Professional Documents

Culture Documents

Gestra NRGT 26 1 NRGT 26 1s

Uploaded by

Voicu StaneseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gestra NRGT 26 1 NRGT 26 1s

Uploaded by

Voicu StaneseCopyright:

Available Formats

Issue Date: 4/06

GESTRA Steam Systems

Compact System for Level Monitoring NRGT 261 NRGT 261S For Marine Applications

Power consumption 5 VA Fuse Thermal fuse Tmax = 102 C Sensitivity Range 1: Water 0.5 S/cm Range 2: Water 20 S/cm Range 3: Fuel oil EL r 2.3 Output 420 mA levelproportional. Voltfree, max. load 500 Indicators and adjustors 2 red LEDs for signalling Level 0 % or Level 100 % within the measuring range, 1 green LED for signalling Level between 0 % and 100 % of measuring range. 1 code switch for selecting the measuring range. 2 trimmer potentiometers for smallpercentage adjust ment of the measuring range. 2 terminal lugs for voltage metering. Cable entry Cable gland with integral cable clamp M 20 (PG 16) (2 x) Protection IP 65 to DIN EN 40050 Max. admissible ambient temperature 70 C Weight NRGT 261: Approx. 1.8 kg NRGT 261S: Approx. 8.0 kg

Product Range B NRGT 261 NRGT 261S

Description

The compact system NRGT 261 works according to the capacitance measurement principle. The NRGT 261 is designed for signalling different levels in conductive and nonconductive liquids:

Water level maintained within the control band defined

GESTRA Steam Systems

by two preset limits. The NRGT 261 has a level transmitter integrated in the terminal box which produces a standard output signal of 420 mA. External switchgear is not required.

GESTRA NRGT 26-1

Function

The principle of capacitance measurement is applied to determine the level. The electrode rod and the vessel wall form a capacitor. If the level of the dielectric located between the two capacitor plates changes, the current which flows through the plates changes proportionally to the level. A dielectric is defined as an insulating substance, which excludes many liquids such as water. In order to receive a useful measuring result the measuring rod, which is completely submerged in the liquid, must be completely insulated. After calibration of the zero point/measuring range (0 % 100 %) of the control unit, the level can be read off from a remote display unit. The level measuring range can be changed during operation.

Design

NRGT 261: Electrode with screwed connection " BSP, DIN ISO 2281. NRGT 261S: Flanged design for marine applications DN 50, PN 40, DIN 2635.

Technical Data

Type approval no. NRGT 261: TV WRS 02391 NRGT 261S: LR 98/20075 RINA ELE/30298/2 GL 9924996HH BV 10617/AO BV NKK A556 DNV A8394 KR HMB 06190MS002 Service pressure 32 bar g at 238C Connection NRGT 261: NRGT 261S: Materials Case Stem Flange Measuring electrodes Electrode insulation Spacer disc Screwed BSP, DIN ISO 2281 Flanged DN 50, PN 40, DIN 2635 3.2161 G AlSi8Cu3 1.4571 CrNiMoTi17122 1.0460 P250GH 1.4571 CrNiMoTi17122 PTFE PTFE (design for marine applications)

Wiring diagram

NRGT 261 NRGT 261S

DC Supply

Mains supply 230 V +/ 10 %, 50/60 Hz 115 V +/ 10 %, 50/60 Hz (optional) 24 V +/ 10 %, 50/60 Hz (optional) 24 V d.c. (optional) Overall length / measuring range See table overleaf

N PE L 420 mA Mains Max. load + 500 Earthing screw 24 V DC in housing

Thermal fuse

140

Important Notes

337.5 Cable required for wiring: flexible multicore control cable, min. conductor size 1.5 mm2.

GESTRA NRGT 26-1

GESTRA NRGT 26-1S

Order and Enquiry Specification

GESTRA Level electrode NRGT 261, PN 40 Mains supply............................................................... Connection............................................................. Inspection............................................................. Length supplied...................................................... mm Fluid..................................................................... GESTRA Level electrode NRGT 261 S, PN 40 for marine applications Mains supply............................................................... Connection............................................................. Inspection............................................................. Length supplied...................................................... mm Fluid..................................................................... The following test certificates can be issued on request, at extra cost: In accordance with DIN EN 102042.1, 2.2 and 3.1B. All inspection requirements have to be stated with the order. After supply of the equipment certification cannot be established. For tests and inspection charges please consult us.

b = 70

339

b = 70

42

42

37

BSP to EN ISO 2281 373 477 583 688 794 899 1004 1110 1214 1319 1423 1528 1636 2156

Flange DN 50, PN 40 62 316 420 526 631 737 842 947 1053 1157 1262 1366 1471 1579 2099

1 2

Key 1 NRGT 261: Max. length of installation at 238 C 2 NRGT 261: Measuring range 3 NRGT 261S: Max. length of installation at 238 C 4 NRGT 261S: Measuring range 1 2 3 4 5 6 0 !

