Professional Documents

Culture Documents

Calibration of Temperature Sensors

Uploaded by

Subhash K0 ratings0% found this document useful (0 votes)

256 views13 pagesCalibration of Temperature Sensors

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCalibration of Temperature Sensors

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

256 views13 pagesCalibration of Temperature Sensors

Uploaded by

Subhash KCalibration of Temperature Sensors

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

Experiment 4

Calibration of Temperature Sensors

I. Objective:

The purposes of this experiment are to: (1) acquaint you with common thermometry instruments,

(2) impart a fundamental understanding of the physical principles that underpin these devices, and

(3) point out the respective advantages and disadvantages that these instruments offer.

II. Apparatus

3 Floppy Diskette (Supplied by the student.)

Personal Computer Running LabView

Keithley 2000 6 Digit Multimeter Equipped with 2000-SCAN MUX Card

Julabo F12-MD PID Temperature-Controlled Bath

Type-J 0.250 Dia. Sheathed Thermocouple Omega GJ QSS-14G-12

Type-J 0.0625 Dia. Sheathed Thermocouple Omega GJ QSS-116G-12

Type-T 0.250 Dia. Sheathed Thermocouple Omega GT QSS-14G-12

Type-T 0.0625 Dia. Sheathed Thermocouple Omega GT QSS-116G-12

Industrial Thermistor Omega ON-970-44006 (10 kO @ 25 C)

Industrial Resistance Temperaure Detector (RTD) Rosemount 563792 1, S/N 0693603

Precision Mercury Thermometer (NIST Certified) Omega GT-3554Y (-1-100 C +/- 0.1 C)

Standard Alcohol Laboratory Thermometer Fisher 14-997

III. Introduction:

Thermometry is an essential element in many industrial processes. For example, when extruding

polymers such as polyethylene, the extruder is partitioned into several thermal zones. The

temperature of each zone must be maintained within strict limits. If for instance, the temperature

in any zone is too great, then the polymer will burn and carbon will be deposited on the interior

walls of the extruder. This carbon is nearly impossible to remove and it has an unfortunate

tendency to break-off when the extruder is in operation. These chunks of carbon contaminate the

end product. The product is subsequently sent to a landfill because it can be neither sold nor

recycled. Clearly, control relies upon accurate measurement of the operating temperatures.

Thermometers:

These devices are the oldest thermometry instruments and their use is well known. Two

thermometers are used in this experiment. One should be familiar with the standard alcohol

thermometer. The precision thermometer uses mercury and it has been calibrated at NIST.

Thermocouples:

These devices consist of two dissimilar metals that are joined at the ends. When these junctions

are held at different temperatures, a thermoelectric potential difference exists. This is called the

Seebeck effect and one may measure the thermoelectric potential ( or electromotive force, emf) to

infer temperature junction temperatures. The potential, temperature range, and sensitivities of

thermocouples depend upon the combinations of wire used. The Type-T thermocouples employ

copper and constantan and the Type-J thermocouples employ iron and constantan.

Thermoelectric potentials are typically small (mV). A calibration relation e.g., formula or table,

relates temperature to thermoelectric potential. The NIST (formerly NBS) thermocouple tables

comprise standard calibrations for the most popular thermocouple types. The accuracy of these

tables is approximately +/- 2 degrees C. Please refer to the introductory section of Experiment 3

for more complete information on thermocouples.

Resistance Temperature Detectors (RTD):

These devices use the property that the electrical resistance of materials varies with temperature.

RTDs typically consist of a platinum wire enclosed within a sheath. The Callendar-Van Duesen

calibration equation,

(

(

O + O = O

) ) ( 01 . 0 ( ) 1 ) ( 01 . 0 (

) ( 01 . 0 ( ) 1 ) ( 01 . 0 ( ) (

) ( ) ( ) (

3

0 0

C T C T

C T C T C T

R R R

|

o

o , (1)

relates wire resistance to temperature. The symbols

0

R , o, |, and o represent calibration

constants. The factory-determined values of these constants are stamped on the metal tag

attached to the RTD used in this laboratory. Record these constants and the serial number of the

RTD in your lab notebook. Note that the constant | is used only when the measurement

temperature is below 0

C, i.e.,

C T 0 when 0 > = | . The manufacturer reports the accuracy of

Eqn. (1) to be 0.06

C over the range from 0 to 100

C when their calibration coefficients are

used. The calibration constants of the RTD are NIST (National Institute for Standards and

Technology) traceable. This implies that the RTD was calibrated against internationally accepted

temperature standards.

