Professional Documents

Culture Documents

4.13.9 Typical Refractories in Industrial Use

Uploaded by

Palash SwarnakarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.13.9 Typical Refractories in Industrial Use

Uploaded by

Palash SwarnakarCopyright:

Available Formats

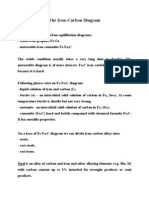

5.

9 Typical Refractories in Industrial Use

Depending on the area of application such as boilers, furnaces, kilns, ovens etc, temperatures and atmospheres encountered different types of refractories are used. Typical installations of refractories are shown in figure 5.6

Refractory lining of a furnace arch

Refractory walls of a furnace interior with burner blocks Figure 5.6

Fireclay refractories Fireclay refractories, such as firebricks, siliceous fireclays and aluminous clay refractories consist of aluminium silicates with various amounts of silica ranging from SiO2 content of less than 78% and containing less than 44% of Al2O3. Table 5.6 shows that as the quantity of impurities increases and the amount of Al2O3 decreases, the melting point of fireclay brick decreases. Owing to its relative cheapness and widespread location of the raw materials used to manufacture firebricks, this material finds use in most furnaces, kilns, stoves, etc.

Table 5.6:Properties of typical fireclay bricks

Brick Super Duty High Duty Intermediate High Duty (Siliceous) Low Duty

Percent SiO2 49-53 50-80 60-70 65-80 60-70

Percent Al 2O3 40-44 35-40 26-36 18-30 23-33

Other Constituents 5-7 5-9 5-9 3-8 6-10

PCE 0C 1745-1760 1690-1745 1640-1680 1620-1680 1520-1595

Firebrick is the most common form of refractory material. It is used extensively in the iron and steel industry, nonferrous metallurgy, glass industry, pottery kilns, cement industry, and by many others.

High alumina refractories Alumino silicate refractories containing more than 45% alumina are generally termed as high alumina materials. The alumina concentration ranges from 45 to 100%. The refractoriness of high alumina refractories increases with increase in alumina percentage. The applications of high alumina refractories includes the hearth and shaft of blast furnaces, ceramic kilns, cement kilns, glass tanks and crucibles for melting a wide range of metals. Silica brick Silica brick (or Dinas) is a refractory material containing at least 93%SiO2. The raw material is quality rocks. Various grades of silica brick have found extensive use in the iron and steel melting furnaces. In addition to high fusion point multi-type refractories, the other important properties are their high resistance to thermal shock (spalling) and their high refractoriness. It finds typical use in glass making and steel industry. The outstanding property of silica brick is that it does not begin to soften under high loads until its fusion point is approached. This behaviour contrasts with that of many other refractories, for example alumino silicate materials, which begin to fuse and creep at temperatures considerably lower than their fusion points. Other advantages are flux and stag resistance, volume stability and high spalling resistance. Magnesite Magnesite refractories are chemically basic materials, containing at least 85% magnesium oxide. They are made from naturally occurring magnesite (MgCO3). The properties of magnesite refractories depend on the concentration of silicate bond at the operating temperatures. Good quality magnesite usually results from a CaO-SiO2 ratio of less than 2 with a minimum ferrite concentration, particularly if the furnaces lined with the refractory operate in oxidizing and reducing conditions. The slag resistance is very high particularly to lime and iron rich slags. Chromite refractories Here, a distinction must be made between chrome-magnesite refractories and magnesitechromite-refractories. Chromemagnesite material usually contain 15-35% Cr2O3 and 4250% MgO whereas magnesite-chromite refractories contain at least 60% MgO and 818% Cr2O3. Chrome-magnesite refractories are made in a wide range of qualities and are used for building the critical parts of high temperature furnaces. These materials can withstand corrosive slags and gases and have high refractoriness. The magnesite-chromite products are suitable for service at the highest temperatures and in contact with the most basic slags used in steel melting. Magnesite-chromite usually ahs a better spalling resistance than chrome-magnesite.

