Professional Documents

Culture Documents

Itp Tank

Uploaded by

Amber ChavezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itp Tank

Uploaded by

Amber ChavezCopyright:

Available Formats

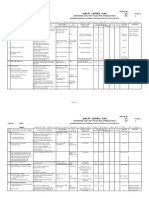

LARSEN & TOUBRO LIMITED

MSQ UPGRADATION (EPCC-1) PROJECT IOCL - PANIPAT

PMC

INSPECTION AND TEST PLAN FOR TANK

PROJECT OWNER PMC CONTRACTOR LEGEND : : EPCC-1 MSQ UPGRADATION : INDIAN OIL CORPORATION LTD.PANIPAT. : JACOBS ENGINEERING INDIA PRIVATE LIMITED : LARSEN & TOUBRO LIMITED

Doc. No:

LT/MSQ/ITP/STR/ST/004 Date: 20.09.07

NA : Not Applicable, HP : Hold Point, W : Witness Point, Rw : Review of SUBCONTRACTOR / L&T's documentation, S : Surveillance by OWNER / PMC, WC : 100% Examination, Spec. : Specification, Dwg. : Drawing, Std. : Standard PT : Penetarnt Testing, MT: Magnetic Particle Testing, PWHT: Post Weld Heat Treatment, IRN: Inspection Release Note INSPECTION WITNESSES/GRADE L&T JACOBS

SL. No.

DESCRIPTION OF ACTIVITY STORAGE TANK

FIELD INSPECTION REPORT FORMAT No.

REMARKS

A 1 2 3 4 5 6 7 8 9 10

PRIOR TO FABRICATION Acceptance of the tanks foundation Materials Filler Materials tests & Approval WPS / PQR Welder Performance Qualification Radiography Procedure Joint numbering in drawings Welding equipment and accessories Tools & Tackles Backing Ovens a) portable b) heavy WC WC WC WC S S S S LT/MSQ/IMIR/GEN/001 Rev.01 APPROVED VENDER FORMAT LT/MSQ/STR/WPS/002 LT/MSQ/STR/PQR/003 LT/MSQ/STR/WPQ/004 LT/MSQ/P/RT/009 APPROVED SKETCHES WC WC WC WC WC WC WC WC WC W W S HP HP S S S S

11 12 B 1 2 3 4 5 6 SL. No.

Jig & Fixtures Suitability of plate bending machine FABRICATION / ERECTION BOTTOM Plate size, marking & cutting Blast cleaning & painting of undemeath bottom plate Plate layout, overlap & Fit up Sequence of welding to follow Size & positioning of backing plate for annular plates Baking of electrodes / Interpass cleaning DESCRIPTION OF ACTIVITY ELECTRODE BACKING REGISTER

FIELD INSPECTION REPORT FORMAT No.

WC WC WC WC WC WC

S S S S S S REMARKS

INSPECTION WITNESSES/GRADE

Signature : Name : Date

Prepared by L&T Checked by L&T Page 1 of 4 Approved by JACOBS

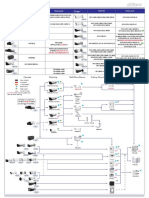

LARSEN & TOUBRO LIMITED

MSQ UPGRADATION (EPCC-1) PROJECT IOCL - PANIPAT

PMC

INSPECTION AND TEST PLAN FOR TANK

PROJECT OWNER PMC CONTRACTOR LEGEND : : EPCC-1 MSQ UPGRADATION : INDIAN OIL CORPORATION LTD.PANIPAT. : JACOBS ENGINEERING INDIA PRIVATE LIMITED : LARSEN & TOUBRO LIMITED

Doc. No:

