Professional Documents

Culture Documents

Kirloskar Oil Engines Ltd. Installation Manual Chapter 1 Drawing List

Uploaded by

Shankar JhaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kirloskar Oil Engines Ltd. Installation Manual Chapter 1 Drawing List

Uploaded by

Shankar JhaCopyright:

Available Formats

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL

Chapter-1 Drawing list

LIST OF DRAWINGS FOR PROJECT EXECUTION (MECHANICAL)

SR. NO. DRAWING NO. 1 2 DESCRIPTION CIVIL DRAWINGS 27.827.11.0.00 POWER HOUSE & EQUIPMENT LAYOUT 27.827.16.0.00 DG SET FOUNDATION BLOCK BASIC DRAWING 27.828.90.0.02 BASE FRAME FOR ENGINE AND ALTERNATOR 27.815.11.0.00 FLY WHEEL COUPLING ASSLY 74.225.40.0.01 LIMIT OF SUPPLY AZ-12832 GA DRG. OF ALTERNATOR 74.640.20.0.00 COUPLING HT WATER CIRCUIT 27.809.21.0.00 HT WATER CIRCUIT SCHEMATIC 70.660.10.0.00 EXPANSION WATER TANK 27.706.10.0.00 CHEMICAL MIXING TANK & PUMP 27.833.10.0.00 PRE HEATING MODULE 27.810.11.0.00 HT WATER RADIATOR LT WATER CIRCUIT 13 14 27.809.20.0.00 LT WATER CIRCUIT SCHEMATIC 27.810.12.0.00 LT WATER RADIATOR FUEL CIRCUIT 27.809.25.0.00 FUEL CIRCUIT SCHEMATIC 74.635.10.0.05 GA DRG. OF FUEL DAY TANK 990 LTRS. 79.824.10.0.00 HSD DRIP TANK WITH PUMP ASSLY. 27.692.02.0.00 FUEL FILTER COARSE 74.649.10.0.00 FINE FUEL FILTER LUBE OIL CIRCUIT 20 21 27.809.22.0.00 LUBE OIL SCHEMATIC 27.808.10.0.00 LUBE OIL COOLER

3 4 5 6 7

8 9 10 11 12

15 16 17 18 19

1.1

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL

Chapter-1 Drawing list

SR. NO. DRAWING NO.

DESCRIPTION

22 23 24 25 26

COMPRESSED AIR CIRCUIT 27.809.23.0.00 COMPRESSED AIR CIRCUIT SCHEMATIC 27.689.10.0.00 COMPRESSED AIR MODULE 27.812.11.0.00 COMPRESSED AND AIR BOTTLE 74.632.12.0.00 MOTOR DRIVEN AIR COMPRESSOR 74.632.11.0.00 ENGINE DRIVEN AIR COMPRESSOR CHARGE AIR EXHAUST CIRCUIT

27 28

27.809.24.0.00 CHARGE AIR & EXHAUST SYSTEM SCHEMATIC 27.650.01.0.03 EXHAUST SILENCER MISCELLANCEOUS XI--08074--M04--01CHIMNEY 27.809.27.0.00 LEGEND AND ABBRIVATION 74.643.10.0.00 WORKING PLATFORM (L.H.) 74.643.11.0.00 WORKING PLATFORM (R.H.)

UTILITY WATER DISTRIBUTION

29 30 31 32 33

1.2

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL

Chapter-1 Drawing list

LIST OF DRAWINGS FOR PROJECT EXECUTION (ELECTRICAL)

SR. NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 16 17 18 DRAWING NO. DESCRIPTION SINGLE LINE DIAGRAM POWER DISTRIBUTION SCHEMATIC OF GCP CUM SYN. PLC WIRING SCHEMATIC OF GCP CUM SYN.PANEL PLC INPUT/OUTPUT LIST SYSTEM ARCHITECTURE OF GCP CUM SYN.PANEL AVR TERMINAL LOCAL SENSOR STAND MOTOR CONTROL CENTRE PANEL DG BREAKER NEUTRAL GROUND RESISTOR PANEL CABEL SCHEDULE CABEL INTERCONNECTION DETAILS POWER HOUSE EARTHING LAYOUT POWER HOUSE CABLE TREY LAYOUT DG OPERATION PHILOSPHY ALTERNATOR MANUAL WITH TEST CERTIFICATE TEST CERTIFICATE OF ALL PANELS

1.3

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 2 - INSTALLATION Technical Specifications forInstallation of DG Set Mechanica/Electrical

TECHNICAL SPECIFICATIONS FOR INSTALLATION OF DG SET (MECHANICAL)

1. UNLOADING OF MATERIAL (Lifting, Leading & Installation) We have to use proper tools, adequate manpower & arrangements to unload the material depending upon its size and weight to avoid damages. For Unloading of engine, alternator and auxiliaries etc., should use hooks which are provided on it for handling with crane otherwise we have to use jacks & sleepers with wrench and wire rope. If crane is used to unload, the capacity of crane should be twice the weight of material Crane documents should be verified before allowing to work as per RTO. Slings of crane should be lubricated and joints of the sling should be examined for perfect fitment with clamping. While unloading the crane should be supported by jacks on both ends and tyres should be locked at both end with some media like sleepers to avoid jerking while unloading. NOTE : Collect a catalogue from crane manufacturer for more informations. No material shall be slinged with any components of machineries like motors, pumps, pipes base frame etc. No body should step on the components to do any work while unloading, leading or at the time of installation. For each sq. mtrs. 4 persons are required for handling of material to avoid any damage to material, what ever may be its weight. All glass parts, instrumentation items, pressure gauges etc. should be handled with care and precautions to avoid damage, no jerks & drops. While handling the material top side mark should always be maintained at the top. NOTE : Enquire the capacity of winch, pulleys used for leading and lifting of materials depending upon the weight. 2. CHECKING OF LAYOUT. Civil layout made by customer should be collected from customer and compared with KOEL layout w.r.t. dimensions, if any variation is noticed enquire with Customer. Locate the direction of power house & co-relate with drawing, than locate foundation blocks of engine and its auxiliaries as per drawing.

2.1

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 2 - INSTALLATION Technical Specifications forInstallation of DG Set Mechanica/Electrical

3. CHECKING OF MATERIAL Check the material as per packing sheets and also cross check with application code, if there is any shortage / damage, intimate to KOEL Ofiice immediately. Examine the material for its condition frequently during the course of commissioning. Inform shortage of material, if any in advance. Make a chart for weekly material consumption and cross check the plan with every day actual consumption. Correctness of material should be checked for weekly plan. 4. PIPING NORMS Each pipe should clearly shows the direction of flow of liquids with arrows. If any doubt in pipe size of circuit, clarify with KOEL AE. 5. PIPING SUPPORTS The pipe must be supported on both side of bend joints, flange joints and Auxiliaries ends within a feet. In every 4 meters of pipeline there should be a support. For supports use 50 x 50 x 5 angles or 100 x 50 x 5 C Channel. Use U clamps, washer and nuts for clamping the pipes with angle & channel. All supports must be painted by BLACK paint, before clamping the pipes. For clamps of pipes to supports, all holes on supports should be drilled and shall not be done by gas cutting. All Supports should be horizontal. At every 5 mtrs. length there must be flange connection except for Fuel. All flange of pipeline should be minimum 100 mm above the trench floor and supports should be 300 mm. above floor level of trench. The vertical gaps between pipe line supports in double tier should be maintained around 300 mm. Lower support should be both side welded in trench and above that, only one support of cantilever type and only one side of trench with a gap of 400 mm. from opposite side of trench. NOTE : Ensure that the trenches are water proof before laying pipelines.

2.2

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 2 - INSTALLATION Technical Specifications forInstallation of DG Set Mechanica/Electrical

6. WELDING The angle between the two pieces of pipes to be welded should be chamfered. The distance between two pipes should be half of the thickness of the pipe, which are to be welded together. Before starting the welding clean the edge to be welded thoroughly and make sure edges are dry. use proper flux for proper welding with correct grade of welding rods. Properly chamfer the edges to be welded. Remove distance piece used to maintain gap between pipes. Root weld and brush it by wire brush before doing 2nd round i.e. there is no any red beed. Capacity of welding machine should be as per the welding rod requirement. Keep all welding rods packets in a dry container. If welding rods are wet they should be kept in a oven for drying before use. Do not use sub-standard, damaged or cracked welding rods. Standard welding rods requirement Seamless pipe : 6013 6010 7018 - Advani S & 2S or equivalent of reputed make. - Deep penetration rod. - Super therm special

S.S. Pipe

S4E 308 - 16 for ss 304 Pipe S4E 308L - 16 for ss 304L Pipe

Selection of current of welding motor for different size of rods. Size of rod 2.50 x 350 3.15 x 350 4.00 x 350 5.00 x 350 Amps 50 - 70 90 - 110 110 - 140 160 - 200

Welding beed should be uniform and @ 1.5 mm, above the surface of pipe. Chipping and wire brushing should be done to take out slag, flex and burgs of welding. If pipe size is more than 4 use clits in between edges of pipes to be welded to make sure both pipes are in correct position. Size of welding rod selection as per thickness of pipes is as below :Pipe Size (mm) 15 NB 20 NB 25 NB 40 NB Root Weld (mm) 12 12 12 12/10

2.3

Main Weld (mm) 10/8 10/8 8 8

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 2 - INSTALLATION Technical Specifications forInstallation of DG Set Mechanica/Electrical

50 NB 65 NB 80 NB 100 NB 150 NB 200 NB 460 OD 560 OD 750 OD 1000 OD

12/10 12/10 12/10 12/10 10 10 10 10 10 10

8 8 8 8 8 8 8 8 8 8/6

Fillet welding should be done for the pipe to the flange and pipe to valves. Gap between pipes and flange face should be minimum 5 mm x 45 Deg. Pipe should be horizontal or vertical when it is welded with valve. 7. WELDING TEST Random test of welding joints is to be done by D. P. Test (10%). 8. HYDRO TEST Pipe should be Hydro tested at following pressure: Pipe line L. T. Water H. T. Water Injector water Fuel Lub Oil Air Pressure 10 bar 10 bar 10 bar 10 bar 10 bar 45 bar

(The Hydro test should be carried out by pump which is to be arranged by contractor) NOTE : The specifications of hand pump required for Hydro test are to be confirmed. Before Hydro test all pipes should be thoroughly cleaned with wire brush chipping at flange end and by water flushing. Any leakage found in the Hydro test should be rectified and pipe should be retested for leakage. Put a air vent at highest point of pipe line while doing Hydrotest which should withstand the required pressure. After Hydro test no work should be done on the pipe line like gas cutting, drilling, welding etc. The pressure should hold, at least for one hour without any leakage. For exhaust and air intake ducting there is no Hydro test.

