Professional Documents

Culture Documents

Optocoupler

Uploaded by

Asghar AliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optocoupler

Uploaded by

Asghar AliCopyright:

Available Formats

Distributed by:

www.Jameco.com 1-800-831-4242

The content and copyrights of the attached material are the property of its owner.

Jameco Part Number 277860

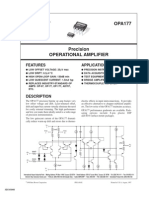

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

PACKAGE

MOC3052-M

SCHEMATIC

ANODE 1

6 MAIN TERM.

6 6 1 1

N/C 3 4 MAIN TERM. CATHODE 2 5 NC*

*DO NOT CONNECT (TRIAC SUBSTRATE)

DESCRIPTION

The MOC3051-M and MOC3052-M consist of a AlGaAs infrared emitting diode optically coupled to a non-zero-crossing silicon bilateral AC switch (triac). These devices isolate low voltage logic from 115 and 240 Vac lines to provide random phase control of high current triacs or thyristors. These devices feature greatly enhanced static dv/dt capability to ensure stable switching performance of inductive loads.

FEATURES

Excellent IFT stabilityIR emitting diode has low degradation High isolation voltageminimum 7500 peak VAC Underwriters Laboratory (UL) recognizedFile #E90700 600V peak blocking voltage VDE recognized (File #94766) - Ordering option V (e.g. MOC3052V-M)

APPLICATIONS

Solenoid/valve controls Lamp ballasts Static AC power switch Interfacing microprocessors to 115 and 240 Vac peripherals Solid state relay Incandescent lamp dimmers Temperature controls Motor controls

2004 Fairchild Semiconductor Corporation

Page 1 of 11

1/20/04

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

ABSOLUTE MAXIMUM RATINGS (TA = 25C unless otherwise noted)

Parameters TOTAL DEVICE Storage Temperature Operating Temperature Lead Solder Temperature Junction Temperature Range Isolation Surge Voltage(3) (peak AC voltage, 60Hz, 1 sec duration) Total Device Power Dissipation @ 25C Derate above 25C EMITTER Continuous Forward Current Reverse Voltage Total Power Dissipation 25C Ambient Derate above 25C DETECTOR Off-State Output Terminal Voltage Peak Repetitive Surge Current (PW = 100 ms, 120 pps) Total Power Dissipation @ 25C Ambient Derate above 25C VDRM ITSM PD All All All IF VR PD All All All TSTG TOPR TSOL TJ VISO PD All All All All All All Symbol Device

MOC3052-M

Value

Units

-40 to +150 -40 to +85 260 for 10 sec -40 to +100 7500 330 4.4 60 3 100 1.33 600 1 300 4

C C C C Vac(pk) mW mW/C mA V mW mW/C V A mW mW/C

2004 Fairchild Semiconductor Corporation

Page 2 of 11

1/20/04

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

ELECTRICAL CHARACTERISTICS (TA = 25C Unless otherwise specied) INDIVIDUAL COMPONENT CHARACTERISTICS

Parameters EMITTER Input Forward Voltage Reverse Leakage Current DETECTOR Peak Blocking Current, Either Direction Peak On-State Voltage, Either Direction Critical Rate of Rise of Off-State Voltage VDRM, IF = 0 (note 1) ITM = 100 mA peak, IF = 0 IF = 0 (gure 7, @400V) IDRM VTM dv/dt All All All 1000 IF = 10 mA VR = 3 V VF IR All All Test Conditions Symbol Device Min

MOC3052-M

Typ*

Max

Units

1.15 0.05 10 1.7

1.5 100 100 2.5

V A nA V V/s

TRANSFER CHARACTERISTICS (TA = 25C Unless otherwise specied.)