LT/MSQ/ITP/STR/ST/004 Date: 20.09.07

NA : Not Applicable, HP : Hold Point, W : Witness Point, Rw : Review of SUBCONTRACTOR / L&T's documentation, S : Surveillance by OWNER / PMC, WC : 100% Examination, Spec. : Specification, Dwg. : Drawing, Std. : Standard PT : Penetarnt Testing, MT: Magnetic Particle Testing, PWHT: Post Weld Heat Treatment, IRN: Inspection Release Note L&T LPI / MPI / Radiography of annular plate butt welds & bottom plate butt welds ( if any ) Vacuum / MPI / LPI of shell portion of the bottom plates Vacuum box test for the bottom plate welding SHELL Plate size, marking and cutting Plate bending, curvature check, stacking Shell course alignments and fit up of vertical and circumferential joints Shell diameter, circularity, perpendicularity, straightedge before welding Visual & Back chip check Second side visual Location, size & alignment of nozzles and other openings. R.F. pads fit up / welding PWHT of RF pad. Nozzles & manhole etc. ( as applicable ) Radiography marking for random radiography only Curb angle and wind girders fit up / welding MPI / LPI nozzles RF pads air test Shell to bottom fit up Shell to bottom I/S welding root run visual / oil chalk test Shell to bottom O/S welding visual & LPI for toe cracks Fabrication & erection of stairways Cleates welding for insulation a) radiography interpretation b) extension marking for repair DESCRIPTION OF ACTIVITY LT/MSQ/PIPE/RGI/014 LT/MSQ/DPT/016 LT/MSQ/MPT/017 SR CHART LT/MSQ/PIPE/RGM/013 WC WC WC WC WC WC WC WC WC WC WC WC WC WC WC WC WC WC WC WC

FIELD INSPECTION REPORT FORMAT No.

JACOBS

8 9 10 C 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

LT/MSQ/DPT/016 LT/MSQ/MPT/017 LT/MSQ/PIPE/RGM/013 LT/MSQ/PIPE/RGI/014 LT/MSQ/DPT/016 LT/MSQ/MPT/017

WC WC WC

S S S

S S S S S S S W S W S W S W S S S S S S REMARKS

SL. No.

INSPECTION SWITNESSES/GRADE

Signature : Name : Date

Prepared by L&T Checked by L&T Page 2 of 4 Approved by JACOBS

LARSEN & TOUBRO LIMITED

MSQ UPGRADATION (EPCC-1) PROJECT IOCL - PANIPAT

PMC

INSPECTION AND TEST PLAN FOR TANK

PROJECT OWNER PMC CONTRACTOR LEGEND : : EPCC-1 MSQ UPGRADATION : INDIAN OIL CORPORATION LTD.PANIPAT. : JACOBS ENGINEERING INDIA PRIVATE LIMITED : LARSEN & TOUBRO LIMITED

Doc. No:

LT/MSQ/ITP/STR/ST/004 Date: 20.09.07

NA : Not Applicable, HP : Hold Point, W : Witness Point, Rw : Review of SUBCONTRACTOR / L&T's documentation, S : Surveillance by OWNER / PMC, WC : 100% Examination, Spec. : Specification, Dwg. : Drawing, Std. : Standard PT : Penetarnt Testing, MT: Magnetic Particle Testing, PWHT: Post Weld Heat Treatment, IRN: Inspection Release Note L&T FIXED ROOF JACOBS

1 2 3 4 5 6

Location & welding of roof supports Alignment & welding of roof structures Plate layout, overlap & fit up Visual check of roof welds Location, size & alignment of roof man-holes & vents PWHT ( as applicable ) FLOATING ROOF

WC WC WC WC WC WC

S W S W S S

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Temporary staging spacing & levels Plate size, straightening & cutting Plate layout, overlap & fit up / welding Buoys fabrications Vacuum testing of roof plate welds Location of sleeve supports Pad plate welding with roof and sleeve support Fixing and welding of Buoys Initial lift Supports fixing through sleeves Seal welding of support sleeves from beneath after dewatering Air test of buoys Pontoon welding location, fixing & welding of man holes, drains etc. Shell to pontoon clearance Seal fixing

WC WC WC WC WC WC WC WC WC WC WC WC WC WC WC W

S S S S S W W S W S W S W S W W

SL. No.

DESCRIPTION OF ACTIVITY

FIELD INSPECTION REPORT FORMAT No.

