Professional Documents

Culture Documents

3-2-29 Paper

Uploaded by

Nurul HudaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3-2-29 Paper

Uploaded by

Nurul HudaCopyright:

Available Formats

1

Javier Trelles, Ph.D., Craig L. Beyler, Ph.D., Jason E. Floyd, Ph.D., Joseph L. Scheffey,

P.E. (Hughes Associates, Inc.), and Kim W. Yee (Naval Surface Warfare Center)

Fire and Smoke Spread Modeling to Support Damage

Control Assessment and Decision Making in

Shipboard Environments

ABSTRACT

Predictive modeling of the spread of fire, smoke,

radiological, chemical, and biological agents is

needed to reduce the manning requirements of

future ships. Physics-based models for fire

hazards do exist but they are not integrated with

the ships sensors and they are not designed to

work as faster-than-real-time advisory tools.

Current generation damage decision and

assessment system uses the Fire and Smoke

Spread Simulator (FSSIM), a physics-based

network model, to pre-compute fire & smoke

scenarios for the systems heuristic fire and

smoke federate. The next generation will

incorporate predictive federates. FSSIMShip is

being developed as the real-time, deterministic

fire and smoke spread model. The objective is

to test and demonstrate a successful prototype

capable of sensor driven predictions of

shipboard conditions operating at or faster than

real time. The results will forecast fire & smoke

conditions in order to support the damage

control decision making process. The effort

involves removing inefficiencies in the source

code and underlying algorithms as well as

incorporating multi-processor ready solvers into

FSSIM. A sensor-driven element is being added

to the model, allowing for continual verification

and adjustment of the fire and smoke spread

prediction outputs. Use of the model in a multi-

processor shipboard computing environment is

envisioned. As such, the algorithms are being

updated for parallel processing. This paper

provides an update on this effort.

INTRODUCTION

In an effort to reduce life-cycle cost, the United

States Navy (USN) currently has a reduced

manning initiative with the goal of cutting

assigned tasks by means of automation and

computer-based decisions. A key to the success

of this initiative is to determine the right balance

of automated control systems capable of

supplementing manning for both normal and

damage control operations. During casualty

operations, manning can be reduced if the ships

automation is capable of determining the extent

of current damage, the likely progression of the

damage over time, and recommend and/or take

action to mitigate the damage quickly and

efficiently. Since damage can progress rapidly,

automation for assessing damage must occur fast

enough that mitigation can have a positive

outcome.

Hence on future naval ships, crew members will

need to concentrate on their assigned tasks or

specialties such as piloting the ship, telemetry,

and weapons command. In a casualty event,

crew members skilled in firefighting will be in

limited supply as compared to current CG-47 or

DDG-51 class ships. The crew will be

complimented by an advisory system that

accurately provides situational awareness and

decision aids about damage control operations.

The present effort supports a small business

innovation and research (SBIR) topic to develop

a shipboard computational titled Model to

Support Damage Control Assessment and

Decision-Making in Shipboard Environments.

Its goal is to reduce the amount of time required

to process damage control information and

estimate casualty spread in order to support

automated damage control systems in real time.

Currently, the Fire and Smoke Spread Simulator

(FSSIM) is the physics-based network model

used to pre-compute scenarios in the heuristic

2

fire and smoke federate of the damage decision

and assessment system (DDAS). FSSIM (Floyd

et al. 2004) presently lacks real-time

performance and sensor interaction. The next

generation of this predictive software,

FSSIMShip, will be developed to provide

shipboard sensor driven, faster than real time

simulations.

The software will be integrated with the ships

sensor and alarm networks. This will ground the

advisory system with the latest situational

updates. In its new incarnation the software will

also have similarities with the Sensor Driven

Fire Model, a fire fighter tool proposed by the

National Institute of Standards and Technology

(NIST) (Davis, Cleary, Donnelly, & Hellerman,

2003; Davis & Forney, 2001) but yet to be

realized in practice.

Speed and the ability to accurately model large,

complexly interconnected spaces equipped with

ventilation, sensors, and suppression systems are

the performance requirements for the model.

Processing requirements, however, should also

be kept to a minimum. While the processing

power planned for future naval ships is

considerable, there are many computational

needs to be supported for both damage control

functions and normal ship operations functions.

The prudent approach, and the one embraced in

this effort, is to minimize the computational

footprint of advisory systems such as

FSSIMShip.

FSSIMShips capability can be envisioned by a

weapons-induced damage scenario onboard a

ship. Immediately after a weapon hit there will

be a period of automatic reconfiguration of

electronic and hydraulic systems in an attempt to

route system capabilities around damaged

portions of the ship. These automated actions

will be largely predetermined based doctrine and

may or may not represent the optimal response.

Following this initial response, further damage

control (DC) activities may be relatively time

consuming. First, information is collected by

the damage detection and control systems. Then

the information is analyzed. Finally, potential

responses are determined and compared to

optimize the response. Any manned response

will involve the times to communicate the task,

complete dressing out, acquire equipment,

transit to the desired location, and gain access.

Any response involving the reconfiguration of

systems will require sufficient time to perform

the reconfiguration and to monitor the results.

At the point in time when either a manned

response is on scene and ready to commence or

a successful system reconfiguration has

occurred, the action that was taken needs to still

be valid. If the recommended action is negated

by further fire and smoke spread, then some

fraction of the time and effort expended on the

action will have been wasted. The ability to

look ahead far enough to avoid recommending

an unsuitable response will greatly improve the

overall effectiveness of the DC effort and

minimize the consumption of ship personnel and

equipment resources. The prediction from

FSSIMShip will complete rapidly enough to

allow the damage control assistant (DCA) to

formulate a response before the prognostic time

window expires. The goal of FSSIMShip is a 30

minute prediction horizon in under 20 seconds.