2.4

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 2 - INSTALLATION Technical Specifications forInstallation of DG Set Mechanica/Electrical

9. ACID CLEANING. Acid cleaning should be done immediately after Hydro test within 4 hours. NOTE : For More details refer chapter : Chemical Cleaning Procedures for Pipes.

10. PAINTING. Preparation of pipe surface before application of paint. a) Remove all oil on pipe surface with the solvent. b) Removal of dirt, loose rust and loose mill scale with scraper or wire brush. c) Flame cleaning if necessary. d) Clean and dry pipe surface with cloth. e) Ensure pipes are degreased properly. First apply red oxide or Primer. After one day apply the 2 coats of paint on pipelines as per following colour codes.

PIPE LINE PAINTING COLOUR CODE

Sr. No. System 1. 2. 3. 4 5 6 7 L.T. Water H.T. Water & Injector Water Lub Oil Fuel Air Exhaust Gas Supports

Colour Sea Green French blue Golden brown Post office red Canary yellow Silicon based heat resistance Aluminium paint (upto 600 deg.C) Bituminous Black

Colour shade as Per IS 5 217 166 414 538 309 -------

Note: Do not apply red Oxide on exhaust ducting.

2.5

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 2 - INSTALLATION Technical Specifications forInstallation of DG Set Mechanica/Electrical

TECHNICAL SPECIFICATIONS FOR INSTALLATION OF DG SET (ELECTRICAL)

1. INSPECTION a) Check whether there is no damage to the panel. b) Check whether all terminal connections and numbering of ferrules are as per cable schedule. c) Check the continuity of each terminal. d) Check for proper tightness of each connection. e) Check for proper earthing of panels. f) Check / ensure fuses provided are of correct rating. g) If any damage, faulty component found out during testing, inform to KOEL HO and ask for replacement. h) Check whether all the live connections are properly covered with insulation and earthed. 2. GENERATOR CUM SYNCHRONISING PANEL a) Check whether there is no damage to the panel . b) Check / Ensure that output of DC-DC convertor supply to panel is 24 volts. c) Switch on PLC and check / ensure its proper working functions. d) Check the input and outputs of PLC are as per requirements. e) Check all safeties by simulation method. f) Check EFMU for proper working condition by simulation method. g) Check whether there is no drop of voltage observed across hour meter connections while hooter is on. h) Check starting of lub oil priming pump and preheating module through GCP. i) Check whether lub oil priming pump, water pump and heaters are operating as per logic i.e. 20 min on and 15 min off. (All the three should run continuously till temp. reaches 50 deg. C and then the cycle should start) . j) Check three attempts start and starting refusal logic functions. k) Check proper operation of start, stop and emergency stop. l) Check the magnetic pickup resistance is more than 500 ohms. (as per requirement.) m) Check whether the over speed safety is operating properly by pressing test push button on EFMU n) Check / Ensure all temperature scanners, pressure indicators etc. are showing proper readings. o) Calibrate all pressure gauges, pressure switches and RTDs installed on GCP & LSS and on all auxiliaries. p) Test each relay, its settings and record the same. q) Check / Ensure operation of breaker through GCP. r) Check whether excitation is not permitted without ready for excitation permission from GCP.

2.6

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 2 - INSTALLATION Technical Specifications forInstallation of DG Set Mechanica/Electrical

s)

Check the following functions are OK. i) Speed raise / Low ii) Voltage raise / Low iii) Manual / auto synchronizing. iv) Breaker closing and tripping. v) Indication for all these operations. vi) Check other functions.

3. NGR PANEL a) Check whether there is no damage to the panel b) Ensure whether resistance banks are not damaged. c) Check whether required No. and proper ratio of CTs are available. d) If possible test the ratio of CTs by injecting primary winding. e) Check whether cables are connected to correct polarity. f) Check for proper termination / insulation of HT cables and ensure that proper type of cable joint kit is used. g) Measure the resistance of whole bank and ensure that it is as per requirement. 4. BREAKER PANEL a) Check whether there is no damage to the panel. b) Rack out the breaker and check that all components are OK. c) Grease the rack and other components, if required. d) Ensure whether breaker can not be operated in half in position e) Ensure proper and easy slide of breaker rack. f) Push the rack inside and check that limit switch is operating. g) Check whether auto and manual charging of spring is proper. h) Check whether breaker ON / OFF operation is proper, both by auto and manual method. i) Check for breaker closed indication on GCP when it is on. j) Ensure tripping of breaker during fault by simulation. k) Ensure auto closing of breaker by simulation check. 5. MCC PANEL a) Check whether there is no damage to the panel . b) Check whether all OLR, Contactors and fuses fitted are of proper range. c) Check whether all switches and contactors are functioning properly. d) Check the interconnection of MCC, ECP and auxiliaries are proper.

6. EARTHING PITS AND EARTHING GRID. a) Check the earthing pit resistance is within limit (Record the same.) b) Ensure the proper connections / joint of each grid. (As per drawing)

2.7

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 2 - INSTALLATION Technical Specifications forInstallation of DG Set Mechanica/Electrical

7. ALTERNATOR. a) Megger the windings. ( Record the same.) b) Check the continuity of windings. c) Check whether space heater is working properly. d) Check whether the diodes are OK. e) Check the Lube Oil / Greasing of bearings. f) Check the proper air gap of excitation field if it is a separate unit. g) Check the CT ratio and polarity. (If applicable) h) Check whether RTDs are properly showing readings.

8.H.T. CABLE a) b) c) d) Megger the Cable and record the same. Take the high potential test. Check for proper termination. Ensure whwther cable jointing is done by using std. material and correctly.

2.8

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 3 - INSTALLATION Statutory Rules & Safety Regulations

STATUTORY RULES & SAFETY REGULATIONS

The details of statutory rules and safety regulations are followed for labour work execution for KOELs erection and commissioning contractor at L&T-IOCL,Panipat Sites. STATUTORY RULES: 01. This being a labour contract, it is obligatory for contractors employees under PF/ESI/WC, schemes and make compliance under various statutory acts, by contractor applicable. It clarified that no reimbursement will be made on account of employers share of PF/ESI by the company. 02. The contractor shall comply promptly with the provisions of contract labour Act and produce the Licence of the Contract Labour Act if the number of labours exceed 19 on any day during contract period. 03. The contractor shall bring only those labourers at the work site / premises who have been issued gate passes / identity cards. the contractor agrees that he shall not retain the gate passes with the labourers engaged by him to restrict unnecessary entries in the premises. The contractor also agrees to return all gate Passes / identity cards to the company as and when contract is over. 04. The contractor will maintain muster roll of his employees engaged in the work site / premises and update their attendance on day to day basis this should be handedover along with a statement showing the ESI / PF contributions to be recovered from the employees, to KOEL / Local Labour Officer as and when required. 05. The contractor will pay wages to the labourers as per rate under the minimum Wages Act notified from time to time by the Govt. Authority. 06. The labourers engaged by the contractor will be his employees and KOEL shall be in no way responsible or liable for their payment of wages / salaries, bonus, gratuity and other allowances, if any. 07. The labourers engaged by the contractor shall abide by all the disciplinary, rules & regulations laid down by the customer / company / end user from time to time. 08. In the event of any act committed by contractors laboures against the interest of the company, the company reserves the right to ask the contractor to remove such labourers without giving notice and contractor is bound to do so. 09. The contractor shall comply with all the rules and regulations under the various Acts applicable to the company. In case he fails to comply with the same and if the company apprehends any breach thereto his contract is liable for termination fortwith. The company also reserves the right to withhold the payment of the contractor. 10. The contractor shall ensure the compliance and provisions of the contract labour Act. The Minimum Wages Act. The payment of Wages Act, The Employees Provident Fund Act, ESI Act, Factories Act, payment of Wages Act. The payment of Gratuity Act and such labour legislations applicable at the relevant time.

3.1

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 3 - INSTALLATION Statutory Rules & Safety Regulations

SAFETY REGULATIONS: 01. The company has set some safety rules to be followed by each person to be employed by the contractor to take care of the safety of the persons, safety of the other people and to ensure the safety of companys properties. These rules are being framed by our safety department and you will follow the same. 02. While working at height all labour must use P.P.E. (Personal Protective Equipments) 03. While working at the height on fragile roofs and other delicate areas special equipment must be used as directed by Safety Dept. Also you will take special precautions while working at height with open busbars open H. T. Lines etc. 04. You will make use of safety belts wherever required. The healthiness of the safety belts should be confirmed. 05. You will bring machines / equipment such as welding machine, drilling machine, gas cutting set, rigging equipment, etc. of proper specifications and safety features. Machines / equipments without safety features will not be permitted for use. 06. While carrying out welding / gas cutting or any other fire hazardous works, ensure that site is made clear of such materials which can cause fire hazard. 07. You will depute your supervisor at site to supervise your workers. No work will be permitted in the absence of your supervisor. 08. You will carry out work against this from 9.00 am to 5.00 pm and weekly work basis. Work after 5.00 pm or on holidays should be carried out only after getting special permission, depending on the works you are working. 09. Workers possessing trade certificate for electrician should only allow to work on live electrical supply systems. The workers deputed by the contractor, as helper should carry out only the labour work and strictly under the supervision of contractors supervisor. 10. While carrying out work you will make proper provisions to take care of the safety and companys machinery / property. Whenever required you will do the work after providing suitable barricades / covers. Whenever carrying work, which is likely to lead harm to other persons, you will see that suitable sign / caution boards are displayed. 11. Whenever working in combined space you will obtained permission from safety department 12. Whenever working near LT / HT cables prior permission / clearance of concerned electrical maintenance department should be taken. 13. All safety rules and codes as applicable to work must be followed without any

exception.