Zirconia refractories Zirconium dioxide (ZrO2) is a polymorphic, material. There are certain difficulties in its usage and fabrication as a refractory material. It is essential to stabilize it before application as a refractory. This is achieved by incorporating small quantities of calcium, magnesium and cerium oxide, etc. Its properties depend mainly on the degree of stabilization and quantity of stabilizer as well as the quality of the original raw material. Zirconia refractories have a very high strength at room temperature which is maintained upto temperatures as high as 15000C. They are, therefore, useful as high temperature constructional materials for furnaces and kilns. The thermal conductivity, of zirconium dioxide is found to be much lower than that of most other refractories and the material is therefore used as a high temperature insulating refractory. Since Zirconia exhibits very low thermal losses and does not react readily with liquid metals, it is particularly useful for making refractory crucibles and other vessels for metallurgical purposes. Zirconia is a useful refractory material for glass furnaces primarily since it is not easily wetted by molten glasses and because of its low reaction with them. Oxide refractories (Alumina) Alumina refractory materials which consist of aluminium oxide with little traces of impurities are often known as pure alumina. Alumina is one of the most chemically stable oxides known. It is mechanically very strong, insoluble in water and super heated steam, and in most inorganic acids and alkalies. Its properties make it suitable for the shaping of crucibles for fusing sodium carbonate, sodium hydroxide and sodium peroxide. It has a high resistance in oxidizing and reducing atmosphere. Alumina is extensively used in heat processing industries. Highly porous alumina is used for lining furnaces operating up to 18500C. Monolithics Monolithic refractories (single piece cast in the shape of equipment such as one for a ladle shown in figure 5.7) are replacing the conventional type fired refractories at a much faster rate in many applications including those of industrial furnaces. The main advantages being: It eliminates joints which is an inherent weakness Figure 5.7 Monolithic lining for a ladle Method of application is faster and skilled measures in large number are not required Transportation and handling are simple Offers better scope to reduce downtime for repairs Offers considerable scope to reduce inventory and eliminate special shapes It is a heat saver Has better spalling resistance

Has greater volume stability

Various means are employed in the placement of monolithics like ramming, casting, gunniting, spraying, sand slinging, etc. Ramming masses are used mostly in cold applications where proper consolidation of the material is important. The same practice can be adopted with both air setting and heat setting materials. Proper ramming tools need to be selected. Castables by name implies a material of hydraulic setting in nature. Calcium aluminate cement being the binder, it will have to be stored properly to prevent moisture absorption. Further its strength starts deteriorating after a period of 6 to 12 months. Insulating materials Insulating materials greatly reduce the heat losses through walls. Insulation is effected by providing a layer of material having a low heat conductivity between the internal hot surface of a furnace and the external surface, thus causing the temperature of the external surface reduced. The insulating materials may be classified into the following groups Insulating bricks Insulating Castables Ceramic fibre Calcium silicate Ceramic coating Insulating materials owe their low conductivity to their pores while their heat capacity depends on the bulk density and specific heat. Structure of air insulating material consists of minute pores filled with air which have in themselves very low thermal conductivity, excessive heat affects all insulation material adversely, but the temperatures to which the various materials can be heated before this adverse effect occurs differ widely. Clearly, therefore, the choice of an insulating material must depend upon its effectiveness to resist heat conductivity and upon the temperature that it will withstand. One of the most widely used insulating materials is diatomite, also known as kiesel guhr which is made up of a mass of skeletons of minute aquatic plants deposited thousands of years ago on the beds of seas and lakes. Chemically this consists of silica contaminated with clay and organic matter. A wide range of insulating refractories with wide combinations of properties are now available. The important physical properties of some insulating refractories are shown in the table below:

Table 5.7 physical properties of insulating refractories

Type

Diatomite Solid Grade

Thermal Max. safe conductivity at temperature0C 4000C .025 1000

Cold Crushing Strength Kg/cm2 270

Porosity % 52

Bulk density Kg/m3 1090

Diatomite Porous Grade Clay High Aluminia Silica

.014

800

110

77

540

.030 .028 .040

1500 1500-1600 1400

260 300 400

68 66 65

560 910 830

Castables and Concretes Monolithic linings and furnace sections can be built up by casting refractory insulating concretes, and by stamping into place certain light weight aggregates suitably bonded. Other applications include the formation of the bases of tunnel kiln cars used in the ceramic industry. The ingredients are similar to those used for making piece refractories, except that concretes contain some kind of cement, either Portland or a high-alumina cement. Ceramic Fibre Ceramic fibre is a low thermal mass insulation material, which has revolutionalised the furnace design lining systems. Ceramic fibre is an alumino silicate material manufactured by blending and melting alumina and silica at temperature of 1800 2000oC and breaking the molten stream by blowing compressed air or dropping the melt on spinning disc to form loose or bulk ceramic fibre. The bulk fibre is converted to various products including blanket, strips, veneering and anchored modules, paper, vacuum formed boards and shapes, rope, wet felt, mastic cement etc. for insulation applications.

Figure 5.8: Ceramic Fibre Insulation

Fibres are usually produced in two temperature grades based on Al2O3 content. A recent addition is Zr O2 added alumino silicate fibre, which helps to reduce shrinkage levels thereby rating the fibre for higher temperatures. Continuous recommended operating temperature for fibres are given in the following Table 5.8:

Table 5.8 Continuous Recommended Operating Temperature for Fibres

1150oC 1250oC 1325oC

A12O3 43 - 47 % 52 - 56 % 33 - 35 %

SiO2 53 - 57 % 44 - 48 % 47 - 50 %

ZrO2 17 - 20 %

These fibres are generally produced in bulk wool form and needled into blanket mass of various densities ranging from 64 to 190 kg/m3. Converted products and over 40 different forms are made from blankets to suit various requirements. Important Properties of Ceramic Fibre The characteristics of ceramic fibres are a remarkable combination of the properties of refractories and traditional insulation material. 1. Lower Thermal Conductivity The low thermal conductivity 0.1 kCal/m hour deg C at 600oC for 128 kg/m3 density blanket allows construction of thinner linings with the same thermal efficiency as that of conventional refractories. Hence, for the same outer envelope dimension the furnace volume is much higher. It is 40 % more effective than good quality insulation brick and 2.5 times better than asbestos product. Insulating property of ceramic fibre is better than calcium silicate product. 2. Light Weight Average density of ceramic fibre is 96 kg/m3. It is one tenth of the weight of insulating brick and one third that of asbestos / calcium silicate boards. For new furnaces structural supports can be reduced by 40%.

3. Lower Heat Storage Ceramic fibre linings absorb less heat because of lower density. Furnace can be heated and cooled at faster rates. Typically the heat stored in a ceramic fibre lining system is in the range of 2700 - 4050 kCal/m2 (1000 1500 Btu/Ft2) as compared to 54200-493900 kCal/m2 ( 20000 250000 Btu/Ft2 ) for conventionally lined system. 4. Thermal Shock Resistant Ceramic fibre lining resist thermal shock due to their resilient matrix. Also faster heat up and cool down cycles are possible thereby improving furnace availability and productivity. 5. Chemical Resistance Ceramic fibre resist most of the chemical attack and is unaffected by hydrocarbons, water and steam present in flue gases. 6. Mechanical Resilience This property permits fibre lined furnaces to be shop fabricated and shipped to site in assembled form without fear of damage.

7. Low Installation Cost No special skills are required as application practices are standardised. Fibre linings require no dry out or curing times and can be heated to the capacity of the burners after installation is completed without concern for cracking or spalling. 8. Simple Maintenance In case of physical damage the defective section can be quickly removed and a replacement piece added. Whole panel sections can be prefabricated for fast installation with minimal down time. 9. Ease of Handling All product forms are easily handled and most can be quickly cut with a knife or scissors. Vacuum formed products may require cutting with a band saw. 10. Thermal Efficiency The low thermal conductivity of ceramic fibre can be advantageously made use of by the lesser lining thickness and reduced furnace volume. The fast response of ceramic fibre lined furnace also allows for more accurate control and uniform temperature distribution within the furnace. The other advantages offered by ceramic fibre are summarized below: Light weight furnace Simple steel fabrication work Low down time Increased productivity Additional capacity Low maintenance cost Longer service life Higher thermal efficiency Faster response