Based on current sensor data and crew reports,

the onboard software will locate actively

burning compartments. Those spaces that are

untenable would be identified so that response

crews would thus avoid these areas. For areas

where sensor data is lost/unavailable, the

software will fill in the information gap. In the

remaining spaces, the software will coordinate

with the functional sensors. All logged crew

reports would be imported by the model. The

continuously updating 30-min projection gives

the DCA a sense of not just the current situation

but also what the near term consequences of the

involved spaces will be.

FSSIMShip will not only predict fire and smoke

spread but will be able to adjust actions based on

effects of deployed automatic fire protection

systems. For example, on future naval ships fire

suppression systems consist primarily of water

mist systems. The quasi-equilibrium

evaporation model of (Back, Beyler, & Hanssen,

2000) is used to rapidly predict the anticipated

temperature drop following water mist

activation. The model uses the provided

3

compartment temperature, estimated fire size

(based on prediction or sensor data), and the

compartment ventilation based on heating,

ventilation, and air conditioning (HVAC) system

settings and portal status to predict the

effectiveness of the water mist system. Hence

the DCA will acquire a sense of what

compartments will need a manned response.

The goal planned for FSSIMship is to provide

the Navy with a real-time fire and smoke engine

to replace the pre-computated fire and smoke

database in support of a damage decision tool

termed Damage Decision & Assessment (DDA).

Overview of the FSSIMShip Network

Model

FSSIMShip is a network fire model written to

simulate the spread of fire and smoke in a naval

vessel. However, there is nothing in the model

to preclude its use for other types of

compartmented structures such as a building. In

FSSIMShip each compartment in a structure is

represented as a single node with surfaces (e.g.,

bulkheads, decks, and overheads) and vent

openings (e.g., doors, hatches, etc.) represented

as node connections.

FSSIMShip encompasses the following

capabilities:

- 1D flow model including friction losses and

temperature-dependent specific heat.

- 1D multiple-layer, temperature-dependent

heat transfer.

- N-surface, gray-gas radiation heat transfer,

including radiation streaming through

openings.

- Bidirectional flow through horizontal

(hatches) and vertical (doors) flow

connections.

- Combustion product species tracking.

- Oxygen and fuel limited combustion.

- Multiple fires and fire spread via

compartment-to-compartment heat transfer.

- HVAC systems including ducts, dampers,

chillers, and fans with forward and reverse

flow losses and multiple fan models.

- Fire detection via heat, smoke, and fire

detection

- Fire spread by compartment-specific

criteria.

- Fire suppression via sprinklers, water mist,

gaseous agents, aerosol agents, and foam.

- Fire spread prevention via boundary cooling.

- Binary control structures used to link

operation of equipment to sensors or times.

- Faster-than-real-time execution speed.

- Both coordinated and complimentary

interaction with shipboard sensors and/or

fire alarm system.

PHYSICS

The core physics of FSSIMShip is little changed

from that of FSSIM. These are briefly reviewed

in the ensuing subsections.

Compartment Flows

FSSIMShip solves lumped, time-dependent

conservation equations for mass, momentum and

energy. Energy and mass are conserved

explicitly, whereas momentum is conserved

implicitly. Energy and mass conservation use a

control-volume approach, where the control

volume is either a single compartment or a

ventilation system node. Momentum is

implicitly solved for at vent connections or in

ducts. The set of equations used is taken from

MELCOR (Gauntt et al. 2000) as implemented

in FSSIM (Floyd et al. 2004). This set of

equations is solved numerically using ordinary

differential equations (ODE) and differential-

algebraic equations (DAE) solvers.

Combustion

Upon activation, FSSIMShip will set up fires

according to inputs from sensors and from the

DCA. These fires will spread according to local

conditions. Ignition of additional fires is

determined at the beginning of each time step.

Each compartment can have a use-type

designation, which denotes a fuel loading and

fuel classification. Separate temperature

ignition criteria are specified for surfaces,

temperature of incoming vent flows, and

4

compartment temperature (Back et al. 2003).

Overhead surfaces have different ignition

temperatures from other surfaces.

Pyrolysis is based on a composite function that

includes

2

t growth, continuous burn according

to local conditions, and polynomial or

exponential decay. Growth is limited by

specification of a maximum pyrolysis rate. The

calculated pyrolysis rate can be reduced by

various mechanisms. If the fire is being

suppressed by an agent, the pyrolysis will be

reduced by a suppression factor. If the fire has

become oxygen limited, then the pyrolysis rate

is determined by a linear function of

temperature. The maximum pyrolysis rate after

oxygen-limiting conditions are reached is set at

the point where the fire became oxygen limited;

the compartment temperature for that point is

also stored. The oxygen-limited pyrolysis rate is

then calculated by the ratio of the current

temperature to the stored temperature not to

exceed the maximum rate. The actual heat

release rate is adjusted to use the calculated

amount of available oxygen.

Species are generated based on the yields for

each fuel being burned. These yields represent

the mass of combustion products formed for a

unit mass of fuel burned.

\Heat Transfer

Convection heat transfer is calculated at each

surface for each time step. Two sets of

convection heat transfer correlations are used.

The first is used for spaces where either no fire

exists or the volume of the space is small in

comparison to the anticipated fire size. The

second set of correlations applies a plume and

ceiling jet model to improve computation of heat

transfer to the overhead. If a surface has been

specified as transparent to radiation, no

convection heat transfer computation is

performed.

