Professional Documents

Culture Documents

Trollope Mining Services

Uploaded by

sizwehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trollope Mining Services

Uploaded by

sizwehCopyright:

Available Formats

Trollope Mining ServiceS A winning trAnsformAtion

www.tmsgroup.co.za

Trollope Mining ServiceS

After being hurt by falling coal prices in 2008, Trollope Mining Services has grown dramatically by taking a more balanced approach

Trollope Mining ServiceS

Caterpillar truck on-site

eadquartered in Johannesburg, 2008. At that time we were still very much Trollope Mining Services focused on the coal mining industry, and in provides expertise in surface particular our contracts with Xstrata Coal. mining services. These The business might have continued to include opencast mining, operate serenely but for the dramatic fall rehabilitation, bulk earthworks, plant hire in the price of coal in 2008, which had and road construction. Much of the work catastrophic consequences for Trollope. involves excavating land and then drilling Back then 98 per cent of company turnover and blasting, stock-piling usable materials was coal-based but the price of coal fell to and removing any rubble. just $50 a ton, wiping out 90 per cent of Trollope Mining had served the domestic company turnover in one month, Hopkins coal industry successfully since 1975, but explains. the events of 2008 brought about a change Hopkins, with a civil engineering in focus and the arrival two years ago of background in construction, entered the fray a couple of years later present managing director Guy Hopkins. with a remit to help Trollope It all started when diversify. It has been a brothers Peter and John gradual process but from an operating turnover of R278 Trollope bought a bulldozer from a military auction and million in 2010 we should achieve R700 million this began to use their equipment year, he predicts. Today at local iron ore mines to Trollopes projected help with bush clearing, he we have 14 different clients operating turnover explains. The business grew from as far away as Australia, this year and they started to acquire Spain and Turkey, who are more equipment which was involved not only with coal operated from the family farm, two-and-a- but also manganese, gold and platinum. half hours north of Johannesburg. We have focused on servicing the junior In 1999 the company was sold to a Black miners who may not have the equipment Economic Empowerment company which or the capital to buy the machinery needed was rolled up into the Mvelaphanda Group, to crush or move earth. he continues. Today we are 30 per cent The move into hard rock signalled a owned by a BEE company called Mntungwa shift in strategy as it meant the companys Resources while John, Peter and Danie Le existing fleet of excavators, crushers and Roux own 70 per cent of the business. By dump trucks needed to be replaced with 2000 the company had grown sufficiently larger machinery. With the transition that we relocated to Johannesburg, and we spent in the region of R300 million to moved into the current headquarters in upgrade to dump trucks from 40 to 100

r700

million

Trollope Mining ServiceS

POWERLINE

SUPPLIER OF BRAKE COMPONENTS FOR ALL MACHINES USED ON OPANCAST MINING

Tel: +27 11 868 4466 Fax: +27 11 868 5409 Fax : 086 607 7143 Cell: 082 893 0901 Email: powerline@yebo.co.za

It has given us great pleasure to be associated with TROLLOPE MINING SERVIES over the last 16 years. Our motto is SAFETY IN THE WORK PLACE and for this reason our Brake Disc Pads, Brake Caliper Seal Kits and the Brake Caliper repairs are of the highest quality and standard. Africa has very different needs and we strive to meet these wherever possible.

Proud supplier to TROLLOPE MINING SERVICE for their Off Road machines and Equipment trollope mining team

inspired

Your weekly digest of business news and views www.bus-ex.com

tonnes, capable of shifting hard rock. We and routine maintenance and minor repairs are constantly reinvesting to ensure that we are carried out on-site at each location as have brand new equipment and excavators necessary. More complex work takes place with an average age of 18 months. in the 1,500 square metre Johannesburg Trollope has a core set of some 200 pieces workshop, built three years ago to house of equipment with a further 200 available 10 bays plus a paint shop, an engine and for ancillary equipment. The company transmission rebuilding shop, a boilermaker operates sites around South Africa and shop, auto electrician division and hydraulic while the main headquarters and workshops cylinder rebuilding shop. Hopkins feels that a change in Trollopes are in Johannesburg, there are bases in Thabazimbi and Ogies and culture has also had a significant bearing on the workshops situated at each turnaround in fortunes. site where Trollope has a contract. Excluding sub-contractors This is essential given the we have just under 1,100 staff and they have been distances involved and the the key to our success, he remoteness of some mining Current number of affirms. It is all about the locations. The company Trollope employees currently has 12 live projects quality of person rather than