Flange PN 40, DN 50, DIN 2527 Flange PN 40, DN 100, DIN 2527 For the approval of the boiler standpipe with con necting flange the relevant regulations must be considered. Vent hole High water (HW) Electrode rod d = 15 mm Protection tube DN 80 Low water (LW) Reducer DIN 2616, part 2 K 88.9 x 3.2 42.4 x 2.6 W

Fig. 1 NRGT 261

300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 2000

48.5

26

42.5

Fig. 2 NRGT 261 S

Examples of Installation

BSP

1 2

BSP Centre distance

4 1 2 3 5 6

DN 20

DN 50

20

5 0

ATEX (Atmosphre Explosible)

10

According the the European Directive 94/9/EC the equip ment must not be used in potentially explosive areas.

20

20

0 !

DN 20 Fig. 4 External measuring pot

90

Supply in accordance with our general terms of business.

20 Fig. 3 Protection tube for installation of electrode inside the boiler

GESTRA AG

P. O. Box 10 54 60, D28054 Bremen Mnchener Str. 77, D28215 Bremen Telephone +49 (0) 421 35 03 0, Fax +49 (0) 421 35 03393 EMail gestra.ag@flowserve.com, Internet www.gestra.de

81019404/406cm 1998 GESTRA AG Bremen Printed in Germany

140 275 375 475 575 675 775 875 975 1075 1175 1275 1375 1475 1975

Compact System for Level Monitoring NRGT 261 NRGT 261S For Marine Applications

Dimensions

173

173

GESTRA Steam Systems

GESTRA Steam Systems

You might also like

- Gestra NRG16-12-NRG17-12-NRG19-12 - eDocument4 pagesGestra NRG16-12-NRG17-12-NRG19-12 - eVoicu StaneseNo ratings yet

- Pce 28Document3 pagesPce 28Pop-Coman SimionNo ratings yet

- Level transmitter optionsDocument2 pagesLevel transmitter optionsmikaellasyNo ratings yet

- 06 Pomocni Sklopnici I RelejiDocument55 pages06 Pomocni Sklopnici I Relejiaksiom007No ratings yet

- Druck PT Data SheetDocument7 pagesDruck PT Data Sheethits289No ratings yet

- Time Control Technique: Timer MK 9906N, On Delayed MinitimerDocument4 pagesTime Control Technique: Timer MK 9906N, On Delayed MinitimerKim Hảo Hoàng NguyễnNo ratings yet

- NivoPress DataSheet 2Document4 pagesNivoPress DataSheet 2Svetlana GabricNo ratings yet

- Nivocont: Conductive Level SwitchesDocument5 pagesNivocont: Conductive Level SwitchesGia Minh Tieu TuNo ratings yet

- CP 060 en PenningvacDocument8 pagesCP 060 en PenningvacMayur ChauhanNo ratings yet

- Vibration limit switch for liquid level detectionDocument4 pagesVibration limit switch for liquid level detectionalexkeserNo ratings yet

- Emp2 Box Pressure TransmitterDocument8 pagesEmp2 Box Pressure TransmitterAsif HameedNo ratings yet

- Apc 2000alw PDFDocument5 pagesApc 2000alw PDFvan_dall_2No ratings yet

- gt403 Ce2Document4 pagesgt403 Ce2SodaDrinkNo ratings yet

- Ca3kn22bd Telemecanique - Unit5.relayDocument8 pagesCa3kn22bd Telemecanique - Unit5.relaykapenziNo ratings yet

- Ti094dae Promag 10 P TiDocument20 pagesTi094dae Promag 10 P TiLê DuyNo ratings yet

- TDA2008Document10 pagesTDA2008miusayNo ratings yet

- BW25Document8 pagesBW25msalem73No ratings yet

- Instruction Manual: Models 7EF and 7HF ControllersDocument48 pagesInstruction Manual: Models 7EF and 7HF ControllerskmpoulosNo ratings yet

- NivoCAP Manual PDFDocument6 pagesNivoCAP Manual PDFarfanNo ratings yet

- Vacuum Gauges 45Document20 pagesVacuum Gauges 45Sameeksha AnandNo ratings yet

- PA2756GR: Mos Field Effect TransistorDocument7 pagesPA2756GR: Mos Field Effect TransistorRjibNo ratings yet