Radiation heat transfer is computed on a

compartment-by-compartment basis using the

beginning of time step surface temperatures,

compartment temperature, compartment gas

composition, and compartment heat release rate.

The heat transfer is calculated using a modified

gray-gas, n -surface net radiation method

(Forney 1991).

Conduction heat transfer is computed from a

one-dimensional (1D) heat equation discretized

with central differences (Strauss 1992) to arrive

at a set of ODEs for each wall. Each 1D

partition/bulkhead is divided into N -1 cells or

nodes with N boundaries. Boundary conditions

are obtained from the convection and radiation

calculations. Each wall can have multiple layers

of materials and temperature-dependent specific

heats and conductivities.

SENSITIVITY AND

UNCERTAINTY

The remaining sections detail new features in

FSSIMShip. Because the DCA is using the data

from FSSIMShip to address an ongoing

situation, it is desirable to give the DCA an

assessment of the accuracy of FSSIMShip

predictions. Hence automatic estimation of

sensitivity and uncertainty are part of every

FSSIMship prediction cycle. Two variables are

currently singled out for this treatment: the

temperature, T , and the spread distance, x .

Hence, if x is the uncertainty in the spread,

the prediction can be written as

. x x (1)

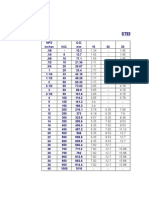

Figure 1. Some standard distributions associated

with measurements.

5

Formally, the squares of the uncertainties are the

variances of the predictions. Each datum has a

probability distribution. In Figure 1 the

uncertainty is shown as the standard deviation of

the symmetric distribution. Skew distributions

are possible as well. For the present analysis,

the top hat distribution is assumed. As Figure 1

shows, it is symmetric about its center and all

values within the standard deviation bounds are

equally probable.

If the uncertainty in a set of parameters is taken

as a given, a formal methodology can be

followed to determined how this is manifested in

variables calculated from this set (ASTM 1998).

The compartment temperature plus the spatially

discretized heat transfer equations in FSSIMShip

form a system of differential algebraic equations

(DAEs). The uncertainty is quantified by

solving the DAE plus sensitivity system for each

compartment and each computational cell. The

uncertainty in the boundary conditions appear as

extra algebraic terms. The sensitivity

coefficients are then used to quantify the

uncertainty in the temperature prediction in each

compartment. The solvers DASPAK 3.0,

CVODES, and IDAS (Hindmarsh 2000;

Hindmarsh 2005; Li & Petzold 1999; Li &

Petzold 2000; Petzold et al. 2006) have the

requisite numerical machinery (such as the

evaluation of the partial derivatives) built into

them to solve these types of sensitivity

problems.

This formal procedure works fine for the

temperature but not for the extent of the affected

areas because spread is determined by the

satisfaction of certain criteria. For example,

when a compartment exceeds an ignition

temperature for a certain amount of time it is

designated as containing a fire. For the extent of

the affected area, use is made of the

characteristic distance (Trelles & Pagni 1997),

( )

,

1

5 / 2

(

(

g p

Q

x

max

c

(2)

where

c

x is the characteristic length scale,

max

Q

is the highest heat release rate from all the fires

that are currently burning, is the ratio of the

specific heats,

p is the ambient pressure, and

g is the acceleration of gravity. The distance

uncertainty as a function of the heat release rate

is

( )

,

1

5

2

5 / 3

5 / 2

max

max

Q

Q

g p

x

(

(

(3)

or, in terms of relative uncertainty,

.

5

2

5

2

Q

Q

Q

x

x

x

max c

= = = (4)

Along the border of the involved compartments,

distance is measured from the origin,

0

x

, to the

edge, x

. The uncertainty in the spread is

therefore

.

0

x x x x

= (5)

The characteristic length in Eq. 2 formally

applies to an unconstrained plume. In a ship, the

plume and fire would be affected by many

factors such as passageway geometry and

ventilation. However, since the plume is

fundamental even in a compartment, it is a

rational starting point. (Hamins & McGrattan

2007) give the example of the flame height

based on the Heskestad expression. Even

though flame height is a distance, because of its

dependency on heat release rate and pool fire

diameter, the asymptotic relative uncertainty of

the flame height scales as Q L

2

1

= . This

is greater than the 2/5 coefficient in Eq. 4. In

general, the complications associated with

potentially multiple fires that have flames

impinging on the rocking overhead of a ship

indicate increased uncertainty. For these reasons

it is believed that the spread uncertainty in Eq. 5,

which was based on Eqs. 2 and 4, is a lower

bound.

6

INVERSE METHODS

A key part of the damage control software for

future naval ships is the integration of sensor

data and crew reports into modeling tools and

damage decision aids such as FSSIMShip. On

the most basic level, FSSIMShip accepts sensor

data as a means of model initialization. Another

opportunity afforded by the sensor and crew

inputs is the extrapolation of these reports to

determine the heat release rate (HRR) of a fire.

The meteorological, geophysical, and

engineering disciplines have developed a variety

of inverse methods in order to obtain model

inputs from sparse readings (Backus 1971;

Menke 1989). The robustness of inverse

methods was improved with the advent of

regularization techniques (Tikhanov & Arsenin

1977).

In the realm of heat transfer, previous studies

(zisik & Orlande 2000) have shown how to

arrive at heat fluxes and heat sources from

temperature measurements made in laboratory

settings. These efforts benefited from the ability

to put as many sensors as would be feasibly

desired within the laboratory sample. The same

can be said for the early sensor-driven fire

model (Davis & Forney 2001) and other fire

protection engineering investigations of

reconstructing fire physics from sensor

measurements (Kramer et al 2003; Padakannaya,

Richards, & Plumb 1994; Richards, Munk, &

Plumb 1997; Richards et al. 1997). This may

not be an option with future naval ships.