High Emissivity Coatings Emissivity, the measure of a materials ability to both absorb and radiate heat, has been considered by engineers as being an inherent physical property which like density, specific heat and thermal conductivity, is not readily amenable to change. However, the development of high emissivity coatings now allows the surface emissivity of materials to be increased, with resultant benefits in heat transfer efficiency and in the service life of heat transfer components. High emissivity coatings are applied in the interior surface of furnaces. The Figure 5.9 shows emissivity of various insulating materials including high emissivity coatings. High emissivity coating shows a constant value over varying process temperatures. The application of high-emissivity coatings in furnace chambers promotes rapid and efficient transfer of heat, uniform heating, and extended life of refractories and metallic components such as radiant tubes and heating elements. For intermittent furnaces or

where rapid heating is required, use of such coatings was found to reduce fuel or power to tune of 25-45%. Other benefits are temperature uniformity and increased refractory life

Figure 5.9 Emissivity of Refractory Materials at Different temperatures

Furnaces, which operate at high temperature, have emissivities of 0.3. By using high emissivity coatings this can go upto 0.8 thus effectively increasing the radiative heat transfer.

You might also like

- Presented To: Engineer Nasir Iqbal Noorani: Submitted By: Faizan FA-15-BME-83 Farhan FA-15-BME-84 Khizar FA-15-BME-046Document19 pagesPresented To: Engineer Nasir Iqbal Noorani: Submitted By: Faizan FA-15-BME-83 Farhan FA-15-BME-84 Khizar FA-15-BME-046Taha KhanNo ratings yet

- Refractory & MaterialsDocument25 pagesRefractory & MaterialsTaha KhanNo ratings yet

- Lecture 15: Application of Refractory MaterialsDocument7 pagesLecture 15: Application of Refractory MaterialsMiguel Kühnert FrichenbruderNo ratings yet

- PEP Session Industrial RefractoriesDocument64 pagesPEP Session Industrial RefractoriesNowsherwan MazariNo ratings yet

- Presentation On Refractories By: Haleem Haider Farrukh Shahzad Muzammil JavedDocument23 pagesPresentation On Refractories By: Haleem Haider Farrukh Shahzad Muzammil JavedwatcharpNo ratings yet

- REFractories FOR GLASS-TRL PDFDocument24 pagesREFractories FOR GLASS-TRL PDFram cNo ratings yet

- Lecture 10Document6 pagesLecture 10Abhijeet BhagavatulaNo ratings yet

- Blast Furnace BF Refractory Lining PatternDocument5 pagesBlast Furnace BF Refractory Lining PatternSarthakShangariNo ratings yet

- RefractoriesDocument6 pagesRefractoriesBHAVINNo ratings yet

- Uses of RefractoryDocument20 pagesUses of RefractoryRicha Tripathi100% (1)

- CA Silicate & Other Insulation - Surface Dew PointDocument5 pagesCA Silicate & Other Insulation - Surface Dew PointjagrutNo ratings yet

- Refractory Lining Project Corrected (Chapter 1)Document7 pagesRefractory Lining Project Corrected (Chapter 1)Don Rayburn PilanNo ratings yet

- Float Glass RefractoryDocument4 pagesFloat Glass RefractorySans SenNo ratings yet

- Gouda Refractories Brochure WEbDocument16 pagesGouda Refractories Brochure WEbjsszep jNo ratings yet

- FHS Ladle Installation Manual Incld OPI - 10.5.2018Document28 pagesFHS Ladle Installation Manual Incld OPI - 10.5.2018Nguyễn ChungNo ratings yet

- PDF Ce Refractory Concrete e 2 2014Document10 pagesPDF Ce Refractory Concrete e 2 2014cristian villegasNo ratings yet

- Magnesite and Forsterite RefractoriesDocument25 pagesMagnesite and Forsterite RefractoriesfayzaNo ratings yet

- RHI MagnesitaDocument2 pagesRHI MagnesitaMauricio MessiNo ratings yet

- Bulletin RHIDocument76 pagesBulletin RHIwaqasaziz786No ratings yet

- Bricks and Shapes 2Document6 pagesBricks and Shapes 2nay den100% (1)

