Professional Documents

Culture Documents

Gelatinized Cereal Binder

Uploaded by

kkamalakannaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gelatinized Cereal Binder

Uploaded by

kkamalakannaCopyright:

Available Formats

STEEL FOUNDERS SOCIETY OF AMERICA

Standard Specification for

GELATINIZED CEREAL BINDER

SFSA Designation: 1 O-6 1 Issued: 1961

R e - P r i n t e d : 1968

1. Scope

1.1 This specification covers gelatinized cereal binder (see notes 1 and 2) for use as a binder in either molding or core sand. NOTE l.-lhe product, gelatinized cereal binder, is produced

from cereal grains. N o t e 2.-Cereal binder is synonymous to the terms corn flour, binder flour, corn binder, process flour, core binder and cereal flours.

5.2 The number of bags sampled for umpire checks shall be according to ASTM C322-56, procedure C. 5.2.1 The number of samples shall depend on the number of units in a shipment. For carload shipments ( 100 to 500 bags), 15 bags shall be sampled at random and a composite sample made. 5.3 Reduction of composite sample 5.3.1 Reduction of the sample shall be accomplished by quartering until a 2-pound laboratory sample is obtained. 5.4 Identification of sample shall indicate material, producer, supplier and date shipment was received. 6. Technical Requirements

2. Acknowledgment 2.1 W h e n specified, a vendor shall indicate this specification number in all quotations and when acknowledging purchase orders. 3. Identification 3. I All containers of cereal binders shall be identified by the words Cereal Binder, and the producer s trade name. Both shall be of a contrasting color to the container. 3.2 The designation Cereal Binder shall be followed by a letter indicating the weight classification; H stands for heavy weight, "M" stands for medium weight and L stands for light weight. 4. Quality

4.1 The cereal binder shall be uniform in quality

6.1 Moisture content 6.1 .1 The maximum water content shall not exceed 10 percent and the minimum content shall be 4 per-

cent.

6.2 Density (heavy, medium, light cereal binder) 6.2.1 The density of cereal binder need not be specified if the additions are made on a weight basis.

6.2.2 When cereal binder additions are made on a volume basis, the density of the cereal binder shall fall within one of the limits specified in Table 1.

6.3 Soluble Material (dry basis) 6.3.1 The range of soluble material shall be within either of the following limits: 6 . 3 . 1 . 1 5 - 15 percent (see Note 3) 6.3.1.2 16 - 3 0 percent (see Note 4 ) N o t e S.-LOW soluble material tends to produce cores of uniform hardness.

and condition, and free from foreign materials. 5. Sample Preparation

5.1 The number of bags to be sampled by the consumer for a routine check of the technical requirements shall be a minimum of 5 bags taken at random to make a composite sample.

N OTE 4.-A high soluble material content indicates that t h e cereal binder tends to migrate to the surface of a mold or core. This makes for a hard surface and leaves the center relatively soft.

6.4 The pH value 6.4.1 The pH range shall be within the limits of 4.5 to 7.0. 6.5 Ash content 6.5.1 The maximum ash content shall not exceed 1.5 percent. T ABLE I-WEIGHTS Heavy Cereal Binder 500-700 g/qt 454-636 g/l 17.5-24.5 oz/qt

OF

C EREAL B INDER Light Cereal Binder 200-3 00 g/qt 18 2-272 g/l 7.0-10.x oz/qt F IG. l-Photograph of Sifter Box

Medium Cereal Binder 300-500 g/qt 272-454 g/l 10.5-17.5 oz/qt

7. Acceptance Tests 7.1 Moisture 7.1.1 Weigh 5 grams into a tared aluminum moisture dish and dry for 1 hour at 120 degrees C (248 degrees F). Remove the dish from the oven and cover tightly; cool to room temperature in a desiccator and weigh. 7.1.2 Calculation: percent moisture=grams loss in weight x 20. 7.2 Density or sifted weight per quart or per liter

- 3 DIA.