The algorithms developed for FSSIMShip use

nonlinear parameter estimation to analyze sensor

inputs from local and nearby compartments in

order to estimate the heat release rate (HRR).

Although inverse methods (Beck & Arnold

1977; Tikhanov & Arsenin 1977) have been

widely explored, they tend to be computationally

expensive. This computational load needs to be

minimized for FSSIMShip. Since FSSIMShip

will be constantly updating itself, previous

sensor results will also be utilized for this HRR

calculation. Inverse methods will only be

possible for compartments with working sensors

that provide numerical readings. They can only

be used from the start of the incident up to the

present time. Once FSSIMShip goes beyond the

present time inverse methods are not possible

due to the lack of sensor input. The next two

subsections detail inverse methods that can be

used to improve the prediction of the heat

release rate associated with a spreading set of

fires.

To recap, in FSSIMShip measurements are used

to set conditions in compartments from the time

of the incident to the present. This sensor data is

utilized in the inverse methods to improve

estimates for key parameters. During this

incident to present period, simulations are still

used to determine conditions in compartments

which (1) do not have sensors, (2) have damaged

sensors, (3) are not reporting sensor readings for

whatever reason, or (4) have sensors that only

provide an alarm of some type, i.e., no data.

From the present to the future FSSIMShip only

simulates conditions with, wherever possible,

the sensors providing initial conditions and

improved estimates for key model parameters.

Compartments lacking this information use the

last set of calculated conditions.

Global Inverse Methods

The classic inverse method is global in scope.

This means that it takes data from throughout

the platform in order to arrive at its estimates.

The general approach is now outlined. Assume

that the heat release rate can be modeled as

( ) t C q

P

N

j

j j f

=

=

1

(6)

where

j

are the parameters and ( ) t C

j

are

functions (typically polynomials of some type),

both with

P

N elements. For example, fire

growth is typically described as

2

t q

f

o = (7)

Here

P

N = 1,

1

= o , and ( ) t C

1

=

2

t . The

goal is to use sensor data to arrive at better

7

estimates of

1

. Even if the simple model of

Eq. 7 is adopted, having a better handle on fire

growth can significantly improve model

predictions. A quadratic objective function, S ,

is defined to indicate the level of agreement

between measured and predicted temperatures.

In order to minimize the difference, the gradient

of S with respect to the parameters is taken and

the result is set to zero. This is analogous to

taking the derivative of a scalar function to

determine its extrema.

The resulting equations form a system of

nonlinear equations. In order to solve it, the

gradient equations are fed to a nonlinear

equations solver such as KINSOL (Collier at al.

2006). KINSOL in turn calls the appropriate

subroutines in FSSIMShip to obtain the

sensitivity Jacobian. KINSOL will work to

satisfy an error tolerance (if possible). These

basic types of algorithms tend to suffer from

difficulties with numerical stability. As an

example of why this is the case, remember the

relationship between the flame height and the

heat release rate uncertainties given above,

Q L

5 . 0 = . For the inverse problem the

heat release rate would be determined from the

flame height. For this case then L Q 2 =

.

This is typical of inverse problems:

measurement uncertainties become amplified.

For numerical methods, the truncation of real

numbers to the n -byte rational numbers that are

available on digital computers can introduce

enough error into the problem to result in an

unstable algorithm. Regularization techniques

add terms to the definition of the objective

function in order to improve the robustness of

the overall inverse method.

Local Inverse Methods

For a ship section modeled as a lumped mass of

compartments, techniques such as deconvolution

(Casey & Walnut 1994) can be used to obtain

the physically meaningful variables from all of

the sensor readings obtained at different

sampling rates. This approach has the advantage

that it is local in scope. It makes use of sensor

data at different sampling rates. The method

works formally for linear problems so the

current set of equations would have to be

appropriately linearized. Much of this work has

already been done in FSSIM, though. The

challenge for FSSIMShip is to arrive at suitable

convolution integrals for the bulk of the

equations that describe compartment

temperature. The applicability of this method as

a substitute for the other inverse methods, which

are global in scope, will then be assessed.

Start

Register Event

Start Time

t

S

No

All

Clear?

Yes

Monitor

Monitor

Sensors

DCA Inputs

Register

Event?

Yes

No

Forecast

Forecast

Report

Record Current

Time t

C

Set Cycle

Final Time

t

F

= t

C

+ 30 min

Review

Predict

Output to

Consoles

Figure 2. Flowchart showing the basic software

architecture of FSSIMShip.

OVERALL SOLUTION SCHEME

FSSIMShip is configured to continuously march

out to a specified time interval beyond the

present. The main loop calls the forcast loop.

(Refer to Figure 2.) This loop has two sections.

The first part is for events from the beginning of

the emergency to the present time. The

information processed in this loop will consist of

new sensor data, new calculations, and

8

previously stored readings and calculations. The

second part of the time marching loop will go

from the present into the future. The state

determined in the first part of the time marching

loop will be used to initialize the deterministic

models. The solution of the governing equations

is realized by the use of DAE solvers. An outer

loop is set up to march through time. (See

Figure 3.) An inner loop is then initiated for

node states at the current time. The solvers are

called for the compartment conditions. They are

then called to solve the heat transfer equations.

If the exit code indicates a successful return then

this inner loop runs for only one count.

Otherwise measures are taken according to the

exit status flag.

Review

Gather

Inputs from

All Sensors

Determine

Compartment

Fire Statuses

Inverse

Methods

Set HRR

Parameters

Predict

Predict

Set

t = t

C

+ At

Determine

Reduced

Computational

Domain

Solve in

Reduced

Computational

Domain

t > t

F

?