1,100

Trollope Mining ServiceS

the machines and it has been a question of nurturing and leading our people in the right direction through much clearer communication channels, whether that is through clear audits and finance reporting or direct decision-making. In the past perhaps with three people running the business the message was not always as clear. With clearer leadership and regular auditing, the business has thrived in stark contrast to South Africas construction industry. Hopkins is mindful of the impact this is having on the commercial mining environment. We are a specialist mid-tier open-cast mining contractor and we are much more astute now. Our biggest risk is the construction slump, with those guys entering our sector without the knowledge and expertise that Trollope Mining offers. Their equipment depreciates much slower

The proSpecT of working ouTSide of SouTh AfricA iS SoMeThing we hAve looked AT for SoMe TiMe buT we will TreAd conServATively

and that affects their rates, while they may not be able to react to customer demands as quickly as we can. We are also working towards ISO accreditation by the end of July which will give us greater opportunity to work with bigger companies from Canada, Germany and the United States who have mining operations beyond South Africas borders. The bulk of the operating procedures are in place and we are just finalising our documentation now. The prospect of working outside of South Africa is something we have looked at for some time but we will tread conservatively and work with companies that know the territories. Our reputation within the industry sets us apart and while we may not offer

Equipment in use at mine site

the cheapest service, we are always willing to get clients out of any trouble and have traditionally delivered what the customer wants. There is also scope for us to enter the construction market when it improves: that is definitely also on the radar. Hopkins concludes: Our turnaround has been phenomenal and we need to carry on growing but not at the same rate: we will look to consolidate now. Our debt ratios will play an important role when we come to replenish our fleet but our main focus is on the bottom line, not simply chasing turnover.

for more information about trollope mining services visit: www.tmsgroup.co.za

Equipment has an average age of just 18 months

Elandsfontein 412Jr, Ekurhuleni Po Box 10046, fonteinriet, 1464 t +27 (0)11 281 6000 www.tmsgroup.co.za

Trollope mining ServiceS

Produced by:

www.bus-ex.com

You might also like

- Reclamation, Treatment and Utilization of Coal Mining WastesFrom EverandReclamation, Treatment and Utilization of Coal Mining WastesNo ratings yet

- Xstrata Copper - Inf Sostenibilidad 2011Document47 pagesXstrata Copper - Inf Sostenibilidad 2011Arturo Pedro Salgado MedinaNo ratings yet

- Amatala ProfileDocument16 pagesAmatala ProfileHazri Bin Hamilluddin100% (1)

- 22-Portland Cement - Its Composition, Raw Materials, Manufacture, Testing and Analysis PDFDocument730 pages22-Portland Cement - Its Composition, Raw Materials, Manufacture, Testing and Analysis PDFNguyen ThanhNo ratings yet

- Corporate Brochure WorldsensingDocument8 pagesCorporate Brochure Worldsensing_ARCUL_No ratings yet

- Logistics Management Business PlanDocument11 pagesLogistics Management Business PlanMuhammad Mudassir IqbalNo ratings yet

- SandDocument165 pagesSandMirceaNo ratings yet

- Final PPT Aluminium IndustryDocument36 pagesFinal PPT Aluminium IndustryDanish Memon50% (2)

- NDEP Annual Report 2014Document91 pagesNDEP Annual Report 2014zeze_13No ratings yet

- (Updated) Aluminium Extrusion CatalogueDocument35 pages(Updated) Aluminium Extrusion Cataloguerulekhalsa100% (1)

- Final Report PTK BMC 2017Document94 pagesFinal Report PTK BMC 2017tkubvosNo ratings yet

- DID Bauxite WMDocument69 pagesDID Bauxite WMGeo Khader Abdul100% (1)

- Canoro-Oil & GasDocument52 pagesCanoro-Oil & GasDEEPAK KALITANo ratings yet

- The 2007 SME Guide for Reporting Exploration Results, Mineral Resources and ReservesDocument47 pagesThe 2007 SME Guide for Reporting Exploration Results, Mineral Resources and ReservesZuhry DizzyNo ratings yet

- Chrome Ore Beneficiation Challenges & LISTODocument8 pagesChrome Ore Beneficiation Challenges & LISTOAlfredo V. Campa100% (1)

- Mine Planning & Design BitsDocument10 pagesMine Planning & Design BitsdileepNo ratings yet

- Safety Management PlanDocument71 pagesSafety Management PlanSamuel Maclean ArthurNo ratings yet

- Sample Pursuasive Letter (Selling Bulk Cement)Document1 pageSample Pursuasive Letter (Selling Bulk Cement)ZepodoxNo ratings yet

- Gold Room SecurityDocument9 pagesGold Room Securitymushava nyokaNo ratings yet

- DatamineDocument1 pageDataminekemalll100% (1)