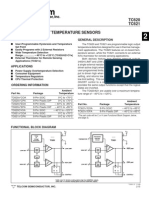

Thermistors:

These devices also use the property that the electrical resistance of materials varies with

temperature. In contrast to RTDs, thermistors are made of semiconductor materials. Unlike

metals, the temperature-resistance dependence of semiconductor materials is strongly non-linear.

Consequently among thermometry instruments, thermistors generally have the greatest

sensitivity, but their useful range is comparatively small. The calibration equation are typically of

the form

( ) ( )

3

ln ln

) (

1

R C R B A

K T

+ + = . (2)

Julabo F-12MD Constant Temperature Bath:

The following diagrams and instructions are exerpted from the Julabo manual.

Operating controls and functional elements

1a

2

3

5

7

4

8

12

21

!

10

11

9

13a

14

15a

16a

17 18

1b

6

24a 24b

13b

15b 16b

23 22

19

Rear view

25

25

1a/1b Mains power switch, illuminated,

for circulator / cooling machine

2 Start / stop key

3 Working temperature T1

4 Working temperature T2

5 High temperature warning limit

6 Low temperature warning limit

7 Safety temperature

8 Adjustable excess temperature protection

(safety temperature)

9 MULTI-DISPLAY (LED) temperature indication

10 Cursors left/right

11 Edit keys (increase/decrease setting)

12 Enter key (store)

Error! Objects cannot be created from editing field codes. Indicator light - Alarm

Indicator light - Cooling

Error! Objects cannot be created from editing field codes. Indicator light - Heating

13a Connector: Control cable for cooling machine

13b Connector: Cooling machine control

14

1 5

6 9

RS232C interface

15a Mains fuses for circulator

15b Mains fuses for cooling machine

16a Mains power cable for circulator

16b Mains power cable with plug

17 Built-in mains outlet for connection of circulator

18 Selector dial for cooling machine

Position "1" for operation with MD circulator.

19 Control cable for cooling machine

21 Removable venting grid

22 Drain tap

23 Drain port

24a Pump connector for feed

24b Pump connector for return

25

Only for water cooled models:

Cooling water OUTLET / INLET

Filling / draining

Filling

Take care that no liquid enters the interior of the circulator.

Recommended maximum filling level with water as bath liquid: 25 mm

below the tank rim

Recommended maximum filling level with bath oils: 40 mm below the

tank rim

ATTENTION: the volume of bath oils will increase due to

thermal expansion when the bath temperature rises.

Exercise CAUTION when emptying hot bath liquids!

Start:

Press the start/stop key.

- The MULTI-DISPLAY (LED) indicates the actual bath temperature.

(example: 21.0 C)

- An illuminated indicator light in the "T1" or "T2" key indicates the

activated working temperature.

Stop:

Press the start/stop key.

The MULTI-DISPLAY (LED) indicates the message "OFF".

Setting the temperatures

Setting the working temperature "T1":

Press the setpoint key .

The indicator light blinks and the value previously set appears on the

MULTI-DISPLAY (LED).

Use the cursor keys to move left or right on the display until

the numeral you wish to change is blinking.

Use the increase/decrease arrows to change the selected

numeral (-, 0, 1, 2, 3, ... 9).

Press enter to store the selected value (example: -15.0 C).

The working temperature is maintained constant after a short heat-up time

(e. g. -15.0 C).

Setting the working temperature "T2":

Press the setpoint key .

Same procedure

as with "T1"

(example: 25.0 C).

Selecting the working temperature:

Press the setpoint key and then enter .

Press the setpoint key and then enter .

Technical specifications

MD

Display resolution C 0.1

ATC - Absolute Temp. Calibration C 3

Heater capacity at 115V Watts 1000

at 230 V Watts 2000

Pressure pump:

pressure/flow rate head max./Lpm 11.5 ft/15

Electrical connectors:

Alarm output 24-0 V DC / max. 25 mA

Computer interface RS232C

Mains power connection V/Hz 115/60

V/Hz 208-230/60

All measurements have been carried out at:

rated voltage and frequency ambient temperature: 20 C

Technical changes without prior notification reserved.