Report

Yes

No

Figure 3. Flowchart showing the sections of the

FSSIMShip software architecture that interact

with sensors and predict the impact of current

fires.

REAL-TIME COMPUTATION

Two techniques will be used to improve run

time performance. Currently FSSIMShip

simulates the entire ship. In general this will not

be necessary for supporting damage control.

Regions of the ship remote from the weapon hit

should not see a significant fire and smoke

spread impact. The time for fire and smoke to

spread to these regions will provide time for

damage control activities to halt the spread of

secondary damage to these regions.

Autonomous suppression systems in remote

regions should be functional (or regain

functionality prior to spread). The candidate

approaches include strict limiting of the

geometric extent being computed, a multi-region

approach where computational fidelity varies

with remoteness of the region (e.g., a hybrid

heuristics-physics model), and multi-block

approach where remote spaces and their

associated ventilation are combined.

Set Openings /

Closings

Identify New /

Extinguished

Fires

Regenerate

Computational

Domain

Update Solver

RHS Function

Initialize

Solver

Call Solver

Any Error

Flags?

Continue

Corrective

Measures

Predict

Set

t = t

C

+ At

Determine

Reduced

Computational

Domain

Solve in

Reduced

Computational

Domain

t > t

F

?

Report

Yes

No

No

Yes

Figure 4. Flowchart showing the section of the

FSSIMShip code that solves the governing

equations. The dashed rectangles on the right

diagram are expansions of the corresponding left

diagram actions.

The bulk of the computation time within FSSIM

lies in matrix-based solvers. Incorporating more

efficient solvers and code structures (Drummond

& Marques 2005) in FSSIMShip will result in

faster turn-around. FSSIM is currently

9

structured as a single processor software tool.

Many portions of the code are easily amenable

to high performance (multiple-processor)

computing (Pacheco 1997). FSSIMShip uses

the Message Passing Interface (MPI) (Pacheco

1997; Gropp, Lusk, & Skjellum 1999; Snir

1998). This allows distributing the calculation

on a set of computers/processors in the data

center. MPI-capable solvers, such as those

available with Argonne National Laboratorys

Portable, Extensible Toolkit for Scientific

Computation (PETSc) (Balay et al. 1997; Balay

et al. 2004), will be employed. The goal is to

perform as many implicit solves in parallel as

possible. The appropriate number of processors

needed to achieve faster than real time goals will

be explored. Refer to Figure 4 for the

envisioned software architecture.

SENSORS AND DETECTORS

For state-of-the-art ships of the future, advisory

software developers will have input on the

number and types of sensors to be installed.

This will allow FSSIMShip to work

cooperatively with sensors. However, older

generation naval vessels are typically equipped

with a fire alarm system which has a limited set

of sensors. There is no guarantee that the

readings from the sensors will be available at a

ship console. More likely than not the fire alarm

system provides just that: an alarm and an

annunciated location and no further information.

For these cases, FSSIMShip will compliment

sensors, filling in the gap afforded by the alarm

interface with simulation data on the conditions

in affected areas. Refer to Figure 4 for the

software architecture that shows how sensor data

will be incorporated into FSSIMShip.

Once sensor algorithms are defined, there

remain significant implementation issues to

optimize their performance with FSSIMShip.

Whenever possible FSSIMShip will be

interfaced with the sensor network. Typical

interfaces are TCP/IP and MODBUS. Since

FSSIMShip needs to address the problem of

incomplete sensor readings, some damage

assessment (Fritzen, Jennewein, & Kiefer 1998)

is necessary within FSSIMShip. In addition,

there are challenges to be addressed in

identifying and implementing event type data

into the simulation. These may include events

like creation of an opening via damage or crew

action, as well as fire mitigation via crew action.

To aid in limiting the range of events that needs

to be considered, it is envisioned that high level

knowledge will be provided to the model from

the DCA or other systems. This is expected to

include clarifications such as fire due to hostile

weapons (for known types) and other

information about the incident that is developed

via the various systems and crew observations.

DATABASE

Because FSSIMShip is an autonomous system,

there will be no need to create an input file as

was the case with FSSIM. However,

FSSIMShip will need access to a database or a

set of databases that contain crucial information

such as ship information and physical constants.

It remains to be determined whether this

information will be contained within the

compiled program or externally. It is currently

expected to be a combination thereof: material

properties can be contained within FSSIMShip

but ship specifics will be contained in data files.

The following is a list of important information

to be contained in the databases.

- Connections based on the ship layout;

- Compartment volumes;

- Wall areas;

- Resistance coefficients for standard objects

such as doors, hatches, ducts, etc;

- Thermal properties for common materials

such as steel and insulation;

- Suppression systems data such as activation

temperatures and response time indices; and

- Detector data such as threshold values and

response lags;

- Sensor locations.

Smart product model development and

implementation could be leveraged to provide

this ship specific data.

10

CONCLUSIONS

The basic framework for shipboard FSS

established FSSIM as an incident modeling and

investigation tool. FSSIM is currently being

transitioned to the real-time, onboard damage

control tool known as FSSIMShip. To

accomplish this, the following changes are in the

process of being made to FSSIM:

- Parallel computation;

- Estimation of uncertainty and sensitivity;

- Creation of ship- and physics-specific

databases;

- Integration with shipboard sensors and/or

fire alarm system; and

- Use of sensor data to improve key model

inputs such as the heat release rate.

Approaches to accomplish this transition have

been detailed above. They will be developed

and refined as the project moves forward.

REFERENCES

ASTM, Standard Guide for Evaluating the

Predictive Capability of Deterministic Fire

Models, E 1355, New York: American National

Standards Institute, 1998.