3.2

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 3 - INSTALLATION Statutory Rules & Safety Regulations

14. All personal protective equipments (safety bolts, hand gloves, aprons, helmets, safety shoes, safety belts, shields, goggles etc.) must be used while working at site.

15. The company may from time to time add, delete, modify or change any rule as and when required.

CONTRACTORS OBLIGATIONS / LIABILITIES: Above rules and regulations are to followed to take care of safety of persons employed by you, Other people working in the company and companys property. These rules are to be followed strictly and wherever in doubt you will clarify with us for the same. Any work carried out without following above rules and regulations will be considered as illegal. The contractor shall identify the company at all times against all claims for compensation under the provision of any law for the time being in force by or in respect of any labours employed by him in carrying out the contract and against all costs and expenditure incurred by the company in connection therewith. It will be contractors responsibility to settle all legal deals of his labourers on their termination and will hand over the copy of the receipt obtained from the concerned labour, in full and final settlement of the claims of whatsoever nature, to the company. In case if any labour engaged by the contractor raises any demand after his termination or after making full and final settlement by the contractor during the currency or after the expiry of the contract, the contractor shall settle the same and no liability will rest upon the company.

3.3

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 4 - INSTALLATION Tools for Installation of DG Set

LIST OF TOOLS REQUIRED FOR INSTALLATION OF DG SET

SR. NO.

A. 1 2 3 4 5 6 7

DESCRIPTION TOOLS FOR UNLOADING AND SHIFTING OF DG SET AND AUXILIARIES

MECHANICAL SCREW JACK 20 TON MECHANICAL SCREW JACK 10 TON SLING / STEEL ROPE / NYLONE ROPE WOODEN SLEEPER CHAIN PULLEY BLOCK 20 TON CHAIN PULLEY BLOCK 5 TON TARPAULIN / PLASTIC SHEET TO PROTECT EQUIPMENTS

QTY

4 NOS 2 NOS AS REQD Min. 50 NOS 2 NOS 1 NO AS REQD

B

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

GENERAL TOOLS

DOUBLE ENDED OPEN SPANNER (10 TO 41 MM) DOUBLE ENDED RING SPANNER (10 TO 32 MM) BOX SPANNER 10 TO 30 MM (1/2 DRIVE) BOX SPANNER 30,32,36,41,46,50 & 55 MM (3/4 DRIVE) BOX SPANNER 60 & 65 MM (1 DRIVE) EXTENSION BAR 6 & 12 LONG (1/2 DRIVE) TOMMY BAR (1/2 DRIVE) RATCHET (1/2 DRIVE) EXTENSION BAR 8 & 16 LONG (3/4 DRIVE) TOMMY BAR (3/4 DRIVE) RATCHET (3/4 DRIVE) REDUCER (1.0 X 3/4 ) REDUCER (3/4 X 1.0 ) ALLEN KEY SET 2 MM TO 19 MM SCREW DRIVER HEAVY DUTY 2 DIFFERENT SIZE ADJUSTABLE SPANNER 8.0 & 12.0 CUTTING PLIER 8 NOSE PLIER 8 CIRCLIP PLIER 8.0 LONG (INTERNAL) CIRCLIP PLIER 8.0 LONG (EXTERNAL) TAP SET 10,12,16,18,20,& 24 MM TAP SET WRENCH PIPE WRENCH 12,18 & 24 FILE ROUGH (ROUND, HALF ROUND & FLAT) 12 LONG FILE SMOOTH (ROUND, HALF ROUND & FLAT) 12 LONG BENCH VICE (HEAVY DUTY) HAMMER (SMALL & BIG) CHISEL 6 & 8 HOLE PUNCH 16,18,20,& 24 MM MALLET / PLASTIC BAR / PLASTIC HAMMER

4.1

1 SET 1 SET 1 EACH 1 EACH 1 EACH 1 EACH 1 NO 1 NO 1 EACH 1 NO 1 NO 1 NO 1 NO 1 EACH 1 EACH 1 EACH 1 NO 1 NO 1 NO 1 NO 1 EACH 1 NO 1 EACH 1 EACH 1 EACH 1 NO 1 EACH 1 EACH 1 EACH 1 NO

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 4 - INSTALLATION Tools for Installation of DG Set

31 32 33 34 35

TIN CUTTER 12 LONG SINGLE ENDED OPEN SPANNER 46,50,55,60,&65 MM FLAT RING SPANNER 60 & 65 MM 8 MM PIPE BENDING MACHINE FOR PR GAUGES ETC. CLEANING TRAYS 2 DIFFERENT SIZE

1 NO 1 EACH 1 EACH 1 NO 1 EACH

C

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

TOOLS FOR WELDING & CUTTING

WELDING TRANSFORMER (ONLY FOR TAG WELDING) WELDING RECTIFIER ROTATING 200 AMPS (FINAL WELDING) WELDING HELMET / SCREEN WELDING BRUSH, HAMMER & CHISEL RIGHT ANGLE 12 LONG GAS CUTTING TORCH WITH EXTRA NOZZLE FLEX HOSE AND REGULATOR FOR SR. NO. 6 SPANNER FOR GAS CYLINDER ELECTRICAL ANGLE GRINDER 4.0 WHEEL DIA ELECTRICAL ANGLE GRINDER 6.0 WHEEL DIA MEASUREMENT TAPE STEEL 3 MTRS MEASUREMENT TAPE 15 MTRS WATER LEVEL MAGNETIC BASE 12 LONG 6/8 MM DIA PLASTIC TUBE 25 MM DIA PLASTIC TUBE NEEDLE PLUM 100 GM WEIGHT HACK SAW FRAME WITH BLADE 12 CENTRE PUNCH 6 LONG CHAIN PULLEY BLOCK 5 & 10 TON SLING / WIRE ROPE / ENDLESS ROPE (DIFFERENT SIZES) NYLONE ROPE 1/2 AND 1.0 DIA D SHAKLES DIFFERENT SIZE CROW BAR 1.0 MTR LONG ELECTRICAL MOTOR DRIVEN PIPE LINE CUTTER WITH WHEEL 10 TO 12 DIA DRILL MACHINE WITH DRILL BITS 1 NO 2 NOS 3 NOS 3 EACH 2 NOS 1 SET 1 SET 2 NOS 2 NOS 2 NOS 3 NOS 1 NOS 3 NOS 20 MTRS 25 MTRS 3 NOS 2 NOS 1 NOS 1 EACH AS REQD 20 MTRS. AS REQD 2 NOS. 1 NO 1 SET 1 NO 1 NO 2 NOS 2 NOS 1 NO 1 SET 1 NO 1 NO 1 NO 1 SET

D

1 2 3 4 5 6 7 8 9 10

PRECISION TOOLS

DIGITAL VERNIER CALIPER (0 TO 300 MM) MICRO METER OUT SIDE (0 TO 25 MM) DAIL GAUGE (0.01 MM) 0 TO 10 MM TRAVEL MAGNETIC BASE FOR DAIL GAUGE STEEL SCALE 0 TO 1.0 MTRS FEELER GAUGE MM (100 MM BLADE LENGTH) SMALL MIRROR FOR DEFLECTION AND ALIGNMENT WORK TORCH WITH CELL MASTER LEVEL GAUGE 6 LONG 0.025 MM/ MTR ACCURACY REAMER SET (REFER COUPLING DETAILS)

4.2

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 4 - INSTALLATION Tools for Installation of DG Set

E 1 2 3 4 5

TOOLS FOR HYDRO TESTING AND ACID PICKLING HYDRAULIC PRESSURE TESTING PUMP WITH CORRECT END CONNECTION AND FLEX HOSE (CAPACITY 50 BAR)

PRESSURE GAUGE FOR HYDRO TESTING PUMP UP TO 60 BAR

1 NO 1 NO 1 NO 1 NO AS REQD

ACID PICKLING PUMP 5.0 HP / 3.5 KW ACID PICKLING TANK (CAN BE FABRICATED AT SITE) 150 LTRS CHEMICALS FOR PICKLING, NEUTRALISING & PASSIVATION

F

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

CONSUMABLES FOR INSTALLATION (MECH)

GRINDING WHEELS FOR 4.0 GRINDER GRINDING WHEELS FOR 6.0 GRINDER HACK SAW BLADES GLASS FOR WELDING HELMET (WHITE) GLASS FOR WELDING HELMET (BLACK) WELDING BRUSH WELDING RODS 2.5,3.25,4.0,5 & 6 MM (ADVANI OERLICON / ESAB) LINE DORI CHALK / PENCIL (WHITE COLOUR) TEFLON TAPE EMERY PAPER ROUGH 60 TO 100 NUMBER EMERY PAPER MEDIUM 300 TO 400 NUMBER EMERY PAPER FINE 600 NUMBER GRINDING PASTE (ROUGH AND FINE BOTH) EMERY STONE / HONING STICK 10 X10 X100 ORDINARY GREASE HAND GLOVES (CLOTH, PLASTIC & ASBESTOS ETC.) M SEAL, ARALDITE & FEVIQUICK CTC, PETROL & HSD FOR CLEANING CLEANING CLOTH, MARKING CLOTH & BANIAN CLOTH ETC. CLEANING BRUSH CELLO TAPE, PERMANENT MARKER SPONGE RUSTOLIN AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD 20 MTRS AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD AS REQD

