Professional Documents

Culture Documents

File 005

Uploaded by

Nurul HudaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

File 005

Uploaded by

Nurul HudaCopyright:

Available Formats

FUNDAMENTAL, ADVANCED & APPLIED RESEARCH & DEVELOPMENT

FUNDAMENTAL, ADVANCED & APPLIED RESEARCH & DEVELOPMENT

STRENGTH OF NAVAL SHIPS, COMMERCIAL VESSELS & OCEAN ENGINEERING STRUCTURES

STRENGTH OF NAVAL SHIPS, COMMERCIAL VESSELS & OCEAN ENGINEERING STRUCTURES

The more stringent requirements for efficiency and cost effectiveness of various marine engineering products are of more and more effect on the design of the ship hulls. Together with improvement of traditional ships the projects are evolving for new application areas requiring advanced engineering and architectural solutions. The non traditional materials like composite materials find wider application. While increased yield strength is of primary goal when dealing with traditional materials, increased wall thickness and introduction of new welding methods are challenging the new projects. Increased dimensions of structures call for new design models and ways to assess mechanical strength. Implementation of new materials, demands for extended service life and less consumption of materials pursue us to look for new structural solutions. In the view of all these considerations experiments using full scale and large scale models are of great importance. They allow us to study the mechanisms of damage initiation and propagation, which is vital for serviceability assessment of new material structural application. Mechanical strength investigations covered the following: Comprehensive analysis of hulls under various service conditions and development of procedures to assess their load and endurance to environmental effects; Investigation of fatigue damage initiation and propagation and ways to enhance durability of the hull structures; Investigation of material behaviour under real operating conditions, search for the most efficient design solutions providing for entire utilization of material strength; Improvement of quality control methods and structures monitoring; Development and practical implementation of new design methods and procedures.

DEVELOPMENT AND JUSTIFICATION OF UNIVERSAL ICE CLASS EQUIVALENCE CRITERIA ACCEPTED BY RECOGNIZED CLASSIFICATION SOCIETIES In recent years, the traffic intensity in the ice covered waters and Arctic seas has considerably increased. The ships operating in these areas have been designed and built for ice classes of various classification societies as per the Client's request. To resolve problems encountered by ship owners, designers, and marine authorities the formalized procedures are required to assess equivalency of vessel capabilities, which had been designed according to various "Rules". Formulation of equivalency criterion procedure is of greater importance in view of new revisions of Ice Rules of Canada, Finland, Sweden as well as RMRS and other standards. The new approaches introduced in the revised Rules with respect to specified ice and sailing conditions and strength regulations rule out the use the old simplified approaches that

were based on direct comparison of parameters required by the Rules (dimensions of typical structures, minimum power, etc.). The obtained results of this study may be used by Marine Authorities and Classification Societies as a guide for resolving issues related to the ship entrance to the ice covered waters and harbours as well as for formulation of the RMRS position when putting together the IACS (International Association of Classification Societies) documents for ice class vessels.

R & D ASSISTANCE TO CALCULATIONS OF STRUCTURAL AND IMPACT STRENGTH OF SUBMARINE HULL AT COLLISIONS AND ACCIDENTS Assurance of damage control and safety (primarily nuclear safety) of submarine at collisions or hitting the seabed due to the flooding requires reliable prediction of load cases, dynamic responses and the scale of potential structural damage as well as evaluation of loads (accelerations) transferred to equipment and affecting the crew. Achieving this target has required to: Identify possible scenarios and design conditions for collisions; Develop a model of plastic deformation and failure (breach) for the submarine pressure hull at collision with the ship stem or fore end of ramming submarine; Make the qualitative analysis of plastic deformation for the submarine fore end when hitting the barrier (hull); the fore ends under study included: Ship end with transverse and longitudinal & transverse framing; Ship end with transverse framing and continuous along the end length longitudinal bulkheads and platforms; Ship end with developed SONAR