INSPECTION WITNESSES/GRADE L&T JACOBS

REMARKS

Signature : Name : Date

Prepared by L&T Checked by L&T Page 3 of 4 Approved by JACOBS

LARSEN & TOUBRO LIMITED

MSQ UPGRADATION (EPCC-1) PROJECT IOCL - PANIPAT

PMC

INSPECTION AND TEST PLAN FOR TANK

PROJECT OWNER PMC CONTRACTOR LEGEND : : EPCC-1 MSQ UPGRADATION : INDIAN OIL CORPORATION LTD.PANIPAT. : JACOBS ENGINEERING INDIA PRIVATE LIMITED : LARSEN & TOUBRO LIMITED

Doc. No:

LT/MSQ/ITP/STR/ST/004 Date: 20.09.07

NA : Not Applicable, HP : Hold Point, W : Witness Point, Rw : Review of SUBCONTRACTOR / L&T's documentation, S : Surveillance by OWNER / PMC, WC : 100% Examination, Spec. : Specification, Dwg. : Drawing, Std. : Standard PT : Penetarnt Testing, MT: Magnetic Particle Testing, PWHT: Post Weld Heat Treatment, IRN: Inspection Release Note

C 1 2 3 4 5 6 7 8 D 1 2 3

TESTING

Correctness of testing arrangements especially size of blind flanges / vents / drains / temporary piping Mechanical / inspection clearance Earthing of ladder and shell Settlement reading during water filling Hammer test Air pressure test Vacuum test Roof collapsibility test in case of floating roof tanks WC WC WC WC WC WC WC WC S S W W S S S S

PAINTING AND INSULATION

Cleaning Painting Insulation WC WC WC S W W

INSPECTION & TEST DOCUMENTS Review test and inspection documents

HP Rw

Signature : Name : Date

Prepared by L&T Checked by L&T Page 4 of 4 Approved by JACOBS

You might also like

- FIELD INSPECTION PROCEDURESDocument29 pagesFIELD INSPECTION PROCEDURESsbmmla91% (22)

- Larsen & Toubro underground piping inspection planDocument4 pagesLarsen & Toubro underground piping inspection planBhavani PrasadNo ratings yet

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankAhmed100% (5)

- Stavanger Tourist SpotDocument96 pagesStavanger Tourist Spotregupathi6413No ratings yet

- Contractor Quality Control Plan For Storage Tank ErectionDocument2 pagesContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- Inspection TankDocument22 pagesInspection Tanksbmmla100% (1)

- Storage Tank Erection Procedure PDFDocument6 pagesStorage Tank Erection Procedure PDFEko Kurniawan89% (19)

- Erection 009 CTP Storage TankDocument44 pagesErection 009 CTP Storage Tankgst ajah100% (1)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuNo ratings yet

- Storage Tank (API 650)Document20 pagesStorage Tank (API 650)sbmmla83% (6)

- Water Fill Up Testing Procedure-R3 07.07.2011sohar 2Document7 pagesWater Fill Up Testing Procedure-R3 07.07.2011sohar 2AjeetKumarNo ratings yet

- Tank Erection ProcedureDocument29 pagesTank Erection ProcedureVisas Siva100% (3)

- Procedure Erection Storage TankDocument7 pagesProcedure Erection Storage Tanknur hudaNo ratings yet

- QCF304 Magnetic Particle Testing ReportDocument2 pagesQCF304 Magnetic Particle Testing Reportminhnn100% (1)

- Tank Erection Itp & Org ChartDocument34 pagesTank Erection Itp & Org Charthasan_676489616100% (2)

- Algeria Oman Fertilizer Project Inspection and Test PlanDocument22 pagesAlgeria Oman Fertilizer Project Inspection and Test Planmister pogi100% (3)

- Choosing Column InternalsDocument7 pagesChoosing Column Internalspetrolhead1No ratings yet

- Choosing Column InternalsDocument7 pagesChoosing Column Internalspetrolhead1No ratings yet

- Prepration of ITP For Storage Tanks Fabrication & ErectionDocument27 pagesPrepration of ITP For Storage Tanks Fabrication & ErectionRamuAlagappan93% (15)

- Quality Assurance Plan for Structural FabricationDocument1 pageQuality Assurance Plan for Structural FabricationproxywarNo ratings yet

- Tank Erection Procedure GuideDocument5 pagesTank Erection Procedure Guidegeorge israelNo ratings yet

- L&T ECCD Inspection & Test Plan for Structural WorksDocument4 pagesL&T ECCD Inspection & Test Plan for Structural Worksmanu_gite100% (2)

- ITP For Storage TankDocument6 pagesITP For Storage Tankittiphon3194% (17)

- ITP For Field Erected Tank Rev ADocument9 pagesITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- Piping Hydrotest Procedure GuideDocument3 pagesPiping Hydrotest Procedure GuideFrank100% (6)

- College of Medicine & Health SciencesDocument56 pagesCollege of Medicine & Health SciencesMebratu DemessNo ratings yet