G

1 2 3 4 5 6 7 8

ELECTRICAL TOOLS

MEGGER 500 AND 1000 V TONG TESTER 0 TO 200 AMPS DIGITAL MULTIMETER (DIGITAL WITH FREQ. MEASUREMENT UPTO 4 KHz) LINE TESTER INSULATION PLIER SCREW DRIVER SET WIRE STRIPPER CRIMPING TOOL FOR INSULATED AND NON INSULATED LUGS UPTO 70 SQ.MM 1 NO 1 NO 1 NO 2 NOS 2 NOS 1 NO 2 NOS 1 NO

4.3

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 4 - INSTALLATION Tools for Installation of DG Set

9 10 11 12 13 14 15 16 17 18 19 20 21 22

EXTENSION BOARD WITH 15 AMPS & 5 AMPS, 5 PIN SOCKETS/ SWITCHES SERIES LAMP SOLDERING IRON, WIRE AND FLUX EARTH RESISTANCE TESTER ELECTRICAL HAND DRILL MACHINE UPTO 15 MM BIT ELECT. DRILL MACHINE WITH MAGNETIC BASE UPTO 30 MM HAND LAMP WITH GUARD AND 20 MTRS CORD NUMBER AND LETTER PUNCH BLADE / CUTTER IMMERSION HEATER BLOWER RELAY TESTING KIT SET OF SPANNERS FOR DOING ALL ELECTRICAL WORK PHASE SEQUENCE INDICATOR

3 NOS 1 NO 1 SET 1 NO 1 NO 1 NO 1 NO 1 EACH AS REQD 1 NO 1 NO 1 SET 1 SET 1 NO

H

1 2 3 4 5 6 7 8 9

CONSUMABLES FOR INSTALLATION (ELECTRICAL)

INSULATION TAPE RED, YELLOW, BLUE & BLACK BINDING TAPE AND BUTTONS (BLACK) ELECTRICAL HAND GLOVES CTC ALUMINIUM TAGS (FOR CABLE NUMBERING) CLAMPS FOR CABLE FIXING IN TRAYS BITUMEN PAINT FERRULES NOS 0 TO 9 T TYPE 2.5 SQ.MM FERRULES NOS A TO Z T TYPE 2.5 SQ.MM AS AS AS AS AS AS AS AS AS REQD REQD REQD REQD REQD REQD REQD REQD REQD

4.4

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 5 - PROCEDURE

Grouting Procedure Document no.-27.400.85.0.00

TECHNICAL NOTE GROUTING PROCEDURE

INTRODUCTION a) b) c) During installation of DG set on the foundation block, grouting is carried out in order. To minimize heat build up on foundation block. To assure precise and unsurpassed contact with baseframe. To provide a high coefficient of friction to help maintain DG set alignment which further reduces possible bearing or crank shaft alternator rotor damage. Generally powdered FOSROCK GP2 is used as grouting compound which is mixed with water along with coarse aggregates or pea gravel of size 6sq.mm. down to obtain free flowing grout. ** Aggregates to be used only for pockets. 1) PREPARATION OF GROUT In order to obtain optimum physical properties with grouts, precise mixing and curing of grout is necessary. A) B) B.1) MATERIAL AND EQUIPMENT REQUIRED FOR PREPARATION OF GROUT FOSROCK GP2 of sufficient quantity. Crushed aggregates or pea gravels of size 6 sq.mm. down to sufficient quantity. A 220 lits. drum for stocking water - 4 Nos. Buckets to carry mixed grout - 6 Nos. Concrete mixer - tilting drum type - 2 Nos. A water can measuring 4.5 lits. capacity. A pan with dry FOSROCK GP2 in case of leaks. Water bath curing compound - 2 Nos. Hammer, Chisels, nails etc. Wire Brush. Sufficient length of MS plates. Masonry tools like pan, trowel etc. MIXING OF GROUT The quantity of grout required is estimated by using the following thumb rule. Weight of FOSROCK GP2 required = 2 x vol. of grouting space. Place about 80% of the water required per batch inside the mixer. Add bag by bag FOSROCK GP2 with mixer running. Add balance about 20% water. Add the crushed aggregates or pea gravel about 50% by wt. of FOSROCK GP2. Mix for 5 minutes. Unload into buckets for transporting and placing. PRECAUTIONARY MEASURES TO BE TAKEN DURING MIXING Do not mix anything else like sand, cement etc. to the grout. Do not pour more that 4.3 liters of water per bag of FOSROCK GP2 for grouting pockets and 4.5 liters. for plain grouting. Mixed grout should be consumed within 20 minutes after mixing.

5.1

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 5 - PROCEDURE

Grouting Procedure

If the ambient temperature is very high (above 40 deg.C) and humidity also is low, the grout tends to lose moisture fast and thus fluidity is reduced. Under such circumstances, mixed grout may have to be consumed immediately after mixing. CHECKS TO BE FOLLOWED BEFORE MIXING Ensure the FOSROCK GP2 used is well protected from moisture and no damages have occurred. No Vibrators are used as a means of mixing. PLACING OVER OF GROUT CHECKS TO BE FOLLOWED BEFORE GROUTING The top surface of foundation block is plane and rigid. The top surface of foundation and bottom surface of baseframe should be free from oil, grease and debris. The foundation block is soaked with water for about 24 hours. Ensure lowering of baseframe and anchor bolts in position. Sole plates (Reqd. if any in relation to alignment) are well levelled. Shuttering around the sole plates with MS angle or wooden block is done. GROUTING PROCEDURE Grout the sole plates individually upto half their thicknesses. Use mixed grout for the space in between sole plates and space around the sole plates. Continue to grout bay after bay in both the sole plates. CHECKS TO BE FOLLOWED DURING GROUTING Pouring of grout should be continuous and from one side to avoid voids. Check for leaks. The leakages can be avoided by applying dry FOSROCK GP2. CURING OF GROUT After 4 hours of grouting the grout becomes hard so water curing is carried out. Curing period should be minimum 6 d

B.2) 2) C) -

D) E) F) -

5.2

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 5 - PROCEDURE

Grouting Procedure

PREPARATION OF FOUNDATION BLOCK A surcharge of 15 mm concrete is provided on the top surface of foundation block. The block surface shall be gently chipped off. There should not be any peak exceeding 10 mm. The top surface of block shall be perfectly cleaned after chipping. Mark the location of chokes (MS Block) on the foundation block just below the jacking bolt location. The bearing area near the chokes to be flattened to the size 250 mm (L) x 150 mm (w). Surface shall be cleaned again. Position the chokes such that length of each block gets equally divided at the centre of jacking hole. Chokes should be longitudinally parallel to the foundation block. The foundation block and pockets shall be soaked with water for about 24 hrs. Remove all remaining water from the pockets. Place all the foundation bolts in the pockets. Place the baseframe on minimum 200 mm height wooden sleepers and align all base frame mounting holes with pocket centres. Clean the alternator mounting pads on the baseframe. Place the alternator on the base frame. Loosely connect the mounting bolts with alternator. Clean baseplate bottom so that it is free from oil, debris etc. Insert foundation bolts from bottom in the baseframe. Assemble nut and washer with foundation bolt. Ensure that bolt projection is about 20 mm above nut top surface. Ensure all bolts are laying straight in the pockets. The foundation bolt should not remain inclined in the pocket. Lower the baseframe (with engine mounted on it) slowly on the choke plates and ensure that it rests firmly on all the chokes. While lowering the base frame make sure that adjacent jacking screws are equally loaded and foundation bolts are in perfect position. Carry out the leveling of baseframe with water level tube and level bottle. The baseframe should be leveled within 2 mm of water level. Note : Engine is mounted on the baseframe. PARTIAL GROUTING OF FOUNDATION BOLT Refer specification No. 27.400.85.0.00 for preparation of grouting material and procedure. Fill 3/4th portion of pockets by slowly pouring the mixed grout. Ensure that there is no air pocket or cavity (voids) in the pocket after poring of grout. After 4 hrs. of grouting the grout becomes hard, water curing is therefore necessary for minimum 6 days. Carry out leveling checks once again before final grouting. Carry out shuttering around the baseframe with MS angle or wooden plate. Fill remaining 1/4th portion of the pocket with mixed grout. Use pure GP2 cement for grouting the space between bottom of baseplate and foundation block top surface. Grouting will be done such that GP2 cement is filled surrounding the baseplate and foundation block top surface. About 150 mm wide layer surrounding the baseplate and 3/4th thickness of bottom plate of baseplate in height will

5.3

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 5 - PROCEDURE

Grouting Procedure

be filled up with GP2 cement. Grouting should be continuous and from one side to avoid voids. Check for leaks. The leakage can be avoided by applying dry FOSROCK GP2. After 4 hrs of grouting the grout becomes hard therefore water curing has to be carried out. Curing period should be minimum 6 days. During curing period, meanwhile remove shuttering and carry out cementing of portion between baseplate and edge of foundation block on all four sides. Provide suitable slope towards the edge of foundation block. TORQUING OF FOUNDATION BOLTS 1) 2) 3) After 6 days of grouting carry out torquing as per sequence given below. First apply 10 kgm torque on centrally located foundation bolt on both sides. Continue applying torque 10 kgm on foundation bolts starting from centrally located bolt towards engine and alternator and simultaneously on both sides. Repeat procedure by increasing torque value by 10 kgm in each step till final torquing of 95 kgm is achieved.