F34 F12

Working temperature range C -34 ... 200 -25 ... 200

Temperature stability C 0.01 0.01

Cooling capacity C +20 0 -20 -30 +20 0 -20

(bath liquid: ethanol) Watts450 320 140 30 200 120 25

Refrigerant R134a R134a

Bath opening/bath depth:

WxD/H Cm. 24x30/15 15x13/15

Bath volume: from...to liters 14 ... 20 3 ... 4,5

Dimensions: WxDxH In. 15x23x25 6x9x10

Cm. 38x58x61 20x36x55

Shipping weigth lbs/kg 106/45 51/23

Mains power connection V/Hz 115/60 115/60

Keithley 2000 DMM:

The use of the Keithley 2000 is described in the following section. One should note that the connections and

measurement procedures are described to facilitate the uncertainty analysis, but physically, these connections are

automatically made by the SCAN-2000 multiplexer card.

Voltage Measurements:

To measure voltage with the Keithley 2000, high and low leads are connected to the inputs depicted in Figure 1.

Hi

Lo

Sense Input

(+) Red Lead

(-) Black Lead

Figure 1: DC voltage measurement instrument connections.

Once the leads have been properly connected, the DCV function is selected---one should watch for the DCV

LEDS to appear when the Keithley is in scan mode during data acquisition. The Keithley 2000 is a 6 Digit

Multimeter. The DC voltage accuracy is listed in Table 1.

Table 1. Keithley 2000 DC Voltage Accuracy

Range Resolution Accuracy (ppm RDG + ppm RANGE)

100.0000 mV 0.1 V 50 + 35

1.000000 V 1.0 V 30 + 7

10.00000 V 10 V 30 + 5

100.0000 V 100 V 45 + 6

1000.000 V 1 mV 45 + 6

Keithley reports their multimeter accuracies with (ppm of RDG + ppm of RANGE), where 1 ppm=10

-6

. For

example, suppose 5.00000 V is measured on the 10.00000 V range. Then the accuracy estimate is (3010

-

6

5.00000 V+510

-6

10.00000 V)= 200 V.

Resistance Measurements:

The Keithley 2000 has two modes for measuring resistance. The two-wire mode is illustrated in Figure 2.

i

V

1

V

2

Figure 2. Two-wire resistance measurement circuit.

One should note that in this mode, the multimeter passes a current through the restive load and it simultaneously

measures the voltage across the terminals. This method is employed to measure the thermistor resistance.

The two-wire mode is simple, but it has the undesirable consequence that the resistance of the lead wires is included

in the measurement. This could introduce substantial error while measuring small resistances.

The four-wire mode compensates for lead wire resistance. The circuit is depicted in Figure 3.

i

Hi

Lo

Sense

Input Hi

Input Lo

Figure 3. Four-wire resistance measurement circuit.

The four-wire technique uses separate wires to apply a current and to measure the voltage drop. Consequently only

the voltage drop across the resistive load is measured, and the effects of the lead resistance are eliminated. The four-

wire method is used to measure the RTD resistance. The connections are illustrated in Figure 4.

Hi

Lo

Sense Input

Red

White

Red

White

Figure 4. Four-wire resistance measurement instrument connections.

The accuracy of the resistance measurements are estimated from Table 2.

Table 2. Keithley 2000 resistance measurement accuracy.

Range Resolution Accuracy (ppm RDG + ppm RANGE)

100.0000 O 100 O 100 + 40

1.000000 kO 1 mO 100 + 10

10.00000 kO 10 mO 100 + 10

100.0000 kO 100 mO 100 + 10

1.000000 MO 1 O 100 + 10

10.00000 MO 10 O 400 + 10

100.0000 MO 100 O 1500 + 30

The measurement accurcies listed in Table 2 apply to both two- and four-wire modes.

Procedure:

1. Inspect all electrical connections. Verify that the Keithley 2000 will use the rear inputs i.e., the Inputs button

is depressed.

2. Verify that the liquid level in the circulator bath is within acceptable limits.

3. Prepare the ice bath. Fill the thermos bottle with ice and DI water so that there are no air gaps. Adding water

serves two purposes. a) Fills all the air pockets in the ice filled thermos bottle and b) Ice water mixture is at 0 C

(which is what we want), whereas just ice could be at a lower temperature than 0 C.

4. Record instrument data e.g., thermometer resolution, RTD calibration constants, and serial numbers.

5. Energize equipment i.e., turn on the F-12 Circulator bath, MD controller, Keithley 2000, computer, and

monitor.

6. Activate the Julabo MD controller and adjust the setpoint temperature to 10 C. One should note that it takes

approximately 35 minutes for the water bath to cool from room temperature to 10 C. The approximate bath

temperature is indicated by the Julabo MD LED display.