DC Characteristics LED Trigger Current, either direction Holding Current, Either Direction *Typical values at TA = 25C Note 1. Test voltage must be applied within dv/dt rating. 2. All devices are guaranteed to trigger at an IF value less than or equal to max IFT. Therefore, recommended operating IF lies between max 15 mA for MOC3051, 10 mA for MOC3052 and absolute max IF (60 mA). 3. Isolation surge votlage, VISO, is an internal device breakdown rating. For this text, pins 1 and 2 are common, and pins 4, 5 and 6 are common. Test Conditions Main terminal Voltage = 3V (note 2) Symbol IFT IH Device MOC3051-M MOC3052-M All 280 Min Typ* Max 15 10 Units mA A

2004 Fairchild Semiconductor Corporation

Page 3 of 11

1/20/04

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

Figure. 1 LED Forward Voltage vs. Forward Current

1.8

MOC3052-M

Figure. 2 On-State Characteristics

800

1.7

600

ON-STATE CURRENT - ITM (mA)

VF - FORWARD VOLTAGE (V)

1.6

400

1.5

200

1.4

TA = -55oC

-200

1.3

TA = 25oC

-400

1.2

TA = 100oC

-600

1.1

-800

1.0 1 10 100

-3

-2

-1

ON-STATE VOLTAGE - VTM (V)

IF - LED FORWARD CURRENT (mA)

Figure. 3 Trigger Current vs. Ambient Temperature

1.4

Figure. 4 LED Current Required to Trigger vs. LED Pulse Width

IFT, NORMALIZED LED TRIGGER CURRENT 25 NORMALIZED TO: PWin 100 s

1.3

TRIGGER CURRENT - I FT (NORMALIZED)

20

1.2

15

1.1

10

1.0

0.9

0

0.8

10

20

50

100

PWin, LED TRIGGER PULSE WIDTH (s)

0.7 NORMALIZED TO TA = 25C 0.6 -40 -20 0 20 40 60 80 100

AMBIENT TEMPERATURE - TA (oC)

IF versus Temperature (normalized)

This graph (gure 3) shows the increase of the trigger current when the device is expected to operate at an ambient temperature below 25C. Multiply the normalized IFT shown this graph with the data sheet guaranteed IFT. Example: TA = -40C, IFT = 10 mA IFT @ -40C = 10 mA x 1.4 = 14 mA

sine wave. Phase control may be accomplished by an AC line zero cross detector and a variable pulse delay generator which is synchronized to the zero cross detector. The same task can be accomplished by a microprocessor which is synchronized to the AC zero crossing. The phase controlled trigger current may be a very short pulse which saves energy delivered to the input LED. LED trigger pulse currents shorter than 100 s must have an increased amplitude as shown on Figure 4. This graph shows the dependency of the trigger current IFT versus the pulse width can be seen on the chart delay t(d) versus the LED trigger current. IFT in the graph IFT versus (PW) is normalized in respect to the minimum specied IFT for static condition, which is specied in the device characteristic. The normalized IFT has to be multiplied with the devices guaranteed static trigger current. Example: Guaranteed IFT = 10 mA, Trigger pulse width PW = 3 s IFT (pulsed) = 10 mA x 5 = 50 mA

Phase Control Considerations LED Trigger Current versus PW (normalized)

Random Phase Triac drivers are designed to be phase controllable. They may be triggered at any phase angle within the AC

2004 Fairchild Semiconductor Corporation

Page 4 of 11

1/20/04

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

MOC3052-M

Minimum LED Off Time in Phase Control Applications

AC SINE

180

LED PW LED CURRENT

LED TURN OFF MIN 200 s

Figure 5. Minimum Time for LED TurnOff to Zero Cross of AC Trailing Edge

In Phase control applications one intends to be able to control each AC sine half wave from 0 to 180 degrees. Turn on at zero degrees means full power and turn on at 180 degree means zero power. This is not quite possible in reality because triac driver and triac have a xed turn on time when activated at zero degrees. At a phase control angle close to 180 degrees the drivers turn on pulse at the trailing edge of the AC sine wave must be limited to end 200 ms before AC zero cross as shown in Figure 5. This assures that the triac driver has time to switch off. Shorter times may cause loss of control at the following half cycle.

