit Roat modul m=2 mm plansaAndrei Dragos StanNo ratings yet

- AI-6C & AI9 Fusion Splicer ComparisonDocument1 pageAI-6C & AI9 Fusion Splicer ComparisonforgetingbluesNo ratings yet

- Tenma - At60d-Eu - Soldering Station, 60w, 220v, EuDocument1 pageTenma - At60d-Eu - Soldering Station, 60w, 220v, EuCristi MihalceaNo ratings yet

- Is IdealSystems Multiproduct IGuide NN W3705 W3710 W3711 W3714 Concealed-System 50-5354-00Document16 pagesIs IdealSystems Multiproduct IGuide NN W3705 W3710 W3711 W3714 Concealed-System 50-5354-00Catalin SpiridonNo ratings yet

- Instructions for Combined Boiler CombustionDocument23 pagesInstructions for Combined Boiler CombustionMavio ViorelNo ratings yet

- MEC701 Lab Manual W2016Document36 pagesMEC701 Lab Manual W2016Akash PatelNo ratings yet

- TX 500/S TX 1000/S "PLUS SERIES": FM Broadcasting ExciterDocument4 pagesTX 500/S TX 1000/S "PLUS SERIES": FM Broadcasting Exciterguestisor100% (1)

- En 1426 2015Document14 pagesEn 1426 2015AndraNo ratings yet

- Instructions for Use and Safety of Vaillant turboMAX Pro BoilerDocument8 pagesInstructions for Use and Safety of Vaillant turboMAX Pro BoilerPaulo BravoNo ratings yet

- GB RO HU - High efficiency wall-mounted gas-fired boilersDocument100 pagesGB RO HU - High efficiency wall-mounted gas-fired boilersAndrei Filip Stefan100% (1)

- Installation Manual Inverter PLATINUM 4300-7200TLDocument82 pagesInstallation Manual Inverter PLATINUM 4300-7200TLJohn Pappas100% (1)

- Aircraft Selection GuideDocument6 pagesAircraft Selection GuideRohit MunaNo ratings yet

- DS HLTP 60 Rev12 1107Document2 pagesDS HLTP 60 Rev12 1107Luisito Aguilar RojasNo ratings yet

- Enhanced P L A P: Olyimide Aminate ND RepregDocument4 pagesEnhanced P L A P: Olyimide Aminate ND Repregoutra_pessoaNo ratings yet

- LDPE-Low Density Polyethylene LTM 2185/47: Typical DataDocument3 pagesLDPE-Low Density Polyethylene LTM 2185/47: Typical DataMohamadMostafaviNo ratings yet

- Sealing and BondingDocument4 pagesSealing and BondingLovv InNo ratings yet

- Polyken 1600 High TempDocument2 pagesPolyken 1600 High TempKyaw Kyaw AungNo ratings yet

- LDPE-Low Density Polyethylene LTM 2119X: Typical DataDocument3 pagesLDPE-Low Density Polyethylene LTM 2119X: Typical DataMohamadMostafaviNo ratings yet

- Aspen Aerogel Pyrogel XT-DSDocument2 pagesAspen Aerogel Pyrogel XT-DSkflimNo ratings yet

- Enum Types JavaDocument3 pagesEnum Types JavaAmandeep PuniaNo ratings yet

- Contoh Spoof TextDocument7 pagesContoh Spoof TextIndrayaniNo ratings yet

- Auto TurnDocument156 pagesAuto TurnrrrraduNo ratings yet

- SD Card Formatter 5.0 User's Manual: June 30, 2017Document11 pagesSD Card Formatter 5.0 User's Manual: June 30, 2017Everton Klinger Sousa SilvaNo ratings yet

- Devops Training in Bangalore - Devops Training in Bangalore MarathahalliDocument8 pagesDevops Training in Bangalore - Devops Training in Bangalore MarathahalliitrainNo ratings yet

- HRMS Applicant Assessment FormDocument12 pagesHRMS Applicant Assessment FormDivya KakumanuNo ratings yet

- Abb FFWD 3 16 V 8 PDFDocument36 pagesAbb FFWD 3 16 V 8 PDFAnonymous N13JdnNo ratings yet

- 24 7 HRM Saas PricingDocument3 pages24 7 HRM Saas PricingRamakanth MardaNo ratings yet

- AART To Revitalize Aarhus Port District With TerracedDocument4 pagesAART To Revitalize Aarhus Port District With TerracedaditamatyasNo ratings yet

- Oleh - Fadli Satrio Fadjri - Prof. Dr. Ing. Ir. Rudi Rubiandini R.SDocument3 pagesOleh - Fadli Satrio Fadjri - Prof. Dr. Ing. Ir. Rudi Rubiandini R.SGusti PanuntunNo ratings yet

- A5 Service Manual 2.8Document223 pagesA5 Service Manual 2.8Anahi Calle Velasco0% (1)

- Aht PQDDocument315 pagesAht PQDsrinivas raoNo ratings yet

- A Homemade Edison Tinfoil PhonographDocument32 pagesA Homemade Edison Tinfoil PhonographGabriel MedinaNo ratings yet

- Android Snake With Kivy, PythonDocument14 pagesAndroid Snake With Kivy, Pythontsultim bhutiaNo ratings yet

- Investment Opportunities in OdishaDocument28 pagesInvestment Opportunities in OdishaNiladri MandalNo ratings yet

- Introduction to Philosophy Class Lesson PlansDocument3 pagesIntroduction to Philosophy Class Lesson PlansJennifer MagangoNo ratings yet

- My Life - An Illustrated Biograp - A.P.J. Abdul KalamDocument76 pagesMy Life - An Illustrated Biograp - A.P.J. Abdul KalamAnonymous OJsGrxlx6100% (1)

- 0111 Tension Load Cell Datasheet enDocument2 pages0111 Tension Load Cell Datasheet enJosipaNo ratings yet

- Network Layer Packet Tracer LabDocument3 pagesNetwork Layer Packet Tracer LabSendy Trias NugrahaNo ratings yet

- Euref2 English PDFDocument10 pagesEuref2 English PDFbasileusbyzantiumNo ratings yet

- Vibration PPV EstimationDocument8 pagesVibration PPV EstimationJensen TanNo ratings yet

- Pune University Simulation and Modeling Question PapersDocument2 pagesPune University Simulation and Modeling Question Paperspradeepkraj22No ratings yet

- Periscope HD Inagip Croatia CsDocument2 pagesPeriscope HD Inagip Croatia CsTran Dang SangNo ratings yet

- C8516-CLT-QMT-0002 Rev.02-Inspection Checklist For Precast Gully InstallationDocument1 pageC8516-CLT-QMT-0002 Rev.02-Inspection Checklist For Precast Gully InstallationJabinNo ratings yet