- A05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C DDocument14 pagesA05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C Dbingmin100% (4)

- 003 ITP UG PipingDocument4 pages003 ITP UG Pipingrvsingh70100% (1)

- Storage Tank Inspection Check ListDocument2 pagesStorage Tank Inspection Check Listparthasarathy281267% (6)

- Erection Procedure For Floating Roof TankDocument10 pagesErection Procedure For Floating Roof Tankabdul1207100% (2)

- Oil and Fat Technology Lectures IV RefiningDocument28 pagesOil and Fat Technology Lectures IV RefiningJakaAbuNo ratings yet

- PROCEDURE FOR TANK FABRICATION & ERECTIONDocument15 pagesPROCEDURE FOR TANK FABRICATION & ERECTIONsenthilkumarsk88% (8)

- 16 JRTP 02 ITP - Rev01Document13 pages16 JRTP 02 ITP - Rev01khsaeed100% (1)

- Tank Erection ProcedureDocument15 pagesTank Erection Procedurejohney294% (16)

- IOCL Static Equipment ITPDocument12 pagesIOCL Static Equipment ITPaamirapi100% (3)

- Equipment Erection, Static and RotaryDocument8 pagesEquipment Erection, Static and RotaryHamada ELaraby60% (5)

- Astm C27Document2 pagesAstm C27nee2790No ratings yet

- ITP For Piping WorksDocument3 pagesITP For Piping WorksOrlando1949100% (3)

- Edible Oil TechnologyDocument12 pagesEdible Oil TechnologyAmber Chavez0% (1)

- Tennis BiomechanicsDocument14 pagesTennis BiomechanicsΒασίλης Παπατσάς100% (1)

- Tanks Installation ManualDocument53 pagesTanks Installation ManualVasuddyas Dsauuyas100% (11)

- Electric Steam Boiler SussmanDocument2 pagesElectric Steam Boiler SussmanChriss VzzNo ratings yet

- Inspection Report: Vaccum Test RecordDocument21 pagesInspection Report: Vaccum Test RecordWahyudi MetrizaNo ratings yet

- STS Co. storage tank fabrication methodologyDocument15 pagesSTS Co. storage tank fabrication methodologypurshottam GHNo ratings yet

- Tank Commissioning ProcedureDocument7 pagesTank Commissioning ProcedureivanrishiNo ratings yet

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Document17 pagesIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedNo ratings yet

- ITP For Storage TankDocument6 pagesITP For Storage TankAhmed Ben HmidaNo ratings yet

- Presentation Repair of Storage TankDocument28 pagesPresentation Repair of Storage TankAbdul ManafNo ratings yet

- 静设备英文 Static Equipment Installation ProcedureDocument6 pages静设备英文 Static Equipment Installation Procedurejie100% (4)

- Checklist Tank NewDocument11 pagesChecklist Tank NewamevaluacionesNo ratings yet

- Larsen & Toubro Limited: Inspection and Test Plan For Above Ground PipingDocument4 pagesLarsen & Toubro Limited: Inspection and Test Plan For Above Ground PipingKheireddine AounallahNo ratings yet

- 10) Itp - Tank Fabrication PDFDocument6 pages10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Chapter-8 Turbine and Governor TestingDocument10 pagesChapter-8 Turbine and Governor Testingafru2000No ratings yet

- SOP Tank ConstructionDocument24 pagesSOP Tank ConstructionSuci YatiningtiyasNo ratings yet

- Hydrostatic and Settlement Tests ProcedureDocument12 pagesHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.Document6 pagesQCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.abdul aziz100% (1)

- Stories of Prophets - 2Document19 pagesStories of Prophets - 2Hadis MusaNo ratings yet

- Itp For Main SteelaaaaaaDocument4 pagesItp For Main SteelaaaaaaaymanmalahNo ratings yet

- ADDC Construction QuestionairesDocument19 pagesADDC Construction QuestionairesUsman Arif100% (1)

- HYSYS Distillation Column Simulation TutorialDocument7 pagesHYSYS Distillation Column Simulation Tutorialcmlim100% (2)

- API 650 12th Edition 2013 - NDT RequirementDocument1 pageAPI 650 12th Edition 2013 - NDT Requirementfarjadulhaq100% (2)

- ITP For CW and ACW Piping WorkDocument8 pagesITP For CW and ACW Piping WorkPhong DoNo ratings yet