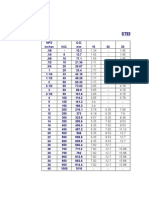

Classification Societies

12

light one year ice

heavy one year ice

ice classes

perenial ice

13

You might also like

- DFH5342Document1 pageDFH5342Nurul HudaNo ratings yet

- DFHW112Document1 pageDFHW112Nurul HudaNo ratings yet

- Gafhsx 1Document1 pageGafhsx 1Nurul HudaNo ratings yet

- Steel Pipes - Pipe Schedule ChartDocument3 pagesSteel Pipes - Pipe Schedule ChartNurul HudaNo ratings yet

- Asme B30Document1 pageAsme B30Nurul Huda100% (1)

- Prakt +kimia+organik+life+skillDocument1 pagePrakt +kimia+organik+life+skillNurul HudaNo ratings yet

- Hex Bolt Unc Series 1 4x20x0 75 Ansi b18!2!1Document1 pageHex Bolt Unc Series 1 4x20x0 75 Ansi b18!2!1Nurul HudaNo ratings yet

- Designmodeler: Workshop 5.1 3D CurveDocument8 pagesDesignmodeler: Workshop 5.1 3D CurveNurul HudaNo ratings yet

- Elastic BeaconsDocument9 pagesElastic BeaconsNurul HudaNo ratings yet

- Analysis and Design of Marine Structures V Digital PDFDocument4 pagesAnalysis and Design of Marine Structures V Digital PDFNurul Huda0% (1)

- SE ThreadsDocument1 pageSE ThreadsNurul HudaNo ratings yet

- Autocrashsimulation InpDocument2 pagesAutocrashsimulation InpNurul HudaNo ratings yet

- Ty PVDocument3 pagesTy PVNurul HudaNo ratings yet

- Method For Finding Stress in Cylinders With Radial NozzlesDocument10 pagesMethod For Finding Stress in Cylinders With Radial NozzlesmatodelanusNo ratings yet

- 25 Abaqus ODBDocument6 pages25 Abaqus ODBNurul HudaNo ratings yet

- SfgawyDocument1 pageSfgawyNurul HudaNo ratings yet

- Fatigue Analysis Tool 1.0Document2 pagesFatigue Analysis Tool 1.0Nurul HudaNo ratings yet

- Generate Response Spectra in MSC NastranDocument16 pagesGenerate Response Spectra in MSC NastranNurul HudaNo ratings yet

- UndDocument1 pageUndNurul HudaNo ratings yet

- Spring Analysis Tool3Document4 pagesSpring Analysis Tool3Nurul HudaNo ratings yet

- Ty PVDocument1 pageTy PVNurul HudaNo ratings yet

- Eval Seismic ReqDocument12 pagesEval Seismic ReqJoe LulekNo ratings yet

- PVEdwg 4225 0 0 PDFDocument3 pagesPVEdwg 4225 0 0 PDFSaša ĐorđevićNo ratings yet

- SfgawyDocument1 pageSfgawyNurul HudaNo ratings yet

- PSI 415 1 enDocument2 pagesPSI 415 1 enAstraopcNo ratings yet

- SfdeaDocument1 pageSfdeaNurul HudaNo ratings yet

- SsaDocument1 pageSsaNurul HudaNo ratings yet

- StyDocument1 pageStyNurul HudaNo ratings yet

- VHNDDocument1 pageVHNDNurul HudaNo ratings yet

- DSFDocument1 pageDSFNurul HudaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Imo Rules Submersible VehiclesDocument24 pagesImo Rules Submersible VehiclesMerrelNo ratings yet

- Submarine - WikipediaDocument32 pagesSubmarine - WikipediaNaheed100% (1)

- Analysis of Pressure Hull Buckling and Vibration Using Finite Element MethodDocument19 pagesAnalysis of Pressure Hull Buckling and Vibration Using Finite Element MethodLishan JayasooriyaNo ratings yet

- Submarines and SubmersiblesDocument28 pagesSubmarines and Submersiblespraveench1888No ratings yet