7. Start up the PC and the Lab4B data acquisition software should start up on its own. If it doesnt or if the PC is

already booted up, click on the Lab4B icon on the desktop. when prompted choose Start New Calibration if

you are starting to calibrate for the first time. If the program had crashed midway and you just started it back on,

choose Continue Previous Calibration.

8. When the bath reaches setpoint temperature, acquire data:

a. Select the trial to acquire (1-10). One should note that 10 measurements are suggested.

b. Read the Alcohol and Mercury thermometers and enter the measurements in the appropriate boxes for these

instruments. These boxes are located below the Data Table. One can either enter the value in these boxes or

set the adjacent slider at the appropriate position. The former is a better option

c. Press the Acquire button to obtain the output from the other instruments.

d. Repeat steps a-c for subsequent trials.

9. Write the data to a file:

a. Press the Write Data to File button.

b. Use the pull-down menu to select the directory to which the file will be written. Please choose the

C:\Lab4B_student directory. This is the default directory that the software prompts you to save in.

c. Name the output file and click Ok. One should note that this file name must be unique and that the

default extension is .txt to ensure that Windows will recognize that it is an ASCII file.

d. Use Windows Explorer to view the data file in notepad.

e. Once you saved the data, you can click on the clear button to clear the data from the screen and proceed to

calibrate at other temperatures.

10. Adjust the setpoint temperature and repeat steps 8 and 9 for bath temperatures of approximately 15, 20, 25, 30,

and 40 C.

11. Copy the data files to the 3 floppy diskette.

12. Press the End DAQ button to stop the VI and close all application windows.

13. Shut down the computer (Using the Start menu).

14. Turn off all equipment.

15. See the TA on duty to check-out.

16. Perform data reduction and uncertainty analysis.

17. Write laboratory report.

Data Analysis:

1. Consolidate the multiple samples to single measurements and estimate total uncertainties:

a. Compute mean measurements of each device at every setpoint temperature.

b. Estimate the precision uncertainties of the mean measurements (assume 95% confidence level).

c. Estimate the bias uncertainties of the mean measurements.

d. Estimate the total uncertainty of each mean measurement.

Document the procedure used to complete steps a-d and tabulate the results of each step. After completing step d,

tabulate setpoint temperatures, mean meaurements and their appropriate uncertainties. A table for each instrument

should be prepared (eight tables). Of note, one must adhere to significant figure reporting conventions to receive

credit for this step. Examine the tabulated results of steps a-d. For each instrument, determine whether bias or

precision limits the uncertainty of the measurement. Which measurements are the most precise? Which

measurements are the most accurate? How could the uncertainties of these measurements be reduced? What factors

contribute to the measurement uncertainty? Which can be controlled and which cannot? Could bath temperature

fluctuates contribute to uncertainty? Does the data support the assumption that the bath temperature is constant?

2. Use the RTD data to determine the bath temperatures. Please note that the Callendar-Van Duesen equation and

the manufacturers calibration coefficients are employed. In addition, estimate the uncertainty in the RTD bath

temperature measurements. One should note that there are essentially two factors that contribute to the overall

uncertainty in this measurement. What are these factors? Which factor dominates? What would one need to do

to improve i.e., increase accuracy, of this measurement?

3. One should recall that a calibration standard is by assumption, error-free. In actuality, they have uncertainty

and calibrating an instrument is essentially a procedure for substituting the uncertainty of the standard for the

uncertainty of the test instrument. Obviously, the uncertainty of standard must be smaller than the test

instrument for this to be a worthwhile endeavor. Thus the instrument with the smallest uncertainty is most

suitable to be the calibration standard. Determine which instrument yields the smallest temperature uncertainty.

Hints: The calibration coefficients of the thermistor are unknown, hence it cannot be a standard. It is better to

use a sensor with NIST traceable calibration as the calibration standard against which the other sensors are

calibrated. If the thermocouple reference tables and the thermocouple voltages were used to estimate the bath

temperature, what would the temperature uncertainties be? Further examination of the tables prepared in step

1d and the results of step 2 should whittle the choices for calibration standard down to two instruments. What

are these instruments? Which device is your choice for the calibration standard?