- Fused and Sintered AluminaDocument7 pagesFused and Sintered AluminaSaragadam DilsriNo ratings yet

- Refractory Lining For Induction Furnace PDFDocument3 pagesRefractory Lining For Induction Furnace PDFmeNo ratings yet

- MonolithicRefractory PDFDocument2 pagesMonolithicRefractory PDFmevaNo ratings yet

- 76-Microsilica-Gel Bond Castables For Rapid Heat-UpDocument12 pages76-Microsilica-Gel Bond Castables For Rapid Heat-UpJagadeesh GuttiNo ratings yet

- Refractor I NessDocument12 pagesRefractor I NesskazamNo ratings yet

- Vesuvius ResearchDocument9 pagesVesuvius ResearchRohit ThapliyalNo ratings yet

- RhiDocument20 pagesRhiOscar Rodrigo Andrade SilvaNo ratings yet

- Introduction To Fused Cast RefractoryDocument7 pagesIntroduction To Fused Cast RefractorypetemberNo ratings yet

- Refractory Use and Consumption in North American Cement IndustryDocument33 pagesRefractory Use and Consumption in North American Cement IndustrygldiasNo ratings yet

- Refractory Doc JunaidDocument3 pagesRefractory Doc JunaidAli ZamanNo ratings yet

- ANTEC - Refractory AnchorsDocument114 pagesANTEC - Refractory AnchorstylerstearnsNo ratings yet

- RHIM ANKRAL RX Success Story - 2021 - EN - 1 RHIDocument11 pagesRHIM ANKRAL RX Success Story - 2021 - EN - 1 RHIlafecapo100% (1)

- SIC Refractory CastableDocument5 pagesSIC Refractory CastableJagadeesh GuttiNo ratings yet

- Refractories 01Document22 pagesRefractories 01dika wahyu0% (1)

- Cement Kiln Refractory Heat Up PDFDocument24 pagesCement Kiln Refractory Heat Up PDFMin Zayar100% (1)

- Yüksek F R N Kanallar Nda Kendili Inden Ak C Boksit Esasl Dökülebilirlerin Geli TirilmesiDocument8 pagesYüksek F R N Kanallar Nda Kendili Inden Ak C Boksit Esasl Dökülebilirlerin Geli TirilmesiOrkun KorkmazNo ratings yet

- Blanket and Wallpaper Linings Design and Installation ManualDocument12 pagesBlanket and Wallpaper Linings Design and Installation ManualMarco Antonio Guevara MartínezNo ratings yet

- Damage of Refractory Bricks Lined in Cement Rotary Kiln: Technical Research Laboratory, Mino Yogyo Co. LTD., JapanDocument10 pagesDamage of Refractory Bricks Lined in Cement Rotary Kiln: Technical Research Laboratory, Mino Yogyo Co. LTD., JapanPham tony1604No ratings yet

- PDF Ce Feuerbetone e 8 2017.en.7Document10 pagesPDF Ce Feuerbetone e 8 2017.en.7Henry SunarkoNo ratings yet

- Allied Mineral Refractory Castable - Refractory Cement - Allied MineralDocument2 pagesAllied Mineral Refractory Castable - Refractory Cement - Allied MineralLeo CrisuNo ratings yet

- Slide Gate System DevelopmentDocument14 pagesSlide Gate System DevelopmentA.S.M. Mosayeb RafiNo ratings yet

- Meltingfurnace 170728094222Document31 pagesMeltingfurnace 170728094222Ninfa LansangNo ratings yet

- Ladle RefractoryDocument26 pagesLadle RefractoryRavindra Kashyap100% (2)

- 2 Introduction-Refractories ApresentaçãoDocument11 pages2 Introduction-Refractories ApresentaçãoBrunoNo ratings yet

- 15 Days Industrial Training Report File: On Sinter & LDP (10/03/2017-24/03/2017)Document21 pages15 Days Industrial Training Report File: On Sinter & LDP (10/03/2017-24/03/2017)Prashant Kumar mishraNo ratings yet