Back, G., Beyler, C., and Hanssen, R., A

Quasi-Steady-State Model for Predicting Fire

Suppression in Spaces Protected by Water Mist

Systems, Fire Safety Journal, 35, pp 327362,

2000.

Back, G., E. Mack, M. Peatross, J. Scheffey, D.

White, F. Williams, J. Farley, and D. Satterfield,

A Methodology for Predicting Fire and Smoke

Spread Following a Weapon Hit, NRL Ltr Rpt

Ser 6180/0014, Naval Research Laboratory,

Washington, DC, 2003.

Backus, G.E., Inference from Inadequate and

Inaccurate Data, in Reid, W. H., (ed.),

Mathematical Problems in the Geophysical

Sciences, Providence, RI, American

Mathematical Society, pp. 1106, 1971.

Balay, S., Gropp, W.D., McInnes, L.C., &

Smith, B.F., Efficient Management of

Parallelism in Object Oriented Numerical

Software Libraries, in Arge, E., Bruaset, A.M.

and Langtangen, H.P. (eds.), Modern Software

Tools in Scientific Computing, Boston, MA:

Birkhuser, pp. 163202, 1997.

Balay, S., Buschelman, K., Eijkhout, V., Gropp,

W.D., Kaushik, D., Knepley, M.G., McInnes,

L.C., Smith, B.F., and Zhang, H., PETSc Users

Manual, Argonne National Laboratory,

ANL-95/11 - Revision 2.2.0, 2004.

Beck, J.V. and Arnold, K.J., Parameter

Estimation in Engineering and Science, New

York: Wiley, 1977.

Casey, S., and Walnut, D., Systems of

Convolution Equations, Deconvolution,

Shannon Sampling, and the Wavelet and Gabor

Transforms, SIAM Review, 36:4, pp. 537577,

1994.

Collier, A.M., Hindmarsh, A.C., Serban, R., &

Woodward, C.S., User Documentation for

KINSOL v2.5.0, UCRL-SM-208116,

Livermore, CA: Lawrence Livermore National

Laboratory, November 6, 2006.

Davis, W. D., and Forney, G. P., A Sensor-

Driven Fire Model, Version 1.1, National

Institute of Standards and Technology,

Gaithersburg, MD, NISTIR 6705; January 2001.

Drummond, L.A. and Marques, O.A., An

Overview of the Advanced CompuTational

Software (ACTS) Collection, ACM

Transactions on Mathematical Software, 31:3,

pp. 282301, 2005.

Floyd, J., S. Hunt, F. Williams, and P. Tatem,

Fire + Smoke Simulator Version 1 (FSSIM)

Theory Manual, NRL, Washington, DC, 2004.

Forney, G., Computing Radiative Heat Transfer

Occurring in a Zone Fire Model, NISTIR 4709,

National Institute of Standards and Technology,

Gaithersburg, MD, 1991.

Fritzen, C.-P., Jennewein, D., & Kiefer, T.,

"Damage Detection Based on Model Updating

11

Methods," Mechanical Systems and Signal

Processing, 12:1, January 1998, pp. 163186.

Gauntt, R., R. Cole, C. Erickson, R. Gido, R.

Gasser, S. Rodriguez, M. Young, MELCOR

Computer Code Manuals: Reference Manuals

Version 1.8.5, NUREG/CR-6119, Volume 2,

Rev. 2, U.S. Nuclear Regulatory Commission,

Washington, DC, 2000.

Gropp, W., Lusk, E., and Skjellum, A., Using

MPI: Portable Parallel Programming with the

Message-Passing Interface, 2nd Edition,

Cambridge, MA, MIT Press, 1999.

Hamins, A., and McGrattan, K. B., Verification

and Validation of Selected Fire Models for

Nuclear Power Plant Applications, Volume 2:

Experimental Uncertainty, U.S. Nuclear

Regulatory Commission, Office of Nuclear

Regulatory Research (RES), Rockville, MD, and

Electric Power Research Institute (EPRI), Palo

Alto, CA. NUREG-1824 and EPRI 1011999,

May 2007.

Hindmarsh, A.C., The PVODE and IDA

Algorithms, LLNL Technical Report UCRL-

ID-141558, December 2000.

Hindmarsh, A.C., Brown, P.N., Grant, K.E.,

Lee, S.L., Serban, R., Shumaker, D.E., and

Woodward, C.S., SUNDIALS: Suite of

Nonlinear and Differential/Algebraic Equation

Solvers, ACM Transactions on Mathematical

Software, 31:3, pp. 363396, 2005.

Li, S., and Petzold, L., Design of New DASPK

for Sensitivity Analysis, Technical Report, Dept.

of Computer Science, Technical Report UCSB,

University of California at Santa Barbara, 1999.

Li, S., and Petzold, L., Software and

Algorithms for Sensitivity Analysis of Large-

Scale Differential-Algebraic Systems, Journal

of Computational and Applied Mathematics,

125, pp. 131145, 2000.

Liley, P. E., Reid, R. C., and Buck, E. (1984),

Physical and Chemical Data, in R.H. Perry,

D.W. Green, & J.O. Maloney (eds.), Perrys

Chemical Engineers Handbook, 6

th

ed., New

York, McGraw Hill, pp. 3-13-291.

Menke, W., Geophysical Data Analysis:

Discrete Inverse Theory, San Diego, CA,

Academic Press, 1989.

zisik, M.N., & Orlande, H.R.B., Inverse Heat

Transfer, New York: Taylor & Francis, 2000.