4. Determine calibration equations for each instrument:

a. The relationship between the thermistor resistance and temperature is non-linear. The expression

) exp(BT A R = , seems to fit the thermistor data well. R is the thermistor resistance and T is the bath

temperature (determined by the calibration standard). Determine the coefficients A and B using linear

regression. Plot both the thermistor data and the fitted line. Also, plot error bars and estimate the

uncertainty in the calibration equation.

b. Determine calibration equations for the thermometers---assuming of course, that neither is the calibration

standard. Use linear regression analysis and estimate the uncertainty in the calibration equation. Do these

instruments have offsets? If so, how do they compare to the instrument resolution?

c. Determine calibration equations for the thermocouples.

5. Compute the sensitivity of each instrument.

References:

The Temperature Handbook Omega Engineering Inc., Stamford, CT 06907-0047

Beckwith, Marangoni, and Lienhard, Mechanical Measurements, Addison-Wesley.

You might also like

- Termometer and Hygrometer Calibration LiteratureDocument2 pagesTermometer and Hygrometer Calibration LiteratureHarryNo ratings yet

- Calibration of Absolute Pressure TransmitterDocument4 pagesCalibration of Absolute Pressure Transmitterget_engineer05No ratings yet

- Transmitter and Smart TransmitterDocument57 pagesTransmitter and Smart TransmitterBHAGSEN PARVATNo ratings yet

- Calibration TolerancesDocument3 pagesCalibration Tolerancesbertan dağıstanlıNo ratings yet

- Seminar Report Temperature Measurement: Submitted To: Submitted By: Dr. N.D. Das Vijay Kumar Mr. B.R. Bundel 7-ME-131-LDocument27 pagesSeminar Report Temperature Measurement: Submitted To: Submitted By: Dr. N.D. Das Vijay Kumar Mr. B.R. Bundel 7-ME-131-LANILBENIWALNo ratings yet

- DP Transmitter CalibrationDocument2 pagesDP Transmitter CalibrationsupercontrollerNo ratings yet

- Method Statement For PH MeterDocument2 pagesMethod Statement For PH MeterMuhamed RasheedNo ratings yet

- Lab Report Temperature TransmitterDocument12 pagesLab Report Temperature Transmitterathira sNo ratings yet

- Calibration 161217162207Document36 pagesCalibration 161217162207Oula HatahetNo ratings yet

- Lab 1 PH Conductivity TurbidityDocument4 pagesLab 1 PH Conductivity TurbiditySumit Priyam67% (3)

- SIP-SOP03-R0-2017 SOP Temperature Transmitter CalibrationDocument2 pagesSIP-SOP03-R0-2017 SOP Temperature Transmitter CalibrationDwi Mulyanti DwimulyantishopNo ratings yet

- 4 Temperature MeasurementDocument113 pages4 Temperature MeasurementAhmed M. El-DyastyNo ratings yet

- Chap 1a - Instrumentation and PID DiagramDocument20 pagesChap 1a - Instrumentation and PID Diagramraj varmanNo ratings yet

- PH Electrodes 2724 To 2726 From GF SignetDocument6 pagesPH Electrodes 2724 To 2726 From GF Signetguita riefNo ratings yet

- METHOD STATEMENT PRESSURE SWITCH UAE Univ.Document2 pagesMETHOD STATEMENT PRESSURE SWITCH UAE Univ.Muhamed RasheedNo ratings yet

- Calibration AllDocument64 pagesCalibration AllVignesh Rajan100% (4)

- Calibration of Differential Pressure TransmitterDocument8 pagesCalibration of Differential Pressure TransmitterLugabaluga100% (1)

- Lab3 Temperature and Calibration - FINALrrDocument6 pagesLab3 Temperature and Calibration - FINALrrDerrick SheeNo ratings yet

- Instrument Calibration ProcedureDocument10 pagesInstrument Calibration ProcedureMohammad Nurayzat JohariNo ratings yet

- Temperature Measurement and Calibration Setup (TH1)Document9 pagesTemperature Measurement and Calibration Setup (TH1)Ndra PompomorinNo ratings yet

- DKD R 6 2 t5 e PDFDocument9 pagesDKD R 6 2 t5 e PDFDragan Ilic100% (1)

- Method Statement For Conductivity MeterDocument2 pagesMethod Statement For Conductivity MeterMuhamed RasheedNo ratings yet

- Calibration ProceduresDocument24 pagesCalibration Procedurestingpadu83% (6)

- Exp3 - Air Pressure ControlDocument8 pagesExp3 - Air Pressure ControlDon LawrenceNo ratings yet

- Loop Cheking ProcedureDocument5 pagesLoop Cheking ProcedureMd Omar FaruqueNo ratings yet