- How To Choise Refractory For Metallurgy FurnacesDocument15 pagesHow To Choise Refractory For Metallurgy FurnacesGuilherme Dos Santos MoreiraNo ratings yet

- Minerals in Refractory Shapes - Which Way NowDocument4 pagesMinerals in Refractory Shapes - Which Way NowEmílio LobatoNo ratings yet

- Mathios Refractories Catalog Web EditionDocument92 pagesMathios Refractories Catalog Web EditionNick Limperios100% (1)

- How Mixing Affects The Rheology of Refractory Castables - Part IIDocument25 pagesHow Mixing Affects The Rheology of Refractory Castables - Part IIVinh Do ThanhNo ratings yet

- Almatis - Andus Buhr - TrendsRefractoriesCleanSteelTechnology - LitcorrectionDocument15 pagesAlmatis - Andus Buhr - TrendsRefractoriesCleanSteelTechnology - LitcorrectionSaptarshi SenguptaNo ratings yet

- Low Cement CastablesDocument53 pagesLow Cement CastablesRahamat ShaikNo ratings yet

- Refractory Lining of Blast Furnace PDFDocument11 pagesRefractory Lining of Blast Furnace PDFceng el samiuNo ratings yet

- Progress and Perspective of Refractory Technology: Technical ReviewDocument5 pagesProgress and Perspective of Refractory Technology: Technical ReviewemregnesNo ratings yet

- 12 Mr. Christensen, Nosering Case StoryDocument20 pages12 Mr. Christensen, Nosering Case StoryJunaid MazharNo ratings yet

- A Study On Indian Refractories IndustryDocument10 pagesA Study On Indian Refractories IndustryMahesh BuffettNo ratings yet

- Ladle Refractory Monitoring WebDocument6 pagesLadle Refractory Monitoring WebsusantaNo ratings yet

- Project Report PDFDocument33 pagesProject Report PDFGAUTAM KUMAR BHATTACHARYANo ratings yet

- FIRE Compendium Series: Refractory Castable EngineeringDocument2 pagesFIRE Compendium Series: Refractory Castable EngineeringKhaled BOUALINo ratings yet

- Furnaces and Refractories: 6. WorksheetsDocument36 pagesFurnaces and Refractories: 6. WorksheetsDHSanjNo ratings yet

- KTDocument10 pagesKTPalash SwarnakarNo ratings yet

- Material Testing Lab: Structures/Motion Lab 20-263-571, Sections 001, 002, 003Document16 pagesMaterial Testing Lab: Structures/Motion Lab 20-263-571, Sections 001, 002, 003med2011GNo ratings yet

- BOOKS - JEST Coaching Physics, Jest Entrance Preparation, Jest Study Material, Joint Entrance Screening Test, JNU, IIT-Delhi PDFDocument2 pagesBOOKS - JEST Coaching Physics, Jest Entrance Preparation, Jest Study Material, Joint Entrance Screening Test, JNU, IIT-Delhi PDFPalash SwarnakarNo ratings yet

- 1Document9 pages1KaushalSinghNo ratings yet

- PNAAP422Document128 pagesPNAAP422Palash SwarnakarNo ratings yet

- Plant LayoutDocument3 pagesPlant LayoutPalash Swarnakar100% (2)

- PNAAP422Document128 pagesPNAAP422Palash SwarnakarNo ratings yet

- Clock FlopDocument16 pagesClock FlopVikram MehtaNo ratings yet

- Lever RuleDocument1 pageLever RulePalash SwarnakarNo ratings yet

- Reserve Bank of India (RBI)Document2 pagesReserve Bank of India (RBI)Palash SwarnakarNo ratings yet

- 06 Strengthening MechanismsDocument63 pages06 Strengthening Mechanismspranavkumarparit100% (2)

- RBI Assistants Exam Model Question PapersDocument40 pagesRBI Assistants Exam Model Question PapersSarath ChandraNo ratings yet