Pacheco, P., Parallel Programming with MPI,

San Francisco, CA, Morgan Kaufmann

Publishers, Inc., 1997.

Padakannaya, K., Richards, R.F., and Plumb,

O.A., Inverse Radiation Solution for Fire

Detection, NISTIR 5499, September 1994,

Gaithersburg, MD, National Institute of

Standards and Technology, 1994.

Petzold, L., Li, S., Cao, Y., and Serban, R.,

Sensitivity Analysis of Differential-Algebraic

Equations and Partial Differential Equations, to

appear, Computers and Chemical Engineering,

2006.

Richards, R.F., Munk, B.N., and Plumb, O.A.,

Fire Detection, Location and Heat Release Rate

Through Inverse Problem Solution. Part 1.

Theory, Fire Safety Journal, 28:4, pp. 323350,

1997.

Richards, R.F., Ribail, R.T., Bakkom, A.W., and

Plumb, O.A., Fire Detection, Location and Heat

Release Rate Through Inverse Problem Solution.

Part 2, Experiment, Fire Safety Journal, 28:4,

pp. 351378, 1997.

Snir, M., et al., MPI: The Complete Reference,

Cambridge, MA, MIT Press, 1998.

Strauss, W., Partial Differential Equations: An

Introduction, John Wiley & Sons, New York,

NY, 1992.

Tikhanov, A.N., and Arsenin, V.Y., Solution of

Ill-Posed Problems, Washington, DC, Winston

& Sons, 1977.

Trelles, J., and Pagni, P.J., Fire-Induced Winds

in the 20 October 1991 Oakland Hills Fire, Fire

12

Safety Science: Proceedings of the Fifth

International Symposium, March 37, 1997,

Melbourne, Victoria, Australia, Elsevier,

London, 1997, pp. 911922.

AKNOWLEDGMENTS

Scott Hill of HAI assisted with the collection of

sensor data and with the preparation of the

software design description.

Javier Trelles, Ph.D., is a senior engineer at

Hughes Associates. He has written models for a

variety of situations including blood

carboxyhemoglobin, thermal decomposition of

materials, spreading of fuel spills, and the

dispersion of smoke under the influence of

various weather conditions. He has conducted

numerous simulation studies. Dr. Trelles is the

developer of many CFD animation and

visualization programs.

Craig L. Beyler, Ph.D., is the technical director

at Hughes Associates. He has extensive

expertise in fire dynamics/fire modeling and has

been the primary editor for the Fire Dynamics

Section of the SFPE Handbook of Fire

Protection Engineering. He has been involved

in model development and use for analysis of

U.S. Navy ships for over 15 years. He is

currently the chairman of the International

Association for Fire Safety Science and the

winner of the Guise Medal, SFPEs highest

technical award.

Jason E. Floyd, Ph.D., is a senior engineer at

Hughes Associates. Dr. Floyds R&D/design

experience includes simulation tools

development, numerical modeling, and design of

large-scale experiments and experimental

apparatus. He is the lead developer of FSSIM.

Dr. Floyd has performed CFD simulations of

various types and is currently a member of the

FDS development team.

Joseph L. Scheffey, P.E., is the Director of Fire

Protection RDT&E at Hughes Associates, Inc.

Baltimore, MD. He received a BS in fire

protection engineering at the University of

Maryland and is a Fellow in the Society of Fire

Protection Engineers. He has over 25 years

experience in managing and directing full-scale

fire tests. He has directed numerous manned

firefighting and damage control tests for the

U.S. Navy.

Kim W. Yee, is the USN DDG 1000 Damage

Control Automation Lead and the author of this

SBIR topic. He has over 20 years of experience

working with the Navys Surface Combatants

HM&E Controls Systems. In his role as

DDG1000 DC Automation Controls Lead, he is

working with industry to develop a Damage

Decision & Assessment (DDA) capability that

addresses Hull stability, Hull stress and fire,

smoke, flooding, Chemicial/Biological spread.

You might also like

- Gafhsx 1Document1 pageGafhsx 1Nurul HudaNo ratings yet

- Method For Finding Stress in Cylinders With Radial NozzlesDocument10 pagesMethod For Finding Stress in Cylinders With Radial NozzlesmatodelanusNo ratings yet

- DFH5342Document1 pageDFH5342Nurul HudaNo ratings yet

- DFHW112Document1 pageDFHW112Nurul HudaNo ratings yet

- Generate Response Spectra in MSC NastranDocument16 pagesGenerate Response Spectra in MSC NastranNurul HudaNo ratings yet

- Steel Pipes - Pipe Schedule ChartDocument3 pagesSteel Pipes - Pipe Schedule ChartNurul HudaNo ratings yet

- Elastic BeaconsDocument9 pagesElastic BeaconsNurul HudaNo ratings yet

- Prakt +kimia+organik+life+skillDocument1 pagePrakt +kimia+organik+life+skillNurul HudaNo ratings yet

- Hex Bolt Unc Series 1 4x20x0 75 Ansi b18!2!1Document1 pageHex Bolt Unc Series 1 4x20x0 75 Ansi b18!2!1Nurul HudaNo ratings yet

- Autocrashsimulation InpDocument2 pagesAutocrashsimulation InpNurul HudaNo ratings yet

- SE ThreadsDocument1 pageSE ThreadsNurul HudaNo ratings yet

- Eval Seismic ReqDocument12 pagesEval Seismic ReqJoe LulekNo ratings yet

- Analysis and Design of Marine Structures V Digital PDFDocument4 pagesAnalysis and Design of Marine Structures V Digital PDFNurul Huda0% (1)

- Designmodeler: Workshop 5.1 3D CurveDocument8 pagesDesignmodeler: Workshop 5.1 3D CurveNurul HudaNo ratings yet