- Calibration of ThermocoupleDocument4 pagesCalibration of ThermocoupleAmar SinghNo ratings yet

- 2.4.temperature MeasurementnewDocument48 pages2.4.temperature MeasurementnewIroshiniNo ratings yet

- CAT CP 1 (T) Calibration of RTDDocument4 pagesCAT CP 1 (T) Calibration of RTDAmar Singh100% (1)

- Temperature Sensors: Sensytemp Tsp311, Tsp321, Tsp331Document40 pagesTemperature Sensors: Sensytemp Tsp311, Tsp321, Tsp331Tin ThanNo ratings yet

- LevelDocument78 pagesLevelvjgeorge100% (1)

- Stability and UniformityDocument6 pagesStability and UniformitymegacobNo ratings yet

- Implementing Calibration ProgramDocument10 pagesImplementing Calibration ProgramcleitonmoyaNo ratings yet

- Calibration Lab MagazineDocument48 pagesCalibration Lab MagazineNizar Alif100% (1)

- THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDFDocument7 pagesTHERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDFGustavo SánchezNo ratings yet

- Basics of Instrumentation & ControlDocument29 pagesBasics of Instrumentation & ControlprathmeshNo ratings yet

- Instrument CalibrationDocument25 pagesInstrument Calibrationsomucdm602350% (2)

- Calibration Interval 1Document7 pagesCalibration Interval 1fajar_92No ratings yet

- Basic Concepts of MeasurementsDocument10 pagesBasic Concepts of MeasurementsRaja Prathap SinghNo ratings yet

- EURAMET-cg-08 V 2.1 ChangesDocument18 pagesEURAMET-cg-08 V 2.1 ChangesGilberto Andrés JuradoNo ratings yet

- Thermomeer PDFDocument7 pagesThermomeer PDFbharatheeeyuduNo ratings yet

- SOP-02 Conductivity MeterDocument2 pagesSOP-02 Conductivity MeterKushal SharmaNo ratings yet

- Calibration With Some ImportanceDocument41 pagesCalibration With Some ImportanceKashif BashirNo ratings yet

- Calibration of Pressure GaugeDocument16 pagesCalibration of Pressure GaugeRITIKA SHUKLANo ratings yet

- Hot Plate Calibration SopDocument3 pagesHot Plate Calibration Sopsharmashyamsingh100% (2)

- Calibration of Pressure Gauges Page 1 of 1 Lit # Pgcalinst.105Document3 pagesCalibration of Pressure Gauges Page 1 of 1 Lit # Pgcalinst.105Phạm Quang HuyNo ratings yet

- Spectrum Analyzer and Spectrum Analysis: Shimshon Levy October 2012Document23 pagesSpectrum Analyzer and Spectrum Analysis: Shimshon Levy October 2012Daniel AguilarNo ratings yet

- ABB - Pressure TransmitterDocument8 pagesABB - Pressure TransmitterD.RameshkumarNo ratings yet

- Calibration of The Temperature IndicatorDocument5 pagesCalibration of The Temperature IndicatorMourougapragash SubramanianNo ratings yet

- Calibration ProcedureDocument28 pagesCalibration ProcedureWilmer EgeaNo ratings yet

- DP Level Transmitter Auto CalibrationDocument12 pagesDP Level Transmitter Auto Calibrationmatthew kagurabadza100% (2)

- Deutscher Kalibrierdienst: Guideline DKD-R 5-1 Calibration of Resistance ThermometersDocument24 pagesDeutscher Kalibrierdienst: Guideline DKD-R 5-1 Calibration of Resistance Thermometersjonh66-1No ratings yet

- Fundamentals of Temperature MeasurementDocument2 pagesFundamentals of Temperature MeasurementAhmed M. El-DyastyNo ratings yet

- DP Transmitter Interface Level Measurement Principle, Limitations, Selection, Installation, Design & CalibrationDocument12 pagesDP Transmitter Interface Level Measurement Principle, Limitations, Selection, Installation, Design & CalibrationsubbaraoNo ratings yet

- Calibration All PDFDocument42 pagesCalibration All PDFMubasher91% (11)

- Calibration Procedure - Pressure TransmitterDocument1 pageCalibration Procedure - Pressure TransmittersathyanduraisamyNo ratings yet

- Module 6 Temperature SensorsDocument20 pagesModule 6 Temperature SensorsJyothi SamanthulaNo ratings yet