- MLN 04Document21 pagesMLN 04abhishek_mishra_51No ratings yet

- Diffraction BasicsDocument18 pagesDiffraction BasicsRock FrancisNo ratings yet

- ReferencesDocument10 pagesReferencesPalash SwarnakarNo ratings yet

- 10 Latches FFDocument32 pages10 Latches FFPalash SwarnakarNo ratings yet

- 10 Latches FFDocument32 pages10 Latches FFPalash SwarnakarNo ratings yet

- Course Mexiko 1 LectureDocument56 pagesCourse Mexiko 1 LecturePalash SwarnakarNo ratings yet

- Iron Carbon DiagramDocument22 pagesIron Carbon DiagramPalash SwarnakarNo ratings yet

- Rectangular Cavity: A Metal Enclosed Box of Volume V A B D TE - ModeDocument8 pagesRectangular Cavity: A Metal Enclosed Box of Volume V A B D TE - ModePalash SwarnakarNo ratings yet

- Iron-Carbon DiagramDocument11 pagesIron-Carbon DiagramrampradNo ratings yet

- Lecture 11Document17 pagesLecture 11Palash SwarnakarNo ratings yet

- Resonant Cavities and WaveguidesDocument52 pagesResonant Cavities and WaveguidesPalash SwarnakarNo ratings yet

- M A N B L D: Waveguide Cavity ResonatorDocument7 pagesM A N B L D: Waveguide Cavity ResonatorPalash SwarnakarNo ratings yet

- 4.13.9 Typical Refractories in Industrial UseDocument8 pages4.13.9 Typical Refractories in Industrial UsePalash SwarnakarNo ratings yet

- Ee 614 RepDocument17 pagesEe 614 RepMilan MakwanaNo ratings yet

- Ca 5Document3 pagesCa 5Palash SwarnakarNo ratings yet

- Fractional Rectangular Cavity Resonator: Progress in Electromagnetics Research B, Vol. 9, 69-82, 2008Document14 pagesFractional Rectangular Cavity Resonator: Progress in Electromagnetics Research B, Vol. 9, 69-82, 2008Palash SwarnakarNo ratings yet

- Part 5: Cavities and Waveguides: PHYS370 - Advanced ElectromagnetismDocument36 pagesPart 5: Cavities and Waveguides: PHYS370 - Advanced ElectromagnetismPalash SwarnakarNo ratings yet

- 4.13.9 Typical Refractories in Industrial UseDocument8 pages4.13.9 Typical Refractories in Industrial UsePalash SwarnakarNo ratings yet

- K.T. Chau, R.H.C. Wong, T.-f. Wong (Auth.), STAVROS K. KOURKOULIS (Eds.) - Fracture and Failure of Natural Building Stones_ Applications in the Restoration of Ancient Monuments-Springer Netherlands (2Document581 pagesK.T. Chau, R.H.C. Wong, T.-f. Wong (Auth.), STAVROS K. KOURKOULIS (Eds.) - Fracture and Failure of Natural Building Stones_ Applications in the Restoration of Ancient Monuments-Springer Netherlands (2Daniel Ruperto CanoNo ratings yet

- CS6411 Network Lab Manual - 2013 - Regulation PDFDocument71 pagesCS6411 Network Lab Manual - 2013 - Regulation PDFjayaprasanna123No ratings yet

- EE223 - Signals & Systems Assignment #3 (CLO#3)Document3 pagesEE223 - Signals & Systems Assignment #3 (CLO#3)haider aliNo ratings yet

- Discovery of A New Energy VortexDocument4 pagesDiscovery of A New Energy Vortexnblack3335140No ratings yet

- Chapter 01 Properties of SolutionDocument70 pagesChapter 01 Properties of SolutionYo Liang SikNo ratings yet

- FTKM 0419 B L (Leaflet)Document2 pagesFTKM 0419 B L (Leaflet)Wan SyahlanNo ratings yet

- Airplane Wing Geometry and ConfigurationsDocument7 pagesAirplane Wing Geometry and Configurationsh_mahdiNo ratings yet

- Ranjit Kumar-Research Methodology A Step-by-Step G-15-16Document2 pagesRanjit Kumar-Research Methodology A Step-by-Step G-15-16Trendy NewsNo ratings yet