- 02 MechanicalDocument44 pages02 MechanicalSigit Bintan100% (1)

- Proper Piping For Vacuum SystemsDocument5 pagesProper Piping For Vacuum SystemsDowni Oader100% (1)

- Nakshatra Exaltation DebilitationDocument3 pagesNakshatra Exaltation DebilitationBhanu Pinnamaneni100% (1)

- Biofuel Industri in Indonesia Some Critical IssuesDocument26 pagesBiofuel Industri in Indonesia Some Critical IssuesarianzNo ratings yet

- Larsen & Toubro Limited: Inspection and Test Plan For TankDocument4 pagesLarsen & Toubro Limited: Inspection and Test Plan For TankABDELKADER BENABDALLAHNo ratings yet

- Itp Tank - 01082023Document4 pagesItp Tank - 01082023vasantha kumarNo ratings yet

- Neo Structo Construction LTD.: Inspection and Test PlanDocument10 pagesNeo Structo Construction LTD.: Inspection and Test Planravi00098No ratings yet

- Typical QAPDocument4 pagesTypical QAPhemantmech09No ratings yet

- Line differential relay test recordDocument7 pagesLine differential relay test recordsamiahmedmansourNo ratings yet

- Docslide - Us - Itp Structural WorkDocument4 pagesDocslide - Us - Itp Structural Workomda4wadyNo ratings yet

- Inspection Test Plan For Tie in Welding: 00 04.01.2010 Review & Approval N.Kumar R. MohantyDocument2 pagesInspection Test Plan For Tie in Welding: 00 04.01.2010 Review & Approval N.Kumar R. MohantyAhmed Lepda0% (1)

- QC Form 11Document2 pagesQC Form 11rashid ahmadiNo ratings yet

- Agung Siswahyu Summary ProfileDocument1 pageAgung Siswahyu Summary ProfileAmber ChavezNo ratings yet

- TSG 021A-15 CSL Plus Series Marketing Brief-LRDocument2 pagesTSG 021A-15 CSL Plus Series Marketing Brief-LRAmber ChavezNo ratings yet

- Skedule Kontruksi Mekanikal Elektrical CPO PlantbetulDocument1 pageSkedule Kontruksi Mekanikal Elektrical CPO PlantbetulAmber ChavezNo ratings yet

- Vacuum Box Bubble Leak TestingDocument4 pagesVacuum Box Bubble Leak TestingashrafhitlerNo ratings yet

- SVW 12 1000kW 41000 To 3412000 BtuhDocument2 pagesSVW 12 1000kW 41000 To 3412000 BtuhAmber ChavezNo ratings yet

- Upload Tentative Conference Program PV Hybrid and BioenergyDocument2 pagesUpload Tentative Conference Program PV Hybrid and BioenergyAmber ChavezNo ratings yet

- Shell For Tee JointDocument1 pageShell For Tee JointAmber ChavezNo ratings yet

- Seminar Islamic Medical Fair 2007Document46 pagesSeminar Islamic Medical Fair 2007Amber ChavezNo ratings yet

- CDM Project Design Document for Fuel Switching in Glass ManufacturingDocument30 pagesCDM Project Design Document for Fuel Switching in Glass ManufacturingAmber ChavezNo ratings yet

- Bmri2017 2370927Document19 pagesBmri2017 2370927Amber ChavezNo ratings yet

- Tool For Measuring Piking: R Nominal Radius of The TankDocument4 pagesTool For Measuring Piking: R Nominal Radius of The TankAmber ChavezNo ratings yet

- Calgary Legends Ammonia Separation Process SimulationDocument1 pageCalgary Legends Ammonia Separation Process SimulationAmber ChavezNo ratings yet

- Pricelist KitazawaDocument10 pagesPricelist Kitazawariff100% (1)

- 50 M3/jam 960 Liter/menit 9,6 JT MCS, 8,7 JTGLP, Elektrik 18,5 KW, 25 HP 7,6 Jt. Couple 1,5 JTDocument1 page50 M3/jam 960 Liter/menit 9,6 JT MCS, 8,7 JTGLP, Elektrik 18,5 KW, 25 HP 7,6 Jt. Couple 1,5 JTAmber ChavezNo ratings yet