- Thermocouples - WikaDocument13 pagesThermocouples - WikaJ BagienNo ratings yet

- TC620 TC621 5V, Dual Trip Point Temperature Sensors: Features General DescriptionDocument6 pagesTC620 TC621 5V, Dual Trip Point Temperature Sensors: Features General Descriptionmiki983No ratings yet

- 11 - Chapter 2 PDFDocument30 pages11 - Chapter 2 PDFSubhash KNo ratings yet

- 12 - Chapter 1 PDFDocument10 pages12 - Chapter 1 PDFSubhash KNo ratings yet

- 07 - Chapter 2 PDFDocument19 pages07 - Chapter 2 PDFSubhash KNo ratings yet

- 12 Chapter7 PDFDocument25 pages12 Chapter7 PDFSubhash KNo ratings yet

- Cotter Joint: Fig 01: Assembled Cottered JointDocument7 pagesCotter Joint: Fig 01: Assembled Cottered JointSubhash KNo ratings yet

- 05 Chapter-2 PDFDocument44 pages05 Chapter-2 PDFSubhash KNo ratings yet

- Cotter Joint: Fig 01: Assembled Cottered JointDocument7 pagesCotter Joint: Fig 01: Assembled Cottered JointSubhash KNo ratings yet

- 1) Avon Electronics, Pune PDFDocument1 page1) Avon Electronics, Pune PDFSubhash KNo ratings yet

- Course Outcomes by Cad CamDocument2 pagesCourse Outcomes by Cad CamSubhash K0% (1)

- FEM Análise para Engrenagens HelicoidaisDocument12 pagesFEM Análise para Engrenagens HelicoidaisFelipe_PalmeiroNo ratings yet

- Assignment ClutchDocument624 pagesAssignment ClutchSubhash KNo ratings yet

- Quotation Requirement of Mechatronices Lab PDFDocument2 pagesQuotation Requirement of Mechatronices Lab PDFSubhash KNo ratings yet

- Assignment 1Document1 pageAssignment 1Subhash KNo ratings yet

- Assignment No: 2: Date:-Dept: - Mechanical EngineeringDocument1 pageAssignment No: 2: Date:-Dept: - Mechanical EngineeringSubhash KNo ratings yet

- META Lab PDFDocument1 pageMETA Lab PDFSubhash KNo ratings yet

- When Is The Report DueDocument2 pagesWhen Is The Report DueSubhash KNo ratings yet

- New Microsoft Office Word Document PDFDocument5 pagesNew Microsoft Office Word Document PDFSubhash KNo ratings yet

- PLC Programming: Department of Mechanical EngineeringDocument6 pagesPLC Programming: Department of Mechanical EngineeringSubhash KNo ratings yet

- Work Reports: Goals of Practical Work Report WritingDocument4 pagesWork Reports: Goals of Practical Work Report WritingSubhash KNo ratings yet

- Selection Subject RelatedDocument1 pageSelection Subject RelatedSubhash KNo ratings yet

- Assignment No - 2 TE Div - BDocument2 pagesAssignment No - 2 TE Div - BSubhash KNo ratings yet

- 1) Magnetic Bearing Technology:: 4) Introduction To Mechanical VibrationsDocument1 page1) Magnetic Bearing Technology:: 4) Introduction To Mechanical VibrationsSubhash KNo ratings yet

- Mechatronices Question Bank Unit Test - IDocument1 pageMechatronices Question Bank Unit Test - ISubhash KNo ratings yet

- Project Report Writing Format - FinalDocument13 pagesProject Report Writing Format - FinalSubhash KNo ratings yet

- Vaccum Braking SystemDocument16 pagesVaccum Braking SystemSubhash KNo ratings yet

- Study of LVDTDocument10 pagesStudy of LVDTSubhash KNo ratings yet

- TransducerDocument32 pagesTransducerSubhash KNo ratings yet

- MECHATRONISCDocument2 pagesMECHATRONISCSubhash KNo ratings yet

- Supreme Inustrial Visit Report 2012 NewDocument26 pagesSupreme Inustrial Visit Report 2012 NewSubhash KNo ratings yet

- Pin On Disc Test ResultsDocument9 pagesPin On Disc Test Resultsgaminigsuresh4069No ratings yet

- RTD and Thermocouple SensorsDocument4 pagesRTD and Thermocouple SensorsCss GaneshNo ratings yet

- Lab #1 Fourier Rate Equation and Thermal ConductivityDocument6 pagesLab #1 Fourier Rate Equation and Thermal ConductivityBakyt SmagulovaNo ratings yet