7.2.1 Equipment (see Figure 1) 7.2.1.1 Flour sifter (4 or 5 cup rotary-crank flour sifter with 18-mesh screen. 16-mesh screen acceptable) 7.2.1.2 Sifter box (see Figure 2 for dimensions)

L- gt Ilh_j

F I G. 2Dimension of Sifter Box container is completely full (approximately 100 to 120 rpm is the proper sifting rate). Starting at one edge, strike off the quart container level with the strike-off bar. Weigh the contents on the balance and record the weight in grams. 7.2.3 Calculations 7.2.3.1 The grams per dry quart can be converted to grams per liter by dividing by 1.1. (U.S. Dry Quart - 1.10120 liters) 7.2.4 Precautions 7.2.4.1 Sifting and weighing equipment should be

7.2.1.3 Standard U. S. dry quart container (manufactured by Ohaus Scale Corp., P.O. Box 276, Union, New Jersey) 7.2.1.4 Strike-off bar (ruler or other thin straightedge, approximately 1 flz inches wide and 12 inches long) 7.2.1.5. Suitable balance (=1 gram sensitivity) 7.2.2 Procedure 7.2.2.1 Fill the sifter with a well-mixed sample of the material to be tested and place the sifter on the funnel. Center the standard dry-quart container under the funnel in the sifter box. 7.2.2.2 The container is filled with the binder by sifting at a uniform, but not too rapid, rate until the

free from excessive vibration. The sifter should always be in the same position when sifting. Do not move or jar the container until after the excess flour has been leveled off. 7.3 Soluble material 7.3.1 Determine percent of dry substance

7.5 Ash Content 7.5.1 Weigh 5 grams of the sample in a weighed platinum or silica dish. Place in a muffle furnace at 1650 degrees F (900 degrees C) for 1 hour with the door of the muffle furnace propped open to allow excess air to the burning sample. Remove from the furnace, cool in a desiccator and weigh. 7.5.2 Calculations: Percent ash=

7.3.1 .1 Weigh 2 grams of sample, transfer to a 200 ml volumetric flask containing about 25 ml of water at 25 degrees C and fill flask with water at 25 degrees C to about 200 ml mark. Let stand for one hour with occasional shaking. Fill flask to mark and shake until thoroughly mixed. Filter at once through a double 18 s cm # 5 88 S & S filter paper. Measure 50 ml of the filtrate and transfer to a weighed evaporating dish. Evaporate to dryness on a steam bath, then one hour in an oven at 105 degrees C. Cool and weigh. 7.3.1.2 Calculations Soluble (Dry basis) = (Gm Residue) (100) (W) (2 gm) (W) _ (Gm Residue) ( 2 0 , 0 0 0 ) % Dry Substance 7 . 4 pH 7.4.1 Weigh 10 gms of the sample, stir into 200 m l of water and shake intermittently for 30 minutes. Determine the pH by electrometric methods using either a Leeds and Northrup pH meter or a Beckman Model H-2 pH Meter employing the #4990-42 Electrode, or a Coleman Model 18A, or other suitable equipment.

grams of ash x 100 5 grams 8. Packaging or Bagging 8.1 Packaging shall be accomplished in such a manner as to insure against loss of material as well as undue exposure to moisture, (see Note 5).

NOTE T.-When cereal binder is packaged in jute bags, it

should be remembered that these containers will absorb moisture.

8.2 The flour, when packaged in containers, shall hold a maximum of 105 pounds. 8.3 Each container shall be legibly marked with the following: (see Note 6 ) 8.3.1 Cereal Binder or trade name in contrasting color to bag 8.3.2 Quantity or weight 8.3.3. Manufacturers name 8.3.4 Weight classification (see 3.2)

N OTE 6.If jute bags are specified or used, a legibly marked tag shall be considered as proper identification.

9. Rejection 9.1 Material not conforming to the specification will be subject to rejection by the foundry.

You might also like

- Internet and Standards Disclosure for Right to InformationDocument16 pagesInternet and Standards Disclosure for Right to InformationakNo ratings yet

- Fiber 01Document4 pagesFiber 01Kim-Kim TorresNo ratings yet

- PGDBST 03Document61 pagesPGDBST 03UJJWAL RAJ SINGHNo ratings yet

- 13t 86 Western BentoniteDocument5 pages13t 86 Western BentoniteCharlie ChongNo ratings yet

- Is 12711 1989Document22 pagesIs 12711 1989Trupti PawarNo ratings yet

- Indian Standard Parameters and Analysis For Atta, Maida and SujiDocument17 pagesIndian Standard Parameters and Analysis For Atta, Maida and SujiVasudeva Prasad Nemala67% (3)