Figure. 7 Leakage Current, I DRM vs. Temperature

10000

Figure. 6 Holding Current, I H vs. Temperature

1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 - 40 - 30 - 20 -10 0 10 20 30 40 50 60 70 80

0.1 -40

IH, HOLDING CURRENT (mA)

IDRM LEAKAGE CURRENT (nA) ,

1000

100

10

TA , AMBIENT TEMPERATURE (oC)

-20

20

40

60

80

100

TA , AMBIENT TEMPERATURE (oC)

IFT versus dv/dt

Figure. 8 LED Trigger Current, I FT vs. dv/dt

IFT, LED TRIGGER CURRENT (NORMALIZED) 1.5 1.4 1.3 1.2 1.1 1 0.9 0.8 0.7 0.6 0.5 0.001 0.01 0.1 1 10 100 1000 10000 NORMALIZED TO: IFT at 3 V

Triac drivers with good noise immunity (dv/dt static) have internal noise rejection circuits which prevent false triggering of the device in the event of fast raising line voltage transients. Inductive loads generate a commutating dv/dt that may activate the triac drivers noise suppression circuits. This prevents the device from turning on at its specied trigger current. It will in this case go into the mode of half waving of the load. Half waving of the load may destroy the power triac and the load. Figure 8 shows the dependency of the triac drivers IFT versus the reapplied voltage rise with a Vp of 400 V. This dv/dt condition simulates a worst case commutating dv/dt amplitude. It can be seen that the IFT does not change until a commutating dv/dt reaches 1000 V/ms. The data sheet specied IFT is therefore applicable for all practical inductive loads and load factors. Page 5 of 11

dv/dt (V/ s)

2004 Fairchild Semiconductor Corporation

1/20/04

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

Figure 9. Delay Time, t(d), and Fall Time, t(f), vs. LED Trigger Current

100

MOC3052-M

t(delay), t(f) versus IFT

The triac drivers turn on switching speed consists of a turn on delay time t(d) and a fall time t(f). Figure 9 shows that the delay time depends on the LED trigger current, while the actual trigger transition time t(f) stays constant with about one micro second. The delay time is important in very short pulsed operation because it demands a higher trigger current at very short trigger pulses. This dependency is shown in the graph IFT versus LED PW. The turn on transition time t(f) combined with the power triacs turn on time is important to the power dissipation of this device.

SCOPE IFT VTM EXT. SYNC ZERO CROSS DETECTOR 115 VAC

t(delay) AND t(fall) ( s)

10

t(d)

t(f)

0.1 10

20

30

40

50

60

I FT, LED TRIGGER CURRENT (mA)

+400 Vdc

RTEST

t(d) R = 1 k

ISOL. TRANSF.

t(f)

FUNCTION GENERATOR Vout

PHASE CTRL. PW CTRL. PERIOD CTRL. Vo AMPL. CTRL.

PULSE INPUT

MERCURY WETTED RELAY

VTM 10 k DUT

IFT

CTEST D.U.T.

X100 SCOPE PROBE

AC 100

APPLIED VOLTAGE WAVEFORM 0 VOLTS

Vmax = 400 V 252 V dv/dt = RC 0.63 V RC = 2

1. The mercury wetted relay provides a high speed repeated pulse to the D.U.T. 2. 100x scope probes are used, to allow high speeds and voltages. 3. The worst-case condition for static dv/dt is established by triggering the D.U.T. with a normal LED input current, then removing the current. The variable RTEST allows the dv/dt to be gradually increased until the D.U.T. continues to trigger in response to the applied voltage pulse, even after the LED current has been removed. The dv/dt is then decreased until the D.U.T. stops triggering. RC is measured at this point and recorded.