- Decade Boxes Portable Test InstrumentsDocument42 pagesDecade Boxes Portable Test InstrumentsAchira DasanayakeNo ratings yet

- Manual Herramientas MastercoolDocument116 pagesManual Herramientas MastercoolJorge Miguel Galarza SandyNo ratings yet

- Controledge Hc900 Io Modules Specifications: 51-52-03-41, November 2019Document35 pagesControledge Hc900 Io Modules Specifications: 51-52-03-41, November 2019Alaa MohammedNo ratings yet

- Summer Training Project Report: "Overview and Role of C & I in Thermal Power Plant"Document109 pagesSummer Training Project Report: "Overview and Role of C & I in Thermal Power Plant"ysr3ee6926No ratings yet

- Cable Schedules SamplesDocument26 pagesCable Schedules SamplesansarNo ratings yet

- Bro Flare Pilot Burner enDocument3 pagesBro Flare Pilot Burner endebasish bhowmickNo ratings yet

- Group 4Document10 pagesGroup 4Abdul MananNo ratings yet

- Ferroli Gázszelep SIT 825 NOVADocument8 pagesFerroli Gázszelep SIT 825 NOVAkerandibNo ratings yet

- Type 0531 Gauge - The Operating Principle of The Thermocouple Vacuum Gauge and Instructions For Building A LowDocument16 pagesType 0531 Gauge - The Operating Principle of The Thermocouple Vacuum Gauge and Instructions For Building A LowgajaramilloNo ratings yet

- IFTPS Retort - Processing - Guidelines - 02 - 13 - 14 PDFDocument65 pagesIFTPS Retort - Processing - Guidelines - 02 - 13 - 14 PDFrocanrol2No ratings yet

- Module 43 - Temperature Measurement: Thermocouple (Application of Joule Calorimeter) & Gravimetry AnalysisDocument30 pagesModule 43 - Temperature Measurement: Thermocouple (Application of Joule Calorimeter) & Gravimetry AnalysislulaNo ratings yet

- OptiBlend ManualDocument82 pagesOptiBlend ManualVijendra PanwarNo ratings yet

- Heat Transfer Lab - Experiment 7 - Heat Transfer From A FinDocument11 pagesHeat Transfer Lab - Experiment 7 - Heat Transfer From A FinJordan Hines75% (4)

- Industrial Measurements With Very Short Immersion: Isothermal Technology LTD HTTP://WWW - Isotech.co - UkDocument5 pagesIndustrial Measurements With Very Short Immersion: Isothermal Technology LTD HTTP://WWW - Isotech.co - UklizarazojavierNo ratings yet

- Jftot II Service RevcDocument94 pagesJftot II Service RevckevinNo ratings yet

- Manual T70.1530enDocument7 pagesManual T70.1530enFelix Bocanegra RuizNo ratings yet

- Eil Cable EntryDocument85 pagesEil Cable EntryHarshkumar PatelNo ratings yet

- PEEDTRONICTM Mark VI For Gas Turbine Control RetrofitsDocument20 pagesPEEDTRONICTM Mark VI For Gas Turbine Control Retrofitsewok2030100% (1)

- ThermocouplesDocument8 pagesThermocouplesRakesh NayakNo ratings yet

- CarboliteDocument2 pagesCarboliteAgus Be PeNo ratings yet

- Invesigatory Project On Seebeck EffectDocument16 pagesInvesigatory Project On Seebeck EffectHardiik Khare67% (3)

- Screw-In Thermocouples With Terminal Head Form J: Technical DataDocument3 pagesScrew-In Thermocouples With Terminal Head Form J: Technical Dataersanjeeb_456No ratings yet

- Waltlow Specialty HeatersDocument17 pagesWaltlow Specialty HeatersEliasNo ratings yet

- BC 404Document3 pagesBC 404Pustinjak SaharicNo ratings yet

- Hvac BMS: HVAC Systems Eng. Ahmed MoustafaDocument126 pagesHvac BMS: HVAC Systems Eng. Ahmed MoustafaBahaa bunniNo ratings yet

- ZWK-I-120KW Intelligent Temperature Controller: WarningDocument5 pagesZWK-I-120KW Intelligent Temperature Controller: WarningErickzelaya2014No ratings yet

- GHT 2474 Chino 12 Point Temperature Recorder AH4712 EOADocument2 pagesGHT 2474 Chino 12 Point Temperature Recorder AH4712 EOAsinar automationNo ratings yet