- Insoluble Matter-2007Document4 pagesInsoluble Matter-2007Bryan Wicaksono100% (2)

- Indian Maida StandardDocument6 pagesIndian Maida StandardRahul Suryavanshi100% (1)

- Grain Fungal Spoilage Test Instructions: Woods End Farm & Laboratories, 2010Document2 pagesGrain Fungal Spoilage Test Instructions: Woods End Farm & Laboratories, 2010Andrew SpardaNo ratings yet

- AASHTO T 166-Standard Method of Test For Bulk Specific Gravity of Compacted Bituminous MixturesDocument4 pagesAASHTO T 166-Standard Method of Test For Bulk Specific Gravity of Compacted Bituminous MixturesDonnabel CaleNo ratings yet

- Consistencia de Pulpas TAPPI240Document3 pagesConsistencia de Pulpas TAPPI240Leidy Diana Cifuentes AriasNo ratings yet

- WSDOT Errata To FOP For AASHTO T 176: Plastic Fines in Graded Aggregates and Soils by The Use of The Sand Equivalent TestDocument10 pagesWSDOT Errata To FOP For AASHTO T 176: Plastic Fines in Graded Aggregates and Soils by The Use of The Sand Equivalent Testfjhg bgmjkfgNo ratings yet

- Fairy Food VisitDocument6 pagesFairy Food VisitLeishangthem Jeebit SinghNo ratings yet

- A5TM D 2974 87 Standard Test Methods ForDocument3 pagesA5TM D 2974 87 Standard Test Methods ForratnaNo ratings yet

- Gravimetric Analysis TechniquesDocument23 pagesGravimetric Analysis TechniquesJAN JERICHO MENTOYNo ratings yet

- M. Mujeeb Ullah, Nutr-401 PracticalDocument16 pagesM. Mujeeb Ullah, Nutr-401 PracticalAli RazaNo ratings yet

- Stas American Astm d2974-87 Material OrganicDocument3 pagesStas American Astm d2974-87 Material OrganicAlexandra PopNo ratings yet

- Moisture Content of Paper and Paperboard by Oven Drying: Standard Test Method ForDocument2 pagesMoisture Content of Paper and Paperboard by Oven Drying: Standard Test Method ForfrostestNo ratings yet

- CODEX STANDARD FOR CANNED SHRIMPSDocument5 pagesCODEX STANDARD FOR CANNED SHRIMPSSoni SularsoNo ratings yet

- Crude Fiber AnalysisDocument3 pagesCrude Fiber AnalysisLUSIANANo ratings yet

- Procedure For Preserving Yeast and Mold Isolates: 1. PurposeDocument9 pagesProcedure For Preserving Yeast and Mold Isolates: 1. PurposeR.GOMATHI RNo ratings yet

- Astm D4Document3 pagesAstm D4Vijayan Munuswamy100% (1)

- Astm d2726Document26 pagesAstm d2726mzaimNo ratings yet

- Lab 4 - Parboiling Rice MillingDocument4 pagesLab 4 - Parboiling Rice MillingKishoree Krishna Kumaree100% (1)

- D 1582 - 98 Rde1oditotgDocument2 pagesD 1582 - 98 Rde1oditotgMarceloNo ratings yet

- The Performance Evaluation of A CassavaDocument9 pagesThe Performance Evaluation of A CassavaAngelica DalogdogNo ratings yet

- Official Methods of Analysis - FlourDocument13 pagesOfficial Methods of Analysis - Flour4gen_5No ratings yet

- CXS - 092e - Codex ShrimpDocument6 pagesCXS - 092e - Codex ShrimpldfdNo ratings yet

- AOCS Official Method Ba 2a-38 (2009)Document1 pageAOCS Official Method Ba 2a-38 (2009)Thanh HươngNo ratings yet

- Practicum Guide: Soil Compaction TestsDocument40 pagesPracticum Guide: Soil Compaction Testssiphokazi mahanjanaNo ratings yet

- 32 20 01Document2 pages32 20 01acetonafloresNo ratings yet

- ASTM D 1334 - 96 Wool Content of Raw Wool-Commercial ScaleDocument3 pagesASTM D 1334 - 96 Wool Content of Raw Wool-Commercial Scalealin2005No ratings yet