Figure 10. Static dv/dt Test Circuit

2004 Fairchild Semiconductor Corporation

Page 6 of 11

1/20/04

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

APPLICATIONS GUIDE

Basic Triac Driver Circuit

The new random phase triac driver family MOC3052-M and MOC3051-M are very immune to static dv/dt which allows snubberless operations in all applications where external generated noise in the AC line is below its guaranteed dv/dt withstand capability. For these applications a snubber circuit is not necessary when a noise insensitive power triac is used. Figure 11 shows the circuit diagram. The triac driver is directly connected to the triac main terminal 2 and a series Resistor R which limits the current to the triac driver. Current limiting resistor R must have a minimum value which restricts the current into the driver to maximum 1A. R = Vp AC/ITM max rep. = Vp AC/1A The power dissipation of this current limiting resistor and the triac driver is very small because the power triac carries the load current as soon as the current through driver and current limiting resistor reaches the trigger current of the power triac. The switching transition times for the driver is only one micro second and for power triacs typical four micro seconds.

VCC RLED TRIAC DRIVER VCC RLED TRIAC DRIVER

MOC3052-M

POWER TRIAC AC LINE R CONTROL RET. Q LOAD RLED = (VCC - V F LED - V sat Q)/IFT R = Vp AC line/ITSM

Figure 11. Basic Driver Circuit

POWER TRIAC RS MOV CS LOAD

R CONTROL RET.

AC LINE

Triac Driver Circuit for Noisy Environments

When the transient rate of rise and amplitude are expected to exceed the power triacs and triac drivers maximum ratings a snubber circuit as shown in Figure 12 is recommended. Fast transients are slowed by the R-C snubber and excessive amplitudes are clipped by the Metal Oxide Varistor MOV. Triac Driver Circuit for Extremely Noisy Environments, as specied in the noise standards IEEE472 and IEC255-4. Industrial control applications do specify a maximum transient noise dv/dt and peak voltage which is superimposed onto the AC line voltage. In order to pass this environment noise test a modied snubber network as shown in Figure 13 is recommended.

Typical Snubber values RS = 33 , CS = 0.01 F MOV (Metal Oxide Varistor) protects triac and driver from transient overvoltages >VDRM max.

Figure 12. Triac Driver Circuit for Noisy Environments

POWER TRIAC VCC RLED TRIAC DRIVER R

RS MOV CS AC LINE

CONTROL LOAD RET. Recommended snubber to pass IEEE472 and IEC255-4 noise tests RS = 47 W, CS = 0.01 mF

Figure 13. Triac Driver Circuit for Extremely Noisy Environments

2004 Fairchild Semiconductor Corporation

Page 7 of 11

1/20/04

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

Package Dimensions (Through Hole)

0.350 (8.89) 0.320 (8.13) Pin 1 ID

MOC3052-M

Package Dimensions (Surface Mount)

0.350 (8.89) 0.320 (8.13)

Pin 1 ID 0.390 (9.90) 0.332 (8.43)

0.260 (6.60) 0.240 (6.10)

0.260 (6.60) 0.240 (6.10)

Seating Plane

Seating Plane

0.070 (1.77) 0.040 (1.02)

0.070 (1.77) 0.040 (1.02) 0.014 (0.36) 0.010 (0.25)

0.320 (8.13)

0.014 (0.36) 0.010 (0.25)

0.320 (8.13)

0.200 (5.08) 0.115 (2.93)

0.200 (5.08) 0.115 (2.93)

0.012 (0.30) 0.008 (0.20)

0.100 (2.54) 0.015 (0.38) 0.020 (0.50) 0.016 (0.41) 0.100 (2.54) 15 0.012 (0.30)

0.025 (0.63) 0.020 (0.51) 0.020 (0.50) 0.016 (0.41)

0.100 [2.54] 0.035 (0.88) 0.006 (0.16)

Package Dimensions (0.4 Lead Spacing)

0.350 (8.89) 0.320 (8.13) Pin 1 ID

Recommended Pad Layout for Surface Mount Leadform

0.070 (1.78)

0.260 (6.60) 0.240 (6.10)

0.060 (1.52)

0.070 (1.77) 0.040 (1.02)