- A 1102Document11 pagesA 1102l461870No ratings yet

- CP 060 en ThermovacDocument14 pagesCP 060 en ThermovacMayur ChauhanNo ratings yet

- SensorDocument6 pagesSensorFarhan ZafarNo ratings yet

- Cable Capacity - Example Calculating 300 MMDocument7 pagesCable Capacity - Example Calculating 300 MMNedunuri.Madhav MurthyNo ratings yet

- Programmable In-Head Universal Temperature Transmitter ConfigurationDocument5 pagesProgrammable In-Head Universal Temperature Transmitter ConfigurationjhuskanovicNo ratings yet

- Hawe Pressure Dt11 d5440t2 enDocument4 pagesHawe Pressure Dt11 d5440t2 enАндрей дронNo ratings yet

- Control RelaysDocument32 pagesControl RelaysAhmed Boussoffara100% (1)

- Tl494 PWM IcDocument10 pagesTl494 PWM IcSai ChandhraNo ratings yet

- D D D D D D D D: DescriptionDocument12 pagesD D D D D D D D: DescriptionManuel Aguado EcheverríaNo ratings yet

- Re7rm11bu PDFDocument7 pagesRe7rm11bu PDFToth VasileNo ratings yet

- Sondaloop Data Sheet 283 Iss L Measuring Range 10m April 2017Document2 pagesSondaloop Data Sheet 283 Iss L Measuring Range 10m April 2017farruscoprdNo ratings yet

- Installation Manual MAS2600Document27 pagesInstallation Manual MAS2600Ketan SarmalkarNo ratings yet

- ADu M3190Document16 pagesADu M3190Varun ThakurNo ratings yet

- DatasheetDocument10 pagesDatasheettenisonNo ratings yet

- K4143Document8 pagesK4143eddy54No ratings yet

- SN74CBTS16211 24-Bit Fet Bus Switch With Schottky Diode ClampingDocument11 pagesSN74CBTS16211 24-Bit Fet Bus Switch With Schottky Diode ClampingBa DuyNo ratings yet

- Sensor de Presion AndersonDocument6 pagesSensor de Presion AndersonHector VelazquezNo ratings yet

- 4 PDFDocument7 pages4 PDFRick CastilloNo ratings yet

- Myrra Transformers CatalogDocument24 pagesMyrra Transformers CataloggksamyNo ratings yet

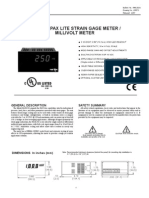

- Model Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedDocument8 pagesModel Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedJosé Tomas CisnerosNo ratings yet

- 8N80Document7 pages8N80niainaeloi_842256206No ratings yet

- LVCN4321Document2 pagesLVCN4321argodumilahNo ratings yet

- TA-Smart EN LowDocument8 pagesTA-Smart EN LowRendiNo ratings yet

- D D D D D D: Description/ordering InformationDocument12 pagesD D D D D D: Description/ordering InformationRao FarhanNo ratings yet

- D D D D D D: Description/ordering InformationDocument12 pagesD D D D D D: Description/ordering InformationNavleen NaviNo ratings yet

- Differential Pressure Transmitter: With Adjustable Span and ZeroDocument3 pagesDifferential Pressure Transmitter: With Adjustable Span and ZeroVidya MuthukrishnanNo ratings yet

- Condenserless Liquid ChillersDocument12 pagesCondenserless Liquid ChillersBader ShrbajiNo ratings yet

- Zelio Time Re8ta31buDocument6 pagesZelio Time Re8ta31buAssis Antoniazzi LavorattiNo ratings yet

- D D D D D D D: Description/ordering InformationDocument17 pagesD D D D D D D: Description/ordering InformationYugi Abdul LathifNo ratings yet

- DC/DC Converters: FeaturesDocument6 pagesDC/DC Converters: FeaturesDalibor CetojevicNo ratings yet

- Technical Requirements for Power TransformersDocument24 pagesTechnical Requirements for Power Transformersni60No ratings yet

- D D D D: Description/ordering InformationDocument18 pagesD D D D: Description/ordering InformationInes Maria CarvalhoNo ratings yet

- SG3524Document19 pagesSG3524Gabriel CamargoNo ratings yet

- Electromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionDocument4 pagesElectromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionAlphatech1No ratings yet

- Features: 46 Series - Miniature Industrial Relays, 8 - 16 ADocument6 pagesFeatures: 46 Series - Miniature Industrial Relays, 8 - 16 AThomas GonzalezNo ratings yet