- Soil and Soil AggregatesDocument4 pagesSoil and Soil Aggregatesgreat_triskelionNo ratings yet

- Soil Sample Analysis UV-VIS SpecDocument5 pagesSoil Sample Analysis UV-VIS SpecNkosiNo ratings yet

- Experiment On: Extrusion Cooking AIMDocument8 pagesExperiment On: Extrusion Cooking AIMShobikaNo ratings yet

- Lab Manual 1Document47 pagesLab Manual 1Tripathi 70No ratings yet

- Objective: Ash-Basic MethodDocument2 pagesObjective: Ash-Basic MethodSaleh Saeed AgbaryNo ratings yet

- Example-14 Dispensing of Raw MaterialDocument4 pagesExample-14 Dispensing of Raw Materialsafitri yonandaNo ratings yet

- C 602 - 95a R01 QZYWMGDocument3 pagesC 602 - 95a R01 QZYWMGHumberto GutierrezNo ratings yet

- Determin of Aero Anaerobic Spore FormersDocument6 pagesDetermin of Aero Anaerobic Spore FormersbhaleshNo ratings yet

- Complete Proximate Analysis For Animal Feed PDFDocument14 pagesComplete Proximate Analysis For Animal Feed PDFtestNo ratings yet

- Paes 203Document7 pagesPaes 203Ryan Anthony LualhatiNo ratings yet

- Acid-Insoluble Lignin in Wood: Standard Test Method ForDocument2 pagesAcid-Insoluble Lignin in Wood: Standard Test Method ForScribdLibros11No ratings yet

- 1065 - Bleaching Powder StableDocument10 pages1065 - Bleaching Powder StableKaushik SenguptaNo ratings yet

- Test Method For The Grain-Size Analysis of Granular Soil MaterialsDocument19 pagesTest Method For The Grain-Size Analysis of Granular Soil Materialsdhan singhNo ratings yet

- D 4503 - 86 r98 Rdq1mdmtodzsotg PaperpaperDocument3 pagesD 4503 - 86 r98 Rdq1mdmtodzsotg Paperpapernica tamNo ratings yet

- C07 - Colour Fastness To PerspirationDocument5 pagesC07 - Colour Fastness To PerspirationChandru TGNo ratings yet

- ASTM D-482 Standard Test Method for Petroleum AshDocument3 pagesASTM D-482 Standard Test Method for Petroleum AshMuhammad AdnanNo ratings yet

- Sand Equivalent Test ProcedureDocument6 pagesSand Equivalent Test ProcedureMohammed KarasnehNo ratings yet

- CT - 214june08 Soundness CA DOT AASHTO T104 ModifiedDocument6 pagesCT - 214june08 Soundness CA DOT AASHTO T104 ModifiedgemotorresNo ratings yet

- Bitumen TestDocument6 pagesBitumen TestSayal SattarNo ratings yet

- Kenchic Broiler Manual PDFDocument29 pagesKenchic Broiler Manual PDFGirish Kumar100% (3)

- Practical Manual - Processing of Spices and Plantation CropsDocument26 pagesPractical Manual - Processing of Spices and Plantation CropsDhaya VNo ratings yet

- Bioplastic from Cornstarch and Shrimp ShellDocument4 pagesBioplastic from Cornstarch and Shrimp ShellELF SJNo ratings yet

- QC Tests For Road Works by Bhavanna Rao DVDocument24 pagesQC Tests For Road Works by Bhavanna Rao DVmilind_0786No ratings yet

- Calidad Del Cocinado de Pasta AACC66-50Document3 pagesCalidad Del Cocinado de Pasta AACC66-50ZacariasNo ratings yet

- Specific Gravity Test Coarse AggregatesDocument5 pagesSpecific Gravity Test Coarse AggregatesAbdullah SimpsonNo ratings yet

- Determination of Moisture: NG Mui CHNGDocument3 pagesDetermination of Moisture: NG Mui CHNGApostolos PatsiasNo ratings yet

- ASTM MATERIAL COMPARISON TABLEDocument10 pagesASTM MATERIAL COMPARISON TABLEMardeOpamenNo ratings yet