Seating Plane

0.014 (0.36) 0.010 (0.25)

0.425 (10.79)

0.100 (2.54) 0.305 (7.75) 0.030 (0.76)

0.200 (5.08) 0.115 (2.93)

0.100 (2.54) 0.015 (0.38) 0.020 (0.50) 0.016 (0.41) 0.100 [2.54] 0.012 (0.30) 0.008 (0.21) 0.425 (10.80) 0.400 (10.16)

NOTE All dimensions are in inches (millimeters)

2004 Fairchild Semiconductor Corporation

Page 8 of 11

1/20/04

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

ORDERING INFORMATION

Option S SD W 300 300W 3S 3SD Order Entry Identier S SR2 T V TV SR2V SR2V

MOC3052-M

Description Surface Mount Lead Bend Surface Mount; Tape and reel 0.4" Lead Spacing VDE 0884 VDE 0884, 0.4" Lead Spacing VDE 0884, Surface Mount VDE 0884, Surface Mount, Tape & Reel

MARKING INFORMATION

MOC3051 V

3 4

2 6

X YY Q

5

Denitions

1 2 3 4 5 6 Fairchild logo Device number VDE mark (Note: Only appears on parts ordered with VDE option See order entry table) One digit year code, e.g., 3 Two digit work week ranging from 01 to 53 Assembly package code

*Note Parts that do not have the V option (see denition 3 above) that are marked with date code 325 or earlier are marked in portrait format.

2004 Fairchild Semiconductor Corporation

Page 9 of 11

1/20/04

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

Carrier Tape Specifications

12.0 0.1 4.85 0.20 0.30 0.05 4.0 0.1 4.0 0.1 1.55 0.05

MOC3052-M

1.75 0.10

7.5 0.1 13.2 0.2 9.55 0.20 16.0 0.3

0.1 MAX

10.30 0.20

1.6 0.1

User Direction of Feed

Reow Prole (White Package, -M Sufx)

300 Temperature (C) 250 200 150 100 50 0 0 0.5 1 1.5 2 2.5 245C peak

230C, 1030 s

Time above 183C, 120180 sec Ramp up = 210C/sec Peak reflow temperature: 245C (package surface temperature) Time of temperature higher than 183C for 120180 seconds One time soldering reflow is recommended 3.5 4 4.5

Time (Minute)

2004 Fairchild Semiconductor Corporation

Page 10 of 11

1/20/04

6-PIN DIP RANDOM-PHASE OPTOISOLATORS TRIAC DRIVERS (600 VOLT PEAK)

MOC3051-M

MOC3052-M

DISCLAIMER FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS. LIFE SUPPORT POLICY FAIRCHILDS PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION. As used herein: 1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) support or sustain life, and (c) whose failure to perform when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected to result in a significant injury of the user. 2. A critical component in any component of a life support device or system whose failure to perform can be reasonably expected to cause the failure of the life support device or system, or to affect its safety or effectiveness.

2004 Fairchild Semiconductor Corporation

Page 11 of 11

1/20/04

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Capacitive SensorDocument17 pagesCapacitive SensorPaul Jazz Lopez100% (1)

- PID Control System Analysis and DesignDocument48 pagesPID Control System Analysis and DesignAsghar AliNo ratings yet

- Practical Guide To AccelerometersDocument3 pagesPractical Guide To AccelerometersShelton Raja100% (1)

- Applied Nonlinear ControlDocument219 pagesApplied Nonlinear ControlFlyfy David71% (7)

- Jura J9.3 Wiring DiagramDocument4 pagesJura J9.3 Wiring DiagramGrom NeposedaNo ratings yet

- Measurements SystemDocument22 pagesMeasurements SystemM Rizal Dwi F0% (3)

- Backstepping PaperDocument3 pagesBackstepping PapermxjoeNo ratings yet

- Sliding Mode Control ExplainedDocument14 pagesSliding Mode Control ExplainedAsghar AliNo ratings yet