5.4

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 6 - PROCEDURE

Alignment Procedure

RELATIVE POSITION OF THE SHAFTS IN THE HORIZONTAL PLANE The measurements show that : A axis is more at right than B one by in the plane of dial gauge C1. B axis is more at right than A one by in the plane of dial gauge C2 Then the relative position of the shafts is as follows : 47 axis A

164 - 70 2 104 - 86 2

=9

= 47

axis B

9 Plane C1 Plane C2

The experience shows that some erectors prefer to realize an intermediary sketch giving the relative position of the traces of the axis A and B in the planes C1 and C2 before carrying out the representation of the axis in the vertical plane and the horizontal plane. With this operation the operators can probably better figure out the axis in the space, this interpretation can be considered as good as the one explained in this note.

6.3

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 7- PROCEDURE

Chemical Cleaning Procedure for Pipe Line

CHEMICAL CLEANING PROCEDURE FOR PIPES

[Chemical Cleaning of the associated piping of DG set subsystem ( Material of construction carbon steel - seamless Tube ASTM A 106)] 1. LOOP FORMATION The various pipes are joined together by means of mating flanges and flexible hoses and formed into a closed loop system alongwith the chemical circulation pump and tank. 2. PREFLUSH The system is filled with water and leak tested, it is then continuously flushed with water into the drain gutter. All high points if any are to be vented regularly till system is completely filled. 3. DEGREASING The objective of degreasing is to remove all the dirt, loose rust and mill scale so as to provide an active surface for acidic solvent treatment. The degreasing solvent to be used is proprietary formulation of an Alkali alongwith a Non lonic Wetting Agent. The degreasing is to be carried out for a period of 2 hrs. at a temp. of 40 Deg. C and flow velocity of 0.2 m/s. 4. FLUSHING Use service water to flush the system till pH is neutral. 5. ACIDIC SOLVENT TREATMENT The objective of acidic solvent treatment HCL 50% (strength 30%) + 50% water is to remove all the rust, mill scale, welding slag and other oxide deposits. The circulation is to be carried out for a period 1-2 hrs. with help of acid circulation pump at flow velocity of 0.3 m/s.During the circulation hammer the pipe loop at regular interval so that welding slag,mill scale get removed.

6. DRAINING & FLUSHING The acidic solvent is drained and the system is flushed completely till pH is neutral.

7. ORGANIC ACID RINSE The step involves the circulation of an ammoniated organic acid (10% Caustic Soda + Water) having an alkaline pH to remove all residual matter and neutralize the acid solvent. The circulation of this is to be carried out for a period for 1 hr. at ambient temperature.

7.1

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 7- PROCEDURE

Chemical Cleaning Procedure for Pipe Line

8. DRAINING & FLUSHING The solution is to be drained completely and flushed till pH is neutral.

9. PASSIVATION The objective of passivation is to form a protective film on the freshly cleaned surfaces. The passivating solution with a sodium nitrite base is circulated for 4 hrs. at ambient temp. The system is drained and inspected. The above procedure is carried out prior to system start up for the purpose of removing mill scale, corrosion and other deposits. The operation provides a thin, uniform protective coating of iron oxide and removes the loose material that might cause damage to systems down stream of piping.

7.2

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 8 - KOELS RECOMMENDATIONS

Note on Water Quality & Recommendation

RE / RAVI / KH -1 / 5516 Date : 05/06/1999

QUALITY OF WATER REQUIRED TO PA6 ENGINES

The raw water available for a cooling tower, could contain following characteristics : Hardness Alkalimetric Content (TAC) Silicon Suspended Matter Chlorine Sulphates Ca Concentration Product < 2500 mg / lit < 400 ppm < 100 mg / lit < 20 mg / lit < 300 mg / lit < 600 ppm < 15000 (F)2

Although chemicals are available to condition such water quality, our experience in the past have shown that the problems occurs due to scaling / fouling and corrosion in the raw water system These problems occurred either due to incorrect treatment, or bad monitoring. Based on past experience, KOEL essentially recommends softened water for use on raw water circuit for PA6 engines, with cooling tower applications. The softened water will have the following characteristics : pH Total hardness Alkalimetic content (TAC) Salinity strength Suspended Matters >6 < 5 ppm < 400 ppm < 300 ppm < 20 ppm

Please note that it is impossible to one treatment procedure for water at all sites. We recommend a pre-survey by water treatment experts from M/s Nalco or M/s Ion Exchange for their recommendations or economical conditioning of water. Si suspended matter concentration, Ca concentration Chlorides + Sulphates will be decided TOS etc. case to case basis on joint consultation with engine manufacturer & water treatment experts. A comprehensive TIN will be prepared on the above subject. Please note, the softened water outlet must be checked periodically and regularly to ascertain the correctness of regeneration frequency. Use of Nalco / Ion Exchange chemicals must not be avoided to use of softener. H. T. Water : KOEL essentially recommends the use of DM water for H.T. water circuit with Nalco / Ion Exchange chemicals.

8.1

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 8 - KOELS RECOMMENDATIONS

Note on Water Quality & Recommendation

Please note DM water being corrosive in nature must not be used without chemicals in H.T. water circuit as this will cause corrosion Before commissioning of DG set, the DM water with chemicals must be kept available so as to ensure their use of correct water quality and chemicals from first instance itself. Also ensure availability of softened water for L.T. Circuit and suitable chemicals during start of set. Ensure the availability of the expert from the chemical supplying company (Nalco / Ion Exchange) to stabilize the water chemistry and recommend correct final dosage of chemicals. Maintain a log book of essential water parameters as suggested by the expert on the site.

8.2

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 8 - KOELS RECOMMENDATIONS

Note on Water Quality & Recommendation

TIN/COOL/VMK/001-00 Date : 14/04/1998

LT , HT COOLING WATER

Unsuitable water, results in scaling, pitting or corrosion. Use of very soft water should not dispense with water treatment, since water absorbs Carbon - di - Oxide which renders it corrosive. LT WATER SYSTEM : LT WATER system can either be. 1) Closed 2) Half Open (for Stationary Plants) 3) Open : With waste water and sea water. Necessary steps to be taken to avoid corrosion, Scaling & to eliminate seaweeds & bacteria. In open system, precautions to be taken are as follows: 1) A suction strainer should be provided and maintained in clean condition. 2) Piping should be reduced so that flow rate should be maintained to avoid temperature raise above 40 oC in order to avoid salt deposition. 3) For application with sea water, pipes, Lub oil cooler and charge air cooler to be waterproof ex. Bronze, Cupro-Nickel. Temperature deviation between system inlet and outlet should range from 10 to 12oC at full load. REQUIRED WATER PROPERTIES : 1) Hardness : Total hydrodynamic hardness should be minimum. Water can be softened by using Soda. 2) pH should be more than 6 3) Chlorine ion content should be minimum (below 100 mg/ lit) 4) Salinity should be less than 200 mg / lit 5) Water should be clean at filling. If required can be cleaned by adding chemicals, further rinsing is necessary since these chemicals are acid. NECESSITY OF WATER TREATMENT 1) To avoid chemical & electrochemical corrosion from different metals which requires basicity (pH) level to be maintained between 7.5 to 9. 2) To avoid scale, liable to reduce wall heat conductivity. TYPES OF TREATMENT 1) CHROMATE: Sodium & Potassium Chromate provides protection on Iron. Their efficiency of antiscaling protection can be increased by addition of organic compounds. For Aluminium and copper since, it is not compatible, it can be gained by adding Borate compound.

8.3

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 8 - KOELS RECOMMENDATIONS

Note on Water Quality & Recommendation

When Chromate drops below 0.5 gm/lit, it becomes dangerous. They are then capable of originating corrosive reaction, chromate level recommended 2.5 to 3 gm/lit. Chromate does not deteriorate with time. 2) BORATE - NITRITE: Mixture of sodium Borates & Nitrites with addition of organic compounds ensure efficient antiscaling action and corrosion resistance for ferrous material. But Nitrites in alone attack on welding therefore other components like borate - benzoates are added. 3 to 5 gm / lit nitric contain is recommended. Nitrite are toxic from absorption of 4 gm of pure nitrite salts. Requirements of Additives : 1) It must prevent corrosion 2) It must prevent precipitation of scaling salts. 3) It should be soluble in water 4) It must be compatible with anti - freeze. 5) It must have suitable pH range . (Stabilising 7.5 to 9) ENGINE REQUIREMENT DATA : 1) FOR HSD HT cooling water temperature at engine outlet 80 to 85 oC - for non pressurised circuit HT cooling water temperature at engine outlet 95 to 100 oC - for pressurised circuit LT cooling water temperature at air cooler inlet 25 to 35 oC. 2) FOR HFO(applicable only for HFO 0 HT cooling water temperature For 0 to 60% MCR : Normal temperature 90 to 95 oC For 60 to 100% MCR : Normal temperature 80 to 85 oC LT cooling water temperature For 100 to 40% MCR : Normal temperature 40 to 45 oC For 40 to 15% MCR : Normal temperature 60 to 70 oC Injector Water Cooling : Injector Inlet temperature : 80 to 85 oC Injector Outlet Pressure : Normal 250 Kpa. QUANTITY OF WATER IN ENGINE (lit) No. Of Cylinders Quantity of Water (Lit) 6 260 8 340 9 370 12 520 16 670 18 750

Nominal Recommended flow rate : 7.5 m3 / hr / cyl

8.4

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 8 - KOELS RECOMMENDATIONS

Note on Water Quality & Recommendation

RECOMMENDED WATER QUALITY

A) LOW TEMPERATURE WATER FOR HT WATER COOLING AND LUBE OIL COOLING SR NO. 1. 2. 3. 4. 5. 6. 7. 8. PROPERTY SPEC.

pH Total hardness (ppm) Alkalinity (ppm) TSS (NTU) Silica (ppm) Chlorides (ppm) Iron (ppm) TDS (ppm)

7.5 to 7.8 300 max 50-150 25 max 150 max 100 max 3.0 max 1000 max

B) SR NO. 1. 2.