- Marble Mining and ProcessingDocument88 pagesMarble Mining and Processingmujib uddin siddiqui100% (2)

- Ghana Petrol Tax Guide 2011Document24 pagesGhana Petrol Tax Guide 2011William PyneNo ratings yet

- Method Statement KgalaDocument3 pagesMethod Statement Kgalashepherd adam100% (1)

- Crusher Supervisor and Operations OverviewDocument26 pagesCrusher Supervisor and Operations Overviewabdelrhmangbr86No ratings yet

- Indian GraphiteDocument12 pagesIndian Graphitearmandoarmando1100% (1)

- Extraction Oil & Gas Company ProfileDocument2 pagesExtraction Oil & Gas Company ProfileAnonymous 8HTodWqnNo ratings yet

- Mining Regulations Safety SummaryDocument120 pagesMining Regulations Safety Summaryaxe100% (1)

- Iberian Minerals - TrafiguraDocument84 pagesIberian Minerals - TrafiguraaaquibnasirNo ratings yet

- Company Profile PT ARAT - 2018Document32 pagesCompany Profile PT ARAT - 2018Ryo NarendraNo ratings yet

- Mine Development and Operations Plan Bellekeno 2009Document78 pagesMine Development and Operations Plan Bellekeno 2009Alireza RastegarNo ratings yet

- G L Smith - PHD - A Conceptual Framework For The Strategic Long Term Planning of Platinum Mining Operations in The South African Context PDFDocument322 pagesG L Smith - PHD - A Conceptual Framework For The Strategic Long Term Planning of Platinum Mining Operations in The South African Context PDFGmmmm123No ratings yet

- Clay Bricks Manufactruing Kiln Zigzag Technology Rs. 33.74 Million Jun-2021Document21 pagesClay Bricks Manufactruing Kiln Zigzag Technology Rs. 33.74 Million Jun-2021ABDUL BASITNo ratings yet

- Gold Mining and Processing in IndiaDocument27 pagesGold Mining and Processing in IndiaSpandan PrasadNo ratings yet

- Honey and Beewax Producers and Exporters Association PDFDocument2 pagesHoney and Beewax Producers and Exporters Association PDFYitades TarikuNo ratings yet

- 28588-Wood PPTsDocument99 pages28588-Wood PPTsIsanka P GamageNo ratings yet

- AB InBev Human Rights Policy PDFDocument9 pagesAB InBev Human Rights Policy PDFcristian quelmis vilca huarachiNo ratings yet

- OCS GROUP LIMITED - Leading U.K. Facilities Management OCS Group Acquires Singapore's Don Thaker Group To Add 1,000 Jobs in Singapore in Next Three YearsDocument3 pagesOCS GROUP LIMITED - Leading U.K. Facilities Management OCS Group Acquires Singapore's Don Thaker Group To Add 1,000 Jobs in Singapore in Next Three YearsWeR1 Consultants Pte LtdNo ratings yet

- Rio Tinto - Supplier Code - en - EXPDocument8 pagesRio Tinto - Supplier Code - en - EXPEnkhee bNo ratings yet

- Chapter 74 - Mining and QuarryingDocument124 pagesChapter 74 - Mining and Quarryingbeku_ggs_bekuNo ratings yet

- Code of Practice for Operators of Quarry Delivery VehiclesDocument134 pagesCode of Practice for Operators of Quarry Delivery VehiclesSudamBeheraNo ratings yet

- Mining EquipDocument2 pagesMining Equipgaurav_mahajan1402No ratings yet

- Newitem 148 Stone Crusher ReportDocument142 pagesNewitem 148 Stone Crusher ReportSaurabh Singh100% (3)

- Oil and Gas ProfileDocument44 pagesOil and Gas ProfileWilsmith SmithNo ratings yet

- Regional Infrastructure Development Master Plan Executive SummaryDocument40 pagesRegional Infrastructure Development Master Plan Executive SummaryLuzuko Terence NelaniNo ratings yet

- Orica ANE Facility GHG AssessmentDocument45 pagesOrica ANE Facility GHG AssessmentlladopiNo ratings yet

- Uganda Petroleum (Exploration, Development and Production) National Content Regulations, 2016Document23 pagesUganda Petroleum (Exploration, Development and Production) National Content Regulations, 2016African Centre for Media Excellence100% (2)

- Dentons - Myanmar Investment GuideDocument28 pagesDentons - Myanmar Investment GuidemikemyintNo ratings yet

- 2015 Diavik Diamond Mine Technical ReportDocument128 pages2015 Diavik Diamond Mine Technical ReportCarlos Orozco100% (1)