- Steel Casting Handbook Supplement 2Document72 pagesSteel Casting Handbook Supplement 2Syed MajeedNo ratings yet

- ASTM MATERIAL COMPARISON TABLEDocument10 pagesASTM MATERIAL COMPARISON TABLEMardeOpamenNo ratings yet

- 40 Tips For Better Life From ISHA YOGADocument3 pages40 Tips For Better Life From ISHA YOGABalasubrmaniyan79% (14)

- 40 Tips For Better Life From ISHA YOGADocument3 pages40 Tips For Better Life From ISHA YOGABalasubrmaniyan79% (14)

- Aluminum Cast&AlloysDocument3 pagesAluminum Cast&AlloyskkamalakannaNo ratings yet

- Good For LifeDocument3 pagesGood For LifekkamalakannaNo ratings yet

- 40 Tips For Better Life From ISHA YOGADocument3 pages40 Tips For Better Life From ISHA YOGABalasubrmaniyan79% (14)

- Jayakanthan Sirukathaigal - Part3Document83 pagesJayakanthan Sirukathaigal - Part3முரளி கிருஷ்ணன் alias முகி100% (5)

- 40 Tips For Better Life From ISHA YOGADocument3 pages40 Tips For Better Life From ISHA YOGABalasubrmaniyan79% (14)

- 40 Tips For Better Life From ISHA YOGADocument3 pages40 Tips For Better Life From ISHA YOGABalasubrmaniyan79% (14)

- Jayakanthan Sirukathaigal - Part3Document83 pagesJayakanthan Sirukathaigal - Part3முரளி கிருஷ்ணன் alias முகி100% (5)

- Tamil MedicineDocument10 pagesTamil MedicinekkamalakannaNo ratings yet

- 40 Tips For Better Life From ISHA YOGADocument3 pages40 Tips For Better Life From ISHA YOGABalasubrmaniyan79% (14)

- Standard Specification For WASHED AND DRIED SANDDocument3 pagesStandard Specification For WASHED AND DRIED SANDkkamalakannaNo ratings yet

- New Approach to Casting Defects Classification and Analysis Using SimulationDocument18 pagesNew Approach to Casting Defects Classification and Analysis Using SimulationkkamalakannaNo ratings yet

- Optimize SEO for Zircon Sand SpecificationDocument4 pagesOptimize SEO for Zircon Sand SpecificationkkamalakannaNo ratings yet

- Ethirparatha Mutham - BarathidasanDocument35 pagesEthirparatha Mutham - Barathidasanjaggi90No ratings yet

- Handwriting Cursive 1Document1 pageHandwriting Cursive 1Jonathon54No ratings yet

- Handwriting Cursive 8Document1 pageHandwriting Cursive 8kkamalakannaNo ratings yet

- Cast Iron EquivalentsDocument8 pagesCast Iron EquivalentskkamalakannaNo ratings yet

- Handwriting Cursive 1Document1 pageHandwriting Cursive 1Jonathon54No ratings yet

- How To Buy Forgings: The Design ConferenceDocument6 pagesHow To Buy Forgings: The Design ConferencekkamalakannaNo ratings yet

- Cast Iron EquivalentsDocument8 pagesCast Iron EquivalentskkamalakannaNo ratings yet

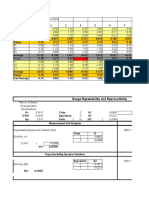

- Gauge Repeteability and ReprouctibilityDocument7 pagesGauge Repeteability and ReprouctibilityAdrián JarablaNo ratings yet

- 10% To 30% Error - May Be Acceptable Based Upon Importance of ApplicationDocument3 pages10% To 30% Error - May Be Acceptable Based Upon Importance of ApplicationktyeoNo ratings yet

- Handwriting Cursive 1Document1 pageHandwriting Cursive 1Jonathon54No ratings yet

- Handwriting Cursive 4Document1 pageHandwriting Cursive 4kkamalakannaNo ratings yet

- Cast Iron EquivalentsDocument8 pagesCast Iron EquivalentskkamalakannaNo ratings yet

- Explorations - An Introduction To Astronomy-HighlightsDocument10 pagesExplorations - An Introduction To Astronomy-HighlightsTricia Rose KnousNo ratings yet