HIGH TEMPERATURE WATER PROPERTY SPEC.

pH Nitrite level (ppm)

7.1 to 7.8 1000-1200

C) DEMINERALISED WATER 1. 2. 3. 4. Conductivity (ms / cm) Total Hardness (ppm) Si O2 (ppm) pH 30 max Nil 0.5 max 8-9

8.5

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 8 - KOELS RECOMMENDATIONS

Note on Water Quality & Recommendation

E) SR NO. 1. 2. 3. 4. 5. 6. 7.

INCOMING WATER FOR CPP PROPERTY SPEC.

Total hardness (ppm) Total Alkaline content (ppm) Suspended solids (ppm) pH Chlorides, Phosphates & Sulphates (ppm) Chlorides (ppm) Turbidity (NTU)

180 max 400 max 20 max 6.5 to 8.5 300 max (Total) 100 max 25 max.

8.6

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL Chapter 8 - KOELS RECOMMENDATIONS

Note on Water Quality & Recommendation

E) SR NO. 1. 2. 3. 4. 5. 6. 7.

INCOMING WATER FOR CPP PROPERTY SPEC.

Total hardness (ppm) Total Alkaline content (ppm) Suspended solids (ppm) pH Chlorides, Phosphates & Sulphates (ppm) Chlorides (ppm) Turbidity (NTU)

180 max 400 max 20 max 6.5 to 8.5 300 max (Total) 100 max 25 max.

8.6

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 9- KOELS RECOMMENDATIONS

Note on Lub Oil Quality & Recommendation

TIN No. : TIN/LO/VMK/001/00 Date : 19/06/1999

LUBRICATING OIL FOR PA-6 ENGINES

High speed diesel engine of our range needs specially tailored lub oil, catering to following conditions: 1) High firing pressure 2) Mean Piston Speed 3) High combustion temperature The above factors results in high stress on mechanical components and lubricating oil SEMT Pielstick has an elaborate approval procedure of lubricating oil for their engines. After through tests on chemical and physical characteristics of lubricating oil. It is subjected to rigerous on field trials, before a certain lubricating oil brand is approved for a specific engine series.

IMPORTANT CHARACTERISTICS OF LUBRICATING OIL :

A) VISCOSITY : To avoid metal to metal contact, it is mandatory to have stable and sufficient thick oil film between cylinder liner and piston ring. Oil from this region is high temperature thereby lower viscosity than when entering in the engine. The viscosity index expressing the temperature dependent of the viscosity is of importance to protect engine components. Lubricating oil viscosity has been chosen as being defined by SAE 40 grade that is between 12.5 to 16.3 cSt at 100 Deg C. In this range, correct lubricating oil film and flow will be made through engine. If the viscosity changes, film thickness and flow will trend towards the values which can be dangerous to the engine.

CAUSE OF DROP IN VISCOSITY :

a) Diesel dilution coming from pump leakage (HSD) b) Unburnt diesel in fuel chamber. c) Leakages through injection pump.

CAUSE OF RAISE IN VISCOSITY :

a) Oxidation, b) Presence of insolubles c) Raw Fuel Dilution Alarm Limit Rejection Limit : 2/3 SAE grade Variation (18%) : One grade of SAE (25% variation of viscosity)

B) TOTAL BASE NO (TBN) :

This value defines the resistance value of lub oil against the corrosion (Mainly sulphuric, generated from Sulphur in Fuel) 3 - 1 9.1

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 9- KOELS RECOMMENDATIONS

Note on Lub Oil Quality & Recommendation

Other than Sulphur, Other engine running condition have an effect on this value. A too cold water will lead to temperature on liner walls lower than dew point of Sulphuric Acid.

CAUSE OF DROP IN TBN

1) High Sulphur Content 2) Bad Adjustment of HT water Circuit 3) Precipitation of additives due to water presence.

LIMITS FOR TBN FOR LUB OIL :

Fuel % Sulphur Mn TBN Gas Oil < 0.1 5 Gas Oil <1 10 Distillates < 1.8 16 Interediates 0.3 - 1.8 1.8 - 3.0 16 20 3-4 20 HFO <5 25 - 28

To keep cold corrosion rate low, neutralisation capacity of lub oil must be sufficiently high. Therefore TBN 40 oil is recommended for HFO Operation.

C) WATER CONTENT :

Presence of water in lub oil is the risk of major break down of engine. The water elimination will be made by centrifuges adjusted as purifier. Normal water content Alarm Limit Rejection Limit : 0.1 % : 0.2 % : 0.5 %

In case of excessive wear, the water content, TBN & lub oil additives must be controlled. (Lub Oil additives trend is to react with water and disappear with it)

CAUSES OF WATER CONTENT IN LUB OIL :

a) Condensation of crankcase wall in humid and tropical zones. b) Engine Leakages c) Leakages in lub oil cooler d) Bad running of centrifuge.

D) FLASH POINT :

It is the temperature at which mist and product are ignited with a flame- hot point (In case of engines) like cylinder and crankshaft or by flame generated by blowby owing to bad tightness of rings. Flash point for new oil : 235 to 240 Deg C Alarm Level : 50 Deg C less than new oils flash point (Higher than 190 Deg C) Rejection Limit : 150 Deg C risk of self ignition and bursting of crankcase.

3-2

9.2

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 9- KOELS RECOMMENDATIONS

Note on Lub Oil Quality & Recommendation

E) DETERGENCY / DISPERSANCY :

Oil has to keep clean the liners, pistons, piston Rings, and ring grooves from the combustion products, This property is called as high temperature detergency. After lubricating the piston and liner, oil returns to sump during which it cleans crankcase walls connecting rods, Crankshafts. This effect is known as low temperature detergency. DISPERSANCY : Ability of oil to maintain in suspension all particles and unburnt components picked by oil in piston, liners etc. All the impurities must be transported to the purifier where most are removed. Dispersancy determined by visual inspection and automatic analysis of a spot. These values allow to define if the lub oil is still capable to clean and maintain the material in suspension.

F) ANTIWEAR AND EXTREME PRESSURE:

Whenever the oil film gets interrupted from or in insufficient quantity, the tribological characteristics have to be supported by antiwear and extreme pressure additives to reduce abrasive and adhesive wear.

G) THERMAL STABILITY :

Oil is exposed to long period of high temperature. Adequate thermal stability is therefore vital.

H) OXIDATION STABILITY :

Oxidation stability is required to prevent oxidation of oil due to high temperature and oxygen surplus in blow by gases and trapped air.

I) LUBRICITY :

Lubricant must be capable of covering surfaces to be protected. Therefore good spreadablity and reliability cohesion to the mettalic surfaces are required.

J) ALKALINITY :

The property permits the oil to react against corrosive wear by neutralising acidic combustion products from fuel sulphur.

K) COMPATIBILITY WITH HEAVY FUEL :

The lubricating oil and fuel should be compatible at prevailing temperature. Otherwise plunger sticking by deposit formation in fuel pump initiated by asphanates drop out from fuel may take place.

3-3

9.3

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 9- KOELS RECOMMENDATIONS

Note on Lub Oil Quality & Recommendation

L ) ANTIFOAMING :

Oil circulation in engine is continuous. During the circulation, air gets mixed with oil intensively. Antifoaming capacity of lubricating oil should be high otherwise which is dangerous for bearing. FUNCTION OF LUBRICATING OIL. 1) Lubrication 2) Cooling 3) Anticorrosion 4) Antiwear

LUBRICATION SYSTEM

I) BEARING LUBRICATION Between crankshaft journal and bearing there must be an oil film of a defined thickness. By considering engine characteristics and temperature requirements, viscosity grade should be selected and specified viscosity grade shall be used. The oil is circulated in crankshaft to reach big end bearing of connecting rod. Here the oil film has to provide an oil film to resist the impact resulting from combustion pressure on piston head. The oil passes towards small end (through connecting rod holes) bearing of gudgeon pin where again oil film is required. A important task of lubricating oil is to cool the bearings (removing frictional heat) II) PISTON COOLING After gudgeon pin, oil enters in the interior as a coolant medium (cooling the piston head). For this oil must have good resistance against deterioration at high temperature which is known as Oxidation Stability. III) OUR LUB OIL CONSUMPTION : Recommended lub oil consumption is 0.8 to 1.2 gm / kwh. optimisation of Piston ring set, piston clearance, liner temperature and its ability to retain the shape and liner surface are prerequisites of lub oil consumption, this rate includes losses in separators / filters. Oil change is required when lub oil consumption gets decreased. reduced oil consumption results in stress on oil, as oil volume will be replenished to lesser degrees by fresh oil. Therefore will require frequent oil changes. It could also indicate a trend of external contamination etc. (Fuel dilution into lub oil or water contamination in lub oil through improper

3-4 9.4

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 9- KOELS RECOMMENDATIONS

Note on Lub Oil Quality & Recommendation

centrifuge settings.)

LUB OIL PARAMETERS RECOMMENDED DURING THE ENGINE RUNNING CONDITION :

Oil temperature at engine inlet : 59 to 61 oC Filtering : 30 m max. and is being changed to 20 m through main filter Glacier for HSD and Alfa - Laval centrifuge for HFO Flow Rate : 5 m3 / Hr - for L engines 10 m3 / Hr - for V engines

VOLUME OF LUB OIL IN THE SUMP (Wet Sump)

For PA6 L and PA6 V st. engines (running on HSD) No. of cylinders 6 8 9 12 16 Max level (Lit) 660 860 960 920 1200 Min Level (Lit) 560 730 810 770 1000 Flow rate through 75 75 75 100 110 3 oil pumps m / Hr 18 1340 1115 120

PE-LUBRICATION PUMP PRESSURE: 6 bar for engine and motor driven pump Volume of lub oil in the sump of PA6V CL Engine : 7,600 Lit (Engine running on HFO with external / dry sump) Volume of lub oil in the sump of PA6L CL Engine : 4,200 Lit (Engine running on HFO with external / dry sump) VOLUME OF LUB OIL IN THE SUMP (Wet Sump) For PA6 L CL and PA6V CL engines (running on HSD) No. of cylinders 6 8 9 12 16 Max level (Lit) 700 910 1020 1500 1980 Min Level (Lit) 600 780 880 1350 1780 Engine Inlet pressure : 6 to 6.5 bar Engine outlet temperature : 73 oC

18 2200 1980

3-5

9.5

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 10- ELECTRICAL SYSTEM

CONTROL PANELS

Following control panels are supplied along with the DG set.