- A Step by Step Guide To Registering A Business in Zambia Simplified ProcessDocument2 pagesA Step by Step Guide To Registering A Business in Zambia Simplified ProcessChancy Moyo100% (1)

- ASGM Partnership Promotes 50% Reduction in Mercury Use by 2017Document24 pagesASGM Partnership Promotes 50% Reduction in Mercury Use by 2017Gloria Moyano Daille100% (2)

- Silica Sand Mining FinalDocument43 pagesSilica Sand Mining FinalChusnadiNo ratings yet

- Nipex RequirementsDocument15 pagesNipex RequirementsAF Dowell MirinNo ratings yet

- CristalMiningCorp BusinessPlanDocument32 pagesCristalMiningCorp BusinessPlanfatimasc100% (1)

- 230 - Metallic - REDDocument19 pages230 - Metallic - REDFaker MejiaNo ratings yet

- First Mining Finance Feb7Document2 pagesFirst Mining Finance Feb7kaiselkNo ratings yet

- Poti Sea Port Oil Spill Contingency PlanDocument105 pagesPoti Sea Port Oil Spill Contingency Plangummy_langNo ratings yet

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDocument4 pagesBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForIbeth S OTNo ratings yet

- News From Lynemouth Special Issue May 2012Document3 pagesNews From Lynemouth Special Issue May 2012api-146740669No ratings yet

- Wise SunumDocument14 pagesWise Sunumayşe çolakNo ratings yet

- 2010 Annual ReportDocument92 pages2010 Annual ReportMichael SerranoNo ratings yet

- Wispeco Aluminium ProfilesDocument22 pagesWispeco Aluminium ProfilesPatrick153No ratings yet

- Supporting Supply Chain Planning & SchedulingDocument8 pagesSupporting Supply Chain Planning & SchedulingsizwehNo ratings yet

- Mvela GroupDocument97 pagesMvela GroupsizwehNo ratings yet

- Mocambique Economic OutlookDocument14 pagesMocambique Economic OutlooksizwehNo ratings yet

- Roll Up SerrandaDocument9 pagesRoll Up SerrandasizwehNo ratings yet

- Mocambique EIA RequirementsDocument23 pagesMocambique EIA Requirementssizweh100% (1)

- Trollope Mining ServicesDocument3 pagesTrollope Mining ServicessizwehNo ratings yet

- Rubis Terminal GBDocument21 pagesRubis Terminal GBsizwehNo ratings yet

- Evaluation of Compressed Natural Gas Fueling SystemsDocument8 pagesEvaluation of Compressed Natural Gas Fueling SystemssizwehNo ratings yet

- Mvelaserve ListingDocument154 pagesMvelaserve ListingsizwehNo ratings yet

- Vidagas LPGDocument29 pagesVidagas LPGsizwehNo ratings yet

- Mvelaphanda CircularDocument134 pagesMvelaphanda CircularsizwehNo ratings yet

- Sustaining The ExpansionDocument15 pagesSustaining The ExpansionsizwehNo ratings yet

- Mocambican Economic OutlookDocument11 pagesMocambican Economic OutlooksizwehNo ratings yet

- LPG Blackmer PumpsDocument16 pagesLPG Blackmer Pumpssizweh100% (1)

- Corken LPG Pumps and CompressorsDocument24 pagesCorken LPG Pumps and Compressorssizweh100% (2)

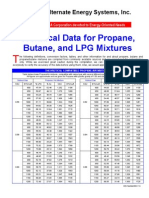

- Technical Data For LPGDocument4 pagesTechnical Data For LPGsizwehNo ratings yet

- Fuel Price WorldwideDocument7 pagesFuel Price WorldwideSoleai CoopNo ratings yet

- Carriage of Liquefied GasesDocument7 pagesCarriage of Liquefied GasessizwehNo ratings yet

- LPG VaporizersDocument8 pagesLPG Vaporizerssizweh100% (1)

- LPG AccesoriesDocument24 pagesLPG Accesoriessizweh100% (1)

- LPG Vaporizer Air Mixing SystemsDocument8 pagesLPG Vaporizer Air Mixing SystemssizwehNo ratings yet

- Sweetening LPG With AminesDocument8 pagesSweetening LPG With AminessizwehNo ratings yet

- LPG Vapour Air Mixing SystemsDocument8 pagesLPG Vapour Air Mixing SystemssizwehNo ratings yet

- LPG AccesoriesDocument4 pagesLPG AccesoriessizwehNo ratings yet

- Human Science BookletDocument12 pagesHuman Science BookletsizwehNo ratings yet

- LPG CompressorDocument38 pagesLPG Compressorsizweh100% (1)