- Investasi Industri Bangunan Tumbuh Tiga PersenDocument9 pagesInvestasi Industri Bangunan Tumbuh Tiga PersenAmber ChavezNo ratings yet

- IJEETC 510fefb81c0a6Document22 pagesIJEETC 510fefb81c0a6Amber ChavezNo ratings yet

- Return Calculations Subordinated Loan With EBITDA ParticipationDocument2 pagesReturn Calculations Subordinated Loan With EBITDA ParticipationAmber ChavezNo ratings yet

- KaiyoDocument35 pagesKaiyoAmber ChavezNo ratings yet

- Methanol: Sodium MethoxideDocument3 pagesMethanol: Sodium MethoxideAmber ChavezNo ratings yet

- Incbio 1ta (2015 En) 1a1b DGB - ProposalDocument16 pagesIncbio 1ta (2015 En) 1a1b DGB - ProposalAmber ChavezNo ratings yet

- Laboratory 4 Two and Three Phase Separators Oct 2, 2002: Che 365 Chemical Engineering Design IDocument1 pageLaboratory 4 Two and Three Phase Separators Oct 2, 2002: Che 365 Chemical Engineering Design IAmber ChavezNo ratings yet

- Reaktor Heat Call ALAT V301-3 HE101 T101 T102 RT102 PANAS UNIT JUMLAH PANASDocument14 pagesReaktor Heat Call ALAT V301-3 HE101 T101 T102 RT102 PANAS UNIT JUMLAH PANASAmber ChavezNo ratings yet

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakNo ratings yet

- Dimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutDocument11 pagesDimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutRizqi RamadhanNo ratings yet

- TP5 W9 S9 R0Document2 pagesTP5 W9 S9 R0DickiEffendy0% (1)

- Combustion Cat 2008Document32 pagesCombustion Cat 2008Miguel LinaresNo ratings yet

- Wirkungen FlechtenstoffeDocument21 pagesWirkungen FlechtenstoffeLogge UliNo ratings yet

- 35.2 - ING - El Puente NewsletterDocument13 pages35.2 - ING - El Puente NewsletterIrmali FrancoNo ratings yet

- Blood Group 3Document29 pagesBlood Group 3Hamirie JoshuaNo ratings yet

- Abundance BlocksDocument1 pageAbundance BlockssunnyNo ratings yet

- Indian Oil Corporation Limited: Bhubaneswar Divisional OfficeDocument3 pagesIndian Oil Corporation Limited: Bhubaneswar Divisional OfficeBinay SahooNo ratings yet

- Specs Mantilla UV BT8800 Oct 2014Document2 pagesSpecs Mantilla UV BT8800 Oct 2014Julio MendezNo ratings yet

- IruChem Co., Ltd-Introduction of CompanyDocument62 pagesIruChem Co., Ltd-Introduction of CompanyKhongBietNo ratings yet

- Workload Assessment in Railway ControlDocument8 pagesWorkload Assessment in Railway ControlbbeeNo ratings yet

- Digital B&W Copiers (D154/D155-NA) Parts CatalogDocument118 pagesDigital B&W Copiers (D154/D155-NA) Parts Catalogkhoi vuNo ratings yet

- BMW Mini COoper Installation InstructionsDocument1 pageBMW Mini COoper Installation InstructionsEdiJonNo ratings yet

- The Relevance of Vivekananda S Thought IDocument16 pagesThe Relevance of Vivekananda S Thought IJaiyansh VatsNo ratings yet

- Electrical EngineerDocument3 pagesElectrical Engineer12343567890No ratings yet

- CE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingDocument36 pagesCE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingCelil OrakNo ratings yet

- GPS and The Quest For Pizza: National Aeronautics and Space AdministrationDocument1 pageGPS and The Quest For Pizza: National Aeronautics and Space Administrationvijay maddiNo ratings yet

- Specifications Sheet ReddyDocument4 pagesSpecifications Sheet ReddyHenry CruzNo ratings yet

- Myths of Greece and Rome PDFDocument247 pagesMyths of Greece and Rome PDFratheesh1981No ratings yet

- Cars Ger Eu PCDocument157 pagesCars Ger Eu PCsergeyNo ratings yet

- Standardization Parameters For Production of Tofu Using WSD-Y-1 MachineDocument6 pagesStandardization Parameters For Production of Tofu Using WSD-Y-1 MachineAdjengIkaWulandariNo ratings yet