- Lecture 24Document2 pagesLecture 24Asghar AliNo ratings yet

- 24 Feedback LinearizationDocument17 pages24 Feedback LinearizationaustinvishalNo ratings yet

- An Open Source Power System Analysis Toolbox: 7% (%#/#,) "3 ? @AB A@C AD@Document56 pagesAn Open Source Power System Analysis Toolbox: 7% (%#/#,) "3 ? @AB A@C AD@Chandan KumarNo ratings yet

- Fuel Burn UpDocument53 pagesFuel Burn UpAsghar AliNo ratings yet

- 1 TransmissionDocument10 pages1 TransmissionEsmeralda TapizNo ratings yet

- Atcs PDFDocument12 pagesAtcs PDFAsghar AliNo ratings yet

- Sliding Mode Control GuideDocument15 pagesSliding Mode Control GuideShouvik ChaudhuriNo ratings yet

- PS Protection ManualDocument32 pagesPS Protection ManualMandip PokharelNo ratings yet

- A Review of Process Fault Detection and Diagnosis Part I Quantitative Model-Based Methods (2003, Venkat Venkatasubramanian, Raghunathan Rengaswamy, Kewen Yin, Surya N. Kavuri)Document19 pagesA Review of Process Fault Detection and Diagnosis Part I Quantitative Model-Based Methods (2003, Venkat Venkatasubramanian, Raghunathan Rengaswamy, Kewen Yin, Surya N. Kavuri)Rogelio16No ratings yet

- Chapter 07Document24 pagesChapter 07Asghar AliNo ratings yet

- Pelvic Inflammatory Disease (PID)Document43 pagesPelvic Inflammatory Disease (PID)Asghar AliNo ratings yet

- PIDtutorialDocument13 pagesPIDtutorialalijnubyNo ratings yet

- Advanced Embedded Systems DesignDocument14 pagesAdvanced Embedded Systems DesignAsghar AliNo ratings yet

- Opa 177Document11 pagesOpa 177Asghar AliNo ratings yet

- PID CONTROL WITHOUT A PHDDocument7 pagesPID CONTROL WITHOUT A PHDEEpro808No ratings yet

- New Approaches To The Design of Fixed Order Controllers: S. P. Bhattacharyya Department of Electrical EngineeringDocument71 pagesNew Approaches To The Design of Fixed Order Controllers: S. P. Bhattacharyya Department of Electrical EngineeringAsghar AliNo ratings yet

- Switching RegulatorDocument6 pagesSwitching RegulatorAsghar AliNo ratings yet

- PD, PI, PID Compensation TechniquesDocument42 pagesPD, PI, PID Compensation TechniquesAsghar AliNo ratings yet

- Chapter 10 PID 1Document36 pagesChapter 10 PID 1Taufiq GalangNo ratings yet

- Strain Gage AccelerometerDocument5 pagesStrain Gage AccelerometerAsghar AliNo ratings yet

- Discrete MathematicsDocument5 pagesDiscrete MathematicsAsghar AliNo ratings yet

- Impedance Measuring CircuitsDocument7 pagesImpedance Measuring CircuitsAsghar AliNo ratings yet

- Report On SiwesDocument10 pagesReport On SiwesDazzy SmoothNo ratings yet

- PSPDocument2 pagesPSPtejjaNo ratings yet

- General Instructions: Universite Du 7 Novembre A CarthageDocument8 pagesGeneral Instructions: Universite Du 7 Novembre A Carthagemakram74No ratings yet

- VP Human Resources Director Operations in New York NY Resume Melanese MoodyDocument2 pagesVP Human Resources Director Operations in New York NY Resume Melanese MoodyMelaneseMoodyNo ratings yet

- EE8261 Electric Circuits Lab ManualDocument56 pagesEE8261 Electric Circuits Lab Manualpapayee lakshmananNo ratings yet

- Liebert Ita 16kva and 20kva - User Manual PDFDocument72 pagesLiebert Ita 16kva and 20kva - User Manual PDFSatheesh Kumar NatarajanNo ratings yet