Generator Control Panel (GCP) Local Sensor Stand (LSS) Motor Control Centers (MCC) Neutral Grounding Resistor (NGR) Breaker Panel.

GENERATOR CUM SYNCHRONISING PANEL Function Synchronization, Protection, Control and Monitoring of DG SET. Features Suitable for Auto/Manual operation. Major Components Programmable Logic Controller. Operator Terminal (Panel View). Protection Relay. Power Meters i.e. KW, KVA, PF, A,V etc. Engine RPM Meter. Turbo charger RPM Meter. Excitation Voltmeter and Ammeter. Engine Frequency Monitoring Unit. Turbo. Frequency Monitoring Unit. Push Buttons and Selector Switches . PROGRAMMABLE LOGIC CONTROLLER Major Items Central Processing Unit. Power Supply. Digital Input Modules. Digital Output Modules. RTD Modules .

10.1

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 10- ELECTRICAL SYSTEM

Thermocouple Modules . Analog (4-20mA) Modules. Panel View ( HMI ). Functions of the PLC. Monitoring of the operating parameters. Operation logic execution. Auto synchronization and load sharing. STARTING INTERLOCK Manual mode Fuel Control Handle should be unlocked. Turning Gear to be disengaged. Level of Water Expansion Tank should be more than low level. Starting Air Pressure should be more than 16 bar. No Safety Stop should be operated. DG Breaker should be in off condition. Lube Oil Priming pressure should be more than 0.5 bar. Engine should not be in running condition. Auto mode HT Water Engine Inlet Temp. should be more than 40 Deg. PRE HEATING AND PRIMING MOUDLE Ability of an engine to take the load rapidly after a standstill period depends essentially on the ambient conditions. More precisely on HT water and Lube oil temperature at the time of starting. DG set is equipped with Pre Heating and Priming module, which maintains a reduced flow of HT water and lube oil in the engine. This equipment allows maintaining water temp. between 40 to 50 deg. in the cylinders and cylinder heads, decreasing the lube oil viscosity and thus avoid the over pressure on starting, ensures an adequate lubrication of all the moving components. Power supply to this module is fed from alternate supply source. MODE OF OPERATION There are three modes to start the DG set. Auto mode : Start of the engine shall be through AMF operation. Engine will be start after checking the following condition. Under voltage relays on GCP/Customer panel senses the bus supply. In AMF mode, these Under voltage relays will give command for starting the DG set.

10.2

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 10- ELECTRICAL SYSTEM

MANUAL MODEIn Manual mode Starting of Engine, Closing of the DG Breaker manual. Closing of breaker may be Either dead bus or live bus. In case of live bus of closing DG Breaker can be momentary paralleled With either of normal incomer. In this Engine starting can only be done After checking all necessary process Permissive.

TEST MODEIn Test mode operation is similar to AUTO operation Grid supply fail signal is given to PLC by simulation. ALTERNATOR Basic Operating Principle Exciting current Ie(dc current from AVR)flows through exciter Stator. It induces emf in exciter rotor(3 Ph).Then It is rectified by rotating diode and field current flows through main rotor winding. The flux due to this current induces an alternating emf in main stator winding. GENERATOR PROTECTION RELAY Combined numerical relay Function REM 543 of ABB make is used for following abnormal protection conditions -Differential -Under Voltage -Over Voltage -Under Frequency -Over Frequency -Earth Fault -Over Current etc. -Reverse Power. Breaker trip command and Engine Stop command will execute through GPR under the above abnormal conditions.

10.3

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 10- ELECTRICAL SYSTEM

AUTO SYNCHRONISATION RELAY Function To check following conditions for parallel operation FREQUENCY DIFF. WITHIN SET LIMIT VOLATAGE DIFF WITHIN SET LIMIT. PHASE ANGLE DIFF. WITHIN SET LIMIT If all above conditions are fulfilled it gives Closing command to the circuit breaker of Which is to be synchronized. GOVERNOR CONTROL UNIT Function To control Speed/frequency of the prime mover (Engine). AUTOMATIC VOLTAGE REGULATOR Function : To regulate the alternator voltage. Operation of AVR AVR senses the voltage signal Um from main stator and adjusts the field Current Ie, as per the set value to regulate the stator voltage. FREQUENCY MOINTERING UNIT FUNCTION Monitoring the speed of engine. It receives following inputs, 24V DC supply. Magnetic RPM pickup input from pickup fitted on the Fly wheel of engine It gives following outputs, RPM>170 (PF output) Threshold 1. RPM>300 (PF output) Threshold 2. RPM>550 (PF output) Threshold 3. RPM>700 (PF output) Threshold 4. RPM>840 (PF output) Engine over speed. Fault (PF output) Speed Sensing Failure.

10.4

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 10- ELECTRICAL SYSTEM

Following indications are used, Thresholds i.e. TH1 to TH4, Over speed . In working order In healthy condition, this indication should be always present. If this indication is not there, either RPM pickup input has failed or connection to the over speed solenoid on compressed air module is loose or broken. Following controls are possible, Test This facility is to be used only when engine is in stopped condition. By pressing this button, engine RPM meter will reach up to 1000RPM and over speed solenoid valve on the air module is operated.

Half speed test This facility is used to check OSPD safety when engine is running at speed of 840/2=420 RPM. Bring speed about 400 RPM and press Half Speed Test button. Slowly start increasing the speed. When indication on RPM meter will cross 840 (actual engine speed 420), OSPD safety should be operate as mentioned above. After operating above tests or in case over speed condition are rectified, press reset push button. In case Engine over speed safety operates, with pressing reset button. Engine cannot be started again. EFMU also gives 4-20 mA output corresponding to engine speed. This output is connected to engine RPM meter on ECP, engine RPM meter on LSS and to 4-20 mA input module of PLC. THERMOCOUPLE Engine is equipped with temperature sensors, to show the temperature of exhaust gas from the respective cylinder heads and the temperature of turbo charger. The thermocouple is used as a sensor. The thermocouple operates on the principle of Seebeck effect, when two dissimilar metals/ alloys are joined together to form a closed circuit and the two junctions are held at different temperatures, then a voltage is generated. This voltage is due to the temperature difference between the two junction. The voltage generated is proportional to temperature. The range of temperature measurement is from room temperature to 600 Deg. C, for all types of engines. Considering the temperature ranges & other factors like, We uses K-type thermocouple as a sensor for exhaust gas temperature and turbo charger temperature measurement. the typical range of K-type temperature sensor is -150 Deg. C. to 1400 Deg. C. TEMPERATURE SENSOR RTD-PT100

10.5

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 10- ELECTRICAL SYSTEM

DG Set is equipped with temperature sensor, to show the temperature lub oil, fuel oil, LT water, HT water temperature, charge air cooler inlet and outlet temperature etc. The resistance temperature detector (RTD) PT 100 is used as a sensor. The RTD operates on the principle of change in the electrical resistance of a conductor takes place when there is change in temperature. The PT 100 is a positive temperature coefficient type RTD, means when temperature increases the resistance of the conductor also increases. The output of the PT 100 is resistance, corresponding to temperature. The PT 100 sensor consist of 3 wires at the output. At 0 deg its resistance is 100 ohm,the resistance increases by 4 ohm for every increase by 10 deg.

MAGNETIC PICK UP( SPEED SENSOR ) The magnetic pickup is used to detect the speed of the prime mover. Engine Frequency Monitoring Unit (EFMU) which is mounted in the GCP is needed to convert the pickups output signal to one usable by the governor amplifier. The magnetic pickup will produce a voltage output , when any magnetic material moves through the magnetic field. Most engines have flywheels or other large gears made up of magnetic material ( usually iron or steel). Magnetic pickups can usually be installed without adding attachments to a gear or shaft. Non-magnetic materials, such as aluminum, brass and some stainless, will not excite the magnetic pickup. Any device which produces a dynamic discontinuity of magnetic material in the field of the pickup will produce an electrical voltage.

LOCAL SENSOR STAND Function Monitoring of pressure parameters. Features Located near DG set for easy monitoring Remote control of engine possible. Major Components Pressure Gauges. Pressure Transmitters. Push Buttons. Indicating Lamps.