- Danfoss Pressure SwitchDocument18 pagesDanfoss Pressure SwitchGirish OniyilNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- 2N3906 General Purpose Transistors: PNP SiliconDocument7 pages2N3906 General Purpose Transistors: PNP SiliconJose G. Cantillo L.No ratings yet

- 2N3906 General Purpose Transistors: PNP SiliconDocument7 pages2N3906 General Purpose Transistors: PNP SiliconJose G. Cantillo L.No ratings yet

- Css Cheat SheetDocument1 pageCss Cheat SheetIvica DumanovicNo ratings yet

- Fix engine codes and diagnosticsDocument4 pagesFix engine codes and diagnosticsVitor Roberto MoreiraNo ratings yet

- Modbus RtuDocument8 pagesModbus RtuVoicu StaneseNo ratings yet

- Dell Studio-1558 Service Manual En-UsDocument49 pagesDell Studio-1558 Service Manual En-UsVoicu StaneseNo ratings yet

- Analysis of Self Excited Induction GeneratorDocument7 pagesAnalysis of Self Excited Induction Generatorsajs201100% (1)

- Release NoteDocument8 pagesRelease NoteVoicu StaneseNo ratings yet

- FastTrack To WirelessSpeedlightsDocument8 pagesFastTrack To WirelessSpeedlightsVoicu StaneseNo ratings yet

- Steinmetz, Charles Proteus - Electric Discharges Waves and ImpulsesDocument172 pagesSteinmetz, Charles Proteus - Electric Discharges Waves and ImpulsesVoicu StaneseNo ratings yet

- Manufacturer: Model: Year: Registration: Mileage: Job Number: DateDocument5 pagesManufacturer: Model: Year: Registration: Mileage: Job Number: DateVoicu StaneseNo ratings yet

- Modbus RtuDocument8 pagesModbus RtuVoicu StaneseNo ratings yet

- Info Iec60870 5 601 Ed1 0 enDocument7 pagesInfo Iec60870 5 601 Ed1 0 enVoicu StaneseNo ratings yet

- Building Automation and Control L System Desi GoDocument52 pagesBuilding Automation and Control L System Desi GoVoicu StaneseNo ratings yet

- Williams Microturbine Diary Lagoon 03-3-018Document8 pagesWilliams Microturbine Diary Lagoon 03-3-018Voicu StaneseNo ratings yet

- M-Bus 012Document36 pagesM-Bus 012Voicu StaneseNo ratings yet

- MpBus 02 eDocument30 pagesMpBus 02 eVoicu StaneseNo ratings yet

- M BusDocument88 pagesM Busakshay_haridasNo ratings yet

- M-Bus 012Document36 pagesM-Bus 012Voicu StaneseNo ratings yet

- MicroturbineSection 3Document18 pagesMicroturbineSection 3Voicu StaneseNo ratings yet

- MBus 03 eDocument26 pagesMBus 03 eVoicu StaneseNo ratings yet

- Telit Wireless M-Bus User Guide r3Document37 pagesTelit Wireless M-Bus User Guide r3Voicu StaneseNo ratings yet

- The Definitive Guide to the M-Bus ProtocolDocument91 pagesThe Definitive Guide to the M-Bus ProtocolZoran MilicNo ratings yet

- Telit SR Manager Tool User Guide r1Document72 pagesTelit SR Manager Tool User Guide r1Voicu StaneseNo ratings yet

- A Microturbine For Electric Power Generation - Paper PresentationDocument8 pagesA Microturbine For Electric Power Generation - Paper Presentationprateekg92No ratings yet

- Kalorimetar Data Sheet UH50 - UH106 101kDocument15 pagesKalorimetar Data Sheet UH50 - UH106 101kbobesponjakockaloneNo ratings yet

- MicroturbineSection 3Document18 pagesMicroturbineSection 3Voicu StaneseNo ratings yet

- CSIR Microturbine Research for Distributed Power GenerationDocument1 pageCSIR Microturbine Research for Distributed Power GenerationVoicu StaneseNo ratings yet

- Paper 10: DYNAMICS BEHAVIOR OF A 30 KW CAPSTONE MICROTURBINEDocument18 pagesPaper 10: DYNAMICS BEHAVIOR OF A 30 KW CAPSTONE MICROTURBINEMAT JIBRUD100% (1)

- Material Data Sheet: Urban@plastum - CZ WWW - Plastum.czDocument1 pageMaterial Data Sheet: Urban@plastum - CZ WWW - Plastum.czDavis GNo ratings yet

- 2008 02 An Investigation Into The Impact of Changing From K0 and K1 Values To API IP Standard Values Stewart Kelton Engineering LTD PDFDocument11 pages2008 02 An Investigation Into The Impact of Changing From K0 and K1 Values To API IP Standard Values Stewart Kelton Engineering LTD PDFAmilkar Kindelan GonzalezNo ratings yet