- Alice Corporation Pty. Ltd. v. CLS Bank International and CLS Services Ltd.Document4 pagesAlice Corporation Pty. Ltd. v. CLS Bank International and CLS Services Ltd.Rachel PauloseNo ratings yet

- Suntay V CojuancoDocument2 pagesSuntay V CojuancoJushiNo ratings yet

- 2 Obligations General Provisions 1156 1162Document15 pages2 Obligations General Provisions 1156 1162Emanuel CenidozaNo ratings yet

- Mock-B1 Writing ReadingDocument6 pagesMock-B1 Writing ReadingAnonymous 0uBSrduoNo ratings yet

- PB13MAT - 13 Project Stakeholder ManagementDocument30 pagesPB13MAT - 13 Project Stakeholder ManagementYudhi ChristianNo ratings yet

- Yale Film Analysis WebsiteDocument5 pagesYale Film Analysis WebsiteizmcnortonNo ratings yet

- Southern Railway, Tiruchchirappalli: RC Guards Batch No: 1819045 Paper PresentationDocument12 pagesSouthern Railway, Tiruchchirappalli: RC Guards Batch No: 1819045 Paper PresentationSathya VNo ratings yet

- PERTANYAAN INTERVIEW WinaDocument2 pagesPERTANYAAN INTERVIEW WinaDidi SetiadiNo ratings yet

- Unit Test 1: Vocabulary & GrammarDocument2 pagesUnit Test 1: Vocabulary & GrammarAlexandraMariaGheorgheNo ratings yet

- Arup Blockchain Technology ReportDocument74 pagesArup Blockchain Technology ReportHarin VesuwalaNo ratings yet

- Safety Guidelines For Direct DrivesDocument9 pagesSafety Guidelines For Direct DrivesJOseNo ratings yet

- Economics 1A and B WorkbookDocument90 pagesEconomics 1A and B WorkbookmrlsrpssqbucxwswfjNo ratings yet

- Amgen Inc. v. F. Hoffmann-LaRoche LTD Et Al - Document No. 423Document19 pagesAmgen Inc. v. F. Hoffmann-LaRoche LTD Et Al - Document No. 423Justia.comNo ratings yet

- 3DO For IPDocument7 pages3DO For IPHannah Angela NiñoNo ratings yet

- Guidance for Processing SushiDocument24 pagesGuidance for Processing SushigsyaoNo ratings yet

- Solutions Manual For Corporate Finance, 6e Jonathan BerkDocument7 pagesSolutions Manual For Corporate Finance, 6e Jonathan Berksobiakhan52292No ratings yet

- International History 1900-99Document5 pagesInternational History 1900-99rizalmusthofa100% (1)

- Christian Ministry Books: 00-OrientationGuideDocument36 pagesChristian Ministry Books: 00-OrientationGuideNessieNo ratings yet

- 268 General Knowledge Set ADocument48 pages268 General Knowledge Set Aguru prasadNo ratings yet

- 28 Nakshatras - The Real Secrets of Vedic Astrology (An E-Book)Document44 pages28 Nakshatras - The Real Secrets of Vedic Astrology (An E-Book)Karthik Balasundaram88% (8)

- JNVD Souvenir FinalDocument67 pagesJNVD Souvenir Finalkundanno1100% (1)

- Best Practices in Implementing A Secure Microservices ArchitectureDocument85 pagesBest Practices in Implementing A Secure Microservices Architecturewenapo100% (1)

- Noise Pollution Control Policy IndiaDocument10 pagesNoise Pollution Control Policy IndiaAllu GiriNo ratings yet

- Schneider Electric Strategy PresentationDocument10 pagesSchneider Electric Strategy PresentationDeepie KaurNo ratings yet

- MCQ PharmacokineticsDocument10 pagesMCQ PharmacokineticsHarshit Sharma100% (1)

- Integrative Paper Unfolding The SelfDocument11 pagesIntegrative Paper Unfolding The SelfTrentox XXXNo ratings yet

- Chapter 2 Phil. HistoryDocument4 pagesChapter 2 Phil. HistoryJaylene AlbayNo ratings yet

- 2023 Civil LawDocument7 pages2023 Civil LawJude OnrubiaNo ratings yet

- QuizInfo8 6 10Document373 pagesQuizInfo8 6 10Gill BeroberoNo ratings yet