10.6

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 10- ELECTRICAL SYSTEM

INDICATIONS 1. HT water Pressure 2. LT water Pressure 3. Lub oil Pressure 4. Injector Water Pressure 5. Fuel Pressure 6. Engine Speed 7. Local control 8. Remote control 9. Engine start permission 10. Engine trip

0-6 Bar (pump outlet) 0-6 Bar (pump outlet) 0-10 Bar (engine inlet) 0- 6 Bar 0-10 Bar (engine inlet) 0-1000 RPM Lamp Lamp Lamp Lamp

Switches 1) Low lube oil priming pressure switchAlarm & Start interlock 2) Low/ Very low lube oil pressure switch 3) Low HT water pressure 4) Low LT water pressure 5) Low fuel pressure switch 6) Turbocharger lube oil inlet pressure Low MCC PANEL Provide the supply to the auxiliaries 1. 2. 3. 4. 5. 6. 7. 8. LT RADIATOR. HT RADIATOR. EMD COMPRESSOR. L.OIL PRIMING PUMP. DRIP TRANSFER PUMP. TURNING GEAR. PREHEATING HEATER. CHEMICAL MIXING PUMP. Alarm/Stop Alarm Alarm Alarm Alarm

10.7

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 10- ELECTRICAL SYSTEM

BREAKER PANEL FUNCTION Vacuum circuit breaker is used to deliver the generated output power to the consumer. MAJOR COMPONENTS VCB trolley rated for 13.1 KA. Metering / Protection CTs and PTs Meters, indicators

METERING DEVICE Ammeter with selector switch Voltmeter with selector switch INDICATIONS VCB ON VCB OFF Auto trip Spring charged

CONTROLS POSSIBLE Local / Remote control selection VCB ON/OFF

10.8

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 11- ELECTRICAL SYSTEM Thermocouple / RTD Calibration Chat

Date :

THERMOCOUPLE CALIBRATION REPORT FORMAT

Sr.No Standard Reading Temp. oC 0 oC 30 oC 50 oC 75 oC 100 oC 150 oC 200 oC 300 oC 400 oC 500 oC 600 oC mV. Output 0 1.2 2.02 3.058 4.1 6.14 8.14 12.21 16.4 20.64 24.9 Observed Reading Temp oC mV.Output

01 02 03 04 05 06 07 08 09 10 11

REMARK :

11.1

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 11- ELECTRICAL SYSTEM Thermocouple / RTD Calibration Chat

TEMPERATURE V/S OUTPUT CHARACTERISTICS OF K- TYPE THERMOCOUPLE

Sr.No 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Temperature (oC) - 150 - 100 - 50 - 25 0 10 20 30 40 50 60 70 80 90 100 120 140 160 180 200 250 300 350 400 500 600 700 800 900 1000 1100 1200 Output (mV) - 4.921 - 3.553 - 1.889 - 0.368 0 0.397 0.798 1.203 1.611 2.022 2.436 2.850 3.266 3.681 4.095 4.919 5.733 6.539 7.338 8.137 10.151 12.207 14.292 16.395 20.640 24.902 29.128 33.277 37.325 41.269 45.108 48.828

NOTE : Add Ambient Temperature.

11.2

INSTALLATION & COMMISSIONING MANUAL Kirloskar Oil Engines Ltd.

Large Engines Division

Chapter 11- ELECTRICAL SYSTEM Thermocouple / RTD Calibration Chat

TEMPERATURE V/S OUTPUT CHARACTERISTICS OF RTD PT - 100

Sr.No 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Temperature (oC) - 150 - 100 - 50 - 25 0 10 20 30 40 50 60 70 80 90 100 120 140 160 180 200 250 300 350 400 500 600 700 Output (ohm) 39.71 60.25 80.31 90.13 100.00 103.90 107.79 111.67 115.54 119.40 123.24 127.07 130.89 134.70 138.50 146.06 153.58 161.04 168.46 175.84 194.07 212.02 229.67 247.04 280.90 313.59 345.13

11.3

Kirloskar Oil Engines Ltd.

Large Engines Division

INSTALLATION & COMMISSIONING MANUAL

CHAPTER-12 HANDING OVER

COMMISSIONING REPORTS

KIRLOSKAR OIL ENGINES LTD.

Large Engines Division 4 MW EMERGENCY DG SET COMMISSIONING REPORTS Project :PANIPAT NAPHTHA CRACKER PROJECT CAPTIVE POWER PLANT

Format No. : KOEL/L&T/EPCC-4/6556/Engine-Alter details/01 ENGINE DETAILS Engine Make Engine Modle Engine Sr. No. Year of Mfg. Speed / MHP Firing order Lube oil Fuel Direction of Rotation : : : : : : : : :

ALTERNATOR DETAILS Make Type Sr.No. KW K.V.A Voltage Current Speed Duty AVR Year of Mfg. Frequency Power factor Excitation Voltage Excitation Current Insulation Class Grease type DE Bearing Type : Type : : : : : : : : : : : : : : : NDE Bearing : :

KIRLOSKAR OIL ENGINES LTD.

Engines Division 4 MW EMERGENCY DG SET COMMISSIONING REPORT Project : PANIPAT NAPHTHA CRACKER PROJECT CAPTIVE POWER PLANT Format No. : KOEL/L&T/EPCC-4/6556/DG Base frame levelling/01 Date : DG SET BASE FRAME LEVELLING

Large

Governor Side

mm

Priming Pump Side 0 Reference set

mm ENGINE

mm

mm

mm

mm Phase side

ALTERNATOR

mm

NGR Side

Remarks - DG Baseframe levelling done with water tube column and reading found within limit

KOEL

L&T

EIL

Sign:

Name:

KIRLOSKAR OIL ENGINES LTD.

Large Engines Division 4 MW EMERGENCY DG SET COMMISSIONING REPORTS Project : PANIPAT NAPTHA CRACKER PROJECT CAPTIVE POWER PLANT

Format No. :KOEL/L&T/EPCC-4/6554/DG Alignment/01 Engine No.DATEAlternator No.-

ENGINE AND ALTERNATOR ALIGNMENT

DIAL ON ENGINE ( C1 )

TOP SIDE 500 ( A ) (B) GOV SIDE (C) BOTTOM SIDE (D) LOP SIDE (F) GOV SIDE 500 ( G ) BOTTOM SIDE

DIAL ON ALTERNATOR (C2)

TOP SIDE (E) (H) LOP SIDE

Gauge Position A B C D

(Indicator is 1/100 of millimeter ) Dial on Engine Gauge Position E F G H

Dial on Alternator

CALCULATIONS If Dial on outer C 1 side of Flyheel DV=C-A/ 2 DH=D-B/2

If Dial on Inner side of Flywheel DV=A-C/2 DH=B-D/2

C1

If Dial on Inner of C li DV=E-G/2 DH=F-H/2

C2

If DV OR DH IS -VE PLOT BELOW ENGINE AXIS.

UP

LOP Side

Engine Axis

Engine Axis

C1

DV Down

C2

C1

DH GOV Side

C2

KOEL SIGN.:

L&T

EIL

NAME: DATE:

KIRLOSKAR OIL ENGINES LTD.

Large Engines Division 4 MW EMERGENCY DG SET COMMISSIONING REPORTS Project : PANIPAT NAPTHA CRACKER PROJECT CAPTIVE POWER PLANT

Format No. :KOEL/L&T/EPCC-4/6554/Web deflection/01 Date : CRANKSHAFT WEB DEFLECTION MEASUREMENT Engine No.Coupled / Uncoupled A E 1 Gauge on balance weight 2 Insure dial when plunger seeezess reading increases 3 Read the reading on dial( Bold & Big) (Upper scale reading ) 4 1 Unit =0.01mm Alternator No.-

Gov. Side C

LOP Side

Guage Position A B C D E DV=[A+E/2-C]/100 DH=B-D

Cylinder No. 5 6

INSTRUMENTS USED ( TYPE,MAKE,SL.NO.):

KOEL Sign : Name : Date: Page 1 of 1

L& T

EIL

KIRLOSKAR OIL ENGINES LTD.

Large Engines Division 4 MW EMERGENCY DG SET COMMISSIONING REPORTS Project : PANIPAT NAPTHA CRACKER PROJECT CAPTIVE POWER PLANT

Format No :KOEL/L&T/EPCC-4/6554/Shim report/01 DG SHIM REPORT Date :

Engine No.-

Alternator No.-

Lube Oil Priming Pump Side B C

Drive End side

Non Drive side

A Governor side

Position Shim thickness in mm Torquing on bolts

KOEL SIGN.:

L&T

EIL

NAME: DATE: Page 1 of 1

KIRLOSKAR OIL ENGINES LTD.

Large Engines Division 4 MW EMERGENCY DG SET COMMISSIONING REPORT Project : PANIPAT NAPTHA CRACKER PROJECT CAPTIVE POWER PLANT

Format No. :KOEL/L&T/EPCC-4/6554/Check points/01 Date :

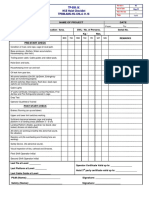

INSTALLATION AND COMMISSIONING CHECK POINTS

SR.NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 DESCRIPTIONS Base Frame to Foundation Bolts (Torque). Base Frame to Alternator Bolts (Torque). Base Frame to Engine Bolts (Torque). Flywheel to Coupling Bolts (Torque). Coupling to Alternator Bolts (Free )(Torque). Coupling to Alternator Bolts (Dowel )(Torque). Number punching on Coupling Bolts. Distance between Fly Wheel Face and Hub. Distance between Coupling flange and Hub after spacer Expansion Bellow Free gap Balance Water Tank fitted at Height of Radiator outlet at the Height of Daily service Fuel tank at the Height of Engine Base Frame Levelling Done With Base Frame Leveling Position HT Water Pipes cleaned with LT Water Pipes cleaned with Fuel Pipes cleaned with Compressed Air Pipes cleaned with Lub Oil Pipes cleaned with 95 Kg.M 95 Kg.M 50 Kg.M 95 Kg.M

0 10 Kg.M + 36 Rotation 0 10 Kg.M + 32 Rotation

VALUE

Yes mm mm mm mtrs. mtrs. mtrs. Water Coulmn ok Acid Acid Acid Acid Acid Water Water Water Water Water Air Air Air Air Air

Note: Confirm the Torque Values as per Drawing.

KIRLOSKAR OIL ENGINES LTD.

Large Engines Division 4 MW EMERGENCY DG SET COMMISSIONING REPORT Project : PANIPAT NAPTHA CRACKER PROJECT CAPTIVE POWER PLANT

Format No. :KOEL/L&T/EPCC-4/6554/AIR RECIVER/01 Date :

AIR RECIVER