- Ecs448 Chapter 5a ArchDocument28 pagesEcs448 Chapter 5a Archdixn__No ratings yet

- Parts Catalog: Surgical TablesDocument55 pagesParts Catalog: Surgical TablessambadeeNo ratings yet

- BP301T Poc Unit IiiDocument15 pagesBP301T Poc Unit IiiSUBHASISH DASHNo ratings yet

- Mathematical Model of Transportation ProblemDocument14 pagesMathematical Model of Transportation ProblemwasimghghNo ratings yet

- A Handheld Gun Detection Using Faster R-CNN Deep LearningDocument5 pagesA Handheld Gun Detection Using Faster R-CNN Deep LearningJanderson LiraNo ratings yet

- Battery Testing Standards and Best PracticesDocument45 pagesBattery Testing Standards and Best Practicesnavi_0403No ratings yet

- Case Analysis SampleDocument22 pagesCase Analysis SampleMicaela EncinasNo ratings yet

- Predicting Residual Stresses Due To Solidification in Cast Plastic Plates VladoTropsaPhDDocument225 pagesPredicting Residual Stresses Due To Solidification in Cast Plastic Plates VladoTropsaPhDAghajaniNo ratings yet

- PartIII Semiconductor at Equilibrium PrintDocument22 pagesPartIII Semiconductor at Equilibrium PrintK.bhogendranathareddy KuppireddyNo ratings yet

- Bearing FitsDocument9 pagesBearing Fitsm2110No ratings yet

- Cisco Nexus 9300 ACI Fixed Spine Switches: Product OverviewDocument7 pagesCisco Nexus 9300 ACI Fixed Spine Switches: Product OverviewMahmoud RamadanNo ratings yet

- Holiday Homework Class 12 MathematicsDocument2 pagesHoliday Homework Class 12 MathematicsKartik SharmaNo ratings yet

- FF7AN - Credit ManagementDocument6 pagesFF7AN - Credit ManagementRoberta FernandesNo ratings yet

- Linear Interpolation Equation Formula Calculator PDFDocument3 pagesLinear Interpolation Equation Formula Calculator PDFMatthew HaleNo ratings yet

- Excel Sales Report TemplateDocument3 pagesExcel Sales Report TemplateMark11311100% (1)

- Bok:978 94 017 9664 4Document215 pagesBok:978 94 017 9664 4fivalen1_443898619100% (2)

- Spring - Design - Important Points and CalculationDocument17 pagesSpring - Design - Important Points and CalculationvenkateswaranNo ratings yet

- Phenomenology and Social Reality - Essays in Memory of Alfred Schutz (PDFDrive)Document316 pagesPhenomenology and Social Reality - Essays in Memory of Alfred Schutz (PDFDrive)Muhammad SyarofuddinNo ratings yet

- Ansi Hi 9.1-9.5-2000 PDFDocument78 pagesAnsi Hi 9.1-9.5-2000 PDFandhucaos100% (1)

- Rough Surfaces in ANSYSDocument17 pagesRough Surfaces in ANSYSIgor BlanariNo ratings yet

- Grade 4 Essential Lessons For 2020-2021-ONDocument10 pagesGrade 4 Essential Lessons For 2020-2021-ONMatt LamNo ratings yet

- 05 Traps PDFDocument17 pages05 Traps PDFDevinaacsNo ratings yet

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Phase Equilibria in Chemical EngineeringFrom EverandPhase Equilibria in Chemical EngineeringRating: 4 out of 5 stars4/5 (11)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86From EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86No ratings yet

- Fundamentals of Risk Management for Process Industry EngineersFrom EverandFundamentals of Risk Management for Process Industry EngineersNo ratings yet

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksFrom EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNo ratings yet

- Biotechnology of Metals: Principles, Recovery Methods and Environmental ConcernsFrom EverandBiotechnology of Metals: Principles, Recovery Methods and Environmental ConcernsNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringFrom EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillRating: 3.5 out of 5 stars3.5/5 (3)

- Coulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesFrom EverandCoulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesAjay Kumar RayNo ratings yet