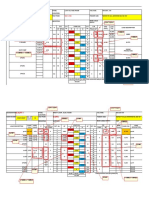

- All Elect Panel Moc Dated 15-03-20Document17 pagesAll Elect Panel Moc Dated 15-03-20nadeem UddinNo ratings yet

- Cambridge IGCSE: PHYSICS 0625/42Document16 pagesCambridge IGCSE: PHYSICS 0625/42Isa ShahidNo ratings yet

- Thermodynamics DTS-11 NVTDocument1 pageThermodynamics DTS-11 NVTUnwantedNo ratings yet

- Chapter 2 KinematicsDocument18 pagesChapter 2 KinematicsEshaal MaryamNo ratings yet

- 3-Taiyo Induction Synch. GenDocument22 pages3-Taiyo Induction Synch. GenaimorNo ratings yet

- International Iec 60076-11 2018Document30 pagesInternational Iec 60076-11 2018sokrat sebti100% (2)

- GBH Enterprises, LTD.: Process Engineering GuideDocument14 pagesGBH Enterprises, LTD.: Process Engineering GuideJlkm BnjlkmNo ratings yet

- PHYS220 - Lecture 1.1Document7 pagesPHYS220 - Lecture 1.1Savio KhouryNo ratings yet

- P2B Electric Forces and Electric FieldsDocument13 pagesP2B Electric Forces and Electric FieldscyruselilNo ratings yet

- Comparison GG Am Fuses EnuDocument2 pagesComparison GG Am Fuses EnuNaveed RabbaniNo ratings yet

- Submitted By:-Nisar Ahmed Khan Roll No. - 00510100613 M.Tech. (RF & Microwave Engg.)Document40 pagesSubmitted By:-Nisar Ahmed Khan Roll No. - 00510100613 M.Tech. (RF & Microwave Engg.)Ashwini Naresh100% (1)

- Medium Frequency Transformer Design and OptimizationDocument8 pagesMedium Frequency Transformer Design and Optimizationfaisal alsaifNo ratings yet

- Effect of corona on transmission linesDocument5 pagesEffect of corona on transmission linesParimal PatelNo ratings yet

- Class XII Physics PracticalsDocument14 pagesClass XII Physics Practicalsraj kushwahaNo ratings yet

- EEC Different Types of Electrical Wiring DiagramsDocument11 pagesEEC Different Types of Electrical Wiring Diagramsyash JadhaoNo ratings yet

- Esci 116N - Differential Equations First Long Examination Instructions: Handwrite Your Answers in Separate Sheets of Paper. After Answering All TheDocument10 pagesEsci 116N - Differential Equations First Long Examination Instructions: Handwrite Your Answers in Separate Sheets of Paper. After Answering All TheBienvenida Ycoy MontenegroNo ratings yet

- Physics-1-Module-5-Laboratory Activity No. 5Document3 pagesPhysics-1-Module-5-Laboratory Activity No. 5Vince GarciaNo ratings yet

- Mini Can Cooler Based on Peltier ModuleDocument76 pagesMini Can Cooler Based on Peltier ModuleShoaibNo ratings yet

- 14technical Specification of 11 KV 22 KV 33 KV Porcelain Pin Insulators 10.09.2020 1Document14 pages14technical Specification of 11 KV 22 KV 33 KV Porcelain Pin Insulators 10.09.2020 1AulinoNo ratings yet

- Solution ChapterDocument7 pagesSolution ChapterabhilashNo ratings yet

- Python enabled solar calculator for homesDocument9 pagesPython enabled solar calculator for homesRahul ChavhanNo ratings yet

- Energy and MomentumDocument20 pagesEnergy and MomentumAndrei Alido100% (1)

- Door Hinge CalculationDocument4 pagesDoor Hinge CalculationRamachandra Bhat HireNo ratings yet

- Heat TransferDocument25 pagesHeat Transfersinghpratibha0% (1)

- Part PFH Optional Requirements For Feedwater Heater (When Located WithinDocument1 pagePart PFH Optional Requirements For Feedwater Heater (When Located WithinJason501No ratings yet

- Curriculum FOR Diploma in Electronics and Telecommunication EngineeringDocument35 pagesCurriculum FOR Diploma in Electronics and Telecommunication EngineeringLokendra BanafarNo ratings yet

- What Is VK and Imag IDocument4 pagesWhat Is VK and Imag Ijhakg_169712275No ratings yet

- Gate 1994 PDFDocument16 pagesGate 1994 PDFVammsy Manikanta SaiNo ratings yet