- Heavy OilDocument6 pagesHeavy Oilsnikraftar1406No ratings yet

- Unlock Business Growth with Data AnalyticsDocument56 pagesUnlock Business Growth with Data AnalyticsAizel AlmonteNo ratings yet

- NOS AdminGuide v411 PDFDocument748 pagesNOS AdminGuide v411 PDFMaeckol Segura PeñaNo ratings yet

- MXL Data SheetDocument10 pagesMXL Data SheetMohamed MeeranNo ratings yet

- Midterm Exam 467 Spring 2024Document2 pagesMidterm Exam 467 Spring 2024Faisal ShahbazNo ratings yet

- VT Teddy BearDocument3 pagesVT Teddy BearSanyee DiehNo ratings yet

- BRKNMS-2573 (2020)Document120 pagesBRKNMS-2573 (2020)Paul ZetoNo ratings yet

- VG278 Series LCD Monitor User GuideDocument24 pagesVG278 Series LCD Monitor User GuideEdsel LoquillanoNo ratings yet

- Narrow Band Powerline Communication Module With Simple MAC User Narrow Band Powerline Communication Module With Simple MAC User Manual Narrow Band Powerline CommunicationDocument8 pagesNarrow Band Powerline Communication Module With Simple MAC User Narrow Band Powerline Communication Module With Simple MAC User Manual Narrow Band Powerline CommunicationAle NqnNo ratings yet

- Combined Deterministic-Stochastic Frequency-Domain Subspace Identification For Experimental and Operational Modal AnalysisDocument11 pagesCombined Deterministic-Stochastic Frequency-Domain Subspace Identification For Experimental and Operational Modal AnalysismasoudNo ratings yet

- OTC 21070 Fluid-Structure Interaction Simulations of A Pipeline Span Exposed To Sea Bottom CurrentsDocument12 pagesOTC 21070 Fluid-Structure Interaction Simulations of A Pipeline Span Exposed To Sea Bottom CurrentsRasheed YusufNo ratings yet

- Aditya College of Engineering: Lesson PlanDocument6 pagesAditya College of Engineering: Lesson Planshiva kumarNo ratings yet

- Information Gathering: Interactive Methods: Systems Analysis and Design, 7e Kendall & KendallDocument55 pagesInformation Gathering: Interactive Methods: Systems Analysis and Design, 7e Kendall & KendallAnonymous hzr2fbc1zMNo ratings yet

- BCA Project-II Submitted By: Srijana Bhatta Aakriti Pokhrel Nirijan Ghatal Kantipur City College, Putalisadak KathmanduDocument25 pagesBCA Project-II Submitted By: Srijana Bhatta Aakriti Pokhrel Nirijan Ghatal Kantipur City College, Putalisadak KathmanduLaxmi PokharelNo ratings yet

- Aoc LC42H063D, LC42H063DDocument133 pagesAoc LC42H063D, LC42H063DsachinNo ratings yet

- Cardiac Science AED Manager User Guide EnglishDocument21 pagesCardiac Science AED Manager User Guide EnglishEnerspect Medical SolutionsNo ratings yet

- Neuromeasure 5 User'S ManualDocument14 pagesNeuromeasure 5 User'S ManualGokulNo ratings yet

- Summer Jobs 2020Document6 pagesSummer Jobs 2020Mohammed AshrafNo ratings yet

- Apple Products TNCDocument80 pagesApple Products TNCabhijit khaladkarNo ratings yet

- 3gpp Specification NumberingDocument1 page3gpp Specification NumberingKrishna Prasad PheluNo ratings yet

- Modelman PDFDocument72 pagesModelman PDFCarlos CamachoNo ratings yet

- Tia Eia 637 ADocument110 pagesTia Eia 637 ApzernikNo ratings yet

- ECE OLED TechnologyDocument22 pagesECE OLED Technologygourav VermaNo ratings yet