- Vibration Damping Materials Installation GuideDocument90 pagesVibration Damping Materials Installation GuideqingtaoNo ratings yet

- SAWE Recommended Practice Provides Weight Classification GuidanceDocument117 pagesSAWE Recommended Practice Provides Weight Classification Guidancejohn kasich100% (1)

- Sub Design Is Not Ship DesignDocument16 pagesSub Design Is Not Ship DesignWasim JanNo ratings yet

- Deep Sea Research Submarine Report PDFDocument128 pagesDeep Sea Research Submarine Report PDFy_596688032No ratings yet

- Submarine TechnologiesDocument18 pagesSubmarine TechnologiesCalvin OhNo ratings yet

- Exploring 95% of the Underwater World in Luxury and SafetyDocument11 pagesExploring 95% of the Underwater World in Luxury and Safetybruce488No ratings yet

- GL Manned Sub RulesDocument14 pagesGL Manned Sub RulesBigTam1981No ratings yet

- SubDocument33 pagesSubflaviagabriela26No ratings yet

- Vol09 Pt01 Issue 01 Submarine StructuresDocument27 pagesVol09 Pt01 Issue 01 Submarine StructuresNguyễn ThaoNo ratings yet

- Def Stan 02-136Document44 pagesDef Stan 02-136carlos aguilar quintanaNo ratings yet

- An Interview With Al Bielek, Co - Al BielekDocument22 pagesAn Interview With Al Bielek, Co - Al Bielekchaab dalilaNo ratings yet

- The Nuclear Hazards of The Recovery of The Nuclear Powered Submarine KurskDocument12 pagesThe Nuclear Hazards of The Recovery of The Nuclear Powered Submarine Kurskjacksonholland8335No ratings yet

- Sumarine Design-Ulrich GablerDocument186 pagesSumarine Design-Ulrich GablerEhsan Amiri100% (6)

- Aurora TowfishDocument4 pagesAurora TowfishRamdan YassinNo ratings yet

- Nas120 wk14 Submarine BucklingDocument18 pagesNas120 wk14 Submarine BucklingHozaifaNo ratings yet

- Vol09 Pt11 Issue 01 Watertight Integrity and Recovery From FloodingDocument27 pagesVol09 Pt11 Issue 01 Watertight Integrity and Recovery From FloodingahmadNo ratings yet

- Tanker Operations A Handbook For The Person-In-Charge (PIC) - 5th Ed. 2018 - by MARK E. HUBERDocument629 pagesTanker Operations A Handbook For The Person-In-Charge (PIC) - 5th Ed. 2018 - by MARK E. HUBERAndis OrravsNo ratings yet

- Understanding Ship Design FundamentalsDocument142 pagesUnderstanding Ship Design Fundamentalsbahrul100% (2)

- D&E MINIATURES 2000 Model Submarine CatalogDocument26 pagesD&E MINIATURES 2000 Model Submarine CatalogDUNCAN0420100% (1)

- NautilusDocument8 pagesNautilusClara BengtNo ratings yet

- Peter Benchley - 1997 - Peter Benchley's CreatureDocument236 pagesPeter Benchley - 1997 - Peter Benchley's CreatureAbhijit Ghosh100% (2)

- SubmarineDocument7 pagesSubmarineAissa Abdoulaye CisseNo ratings yet

- How Does Submarines Submerge and FloatDocument15 pagesHow Does Submarines Submerge and FloatYash YadavNo ratings yet

- Submarine Construction Ulrich Gabler 1972 PDFDocument186 pagesSubmarine Construction Ulrich Gabler 1972 PDFTheodoros Vrakas100% (1)

- Submarine DesignDocument5 pagesSubmarine Designnallay1705No ratings yet

- Technical Considerations in The Design, Engineering, Construction and Installation of The Poseidon Undersea ResortDocument16 pagesTechnical Considerations in The Design, Engineering, Construction and Installation of The Poseidon Undersea ResortDeepa AnoopNo ratings yet