- 25 Abaqus ODBDocument6 pages25 Abaqus ODBNurul HudaNo ratings yet

- Asme B30Document1 pageAsme B30Nurul Huda100% (1)

- PVEdwg 4225 0 0 PDFDocument3 pagesPVEdwg 4225 0 0 PDFSaša ĐorđevićNo ratings yet

- Fatigue Analysis Tool 1.0Document2 pagesFatigue Analysis Tool 1.0Nurul HudaNo ratings yet

- SsaDocument1 pageSsaNurul HudaNo ratings yet

- PSI 415 1 enDocument2 pagesPSI 415 1 enAstraopcNo ratings yet

- Ty PVDocument3 pagesTy PVNurul HudaNo ratings yet

- Spring Analysis Tool3Document4 pagesSpring Analysis Tool3Nurul HudaNo ratings yet

- Ty PVDocument1 pageTy PVNurul HudaNo ratings yet

- UndDocument1 pageUndNurul HudaNo ratings yet

- SfgawyDocument1 pageSfgawyNurul HudaNo ratings yet

- SfgawyDocument1 pageSfgawyNurul HudaNo ratings yet

- VHNDDocument1 pageVHNDNurul HudaNo ratings yet

- StyDocument1 pageStyNurul HudaNo ratings yet

- SfdeaDocument1 pageSfdeaNurul HudaNo ratings yet

- DSFDocument1 pageDSFNurul HudaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- PS Neo HSK2LCD ICON LED RF Keypad v1 0 Installation Guide R001 en FR Es PoDocument40 pagesPS Neo HSK2LCD ICON LED RF Keypad v1 0 Installation Guide R001 en FR Es Po7seguridadNo ratings yet

- Organizing and Delivering A Memorized SpeechDocument9 pagesOrganizing and Delivering A Memorized SpeechJanice L. Langit100% (4)

- Disappearance of Madeleine McCannDocument36 pagesDisappearance of Madeleine McCannCopernicNo ratings yet

- Statement Bank MBBDocument11 pagesStatement Bank MBBminyak bidara01No ratings yet

- SSRN Id26238Document21 pagesSSRN Id26238Ayame KusuragiNo ratings yet

- Bolt Jul 201598704967704 PDFDocument136 pagesBolt Jul 201598704967704 PDFaaryangargNo ratings yet

- Academic Writing & IdentityDocument218 pagesAcademic Writing & IdentityGustavo RegesNo ratings yet

- Mini Centre CatalogDocument26 pagesMini Centre CatalogJohn EarleyNo ratings yet

- Robotic End Effectors - Payload Vs Grip ForceDocument8 pagesRobotic End Effectors - Payload Vs Grip ForcesamirNo ratings yet

- Process of Producting High Carbon Ferro ChromeDocument5 pagesProcess of Producting High Carbon Ferro ChromeSantosh Kumar MahtoNo ratings yet

- Amway Final ReportDocument74 pagesAmway Final ReportRadhika Malhotra75% (4)

- Canterburytales-No Fear PrologueDocument10 pagesCanterburytales-No Fear Prologueapi-261452312No ratings yet

- Air Con LouvresDocument1 pageAir Con LouvresChung May LynnNo ratings yet

- Theory Is An Explanation Given To Explain Certain RealitiesDocument7 pagesTheory Is An Explanation Given To Explain Certain Realitiestaizya cNo ratings yet

- L P 10Document13 pagesL P 10Bình Minh HoàngNo ratings yet

- 03 Seatwork 1 ProjectManagement SenisRachelDocument2 pages03 Seatwork 1 ProjectManagement SenisRachelRachel SenisNo ratings yet

- History of English Prose PDFDocument21 pagesHistory of English Prose PDFMeisyita QothrunnadaNo ratings yet

- Primary 2 (Grade 2) - GEP Practice: Contest Problems With Full SolutionsDocument24 pagesPrimary 2 (Grade 2) - GEP Practice: Contest Problems With Full Solutionswenxinyu1002100% (1)

- Potato Peroxidase LabDocument2 pagesPotato Peroxidase LabKarla GutierrezNo ratings yet

- So You Want To Be A NeurosugeonDocument10 pagesSo You Want To Be A NeurosugeonColby TimmNo ratings yet

- Security Testing MatDocument9 pagesSecurity Testing MatLias JassiNo ratings yet

- History shapes Philippine societyDocument4 pagesHistory shapes Philippine societyMarvin GwapoNo ratings yet

- The Transformation of Metaphysical ScienceDocument7 pagesThe Transformation of Metaphysical ScienceblavskaNo ratings yet

- PPM To Percent Conversion Calculator Number ConversionDocument1 pagePPM To Percent Conversion Calculator Number ConversionSata ChaimongkolsupNo ratings yet

- Pmls 1 Final Exam Reviewer: Clinical Chemistry ContDocument14 pagesPmls 1 Final Exam Reviewer: Clinical Chemistry ContPlant in a PotNo ratings yet

- Complimentary JournalDocument58 pagesComplimentary JournalMcKey ZoeNo ratings yet

- 20comm Um003 - en PDocument270 pages20comm Um003 - en PRogério BotelhoNo ratings yet

- Preparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimDocument9 pagesPreparatory Lights and Perfections: Joseph Smith's Training with the Urim and ThummimslightlyguiltyNo ratings yet

- Asus X553MA Repair Guide Rev2.0Document7 pagesAsus X553MA Repair Guide Rev2.0UMA AKANDU UCHENo ratings yet

- FED - Summer Term 2021Document18 pagesFED - Summer Term 2021nani chowdaryNo ratings yet