- Price Capping MechanismDocument14 pagesPrice Capping MechanismsizwehNo ratings yet

- Methodology To Approve Maximum Prices For Piped GasDocument42 pagesMethodology To Approve Maximum Prices For Piped GassizwehNo ratings yet

- Central BankDocument65 pagesCentral BankFarazNaseer100% (1)

- Bolsas Transfer FKDocument7 pagesBolsas Transfer FKBelèn Caridad Nelly Pajuelo YaipènNo ratings yet

- Safety of High-Rise BuildingsDocument14 pagesSafety of High-Rise BuildingsHananeel Sandhi100% (2)

- VSP-12Way - Is Rev.03Document55 pagesVSP-12Way - Is Rev.03Marcelo AlmeidaNo ratings yet

- Rust Experimental v2017 DevBlog 179 x64 #KnightsTableDocument2 pagesRust Experimental v2017 DevBlog 179 x64 #KnightsTableIngrutinNo ratings yet

- Successful Organizational Change FactorsDocument13 pagesSuccessful Organizational Change FactorsKenneth WhitfieldNo ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesAdonis BesaNo ratings yet

- Maths Lit 2014 ExamplarDocument17 pagesMaths Lit 2014 ExamplarAnymore Ndlovu0% (1)

- How To Make Pcbat Home PDFDocument15 pagesHow To Make Pcbat Home PDFamareshwarNo ratings yet

- Reynold's Number Flow ExperimentDocument8 pagesReynold's Number Flow ExperimentPatrick GatelaNo ratings yet

- 10 Consulting Frameworks To Learn For Case Interview - MConsultingPrepDocument25 pages10 Consulting Frameworks To Learn For Case Interview - MConsultingPrepTushar KumarNo ratings yet

- Numark MixTrack Pro II Traktor ProDocument3 pagesNumark MixTrack Pro II Traktor ProSantiCai100% (1)

- BILL OF SALE Pre ApproveDocument1 pageBILL OF SALE Pre ApprovedidinurieliaNo ratings yet

- Personal InsuranceDocument11 pagesPersonal InsuranceSumit Kumar SharmaNo ratings yet

- Macdonald v. National City Bank of New YorkDocument6 pagesMacdonald v. National City Bank of New YorkSecret SecretNo ratings yet

- FZ16 9B 1KD2 (Patada) PDFDocument62 pagesFZ16 9B 1KD2 (Patada) PDFPanthukalathil Ram100% (1)

- The Punjab Commission On The Status of Women Act 2014 PDFDocument7 pagesThe Punjab Commission On The Status of Women Act 2014 PDFPhdf MultanNo ratings yet

- NDU Final Project SP23Document2 pagesNDU Final Project SP23Jeanne DaherNo ratings yet

- Bajaj 100bDocument3 pagesBajaj 100brmlstoreNo ratings yet

- Responsibility Centres: Nature of Responsibility CentersDocument13 pagesResponsibility Centres: Nature of Responsibility Centersmahesh19689No ratings yet

- Jodi Ridgeway vs. Horry County Police DepartmentDocument17 pagesJodi Ridgeway vs. Horry County Police DepartmentWMBF NewsNo ratings yet

- Exam Venue For Monday Sep 25, 2023 - 12-00 To 01-00Document7 pagesExam Venue For Monday Sep 25, 2023 - 12-00 To 01-00naveed hassanNo ratings yet

- Pike River Case StudyDocument7 pagesPike River Case StudyGale HawthorneNo ratings yet

- Organization Structure GuideDocument6 pagesOrganization Structure GuideJobeth BedayoNo ratings yet

- Kunci Jawaban Creative English 3BDocument14 pagesKunci Jawaban Creative English 3BLedjab Fatima67% (3)

- Stage 1 Isolating Boiler Feed Pump 1. PurposeDocument3 pagesStage 1 Isolating Boiler Feed Pump 1. Purposejoseph kamwendoNo ratings yet

- (Jf613e) CVT Renault-Nissan PDFDocument4 pages(Jf613e) CVT Renault-Nissan PDFJhoanny RodríguezNo ratings yet

- Introduction to Human Resource Management Functions and Their ImportanceDocument23 pagesIntroduction to Human Resource Management Functions and Their ImportancedhrupaNo ratings yet

- 16 BPI V FernandezDocument1 page16 BPI V FernandezAngelica Joyce BelenNo ratings yet

- 【4DI+4DO】MA01+-AXCX4040 UserManual EN v1.1Document36 pages【4DI+4DO】MA01+-AXCX4040 UserManual EN v1.1RioNorte LojaNo ratings yet